by Tom Gaylord, a.k.a. B.B. Pelletier

Today’s report is a guest blog from reader /Dave. It’s his first report of a beautiful Walther LG55 he recently acquired.

If you’d like to write a guest post for this blog, please email me.

Over to you, /Dave.

This Walther LG55 is another used gun that I bought from a reputable seller on the Yellow Classifieds. B.B. asked me to share my impressions with you after I received it. For a lot of people here, this well be a repeat of how to evaluate a used gun. Most people here know, or at least have an idea, of what appeals to them before buying a used gun. Some don’t like to risk money on a used gun, which I completely understand, having been burned once or twice. For those of you that do take risks, here ya go!

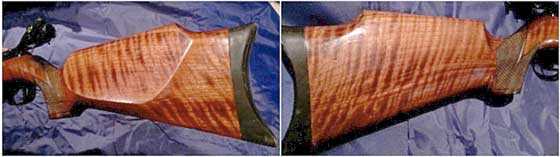

This curly walnut stock caught my eye right away!

After my new gun arrives, I generally give it a once-over, looking for any obvious faults and to find out if I need to do any serious work on it. I was happy to get this rifle after delays by the shipping company. The wait, which is normally pretty hard, was extended by more than another week while the shipper decided where it was really supposed to go. When it finally arrived, I was like a kid at Christmas trying to figure out the fastest way to get my new of gun out of the box and out of the paper, tape and bubble wrap that were quite generously used.

After freeing up the rifle and then unwrapping the rear target site, which had been removed and wrapped separately to prevent damage, I quickly mounted the site and brought it into the bright kitchen light to show off my treasured wood to my wife. She said that it looks alive, like a fish swimming! A great improvement over, “I’m not interested in that stuff”! So, I took off down the stairs with a big grin on my face to my little 9.5-yard range to try it out.

The curl goes all the way through the stock.

Giving the gun a quick once-over to make sure all was in place and not loose, I broke it open and cocked it. Man — this thing is easy to cock! A six-year-old could shoot it if he could hold it up. My old bathroom scale says it takes 18 lbs. to cock, and it weighs about 8 lbs. Even at 8 lbs., it should be an all-day shooter for me!

Barrel patina.

I took a couple of shots at about 5 feet and then 15 feet to see if it would stay on the paper and to check function. “Check function”… uh-huh! That’s the adult way of saying, “I really can’t wait long enough to go over this thing in detail. I gotta shoot it NOW!” Yes, just under the surface, I’m still just a 10-year-old boy!

What you don’t see in the pictures is that the stock is scratched up. The barrel and compression tube are about a quarter to a third speckled with surface rust that’s not pitted. It’s more like the bluing wear from many hands, rather than neglect. Even with these faults, I’m inclined to just treat the whole gun with oil but not refinish it. Most of the scratches in the stock would vanish with a light sanding, but there are a few that would alter the stock’s original lines if removed. Since I’m not really a big fan of wood filler and refinishing over scratches doesn’t look right, I’ll leave it alone. I kind of like this gun the way it looks, anyway. It speaks of a long life of use and enjoyment that would be lost if I dolled it up too much.

One of the worst dents on the bottom edge of the stock. Some of the wood fibers are cut, so I don’t think this will steam out cleanly without leaving a hash mark. There are a couple more on the forearm that are as deep.

First results from my Competition Electronics ProChrono Digital chronograph with RWS Hobby pellets weighing 7.0 grains was around 412 f.p.s. Not that encouraging, considering a quick online search finds that LG55 rifles should shoot around 550-575 f.p.s. at sea level. I’m shooting at just over a mile high in elevation, so I don’t expect to ever make that 575 f.p.s. mark, but somewhere around 525 f.p.s. would leave me tickled pink! But, the rifle is shooting very consistent within a few f.p.s. around 412, so I added a few drops of heavy silicone dashpot oil to the chamber and let it sit a few minutes.

I checked the breach seal while adding the oil, and it looks like it’s in good shape, smooth and standing just a little above the surrounding metal. Tissue paper laid over the breach while firing confirms a good seal. If the tissue doesn’t move, there isn’t enough air leaking through to matter. No oil spray on the tissue is another good indication the breech is tight.

The oil in the chamber brought the velocity up to around 468 +/- 2 f.p.s. right away with no excessive smoke due to the low power of this target gun. That number goes up more after the gun has set for awhile, then drops back off while shooting. That’s still encouraging. Along with the smooth, un-twangy solid thwack when the rifle fires and no grinding with a positive click of the sear falling into place when it’s cocked, that tells me the gun probably just needs a new piston seal. The piston seal on this gun is synthetic, so the oil is just a temporary fix/diagnostic tool. It will need to be replaced to regain its velocity potential.

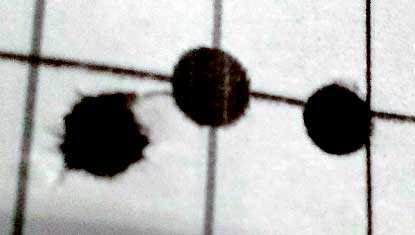

The difference on the target between 500 f.p.s. of the LG55 and 750 f.p.s. from an HW57. A faster pellet cuts cleaner and is much easier to score or measure when your target isn’t exactly square to the shooting lane. A slower pellet has more tear-out.

While shooting through the chronograph, I noticed that I’d run out of adjustment on the sight and my groups were still hitting an inch high and to the left. Oh no! Shipping damage? Bent sight? Major tweaking might be needed! Ok, calm down and take a good look at things. First, I sight along the compression tube and barrel under a light to see if it’s out of line. Looks pretty straight there. Check the sights. Tight and straight. Front sight is straight and the target insert is correctly seated in its notch, so on to the rear. The click adjustments run full travel on the rear peep sight, and it doesn’t appear to be bent. The sight base seems to be clamping the dovetails correctly. Hmmmm. Ok, loosen the knurled knob and take off the sight to examine it closely. All appears good, so I centered the adjustments, and the peep is right in the middle. No problem here. More thinking….

I decided to remount the rear site and noticed that there are markings and grooves on top of the rail. I lined up the front of the sight with one of those marks. Ah-ha! The knurled nut now travels much closer to the base when I tighten it. The nut has a collar that extends into one of those grooves, locking the sight in place! After tightening it up, I decided to take a shot at a new target. Nine ring! Another shot. Another nine, breaking the ten ring! Great, that was the problem!

In my over-anxiousness to shoot, I’d missed seeing the grooves while mounting the sight and it wasn’t seated properly on the rail. This is what threw off my point of impact. No barrel tweaking or major work other than a seal replacement is required! I’ve found a source for the seal and some other parts for this old gun at JG Airguns. I may make a seal mod with some Teflon round stock and a quad-seal o-ring (like I did with my TF99) if I can’t get this one soon enough.

Notice the horizontal lines on top of the compression tube, in between the dovetails. The front of the sight must be aligned with one of these in order for the locking collar (beneath the knurled nut) to slide in and out and secure the sight from sliding.

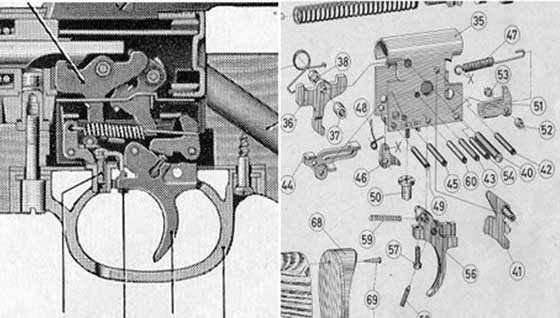

The trigger has a really long first stage, and there’s even a little slop in the trigger blade before it starts. I need to do some more research online for adjustment procedures to see if that can be reduced. If not, I’ll leave it as is and just get used to it because it has a light first stage (almost a take-up) followed by a nice, clean, very light and predictable break. It makes the Rekord trigger on my HW57 feel heavy. Definitely not a modern lawyer/liability trigger here!

LG55 trigger adjustment screws.

Walther has diagrams of the LG51’s trigger on their website, but I don’t think it’s the same as the LG55’s trigger. The LG55 trigger is shaped different and has more adjustment screws. I’ll need to fiddle around with them to see which one does what, unless someone can point me to the info I need. However, an online search has brought me these drawings that give me a better idea of what’s what.

I’m pretty sure I can figure out which screw does what. The only thing that confuses me here is the far left collar (number 50 in the picture on the right), which has click stops when you adjust it…much like a scope turret. Thanks to the kind souls who posted these pictures on the Yellow Forum a while back!

I was curious about when this rifle was made but couldn’t find any definitive information from Walther online. From what I could find in the forums from others who’ve paid Walther for their serial number lookups (and doing a little SWAG), S/N 086xxx tells me this rifle is 50+ years old. So, it was built back in the days when people took a little more time and pride in their work. A time before time studies and efficiency experts set unrealistic bars for production people to meet. But, I digress. I just like old guns!

I would normally run an accuracy test at this point, but I really need to first fix the compression seal to get the velocity back and stabilized. The accuracy and velocity test will be in Part 2. So far, even though I need to do a little work on it, I’m completely happy with this purchase.

I like the gun alot. The sight is nice also. But the stock. That’s a different story. I absolutely love the wood.

Thanks, GF1! I really lucked out nabbing this one!

/Dave

/Dave,

Great write up.

What a find! The flame in that stock is magnificent.

It’s amazing how many different triggers Walther put in their LG55’s. You have a later trigger. Screw 1 (collared screw at the very front of the trigger guard) is the adjustment for your second stage. Counterclockwise is lighter pull weight. The screw behind it adjusts the first stage. Clockwise shortens the length of pull.

ps-behind screw #2 is a small set screw. This is usually covered with varnish to discourage owners from tampering with it. This screw regulates sear engagement. Unless you really know Walther triggers I would advise against touching this screw. I only mention it because it elevates this vintage triggers above the coveted rekords.

pps-if you’re interested in a variety of inserts for your front sight and/or an adjustable iris for your rear diopter to add spice to your shooting enjoyment let me know. We’re not far from each other and I might be able to help.

Kevin

Thanks, Kevin! I appreciate the offer, as well as the info on the trigger. I’ll try to stop by sometime this month if you’re going to be around. I think I still have your email if it hasn’t changed within the last couple of years.

/Dave

/Dave,

Same email for years.

kevin

Hello /Dave and Fellow Airgun Buffs

A great write-up on your new to you Walther LG55 air rifle. I can but lust over the smooth lines and elegant curves of the stock. Is this wood flame maple per chance? The target airguns of this vintage, have a special appeal to my eyes. You are correct about the quality of workmanship put into your gun. Personally, I would not do too much about the bumps and pits in the stock. They seem to speak of the journey this rifle has taken on the way to becoming yours. You have every right to be proud and even brag a bit. I don’t think anyone need tell you to enjoy your acquisition.

Ciao

Titus

Titus,

I know that wood looks like maple, but I believe it is actually walnut. I have encountered walnut stocks with figure like this before — though this one is the most extraordinary figure I’ve ever seen.

B.B.

Thanks, Titus! It is really walnut. Pardon the lousy phone pictures, but in real life you cansee open grain. Maple and beech both have closed grain so I’m sure this one is some variety of walnut, although I couldn’t tell you which.

/Dave

Now you are really making me wish I had bought it. Oh well, if I had I probably would not have picked up my BSA. That is one sweet find. If you get tired of it, pass it my way.

RR,

Are you saying he got this at Roanoke?

B.B.

BB,

I got this one from Matt Cooney on the yellow classifieds. As much as I’d like to go, I’ve never been to Roanoke…

/Dave

/Dave,

I’m so glad to hear that. I would have been very sad to know I had passed this rifle up.

You have a real winner. You’re going to love it.

B.B.

I saw it right after it was posted and almost went for it, but decided not to. It is mighty pretty, but not quite what I was looking for.

/Dave,

I have to tell you that Edith comments that your stock is the most beautiful wood she has ever seen. I asked her about my Ballard stock and she said yours is better.

By all means, wipe that wood down with Ballistol. If you think it looks like a hologram now, just wait until you have done that!

Great part 1, by the way. Can’t wait to see how she shoots — after the fix, of course.

B.B.

Thanks, Edith! And thanks again Tom, for letting me share it with everyone! Hardly a day goes by that I don’t go downstairs and at least pick it up and admire the wood! I’m really happy with it despite the scratches. Oil looks great on the stock!

/Dave

Vintage Walther wood is known for being a cut above the crowd. The wood on /Dave’s LG55 is exceptional. Here’s another Walther LG55 that has nice wood:

http://www.network54.com/Forum/405945/thread/1349056087/Walther+LG55+DST+Tyrolean

kevin

Kevin,

That wood is gorgeous!

B.B.

B.B.,

Thank you.

Walther made some masterpieces back in the day.

Did you scroll down towards the bottom of that thread and see pictures of Vlad’s LG55? Looks to be the sister of mine.

kevin

Kevin,

I didn’t, but now I have. You’re right! It looks like a twin.

B.B.

I have Kevin’s two ugly sisters in my stable.One with double set triggers,both Tyroleans and also “gently conserved” because if Kevin wasn’t going to refinish w/ 40+ yrs experience (not to mention a true “gift”) I sure as heck wasn’t going to!! They are both drill press accurate @ 10M from a rest.

Yea, yea, yea, they are indeed sweet eye candy, but did you see that scoped BSA!

both of those stock are sweet. i like how you can follow the hard grain through the checkering in the first one

Kevin,

Those are real beauties! I’d almost be afraid to pick one of those up and shoot it! Almost….. I love the Tyroleans! One is definitely on my list of eventualities. I was actually looking for one when I got this, but I just couldn’t pass this one up….

/Dave

/Dave,

That’s my rat gun that I keep by the back door. If you stop by you can shoot it.

kevin

Kevin,

If that’s your rat gun, I really gotta see the others! I’ve got a little time next week and the week after Christmas if you’re around. I’ll send you an email when I get it figured out which days I have.

/Dave

/Dave

That’s a really good looker, Dave. Can’t wait to see some paper after you get the new seal in.

twotalon

Thanks, tt! The seal was just shipped, so hopefully I’ll get this done soon barring any other difficulties.

/Dave

Dave,

That’s some really beautiful wood! I love this structure and I know it, It takes a specific wood and a specific cut to create such texture.

The only bad thing about this “fire” structure is that it’s prone to loosing some wedge-shaped pieces on curved surfaces (just like it happened in your case on below) and deterioration of wood’s strength with age. It can be prevented by some really deep treatment with lineseed or tunga oil (actually sometimes it’s boiling) or very thorough and coat-on-coat covering. I once restored such dent on below by carefully sawing off all the bottom flat and glueing there a thin layer of beech then a 3/4 inch thick bar of blackwood and reshaping the forend to be my favorite “pumped equilateral triangle” shape.

On trigger – I would try to wash it with WD-40 and toothbrush and blow thoroughly with air, just to get rid of any old grease. Sometimes that can do wonders.

And I would be very-very meticulous on screws (especially front ones) and the way they’re holding in an old wood. Holes can be all chewed up and weakened with age, so good brass cups set on a good deal of epoxy can give some more accuracy without intervening with overall look of the rifle.

duskwight

Nice tips! Spasibo, duskwight! That isn’t a lost wedge, just a bad ding. I haven’t taken the action off of the stock yet, but that’s coming soon since I already have the seal on its way. I’ve had good luck in the past reinforcing the wood! screw hole with thin epoxy or cyanoacrylate applied before the wood gets stripped out. So far I haven’t found any cracks in this piece.

/Dave

Howdy Slasher Dave, Atta boy! Great report & congratz. Shoot/ride safe.

Beaz

Thanks, Beaz! We’ve got cold, nasty weather headed our way, so I’ll be ridin’ my Jeep for a while.

/Dave

Readers may be confused by the chronograph portion of your post, where you state that the manufacturer of the ProChrono Digital is “CED.”

Competition Electronics makes the ProChrono Digital Chronograph, which is what your link connects to.

Competitive Edge Dynamics (CED) makes the CED Millenium chronograph. The current model is the CED M2. You can see it here: http://www.cedhk.com/shop/products/CED-M2-Chronograph-Set.html

As you can see from reading the two different product web sites, they are significantly different – both in capabilities and price.

redlace,

I made that link, based on how /Dave named the chronograph. Perhaps that was my mistake?

B.B.

Based on his statement, “First results from my CED ProChrono Digital chronograph with RWS Hobby pellets” I believe you made the correct link. The confusion stems from /Dave’s conflation of the two company’s names:

Competition Electronics – makes the ProChrono line

Competitive Edge Dynamics (CED) – makes the Millenium line

By calling his chronograph the CED ProChrono Digital, /Dave has created a manufacturer/product combination that does not exist. It leaves readers to wonder if he has a ProChrono or a Millenium.

Thank you for the correction, redlace. My mistake. It is a CE ProChrono Digital, not CED.

BB or Edith, can you correct that for me, please?

/Dave

/Dave,

I corrected it. Thanks, guys!

Edith

Nice grain in the wood. I notice that women, at least non-shooters, have a different take on guns. They are inordinately concerned about the looks. Yes, I’ve noticed that faster pellets make smaller cleaner holes. That may be a reason why my B30 seems to consistently shoot better than my IZH 61.

Kevin, nice to hear the confirmation about the Aimpoint. With the cheaper one you might have gotten lucky although it’s possible that whole brand is good, not just your copy of it. I’ve heard rave reviews of the EOTech sights, but their prices are through the roof.

Matt61

Matt61,

For what it’s worth, I shoot with two guys that liked the ultra dot match dot sight so much on my pistol that they each bought one for their pistols. These were purchased in the past two years and have worked flawlessly for them on their guns. Mine has never given me a bit of trouble.

kevin

Matt61,

I have never met a female shooter who cared more about the gun’s looks than how it felt in her hand, on her shoulder or how accurate it was. Non-shooters may concentrate on looks because they don’t know what else to comment on. Most women and men…shooters and non-shooters…think that all guns are accurate, so there’s no need to actually comment about that.

Edith

Well….. Guilty…… I did like this one’s looks. But I promise to out it through the ringer after the seal change!

Nice one /Dave! Very classic air rifle looks; rare that a rifle can bear the addition of that much stripe/figure without getting overbearing, but that one wears it elegantly. Enjoy, and I’ll look forward to future installments.

Thanks BG! Hopefully I can get the fix and the next report on how it turns out done before the end of the year. I just got assigned a bunch of overtime that I didn’t really want….

/Dave

I like the wood on this gun. I’d probably pull it apart, sand the metal down to bare metal and reblue the entire thing though. I’m fairly picky about the condition of my guns. It needs to look great!

I bought a few used guns but only reason I buy them used is because they were guns that Michigan has totally crazy rules about. I don’t see how a pellet pistol that fires a pellet through a rifled bore at 495 fps is any more dangerous than one that fires a bb out of a smooth bore at 495 fps, yet I have to treat a pellet pistol like a real 1911 if I buy one new. I have to have it sent to an FFL dealer, go through a background check, get a pistol purchase permit or an concealed carry permit. I’m not going to go through all that for a bb gun. But for rifles it’s new or nothing for me.

Ah… You remind of the second reason I need to sign up for the CCW class…

I won’t do it just for a pellet pistol with a rifled bore. That’s beyond crazy politically. That might even top California for crazy liberal gun control laws….Well maybe not since California now has special police teams who’s only job it is to go without a warrant to people’s homes and confiscate legally purchased guns for any infraction such as a speeding ticket, traffic accident, misdemeanor shoplifting, owing back taxes etc.

John,

Michigan’s leadership sounds like typical reactionaries that can’t think their way through anything in a logical manner…. We’ve just pressured another idiot into resigning her house seat here in Colorado. Hopefully we can continue the trend back to people showing a little sense.

/Dave

To be fair there are some worse ones out there California is becoming a police state. New York has some seriously draconian gun control, and Illinois is the last state in the nation to allow concealed carry. People wouldn’t have that much if the U.S. Supreme Court had not ordered their politicians to allow it. Even then they tried to get around it by making concealed carry too complicated. A friend of mine that lives in Illinois tells me they have to have a valid FOID card for anything over a .18 caliber pellet rifle. I simply have to treat any air pistol with a rifled barrel under 26 inches long as if it were a 1911 or other powder burner and I have to go through a gun dealer to buy anything with a shrouded barrel or permanently attached silencer….as if that makes them more dangerous.

Take into account that, two years ago, I WAS in the PRCa…

At that time, at least, pellet pistols AND shrouded pellet rifles were readily available.

And, at that time, a CCW from any county other than the unpopulated northeast counties practically required buying the sheriff <G>

MI is a shall-issue state, and if a one-day class is sufficient… Fine (heck — before the PRCa approved pepper spray for open sale, I DID take a four-hour class to obtain a permit for CN tear gas [as I recall, CS was never legal for general public]… And “stun guns” [the non-shooting type yet — where you had to hold the electrodes to the perp] were readily available at sporting goods stores — whereas MI requires a CCW for THEM; I used to carry one in the center console of my Jeep)

Wulfraed,

Comments like yours remind me why I love Texas so much. I literally thank God every day for letting us live in this great state.

Edith

That is a nice find.Reminds me of the Winchester333 I picked up this summer at the Windsor Ct show on Jan Kramer table.