by Tom Gaylord, The Godfather of Airguns™

Writing as B.B. Pelletier

This report covers:

• The competition: Where does the Dan Wesson sit?

• You asked for this!

• Where’s it made?

• Details, details

• The big difference!

• Sight options

• Scope rail not strong!

• Reloading speed depends on loading the cartridges

• Things so far

Yes, friends, this report is about a Dan Wesson pellet revolver! It looks like a BB gun, but this one shoots lead pellets. I selected the 8-inch black gun because that’s what I prefer. There’s also a silver-colored version with a 6-inch barrel that more closely resembles the stainless steel firearm.

The competition: Where does the Dan Wesson sit?

I don’t usually do this, but in this case I believe a look at what’s already out there is warranted. This airgun retails for $160. On the low end, the Crosman Vigilante retails for $50; and on the high end, the S&W 586 sells for $260. So, the Dan Wesson sits in the middle.

I’m not going to compare performances of these 3 guns because that quickly devolves into a, “Which brand do I like the most” competition. Because there are so few pellet revolvers on the market, I think it’s good to note where this one is positioned. The maker advertises a velocity of 426 f.p.s. That’s pretty zippy for a pellet pistol, and we’ll test that in the next report.

You asked for this!

Every time I review a nice BB revolver, there are always people saying they would buy one if only it shot pellets. Well, this one does, so no complaints! I also like the other 2 pellet revolvers mentioned above; and if this one turns out to work well, I think it’ll be a fine addition to the market. The S&W can put 10 shots into 1.30 to 2 inches at 10 meters in my hands. It’s been 2 years since I tested one of those, and here’s a link to that report.

Where’s it made?

The CO2 revolver is distributed by Action Sport Games and made in Taiwan, where it appears to have been converted from an airsoft gun. While the manual is clean and larger than a typical Asian airsoft manual, the illustrations are still very characteristic of airsoft manuals. The instructions are written clearly, though you can tell they’re translated because of things, such as the rear sight notch being called the “aiming hole.”

Airsoft manufacturers are making inroads into the conventional airgun market. That’s a good thing because airsoft guns generally have a lot of realism. Since they’ve been mimicking firearms for decades, these guns follow the lines of the firearms they copy more closely than many airguns. And airsoft manufacturers know the importance of all-metal frames and exteriors. They don’t try to get by with plastic parts when the guns get up into the price range that this one sells for. This one has all metal parts on the outside and weighs 36 oz. — lighter than the Dan Wesson model 715 revolver it resembles, but still heavy enough to hang well in your hand.

Details, details

This is a double-action revolver with an 8-inch rifled steel barrel. It can also be cocked and fired single-action if desired. The finish is a black that resembles the black oxide found on steel guns these days, though this metal is non-ferrous. A magnet informs me that many of the action parts are made from steel, but the outside of the gun is non-ferrous metal.

The grip angle is steeper than either a Colt or Smith & Wesson revolver. Some (like me) will like it, while others may find it strangely vertical. Of course, the CO2 cartridge lives inside the grip, which is opened by pulling back on the grip panels. The panels resemble the soft material used on firearm revolvers to counter recoil; but since there’s none with a CO2 gun, they’re hard plastic. I found the grip panel (it’s really a single piece) comes off easily if you don’t pinch it while pulling back.

The grip shell is pulled straight back to open the gun for installing a CO2 cartridge. The shell is hinged at the top and doesn’t come completely off the frame. This photo also shows the cylinder release pushed forward to open the cylinder — and back to put the revolver on safe.

The cylinder swings to the left side of the gun, and on this gun that’s all there is to it. The pellets are held in simulated brass and plastic “cartridges” that act and handle like real firearm cartridges. They allow the gun to be loaded and emptied exactly as the firearm is loaded and emptied.

The cylinder swings out of the frame to load the gun and eject the empty shells after firing.

The big difference!

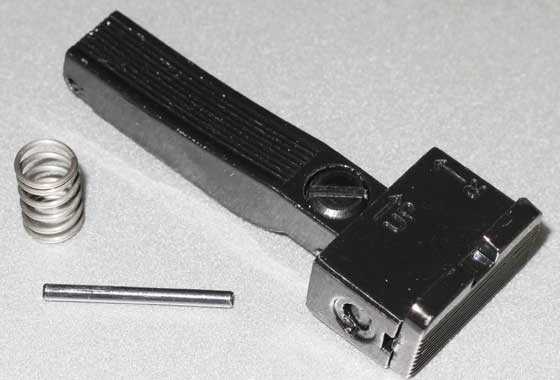

What sets this pellet revolver apart from all the rest is how it contains and shoots the pellet. There are brass cartridges that appear to be the same as .357 Magnum cartridges. Into each, a black plastic “bullet” is screwed. Only this bullet never leaves the gun. It’s really the chamber that holds the pellet, and the shell is nothing but a conduit for the gas to follow to push the pellet into the barrel. The picture tells the rest of the story.

The pellet is held in the black plastic head of each shell. When the gun fires, gas rushes down the tube formed by the shell, pushing the pellet into the barrel.

The gun comes with 6 cartridges, and a set of 12 additional cartridges may be purchased for $30. If you have the gun, you’ll probably want some of these. They will make reloading the gun go faster — especially when the speedloader is used.

Sight options

The Dan Wesson comes with a crisp set of adjustable sights. The front has a white dot for rapid acquisition, but the post is square. The rear notch is fully adjustable. But, wait! There’s more!

Every pistol also comes with a Picatinny rail that can be installed in place of the rear sight, readying the gun for optical sights. Many of you will welcome this feature, which is included in the package. The gun also comes with a speedloader that handles the shells in the conventional manner and an Allen wrench to attach the scope rail.

These accessories come with the gun. The Picatinny rail is installed in place of the rear sight, and the Allen wrench tightens the screws. The speedloader works the same as all speedloaders.

Sight rail not strong!

The design of the Picatinny rail didn’t seem robust to me, so just for grins I mounted it on the gun. It’s very fragile; and, in my opinion, it can’t support an optical sight of any weight. It’s held in place by a single jam screw that pushes against the top of the barrel and a thin narrow dovetail on the barrel’s top. The rear screw goes all the way through its hole and past it, supporting nothing. I won’t be testing a scope with this revolver.

The rear sight comes off the revolver so the Picatinny rail can be attached.

The rear sight, on the other hand, is well-designed and appears to have no flaws. That’s how I’ll test the revolver’s accuracy.

Reloading speed depends on loading the cartridges

The revolver can be loaded fast once the 6 cartridges have pellets in them, but loading each cartridge takes time and is the revolver’s Achilles heel. They load in the same way that Brocock Tandem Air Cartridges (TAC) did without all the extra maintenance, and they were what killed the Brocock gun sales. It took too long to assemble and load the cartridges.

Things so far

There are some good points and some that aren’t so good. From a functionality standpoint, this revolver should work well. I can’t wait to see how it does on paper.

Dan Wesson revolver is a new addition in the world of pellet pistols.

This is proof that our voices have been heard!..With that said,Crosman!- Bring back the 600!

Reb

Buldawg,

The lack of space and my ability to navigate seemed to necessitate a new beginning. I took the stock over to show the guy I got it from tonight and ask him what was going on with his 140. I’m gonna rebuild his gun, whether he wants me to or not, Kinda like a Intervention,I don’t think he’s ever shot it. It’s his pride & joy! Where did you get your quad-seal and other gaskets?

Reb

Reb

I got my seals and piston cup off of ebay. There is a kit for sale on there right now for 45 bucks. You can sometimes find the seals and cup cheaper individually but not always and they may or may not be cheaper. Here is the ebay page link with the complete kit.

http://www.ebay.com/itm/321360069804?ssPageName=STRK:MEWAX:IT&_trksid=p3984.m1423.l2649

This has every seal and cup for the pump piston that is needed to rebuild a 140.

If you get the kit you can go to Pilkgun.com for picture instructions on how to make a washer setup to be able to press the old cup off the piston rod assy and install the new felt and cup onto the piston rod.

Let me know if you go that route and need help finding the info to replace the piston cup.

Buldawg

The first thing I checked was whether the piston seal would bounce back and be usable, and it did! All the air is escaping through the transfer port.Thanks for the link! His wife is coming by in a little while to pick up a sgn frame to advertise their garage sale and I’ll show it to her then.

Reb

Reb

If the air is escaping thru the transfer port on the 140 when you pump it, it means the quad seal on the valve end cap is no good or the hammer is not holding the valve cap closed on the end of valve.

The 140 and 1400 are known as self cockers which means that the guns cocks itself when fired, you do not physically pull back a bolt or other lever to cock the hammer into a loaded position. they operate just the opposite where the hammer holds the valve cap closed against the valve end and the sear keeps the hammer from allowing the valve cap to move backward letting the air out of the valve until the trigger is pulled and once the air is released from the valve the spring pressure on the hammer forces the hammer back against the valve cap and pushes it closed on the valve thereby self cocking the gun so that all you have to do to shoot again is pump it up, load a pellet and pull the trigger. Hence the term self cocker.

If you are hearing air coming out from around the transfer port or out of the breech area it is indicating that the Quad seal on the valve cap is leaking or the hammer is not closing it properly.

Here is a detailed visual rebuild instructions for the 140, you should be able to see what I am talking about from it.

C:\Users\Michael\Documents\Crosman and firepower gun Info\crosman 140 rebuild info.mht

Let me know if you have any more questions, the plastic cup seal generally does not wear out and as long as it does not have any nicks or pieces missing from the sealing edge of the cup it can be reused, but if you want to get the complete kit and replace the cup let me know and I can send you instructions on how to remove and install the cup as it has to be pressed on and off the piston rod.

I have got my 2289 back together as a pistol and have the 2240 22 cal just about together, but am trying to decide if I want to buy a Prod hammer spring adjuster parts or make one from the stock end cap. I am calling crosman to see how much the hammer spring adjuster parts are and then I will make my decision and get it done.

Buldawg

Buldawg,

Thank you for all that information and the link! Sometimes I have good luck with them and sometimes not.When I first saw this gun I went home to get my oil because it was very dry and I had learned how involved the piston rebuild was. I always prefer to do the least amount of work required to attain the desired results. What I expect to see when I get into it is a quad seal that is cracked in at least one place and very dry except for the fresh oil that’s being circulated by the now working piston seal and will probably crumble on extraction. I have seen video of quad seal replacement.I remember explainig a 880 rebuild and it sounding a lot like that.I can’t wait to see inside this gun! I’ll go see what’s in that link.

Reb

Buldawg,

I never got the link you posted to work But I dug a couple up. This is a 2 part 140 walk through for posterity sake just in case anyone else needs to go through onehttps://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&cad=rja&uact=8&ved=0CB0QtwIwAA&url=http%3A%2F%2Fwww.youtube.com%2Fwatch%3Fv%3D3ontC6Rk4rE&ei=bS3qU6P2OcfC8QGdnIHICg&usg=AFQjCNFXegfiD2_aZ8tBDh3WJ7lbk3icbA&sig2=bixYRMttZ1bHSbH38Pys_g

Reb,

Your link got all messed up. This should work:

https://www.youtube.com/watch?v=3ontC6Rk4rE

Edith

Thank you Edith! I believe you too. My day wasn’t going well enough to hang out and see what could happen next. I took one of my blood pressure pills and went for a ride. I hoped for the best and that was a nice welcome.

Reb

Reb

Try this link and see if it works. You are right that the quad seal is probably shot.

http://anotherairgunblog.blogspot.com/2010/02/some-more-notes-on-reassembling-crosman.html

Hope this one goes thru for you and good luck with the build.

Let me know if you need help with any of it.

Buldawg

Reb

On the link I just sent you it is 2 or 3 parts to it and you have to look on the right side about half way down where it says crosman build part 2 and part 3.

The hard piston cup seal very seldom wears out and only needs the felt oiled real; good once you get the quad seal replaced.

Buldawg

buldawg

I left you a reply over on the 1077 article about the 2240.

Did you get the 2240 with the .22 cal. barrel together?

And I have some news on the Hatsan QE. I had some great shooting weather the last two days. Absolutely no wind blowing both days. Humidity was low 40% (for my area anyway) and in around 82 degrees.

I was really able to work on the fill pressure and grouping with the Hatsan. I tryed several different pellets. But the Crosman premier heavy’s 10.5 grn. in the box was the winner. And the gun likes to be filled to 2800 psi.

The JSB’s and other pellets were getting around a 1” group at 50 yrds. Sometimes a little smaller. Sometimes a little bigger. The premiers are getting every time around a .500” to mid .600” group from center to center.

And here is the part that’s kind of strange because my other pcp guns don’t show this like the Hatsan does. Above 2800 psi the pellets wont group good. It would throw out flyers also. And the same happens when I go past 20 shots. I even tryed 3100 psi with three clips (30) shots and that last clip would start opening up the group and throwing flyers just like it does above 2800 psi.

So the magic combination on my Hatsan so far is the 10.5 premiers in the box with 2800 psi start pressure and 2 clips (20) shots. I did 17 fills on the gun yesterday testing. And that’s what produced the best groups. That was a little over 500 shots with it for the day.

And the weather definitely helped out. And I was able to get some good testing in. Oh and forgot I was drawing 4 dots on printer paper and taping it to my phone book and 2×4 pellet stop. I was shooting 5 shot groups with the two clips.

It was closer to a bit over 400 shots. Not 500.

I forgot that I wasn’t shooting 30 shots every fill. Probably 9 of those fills were 20 shots per fill.

Gunfun

I saw your post on the 1077 blog and will just answer here,

Yes most all automotive A/C systems have a desiccant bag in them either in the accumulator in GMs or in the receiver/dryer in the older systems that had the sight glass in them to tell when the system was full and have just seen to many rupture to leave the paper bag in mine.

I got my 22 cal most of the way together but noticed that when you screw the hi-pac cylinder in place in the 2240 tube and manually operate the hammer to check for full valve stem travel in the valve that the valve will only open about 3/4 of it travel and then the piercing end hits either the black seal that comes in the kit or the inside edge of the hi-pac cylinder, so I am checking that and may either drill out the end of the hi-pac cylinder a little bigger so it clears the piercing end of the valve or cut off the piercing end of the valve stem. I am anal when it come to everything being perfect.

I am also going to call crosman because when looking a the stock end plug to drill it for an adjustable hammer spring adjuster it would not really have enough threads to thread a guide in without over adjusting the spring just to have good thread engagement. In some research I found that the Prod has a adjustable hammer spring end cap as a stock feature and that it would be a perfect fit in 2240 tube so I am calling crosmamn to see what the cost of the end cap and spring guide are and if they are cheap enough I will order them instead of making one from the stock cap.

Its the little details that always bother me and slow a project down until it meets my anal perfection.

So yes I have made headway, but no it is not how I want it to be yet so some more time to get it right and then the 177 will be faster because I have worked out the growing pains with the 22 cal conversion.

Looks like you got your hatsan figured out pretty good with fill pressures and pellet groupings, that sound like some good groups for sure. Glad it is working good for you and sound like you are happy with it. I got lucky and found some 10,5 CPs in the tin a wally world the other day for 8.43 per 500 which is a good price at 9.42 out the door with tax so I can see how my 40 buck springer like them.

I will keep you up to date with my 2240 conversions as I get the little issues worked out, I really don’t want to cut the stem on the valve off so I have to check to fit off my 177 conversion valve fit in the end of the hi=pac cylinder to see how much I would have to drill the cylinder out to clear the stem end without contact at full open position of the valve stem.

Buldawg

buldawg

Check towards the bottom of the page on the 1077 report. I posted a link yesterday to the RAI website. He sales adjustable end caps seperatly from his AR butt stock adapters. Check it out.

And very happy with the Hatsan after yesterday.

And let me know what happens with that piercing stem. But a question. The striker can’t push the stem open the full distance? I may be wrong but I dont think the valve is suppose to open very far when the striker hits it. And also when you fill the gun with air it should push the piercing pin in. I dont think it will interfere with the hi-pac.

Gunfun

I have seen the spring adjuster on the RAI site and he wants 43 bucks for one, I will bet that the Prod parts from crosman are quite a bit cheaper. I know if I ever wanted to put the tactical stock on one of them that all I would need is his adapter for the Prod if I had the adjuster from the Prod already on my 2240s.

I know that the valve will probably never open that far with HPA in the gun but when used with CO2 the valve does open its full travel because the pointed end of the piercing part of the valve stem is what punctures the CO2 cartridge so it has to move its full travel to be able to pierce the cartridge. I have just went and checked the valve stem and the piercing part of the valve is a loose fit in that it will spin and wiggle back and forth in the end of the valve stem but it does not compress at all and the loose fit is to allow for machining tolerances so that when you load a CO2 cartridge in the gun and fire it the first time the piercing stem will be able to line up with the hole in the end of the valve body and pierce the CO2 cartridge without binding in the valve body.

Whether of not the valve stem moves that far when using HPA or not it should not contact the end of the hi-pac cylinder for any reason, because if I install an adjustable hammer spring end cap and want to adjust it for maximum power full dump scenario I do not want the piercing stem to hit the hi-pac at all.

I guess it comes from working at Harley as research and development mechanic in that I check and double check every part and it interaction with all other parts that it is in the vicinity of for proper fit and function and clearance or interference issues. I see the fact that the piercing stem part of the valve stem contacting the hi-pac cylinder on the full travel that the hammer is capable of moving in the slot on the top side of the tube as an issue and interference problem that needs to be corrected for proper operation and durability of the overall product. Remember that is were I worked at Harley was durability and if there was any issue with fit or function it was my job to find it and report it and suggest on how to correct the issue. The same goes for fixing cars for a living for 45 years in that ” if you don’t have the time to fix it right the first time where are you going to find the time to fix it right the second time”. That motto and work ethic is why my comeback rate in the automotive and research and development jobs that I have done for 45 years is less than 1% for total work performed. I was never one of the fastest mechanics in dealer ships or at Harley but while the fast mechanics were having to go back and fix there mistakes/oversights of a repair I was still making money because you don’t get paid for a comeback when working flat rate.

So in short I will correct the issue before completing the build and I feel that hi-pac did not properly test their product for all fitment and function issues before selling to the public. but then again as I have stated before I am an anal perfectionist when it comes to my toys of any sorts.

Also one thing that I do not like that I think crosman dropped the ball on also is the way the valve is held in place in the tube ,it has the screw that threads into the valve and prevents it from moving back and forth in the tube because the head of the screw is a loose fit in the tube and when you screw the hi-pac cylinder or even a CO2 cartridge in place in the tube it forces the valve rearward in the tube and causes the transfer port to be miss aligned with the hole in the tube going to the barrel port and over time it will wear on the transfer port bushing and either wear it till it fails or elongate the hole in the tube. So I will be looking at hat issue also, I just can’t help it as it is in the details that make life what it is.

I will let you know when it is up and shooting and I already have decided to drill the end of the hi-pac to clear the piercing end of the valve.

Buldawg

buldawg

I left a reply earlier but dint go through. I will try now.

Yes I have seen the transfer port hole not lied up with the tube before. Both of my 2240’s were centered good. I have made bushings in the past to press fit over the head on that bottom screw that holds the valve in place. That works nice.

And how much bigger are you going to drill out the hole on the hi-pak. Is it going to make the sidewall thickness to thin. Dint know if you thought about that.

And one last thing. I think I know what made the premiers work better. The hole depth in the back of the pellet aint as deep as the other pellets I tryed. I believe the bolt probe is seating the pellet deeper in the barrel. Kind of like you can do with a break barrel gun. Plus the pellet is farther in the barrel past the transfed port hole. I have seen that help on guns with te transfer port hole on the bottom of the barrels.

I made the lead in chamfer on that 60c barrel deeper and then machined some of the face of the barrel off also. That way the barrel fit deeper in the breech. I did have to open the transfer port through hole in the barrel up and also the spot for the transfer port bushing to fit. And also the hole int bottom of the breech had to be opened up for the transfer bushing to fit. That way it allowed the pellet to seat deeper. I have been wanting to make a bolt with a longer probe to try in my Disco barreled 2240 just to see if it helps. And another thing on my to do list. 🙂

Gunfun

Go to the bottom as it is starting to get thin.

Buldawg

I have wanted to get an ‘action pistol’ for some time now, but have waited till there was one that fired pellets and either had blow back or in this case the imitation bullet. I would have loved to have got a Magnum Research Desert Eagle when they were available and still would if the opportunity arose, however they are as rare as diamond dusted manure. Well it looks like all my waiting has finally been rewarded and by hook or by crook i am getting me one of these, also looking forward to the rest of the report with great anticipation.

TTFN

Best wishes, Wing Commander Sir Nigel Tetlington-Smythe.

Very nice looking copy of a Dan Wesson revolver.

I shot the first perfect 40 X 40 score in IHMSA (International Handgun Metallic Silhouette Asso.) competition with an 8″ Dan Wesson .357 super mag, or also called a “.357 maximum”. This competition was shot from 50 meters to 200 meters using iron or open sights. The super mag used a case that was 1/3rd longer than a standard .357 mag case. In theory it shot as hard as a .44 magnum, but had better trajectory at the longer distances. I re-loaded mine just hot enough to knock down the steel ram targets at 200 meters, but not so hot that I couldn’t shoot it with accuracy. The clean score came at a state championship in Texas in the early 1980’s. That was a long time ago when I still had good eyesight 🙂

I have the airsoft version of this pistol in 6″ barrel. It’s a fun gun to learn with. I made a short video of using it: https://www.youtube.com/watch?v=v0TvNnfoTPQ&list=UUM7r7ajZG5n_vjGBZNkjdMA

I need a scatter gun to kill rats inside, my gamo shotgun is too long etc, can I use the gamo shotshells in this or the bb or air soft versions, that would do what I need I think,, …what do u think, also somebody need to put out a high velocity aid handgun that uses shot shells

plz send me an email too, I can’t always find this page

dapt@austin.rr.com

thx

D

Is it possible to get replacement parts for ASG guns? I’m thinking bb version to pellet conversion here.

And I bet I’m not the only one.

Good luck with that!

I lost the front sight (flew off with the blowback) on my tanfoglio witness 1911 and there was no way to order a sparr from them. They sent me searching high and low on airsoft websites.

If it’s out of warranty you seem to be on your own.

And if I remember right you can’t deal with ASG or the mothership Cybergun. You have to deal with Palco sports and if they haven’t changed they’re a pain in the you know what.

J-F

Dangerdongle,

Maybe I am wrong, but looking at my airsoft version of this revolver, it sounds like this conversion would involve changing the barrel only, and adding cartridges for pellets. Unless they created a new cartridge that is dimensionally incompatible with the previous one for BBs. Airsoft and steel BB versions differ very little between them, so I am guessing any of them could be used as a start for such a project.

B.B.,

I have 8 inch, 6 inch, and snubby versions of the Dan Wesson BB revolvers, so obviously I am a fan. As soon as Pyramyd AIR got these pellet Dan Wessons in stock, I bought one, an 8 inch in black just like the one you are testing.

if I may, I would like to add just two things to your first installment on this airgun. First, I actually have found the involved loading process to make the whole shooting experience more deliberate and more pleasurable than simply snapping magazine after magazine into an air pistol. The whole thing, shooting an entire 12 gram CO2 cartridge, is over in a five minutes! This slower, deliberate process adds to the enjoyment for me, AND it allows the gun to cool off a bit now and then. I do not believe that a speedloader would make the loading process significantly faster, unlike the BB versions.

To those who absolutely must always “buy into” our present immediate gratification culture, I would suggest that the road is at least as important as the destination. Specifically, the loading and preparing for shooting is at least as big a part of the process as is pulling the trigger.

Second, you mentioned that the pellet holders are plastic. I was so certain they were pot metal that I went over to mine and checked it out a few minutes ago, and while they are not magnetic, for the life of me I cannot tell if they are plastic or pot metal. They have a lot of weight to them, so if they are a plastic, it must be one heckuva dense one. Still, I have chosen to use narrow-head, wide-skirted, pure lead pellets, so no Crosmans for mine! Hobbies work well, I think.

I look forward to your next installment on this one, and thank you for reviewing it.

Michael

Michael,

There is wisdom in what you say. Slowing things down is one reason I reload for my firearms. And one reason I like multi-pump pneumatics so much.

It flies in the face of instant gratification, but the slower pace is what I prefer, like you.

B.B.

B.B.,

First, I meant allow the gun to warm up, not cool down. (Must . . . drink . . . more . . . coffee.)

I am reminded of two modern classic books that sound intimidating to a lot of folks but are actually easy to appreciate and learn from: Zen in the Art of Archery, by Eugen Herrigel, and the many books it has inspried, most famously Zen and the Art of Motorcycle Maintenance by Robert M. Pirsig. I also plan to read the highly acclaimed One Arrow, One Life: Zen, Archery, Enlightenment, by Kenneth Kushner. I know a number of folks who recommend reading Herrigel first, immediately followed by Kushner.

More recently there have been books I am not familiar with, but they include Zen, Meditation & the Art of Shooting, by Ray Mancini and The Armed Option: Zen in the Art of Combat Pistolcraft, by Warren W. Butler.

“If it is worth doing, it is worth doing slowly.” — Michael O’Gorman

Michael

Thanks for the title One Arrow, One Life; Zen Archery. BB looking forward to the rest of this report. I have the bb version and I like it!

B.B.,

For the same reason (in addition to improved accuracy) I always single load my rifles, even if it comes with a mag or clip.

G&G

That is a good looking pistol. And it looks to be good quality.

B.B.

Thanks for the first installment on the Dan Wesson pellet revolver. I’ve got the 6 inch and 2 snub nose (one golden brass, one chrome) Dan Wesson BB revolvers with about 50 BB shells, and I really enjoy them when I can get around to shooting them. I’ve been against buying the Dan Wesson pellet revolver precisely because of the extra time required to load the pellets which no doubt takes longer than loading BBs. Can you ask ASG if they ever considered making the shells to load the pellets from the back end rather than in the nose? If the pellets loaded into the back end of the shell without having to unscrew a cover, I might be more inclined to consider buying this pellet revolver.

Charles,

ASG is a marketing group. They don’t make the guns — they import them with their name on the box. They have little to no control over what is made — only what they put their name on.

B.B.

ASG = Action Sport Games

They’re located in Denmark. Up until recently, they’ve been concentrating on airsoft guns. Here’s the company history from their website:

ActionSportGames is a worldwide leader in the business of replica firearms and accessories manufacturing – including Airsoft guns, Airguns, Co2 guns and firearms replicas. We specialize in 1:1 scale replica guns and accessories for fun, action, sports, entertainment and collection. The assortment consists mainly of licensed models and exclusive subbrands of ActionSportGames. ActionSportGames was founded in April 2003 as a merger of the two largest Danish distributors of Airsoft Guns and accessories, Pedersen & Grobelnik A/S (founded 1992) and Vestergaard ApS (founded 1960). One of our goals is to become the preferred supplier in the firearms replica business through worldwide license agreements, quality brands and premium service – before, during and after sales.

Edith

Thanks Edith,

I think I had read that at one time and been aware that ASG is primarily a marketing group, but with everything else I do that bit of knowledge got crowded out of my memory. That said, do you happen to know what company actually manufactures the Dan Wesson pellet revolvers?

Charles,

I don’t know who makes the guns. I do know that the original Dan Wesson BB gun was brought into the U.S. via Gamo under their Aftermath brand, which is mostly airsoft products. Since Gamo didn’t bring in the other Dan Wesson guns, I guess ASG snagged a deal with the mfr.

Edith

B.B.

What you said about the weaver / picatinny rail mounting got me thinking about something. After you slid the rail onto the dovetail, did you reinstall the original rear sight or leave it off? When I mounted the rail on my 6 inch Dan Wesson BB revolver, I reinstalled the rear sight after sliding the rail onto the dovetail. Both rail mounting screws had something solid to press against so that the rail was very stable. For a short while I had a CenterPoint MultiTAC dot sight mounted on the revolver until I decided it made the gun too heavy. I recently bought one of the CenterPoint Quick-Acquisition laser sights to test on the revolver. At about 1.6 oz, it’s much lighter than the MultiTAC dot sight’s 6.5 oz.

Charles,

I didn’t reinstall the rear sight. Perhaps that is what is missing?

B.B.

B.B.

I wasn’t sure, but I thought you might not have reinstalled the rear sight. Do that and the rail should mount securely. The down side to mounting any kind of sight on a pistol / revolver top rail is that the pistol / revolver will no longer fit in a standard holster. I currently use a UTG holster I bought from Pyramyd AIR, but if I want to mount a laser or optics on top of the revolver, I might want to find a holster with a cut-out slot in the side to accomodate the top mounting.

B.B.

So, it seems that sometimes they hear our prayers. Well, at least sometimes 🙂

Very good revolver indeed, a must have for me, since everybody knows I’m a long revolver fan.

Our prayers were heard, but not till the very end I’m afraid. The problem, I believe, is with the “cartridge”. Loading a pellet to the front leaves too much of a dead volume behind, which in case of CO2 with its low pressure and pistol-sized valves can steal quite a deal in FPS – and that’s critical when you shoot a modest-speeded gun like this revolver. That, I think is a thinking inertia at its best. By the way, loading pellets to the very rear of the cartridge could successfully imitate shot/unshot pistons and allow for a quick inspection of the gun and spent/unspent rounds. Perhaps they’ll hear this prayer too 🙂

Right now I’m finishing my new CO2 revolver, modified to be something of a “long range match” format. Veeeery long sleeved barrel and plywood “sport-style” grip. Hope to finish it by next weekend and I will share some photos and shots.

duskwight

(Repeating to myself: “I have enough air pistols already….I have enough air pistols already…. I have enough….”

Hm, doesn’t seem to be working. But I will try to hold out until they add a snobby version….

Mike U,

Sorry, but like everyone else here, you’re horribly addicted to your airguns. LOL. I started this hobby two years ago with a Crosman 357 6 inch revolver and the Beretta PX4 Storm. I now have at least 2 dozen pistols and 4 rifles. Like you, I’m trying to reign it in, but I keep remembering that KWC has introduced a blowback version of the Luger Parabellum P08 which will surely be better than the Umarex version which doesn’t have blowback, and I just gotta have that blowback version.

Hi BB,

I try to mount a tasco 3×32 pistol scope using the weaver rail coming with the gun, this rail have too much tolerance ( may be 1 – 1,5 mm) with the dovetail profile in the top of the barrel, and is very easy the scope fall away together with the weaver rail.

The smalls screws coming with ther weaver rail marks the beautifully finish on top of the barrel (my is 6″ inox finish) and anyway don’t work at all.

BRGRDS

Pietro

Pietro,

Thank you! I did not even mention that the screw marks the top of the barrel like you said, but I noticed that, as well.

I think I will use open sights, only.

B.B.

Hi BB,

The new pellets shells is made in brass (shell) and may be anodized aluminium (false bullet) where inside is a pellet receiver in plastic or Teflon, the cost is double of the BB type but the apparel quality is really better, during shooting a lot of co2 coming out from drum sides, I think this reduce the pellet velocity.

I didn’t chrony, but I will do it next week.

BRGRDS

Pietro

B.B.,

I am one of the squawkers regarding making pistols as pellet shooters instead of BB shooters. It’s always just been a matter of accuracy for me. So, that makes this revolver very interesting to me. I already have the 8″ BB version. I am waiting anxiously for your next report on this one. Unfortunately, I have read several reviews on this gun that say it is shooting roughly 100 FPS less than the manufacturers claimed velocity of 426 FPS. I am seriously hoping that your results prove them wrong.

G&G

G&G,

We shall see.

B.B.

G&G,

The internet is loaded with instructions for performing a power modification for these Dan Wessons. Obviously, Tom will not be testing this, but you should know that these revolvers can easily be hot-rodded.

Michael

Gunfun

Thats what I was going to try and do was to make a bushing to make the keep the valve centered because mine will move foreword and backward and the port is centered right in the middle. I have drilled the port in the valve to 11/64″ and spot faced the seat to 1/4 ‘ and about .050″ deep so it hold the ice maker tubing in place under the high pressure’s. I will do the same on the barrel also.

On the hi-pac I was hoping to only have to chamfer the lead in edge of the hole to allow the pointed taper to go into the hi-pac without actually drilling out the hole completely and remove the binding condition. I still have the valve out of the one for the 177 so I can use it to check to see if I can just put a slight chamfer in the hole to provide clearance.

You are probably right about the CPs doing so good because of the short skirt recess which would allow for the pellet to seat deeper past the port. I use the hollow bolt probe myself as I think they allow better air flow to help expand the skirt to the barrel when the air first hits the back of the pellet. They have a long probe end also so it pushes the pellet in as deep as a pin type and I just think the hollow ones flow better than the long pin ones but I have no scientific proof just theory and seat of the pants.

Yea I have been doing a lot of thinking on the 177 barrel and how to make the lead in part for the pellet and probe o-ring. Do you remember any of the measurements or can you measure any of your barrels to give me an idea of the dimensions as I don’t have anything in 177 caliber for crosman guns or breeches to use as a guide or to measure from, so I was just going to use the trial and error approach with the 177 hollow bolt probe that I plan to use by measuring the probe dimensions and machine the bore and lead in to fit the probe and place the transfer port at the same place as one of the 2240s original barrels. What I really need is the diameter of the O-ring sealing area and the dia of where the lead into for the pellet to go past the transfer port and into the rifling.

I will worry about that when I get the 22 done and shooting .

Buldawg

buldawg

Some measurements. I do think it was a #4×60 degree center drill I used for the lead in chamfer. I think I went .080” deeper on the lead in and I cut the back of the barrel and then faced it off so I could push the barrel back to the bolt farther then I needed with the bolt locked down in the firing position.Then I locked the barrel in place when it fit nice snug to the o-ring on the bolt. Then I had to take apart and drill the bottom of the breech bigger for the transfer port bushing.So yes a lot of taking a part and putting back together and fitting.

That was always the thing about my cars at the dragstrip. It looked like the car was easy to make run fast but they never knew what I really went throujgh to get them like that.

Gunfun

That’s is a starting point that I can work with to get the angles right and depths. You are right when modifying anything such as guns, cars or whatever there is always issues that require a lot of assembly and disassembly to fit and refit until it is right.

That’s why people can’t understand how my 38 year old Harley will out run their new Harley so easy, it took me three years to build it the way I wanted it and how it all needed to work together so it made the torque and horsepower needed to out run the new bikes. On the dyno at Harley where the new CVO 103 ci bikes were making 80 HP and 90 FT/LBs torque my old shovel would put down 110 HP and 115 FT/LBS torque from 3 to 6000 rpms with a almost flat torque curve from 2000 rpm up to 6000 rpm out of a 88 ci motor that was built for the most torque between 2 to 6k. I put 5 grand in just the motor do be able to make twin cammers pissed off when an old shovel would out ruin the babies.

Its all in the details and having a head of service at Harley that had been there since the 60s and worked in the tuning dept for Harley racing when the shovel was built and being drag raced did help a little bit I will admit and when I told him what my plans for the shovel were he jumped in head first and sent me all kinds of tuning secrets and tips to get the most out of the shovel and even help source some old pieces needed to make it fast and durable from obsolete racing parts of the Harley shovels that were sitting on shelves collecting dust.

They will get done to my strict standards as I cannot just accept anything below my very best efforts when I start a project and it earned me the nickname as a kid of “MOTOR ” by all my child hood buddies and my best friend the actor still calls me by that name.

It fits me perfectly so I don’t complain as we always had the fastest dirt bikes in Cocoa Beach when growing up.

Buldawg

buldawg

I was lucky as a kid and had one of the older men in the neighborhood take me under his wing if you will. And I believe I mentioned that before. And he was one of my dads friends so that helped out also. But he still had back in 77 a 62 Bel Air with the aluminum hood and front fenders and bumpers that he bought new and team raced with Chevy. It had the swiss cheese frame and acid dipped body. The car was only primered with that redish brown primer then waxed with no intention of painting the car a color. It had the Z11 427 which was based off of the 409. And of course the Muncie 4 speed. He was just exhibition racing it when I was starting to drive back in 77. All I can say is it was a wild car to see run. And you wouldn’t believe all the cars he had sitting on his farm.

But that’s probably was one of the things that got me hooked with dragracing. And me and my brother was probably the first in or area to start messing with nitrous. That was around 1980 in a big block 71 Camaro my brother had. It was all over after that. I built that altered 72 purple Nova and had the bottle in it that I know you remember me talking about. But when we started running the bottle you learn real quick about how to read plugs and tune. Well that’s what I did and I started rebuilding carbs and porting heads and tuning the peoples cars. And that’s How I got my knick name back then. I will tell you what it is and then your going to know my first name. And maybe that’s part of why I never sign my name after a reply. But ”Nitrous George” is what everybody calls me to this day. My one buddy that got it all started back in the 80’s could draw real good and he airbrushed a few t-shirts for us guys with our cars on the front and on the back of the t-shirt it said. Tuned by Nitrous George. And we would keep updating our quickest run with a black permanent marker on the back of the shirts. My one buddy that had a 69 Goat was putting kill marks on the back of his t-shirt for every car that he beat. He would never write his time down.

I know a long story that really makes no sense but that’s the way it was back then were I grew up at. And I do miss those days but glad I lived them. Oh and but did I ever mention the black 2005 Dodge SRT-4 that I bought new and built a engine the old school way and with the stock turbo was making a hair over 500 horsepower. And yep Nitrous George was still alive. It had the bottle on it. It was running in the mid 11’s@130 mph.

Anyway I will stop now. And as always let me know the progress you make on the 2240 stuff. And I wonder if there is anybody else secretly building one of the 2240 conversions and they haven’t said anything yet.

Gunfun

I posted a reply this morning but it must have got lost. Yep I was the neighbor hood gearhead with all my friends growing up and two of my buddies and me had Yamaha dirt bikes that I had built the top ends and port matched the pistons, shaved .050″ off the heads and my buddies 125s I put 250 carbs on and jetted them and my 175 I put a 360 carb on it and there was no one in town that could out run us. We would walk off and leave 250s and 360s all day long. Then my best friend ( Skippy the one that is an actor ) found us two 74 Yamaha SC500 MXs that the local dealer was getting rid of because their team riders could not ride them as fast as the 360s because they were to fast for the drum brakes that they had, with stock factory sprockets and four gears they would do 105 mph and do 80 mph wheelies with just a twist of the throttle. I still have mine although it does not run anymore, it needs crank seals which I have but there is no way I could even think about riding it now because it would hurt me in less than 5 minutes on it.

Back to air guns. I finally got my 22 cal hi-pac done . I made a bushing for the valve screw to keep it centered and drilled the end of the hi-pac out from 7/64″ to 1/8″ so the valve piercing end would not bind. Got it all put together and went back with the stock hammer spring and filling to 2000 psi for now, I ordered two benji Prod adjustable end caps and spring guides today for 35 bucks and when they get here I will install them and the heavy spring and then go to 3000psi.

I did shoot it some today and was getting ready to start some chrony testing when a yellow jacket got mad at me and decided to nail my right ear lobe, so that ended the shooting for today as my ear is swollen and throbbing. I do know that I filled it to 2k and shot about 10 to 12 shoots before I got stung and when I went to top it back to 2k it was only at 1500 psi so it is just sipping air now and you could tell that the pellets were not moving much faster than when it was new with CO2.

I will get some numbers tomorrow when my ear is not throbbing so much and see what it is at in just stock setup at 2k psi and then when I get the adjusters I will crank it up to see what its max capabilities are. and let you know.

My 177 breech and the 2250 forearms will be here tomorrow so I can get started on the 177 hi-pac and install the forearms after I make a rear bracket to hold the rear on as I have the front barrel band with the tab to hold the front end on, the rear brackets are obsolete so I will have to make them.

Let you know some number tomorrow.

Buldawg

buldawg

I do mis those hot rodding days. Seems that the time and money always seems to go other places now days. Plus I’m hooked on this air gun stuff again. I started back with airguns again in around 2009 after I was getting better from my colon operations.

And bummer about the yellow jacket. I got it by one in the back of my neck one time. Definitely not fun stuff. But glad you got to shoot your 2240 a bit.

And BB’s blog for tomorrow is the 2240 conversion. So just post your info over there. That way the people reading can get all this info we have been talking about lately. I will be watching for your reply.

Hurray! Pellet shooting action pistol! Now if it shoots accurately and comes in 2.5 snub I am an owner. It would make a perfect trainer for my .32 S&W snub nose powder burner.

Count me as well among those who want to see more offerings patterned after the little wheelguns. Personally, I’d love to have both an Airsoft and a pellet option in S&W 2″ J-frame format–something that would even fit existing leather–regardless of the powerplant.

Ton,

You own a S&W 31? I am jealous. What a gun!

I have 2 Hand Ejectors in .32 S&W and I love how they don’t recoil. Even my Ruger Single Six in .32 H&R is a gentle gun.

B.B.

B.B.,

Does the Pyramdy Air website states which pellet (NOT BB) guns has the realistic looks and feel of a real gun?

Joe,

I doubt it. That is a judgement call, not an absolute, so each person has to use their own judgement.

B.B.

B.B.,

Thanks for the reply. I cannot make any Judgement call unless I am actually holding and seeing the airgun, and buying online from pyramydair doesn’t allow me to do that. I was hoping that pyramydair website will say something like this “this airgun has the look and weight of the real gun; it is constructed of metal and function like a real gun.”

Joe,

Edith will look at your request and see whether it can be done. It sounds easy, but not everyone knows what all firearms look and feel like. So doing this means getting the right person to look at each gun.

Now I can make such comments in my reports easily enough and I do all the time. But I only look at a small representation of all the Pyramyd AIR carries.

It might be easier for you to ask PA about any gun you are interested in.

B.B.

Joe,

I say whether or not a gun has the look, feel, heft and action of the firearm. If it doesn’t say that in the description, it’s because I don’t know or it doesn’t.

Thanks,

Edith

B.B and & Edith,

Thank you for your replies. Some people including myself that want to buy a “firearm look alike” airgun is because it “looks like” the real gun, and we hope that it feels and function like a real gun.

B.B and & Edith,

Thank you for your replies. Some people including myself that want to buy a “firearm look alike” airgun is because it “looks like” the real gun, and we hope that it feels and function like a real gun.

Joe,

Looks like and functions like can be different. Case in point is the Umarex P08 pistol I tested recently that looked realistic but didn’t have a working toggle action. Now they have one that does.

B.B.

BB

did you say thet the P08 now comes with a working toggle?

jdb,

Yes I did. Edith just told me about it. I don’t think it’s available yet. There is also a full auto Mauser pistol coming that looks just like the Schnellfeuer.

B.B.

Guys, I’m playing “BB” here. This fellow posted this plea to an 8 year old blog. Hopefully one of you can help him out:

Gene Says:

August 19, 2014 at 7:07 pm

My best friend who is dying, had a Buzz Barton BB gun when he was a kid. He always talked about it. I have found a rifle to give him, but I cannot find a sight tube. I wand to give it to him for Christmas.

At almost any price, can you please help me find a sight tube ?

Thank You. Gene Small Albany, Oregon