by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Seemed simple

- The back door

- Use penetrating oil

- Pop the end cap loose

- Gun comes apart

- The piston

- Constriction cleared!

- What’s next?

Today is the day we tear into the Hammerli trainer for the K31 Swiss rifle. Before I took on this project I studied the trainer carefully for several days. I wanted to know if there were any surprises in store when I tried to disassemble the mechanism. The Swiss have a saying, “Never use one part when five will do.” That’s my way of suggesting that the Swiss engineering can sometimes be overly complex.

I had already determined by running a cleaning rod down the muzzle that there was an obstruction of over an inch in the barrel at the breech. Experience told me it would be several BB jammed together, with perhaps some other things that shouldn’t be there. It had to be pushed out.

Seemed simple

My examination revealed that the design of the trainer powerplant appeared very straightforward and even simple. Let me show you what I saw.

The problem was a constriction inside the barrel. The easiest way to clear it would be to take the barrel off the trainer and push the constriction out. The barrel is held on by two very small slotted screws at the back periphery. The screw heads looked a little messed up when I examined them, so I put on a magnifying hood and looked closer. Lo and behold, both screws are staked! And the stakes are deep. Someone really did not want this barrel to come off this trainer under normal circumstances!

That deep stake in the screw head prevents it from turning. Try to loosen it and you will likely bugger the slot.

The back door

The other way to clear the barrel would be to strip the powerplant of all its internal parts and push the BBs out with a rod through the muzzle. With nothing in the way they should come right out. But was the trainer as straightforward as it appeared, or were there surprises inside, just waiting for me?

After examining the action it seemed like the easiest thing to do was to remove the end cap and then the mainspring and piston. If this action really was straightforward, that would leave the spring tube hollow and allow the BBs to be pushed out of the gun.

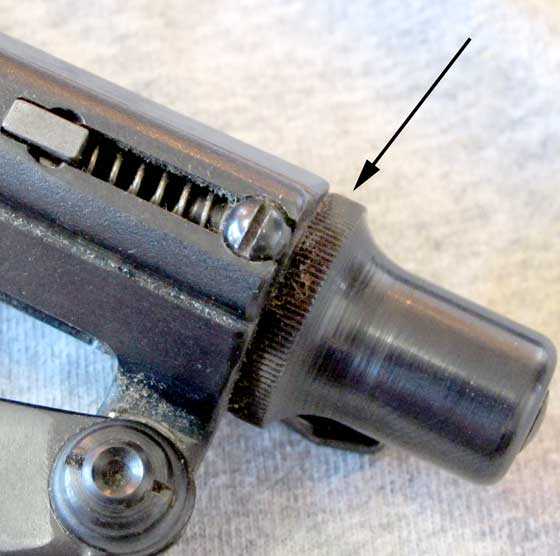

The end cap has a narrow knurled band (arrow). It appears that should be used to unscrew the cap and remove the mainspring. But that sear bar on top (top left in this picture) may be a problem.

This view shows the plug (arrow) that holds the sear spring and sear in place. Remove that screw and the plug should come out with its spring.

I removed the screw that holds the sear plug in place and removed the plug and screw. That gave me a better view of the end cap.

With the sear plug and spring out of the gun I could clearly see the end cap threads. The sear bar is still captive.

Once the sear plug and sear spring were out I could see the threads that held the end cap in the action. It appeared that all I had to do was clamp onto that knurled ring of the end cap and unscrew it from the main tube. I tried it first by hand with no success. Then I grabbed the knurled edge with cannon plug pliers (pliers with curved jaws that have nylon pads in them) and tried again. Also unsuccessful. I had to use more force, and this was getting into a dangerous area where I could mar the finish or damage the trainer in some way. So, I pulled out my secret weapon — my buddy Otho.

Use penetrating oil

He told me to put some penetrating oil on the exposed threads of the end cap and to keep on doing it for a day. I used Kroil, a product I have a lot of faith in.

Otho was a turbine engine mechanic for the Army and has forgotten more about fine maintenance and careful work than I will ever know. So I took the trainer to his house and we set about working on it. When I say “we,” I mean I did whatever he told me to.

Pop the end cap loose

First, he clamped the knurled ring of the end cap in his vise that has copper jaws. I grabbed the action and tried to turn it. I got a bump that felt like a release, and when we examined the knurled ring there were no signs of slippage. The end cap had broken free! That Kriol I used had done its job.

Next he grabbed the knurled ring with a pair of cannon plug pliers and tried to turn it. It was stiff, but it did turn. After a few turns it got much easier, which was the Kroil kicking in.

Otho turns the end cap with cannon plug pliers.

Finally the cap got so loose that Otho was about to unscrew it the rest of the way. When it released the mainspring was under some tension and popped out about an inch.

The mainspring is under this much tension.

Gun comes apart

Now the mainspring came out with the end cap. The sear bar was also freed and slid out of the action. Now it was time to remove the piston. I stuck a screwdriver blade into the cocking slot of the piston and pushed it to the rear. It was very tight, which in this case is a good sign. After a bit of fiddling it came out and we can now examine it.

The piston

The piston is a similar to the plunger than’s in a common Daisy BB gun. It looks partly like a standard pellet rifle piston but there is one important difference. It has a long air tube in front that pushes the BB out of the breech and up the barrel, accelerating it to around 50-80 f.p.s. When the piston gets to the end of its travel, compressed air is forced through several small holes at the base of the air tube and travels up the tube to get behind the BB. That compressed air is what blasts the BB to its top velocity, which in this case is around 200-250 f.p.s. I’m just guessing at this, because I haven’t tested this one yet, but in Smith’s book he put the velocity at 250 f.p.s.

Here is the piston out of the gun.

The piston seal is leather, like we all thought. It looks very good, but it’s definitely dry. I need to soak it in household oil for a couple days before putting it back in the gun. That gives me time to clean the compression chamber.

We noticed that the air tube was bent. It would not go all the way into the muzzle without a hard push. That means it’s doing the same thing at the breech, were it lives. And that means power will be lost to excessive friction.

The air tube is bent. That’s not good.

Undoubtedly the tube was bent from slamming into the breech constriction repeatedly. It had to be straightened, but because it is hollow we ran the risk of snapping it off and having to start from scratch. There are no replacement parts for these trainers. Otho carefully applied sideways pressure and straightened the tube until it slid into the muzzle easily. Problem solved!

Constriction cleared!

I used a .177 cleaning rod down the muzzle to push the constriction back through the now-empty spring tube. And I found exactly what I expected to find — seven steel BBs and three pieces of lead — one grossly oversized. The steel BBs all have flat spots on them from repeated blows of the air tube, as shot after hopeful shot was attempted over the period of who-knows-how-many years.

These steel BBs and pieces of lead were lined up in the breech of the trainer.

The last picture I’ll show you is of the leather piston seal and the air holes at the base of the air tube. Those familiar with BB-gun construction will see the resemblance right away.

Here you can see the leather piston seal and the air holes at the base of the air tube.

What’s next?

The next step is to clean everything, soak that piston in oil and then assemble the trainer. After that I fully expect it to function as it is supposed to.

Enjoyed this report! On a recent purchase of a 310 had a similiar problem which had four BBs stuck in the barrel! Because they were steel I was able to remove them! While on the subject? Do you feel that the Smart Shot lead balls 4.4 would work in the 310? Thank you! Semper fi!

That is without a doubt well constructed. I can see evidence of such in every photo. Probably a good thing also or ignorance would have destroyed it. Was the bore damaged any?

You had me gripping the arms of my chair until “we” discovered what the barrel obstruction was! This blog unfolded like a good murder mystery.

I second that!!

Jim

Really fun article, B.B. I enjoy watching you and Otho do the stuff that I wouldn’t have the guts to do!

I am one of those who is NOT familiar with BB gun mechanisms, and I’m surprised to hear about that funny air tube. I’m a little surprised that it works at all. How useful do you think that initial hammer blow from the air tube is, compared to the “traditional” blast of air from the piston? How do you reckon a powerplant like this would work without the air tube? If the tube had been in worse shape on this trainer, could you have simply done without it?

Thanks,

Jan

Jan,

That tube is why we have BB guns. Without it I think the velocity would probably be 100+ f.p.s. less, if the BB would even clear the muzzle.

This mechanism is a 2-stage powerplant. That tube is the first stage. It has to be present or stage 2 doesn’t work.

B.B.

B.B.,

The Haenel 310 has the same air tube attached to its piston; it reminds me of a scaled up BB action.

I think one purpose of the air tube is to limit the rate at which the air travels up the barrel, with the benifit of still having a cusion of air to stop the piston during a dry-fire. I have accidentally dry-fired my 310 a couple of times; the firing cycle is slightly harsher than normal but nothing like dry firing my P1.

Paul in Liberty County

BB

Going off topic here but I am very interested in a gun that Hatsan had on display at this years SHOT show and I just saw in a review of the new 30 cal spring gun in the 135 line.

Its the AT44 Nova gun that has the 500cc bottle in front of the stock under the barrel. My question is do you know or have any info on if it will be ordered by PA for sale here in the future or not and if it will be do you have a tentative date for release of it.

Any info you can provide would be much appreciated as I am very interested in buying one and if you can put a bug in PA’s marketing ear to look into offering it for sale here I would be very grateful.

Thanks BD

BD,

I giuss you didn’t see the SHOT Show report tjios year? I covered the new Hercules. It’s not an AT44. It’s much larger than that. See it here:

/blog/2016/01/2016-shot-show-day-1/

I’m sure Pyramyd AIR wil stock it when it comes out, but that will be later this year.

B.B.

BB

I did read your reports on the SHOT show and I am not talking about the Hercules gun but another gun that Hatsan had on the wall rack two guns above the 30 caliber Patriot 135 spring gun.

Its a AT44 Nova that is based on the AT44 platform but has a 500cc bottle instead of the normal air cylinder. See link bellow.

http://www.gatewaytoairguns.org/GTA/index.php?topic=102022.msg959426#msg959426

This is the gun I am interested in and wonder if PA has any plans to import and sell it.

BD

BB and all

I just got an email from Tyler at PA and they will be selling the Nova when it is available so will just have to keep an eye out for when its in stock and ready to sell if you are interested.

I know I am with a high shot count they show of 120 in 177, 98 in 22 and 88 in 25 cal.

Please test it when you can BB

BD

BB

Here is a link to the 2016 Hatsan lineup and the Nova is part of it.

http://www.hatsan.com.tr/assets/2016_new_pcp_air_rifles.pdf

BD

Congrats BB! It’s sort of like unwrapping a present!…. sort of…

Good morning B.B.,

Good idea to let everyone know about Kroil. I learned about Kroil from a retired US Air Force Turbine mechanic about 20 years ago. Have tried other products like PB Blaster since but none work as well as Kroil on the old cars and motorcycles we work on. Not the least expensive product out there but that’s ok. It works.

Hope you have a good week sir!

Perry

I hope you got in it right!

It can be a bummer getting a new gun and having to fix it before shooting it but when it’s something hard to get it can be very rewarding to put a few hours into.

🙂

I’ll probably tear into this newest 2200 that I just picked up for $20 OTD.

This time it’s something simple so I should be in and out in an hour or two which is great because I already have 5 completely stripped down and I’m not trying to add to that.

Can’t wait to see how it shoots!

B.B.,

As for this BB gun mechanism, is that also the design for Daisy Model 25? I ask because a few years ago my early version Daisy 25 went from shooting nicely to having a complete lack of resistance on the cocking arm. Not wanting to muck it up and as it is more a family heirloom than something I shot much, I have left it alone. Still, what is the likely broken part? The mainspring? A damaged air tube?

Michael

Michael,

The air tube breaks in Number 25s more often than anything else. But there would still be tension on the pump handle from the mainspring. You have a broken cocking lionk I think.

This guy can fix it.

Larry Behling 315-695-7133 or co2bbjlts@juno.com

B.B.

BB

I think if you would of stood the action with the barrel pointed up and the end cap on a peice of cardboard on a hard table. You could of used a little downward pressure on the end cap and it may of relieved some of the spring pressure. The cap may of turned easier when you unscrewed it.

Have you tryed yet just to see if it will go back in easy? That could be a little tricky screwing the end cap in with the added spring pressure. But you don’t have to say. I’ll wait till you do the report when you assemble it. 🙂

GF1,

It’s back together already. Super easy to do, now that I have loosened everything.

B.B.

BB

Good deal.

That leather piston seal looks new!

Judging by how difficult this trainer was to take apart it seems like no one has ever been inside to molest this beauty. Can’t help but wonder if the last 3, 4 or even 5 owners tried unsuccessfully to shoot it, gave up and put it back in the box.

All these reasons explain the exceptional condition of this piece. What a find. Terrific report on putting this one back into service.

kevin

Readers on Friday’s Hakim report commented that the Garand required careful reloading components for reliable functioning. My Garand has never failed to function using a multitude of safely worked up variations of powder, brass and bullet weights. It even digests 220 gr roundnose bullets which are much heavier than the military bullet. I’m not disputing that someone’s rifle has problems. I do believe that Garands in general were and are extremely reliable.

Decksniper

B.B., with regard to this blog what interests me the most is how different people come up with variations of a theme, in this case a spring piston air gun.

As for me, I managed to shoot a few pellets and practice two eyes open with the scope.

My initial experience yesterday was rather awful. I decided to shoot some Crosman Piranha pellets. I noticed that there was quite a bit of variation in the fit when I loaded a pellet. I didn’t use any kind of seater other than me thumb. It was so bad, I was concerned there was a problem with the power plant. Some pellets were hitting nearly a foot lower than my aim. Also I am shooting at an adhesive target with an old metal computer cover. Even pellets that hit on the metal were obviously not hitting with the terminal energy. Pellets that hit with sufficient force flatten out and look like a little sunflower – those that hit the adhesive target actually stay where they hit. I collect them with I peel the target off.

I checked that everything was tight and switched to Crosman Premium Hollowpoints. The experience was like night and day. I shot another 25 rounds from the same 25 yards and came away quite pleased (with the pellets, the Titan and with myself).

I closed one eye long enough to insure I had a good sight picture then completed the task with both eyes open, well, except when I forgot to open the closed one. The shooting is good; I just have to practice opening my non-dominant eye.

I do wonder about the Piranhas. Were some so loose in the barrel that air rushed past them, leaving little to push them well. Kind of makes me want to take another look at a pellet gage. Or at least I will need to seat the Piranhas better and see how it goes.

~ken

Ken,

Anytime a pellet has a name like Piranha, or Zombie or whatever, I pretty much write it off. That pellet has the kiss of a marketing department on it with a goofy name like that. If the company has to dress it up that way to sell it, it’s a sure bet it isn’t good.

B.B.

B.B.,

I won’t regret purchasing one tin of Piranhas, but they’ll be hard pressed to get me to purchase another. Thank you for you insights. I will keep them in mind.

~ken

Ken

I picked up a tin of those things just for kicks . They were drop in loose, and shotgunned all over .

Might have been ok plinkers if they had at least fit .

twotalon

Twotalon,

You make me feel better. I won’t shoot these pellets at all without attempting to seat them better.

If I didn’t tell you before, I will tell you now how much I appreciate your support after my neck operation. I had good support from everyone here, but you are the only one other than B.B. I have a personal email address for. Thank you, Art – then, now and always.

~ken

Ken

If you have to push the heads in, then do so . If they want to fall in, then throw them away .

twotalon

Twotalon,

That sounds like the best advise of this kettle of fish.

~ken

Ken

I tryed the pirahnas. Everything you said about them is exactly what I seen.

They look just like premiers but with the funny hollow point. But they sure do vary in size. Some load in the barrel so loose you think they will fall out, others fit nice and some where very hard to load in the barrel. And groups were just as bad. They sure don’t have the fit of the premiers.

I hope you try to stick with shooring with both eyes open. Maybe you can explain some of the difficulty’s you have trying it and how you over came them. I have shot that way for so long its natural. So its hard for me to remember what my eyes did when I tryed to start shooting that way. Interested in hearing about it as you go.

Gunfun1,

You also verify my experience with these pellets. I thought they might be based on the Primiers but the quality control appears to be absent.

Based on my limited experience, I don’t believe I am going to have much trouble at all shooting with both eyes open through the scope. I may be able to stop closing my non-dominant eye at all at some point. For now it seems to work if I close it while I ensure I have a good sight picture, then open it. I certainly relieves the strain of holding the sight picture. I’ll let you know, but I think it will be fairly easy for me. I already shoot pistol with both eyes open.

~ken

Ken

Oh if you shoot pistol that way I bet you will adapt very easily. But did you notice that the sight picture is brighter with both eyes open even shooting with a scope.

And yep since the piranhas was made by Crosman and resembled the premiers I thought they were going to be good. Definitely not the same quality control when they produce the pirahnas.

Gunfun1,

It has been warm and sunny here in the Houston area. I had a nice day to shoot and practice opening both eyes. I can’t say yet how much difference I notice in the sight picture, but I do know that trying to close just one eye definitely is unnatural and puts a bit of strain on the open eye. I anticipate the sight picture will be better or will be better much longer than trying to shoot with one eye open.

Shame on Crosman for letting this shoddy product be put on sale, and then to charge as much as they are.

~ken

Ken

Maybe they will tighten up the quality control at some point in time. But the question is when. And do I want to take a chance again and they are still no good.

That’s the problem. And if they are a new product I would think that they would try to make a good first impression. Crosman products are usually pretty good quality. But they didn’t get the pirahnas right that’s for sure.

Well maybe somebody will try at some point and time and report if better or not. Just have to wait and see.

Gunfun1,

Even if Crosman improves the Piranha pellet, I don’t think is is worth more that Premier pellets. My initial interest was about whether or not the “teeth” made any substantial difference. Not enough to count, in my estimation. I am grateful the Premiers are a good and easily obtained pellet.

~ken

Ken

With you on that.

Ken,

I like to switch over between right and left handed shooting as it strains the muscles less. I then also change over from right to left eye. When practised it gives you an easy control over which eye sees what and it is fun for me to see how fast you get used to switching over.

Strange enough it does not make much difference in points when shooting 10 mtr if I change over from right to left. I do use different pistols though as the sights are slightly different set. With scoped rifles I do not have a sight difference between the eyes.

Regards,

August.

August,

Thank you for this. I had already forgotten something I read not long ago. The writer advocated changing let to right and back with both long guns and hand guns. Of course, this was essentially an article about combat shooting, but it made sense.

You have reminded me and I see about adding this to my repertoire of options.

~ken

BB or anyone- I’m just trying to find out if Airgun Labs are going to resume offering the Disco Double kits any time soon. I want one of them!

Bruce

Bruce,

Why don’t you contact them and ask?

B.B.

BB,

I checked their site and they say”Please don’t email to ask about it, they will post on their website when they are caught up “. Oh well, I guess l will have to practice my patience mode! Thanks,

Bruce

Bruce,

Here is a little prayer, “Dear Lord, I need patience, and I need it RIGHT NOW!”

B.B.

BB,

I think I need some kneepads, and now I have found the FX Wildcat in .25 cal.! Some very impressive guns throughout their line! I guess I should get the heavy duty kneepads!!!

Bruce

B.B.,

It was here that you wrote about you brother in law, Bob, and his red dot sight with changeable reticles:

/blog/2015/07/back-to-the-basics-scope-tips-part-4/

That was not something I was aware of. So, I have looked into red dot sights and discovered a variety of technology all with the name “red dot”. Wow!

~ken

Paul in Liberty County, Haenel 310! Thank you for your remarks. I agree with you on “scaled up BB Action”! I also will choose the Haenel 310 4.4mm over or instead of BB rifles for target shooting. Any thoughts on H&N Smart Shot copper coated lead balls being shot in the Haenel 310? Manufacture states they are 4.35mm size? Or anyone else out in blog land care to add or comment on the lead balls to be used in the Haenel 310 or for any other lead ball shooting rifle or pistol? Semper Fi!!

So, is Kroll some kind of super-lubricant? I have barrel obstructions on the brain after my experience with the chamber flag melting in my Saiga AK. There is actually a body of information about this among shotgunners who get plastic fouling from wads whatever that is. Based on their experience, I am in the clear. They said that Sweet’s 7.62 will turn plastic into “bubbly gunk” that can be pushed out with a cleaning rod. I can believe that since the solution is so caustic that I expect it would dissolve anything. And I left it in the barrel for the maximum recommended time as I swabbed away. The advice also says that no plastic can stand up to a bronze brush, and the barrel got plenty of that. Visual inspection shows nothing in the barrel.

But I am taking no chances with my heirloom Saiga from a Russian factory which may never be available again, and it could also be an MOA shooter. I just bought a borelight for an even more careful examination. So, how exactly does one use the borelight? It has what looks to be a small bulb on a flexible wire attached to a handle. My chamber flag melted at what looks to be about 5 inches from the chamber. Do I shine the light at the chamber end? Or do I stick it down the muzzle? If the latter, I wonder if that will improve on my current method of pointing the rifle at a ceiling light and looking through the breech end. As a final measure, I’m counting on those 5000 degree temperatures in the barrel to obliterate any plastic that I miss.

Chris, thanks for indulging me, and I’m glad you got something out of the Jaws of the Subconscious. It is another name for a known phenomenon. Still, the great physicist Richard Feynman says that terminology is a form of knowledge. That may apply in relation to the concept of rhythm in shooting. I love to be in that mode. By the way, I tend to get better the rounds I shoot in a session, but there’s never a guarantee. However, I have found rhythm to be dangerous because once it goes, you’ve got nothing. I found that out in my disastrous high school career on the rifle team. I started off great and got to thinking I was some kind of natural shot. But then, one day, I got self-conscious. I realized I didn’t really know how I was doing what I was doing. Then, it all went away. Panic ensued, and we will ring down the curtain on the rest of that sorry tale.

Now in my more mature phase, the Jaws are an antidote for that by helping me to focus on each shot. Blog reader and great shot, Victor, tells me that elite competitors make use of rhythm, so I try to ride it. But I never depend on it. The Jaws are a timeless feeling of a permanent present and nothing else exists when they chomp down. B.B. once said that during his competitive shooting days, he never quite figured out how to stay in the winner’s circle like the high masters. I’ll never even get in there, but pretending that I did, my strategy would be to say that there is no problem because there is no future of winner’s circles because there is no future. In fact, from a certain point of view, there is no winner’s circle either…which leaves me back in my five yard range. 🙂

Matt61

Matt,

I don’t know what Kroll is, but Kroil is penetrating oil.

As for the bore light, you shine it from the opposite end of the barrel as you look through.

B.B.

Matt61,

Perhaps,… being calm, relaxed, no real thought on any planned outcome, focus on task at hand, yet not too hard, executing the shot in your mind,.. without ever picking up the gun. For me, the longer I am shooting, the better I get, usually. Often, in retrospect,.. it is when I “think” less.

I can relate to your high school experience, though not directly. Through life, I have tried many new things. Like you, I seemed like a “natural” right out of the gate. And, like you, things went South from there.

Of course,.. practice and knowledge of proper technique helps. But,.. like a kid trying to shoot for the first time,.. they do not know they can’t shoot, they do not know all the proper techniques,…all they know is that they like it,.. a lot,.. and like any kid,.. think they will be great from the start. The mind is simple, unclouded of details and full of confidence.

So,.. maybe there is something to be said for trying to get back to that kid “state of mind”.

Which also relates back to the saying the it’s hard(er) to teach an old dog new tricks,.. as opposed to a pup.

😉 , Chris

Hi Matt,

Would like to exchange a couple of thoughts about the Jaws. Would you mind contacting me off-line so we don’t hijack BB’s blog?

Can be reached at hankvanderaa(at)gmail(dot)com

Thanks,

Hank

If I had remembered the Air Gun Academy episode on dot sights I wouldn’t have been quite as “enlightened” in just the last few days.

https://www.youtube.com/watch?v=S-1lgK8KHeE

~ken

B.B.,

Have you ever tried neatsfoot oil on leather seals? Most of the stuff you can find at local stores looks and smells like light machine oil. I got ahold of some of the real thing. It smells peculiar to say the least since it is pressed from cow leg bones.

I knew a guy who was assigned to the USS Enterprise for helicopter engine repair and then went on to do diesel engine and HVAC maintenance. He said one of the best penetrating oils is used transmission fluid. I believe he said that the detergent in the fluid breaks down over time from the heat. Not sure what that does but it was mentioned that wrapping anything frozen tight in a rag dipped in it overnight would have it loosened up by morning. I have yet to try this though.

Paperweight,

No, I haven’t tried Neatsfoot oil on leather seals. It migh do well at that.

B.B.

Decksniper– For many years, my match load was the 180 grain Sierra matchking with 55 grains of the original 4831 powder. I used it in 3 M1,s. The one that I shot the most had a straight cut operating rod ! I have had this rifle since 1962. According to many of the shooters and gunsmiths that have met (and many articles in shooting publications) I should have a bent and broken rod, because the port pressure is too high. I don’t, but perhaps I am lucky, because I have seen several M1,s that were jammed or disabled because of improper hand loads. Yes, the M1 is a rugged rifle when judged by auto loader rifle standards. But it can also be delicate and fussy when it comes to hand loads. A less powerful cartridge (7×57 or .276 Pederson) would probably make the M1 even more reliable. ED.

Ed,

I always look forward to your posts. I’m also looking forward to B.B.’s hopeful article on handloading for the M1, and I hope you’ll chime in there.

I’m fixing to try my first service rifle match. Any special wisdom for a first timer?

-Jan

PS In the 53@ years that I have been shooting M1,s, I have had to replace one broken part. In 1964 I broke a firing pin during dry fire practice. Ed

Just wanted to jump in here, on the Showtime series “Billions” there was a scene in last night’s episode that found one of the main characters playing “shoot the red star out” at a carnival. The only think that I thought was a bit hokey was that there appeared to be laser dot sights on the guns.

Kevin in CT

Kevin

They probably spiffed it up some for tv to make it a little more exciting. Give it some more visual effect.

But still cool they had a scene in there shooting the red star. I bet it caught your attention when you was watching the show. It would of caught mine.

B.B.,

Great article. I love it when you tear into something as that has been my second nature most all my life. Nice pictures as well,…as usual. Congratulations on getting the ol’ girl un-stuck.

I tried to get in to see one of my doctors today but no appointments were available so I went to the ER and been here since 10:00 and all they’ve told me so far is they’re transporting me to Abilene to learn more about why my left foot has an inadequate blood supply.

They pulled me outta the room and have me in front of the ER desktop awaiting transport now. It’s been a long 10 hrs!

Hope everything turns out for the better.

It’ll be alright if I can get the doctor up before lunchtime I may be home tomorrow night.

Jan—What rifle are you using? At what distance(s) will you be shooting? What are the weather conditions at the range? what direction will you be shooting? Will you be shooting facing the sun? Have you been able to practice at that range? Most of the service rifle matches that I shot were at 200 yards. The ranges at New Jersey, Connectuct and Long Island were in areas that did not permit longer ranges. Once a year I was able to shoot at fort Dix. They had a 6oo yard range. Good luck and keep us informed re your experiences at the match. VERY IMPORTANT–be sure that you know the range commands and the course of fire before you go on the firing line. Ed

Hi, Ed. I’ll be using my M1 rifle. I think I will try 100 yard matches at my home club, and 200/300/600 yard matches a couple of hours away in my home town. My home range is limited to 100 yards. so that’s the only range I’m zeroed for and practiced at! If I play my cards right, maybe I can get out to that 600 yard range before I jump into a match. If not, I’m not a cut-throat, and can probably enjoy myself with a shaky last-minute or software zero and a low score. Best guess at weather will be March/May/July Maryland wx. No clue about the sun angles!

I hate to make it about the equipment and make purchases before trying out even one match, BUT… I have no spotting scope, nor a tripod type thing to mount it on. Is that gonna be a big hassle?

I also haven’t yet practiced loading just two rounds into the Garand. How do you prefer doing that? Purchase two-round clip gadgets or learn to do it with regular clips? I get the impression that some types of matches include this initial load “on the clock” and others don’t? CMP v. NRA? Maybe that decides the matter?

I also wonder what sort of ammo might be best to practice with? Is this also a function of the type of match? Am I reading correctly that some matches issue ammo that you must use, and some allow BYO?

In cases where you might be seeing a type of ammo for the first time, or embarrassingly encountering a new-to-you distance, do you typically get some chance to sight in? It looks like, at least for some of the local CMP matches, you perhaps do get some sighters, but maybe only a couple, and maybe on the clock?

Blush. Thanks!

-Jan

PS Connectuct

PPs my spell checker is not working, and I am too lazy to get my dictionary, but you can probably figure it out anyway. Ed

Out of curiosity I had tried a tin of the Piranhas as well and ran them through the Pellet Gauge to see if there is decent consistency and the only answer is that there isn’t. The tin I had ran the entire range of the gauges size holes and a number that were either to small or too large for the gauge to measure.

The majority of them landed within the ranges 5.51-5.57 with something like 50-60 pellets for each of those sizes. On top of that they are not an easy pellet to gauge due to the raised ring around the head of the pellet, often times it was tough to determine if a pellet was too large for gauge hole or was the gauge just simply getting hung up on the edge of that ring. My Discovery seemed to prefer the 5.53 units and shot them in the same hole at 10 meters, looking forward to trying them at longer ranges once spring arrives.

BB, how about a reply to my first reply? About Smart shot lead? Your opinion in shooting them in a Haenel 310! If you have an answer or don’t want to answer or overlooked the question? That’s okay! Thank you ! J.LEE

J.Lee,

I get so many comments each day that I sometimes don’t get to answer all of them.

Just try the Smart Shot in your 310 and see what I dopes. That’s the only way to lnow.

Yes they are smaller but they shouldn’t case any problems in the action.

B.B.

Jan– I always used an 8 round charger, inserted empty into the M1, and then loaded 2 rounds. I have seen home made 2 round clips that required a tool to remove them and commercial chargers that got ” lost ” when they were ejected. There were scroungers who always wound up with more cases and clips than they fired. Why give them an expensive clip? A spotting scope is a good idea. Binoculars take too long to use. At 200 yds you should be able to see the spotter discs, but you will need a scope for the longer ranges. You should get the match rules, and learn them before the match. You don’t want suprises while on the firing line. You should use the same ammo for practice that you will use in the match. In my case, it was easy. One of our club members was in the Guard, and was a good friend of the supply sargent. A lot of guardsmen qualified with a pencil, so the sargent made some money selling us the left over ball ammo. I remember that I paid .05 per round. Try and get in touch with the RO or people who shoot in the matches that you want to enter. They should know the rules and course of fire. Keep in touch and let us know how you did.. Ed

Thanks, Ed! I’m really looking forward to giving this a try. I’ll plan to pick up a spotting scope. It’s not like it wouldn’t be useful for a bunch of other stuff. And I’ll see about digging up some dummy rounds to practice the two-round load at home.

Boy, a nickel a round! I just ordered some surplus for 10x that, and felt like I got a decent deal! At that price, I’d have a shoulder bruise almost as big as my smile! As a non-handloader (yet!), I’ve had some pretty good luck with the surplus ball ammo, but the best groups from my M1 so far, by a pretty good margin, is some of the $1.30/rd stuff. Sigh. I’m very interested in handloading, but it seems like it’d be quite a project getting up to speed.

Thanks,

Jan

Well the procedure is over and my understanding is that they did an angioplasty and installed one stent.

My foot is still cold and numb.

THANK YOU!