by Tom Gaylord

Writing as B.B. Pelletier

My Swedish Excellent CII rifle is a multi-pump pneumatic.

This report covers:

- Update on the Hammerli trainer

- History

- The gun

- Barrel and breech

- Rifling

- Preparing to fire

- Sights

- Stock

- Value

- What’s next?

Update on the Hammerli trainer

Before I get into today’s report I want to give you an update on the Hammerli trainer for the Swiss K31 rifle. I am having trouble getting it to work after disassembly and cleaning. There is a small ball bearing that connects the trainer’s sear with the piston, and that ball has to be assembled in exactly the correct fashion (I believe) before the gun will remain cocked and fire. It has to travel in two raceways — one on the sear bar and the other on the piston, and there are holes it must be forced through at critical times in order to provide clearance for the parts to move against each other. My gun buddy, Otho, looked at it with me, and after two hours of working with it he decided that the man who invented such a complex system was probably on the verge of insanity.

I will keep on working with it and I have confidence that I will eventually get it working again. Until then we will look at other historic airguns — starting with today’s topic rifle, the Swedish Excellent.

History

The Excellent is an airgun about which I know very little. What I do know comes from the Blue Book of Airguns, 11th edition. That material was provided by American airgun collector Ingvar Alm, who is a lexicon of information about the Excellent.

Their first airgun was patented in 1904, so they are almost as old as the Benjamin Air Rifle Company. In 1908 they patented a CO2 airgun. They also made an odd top lever spring-piston rifle for a brief time in the early 1920s, as well as a triggerguard-lever rifle.

They also made three versions of breakbarrel springers. The first one was made from 1933 to 1949 and the second and third were more robust guns made from 1949-1959.

Their pre WWII production is estimated at 8,000 rifles. They actually made 3.500 rifles during the war, from 1943 – 1945. From 1945-1970 they produced as many as 25,000 rifles.

They also made pistols. One was a spring piston model, sold as the Model 1950. It shot .177 lead pellets and had its mainspring concentric with the barrel. It was made from 1950 to 1959. The Phantom BB pistol was a 10-shot smoothbore repeater was made from 1953 to 1959. The Blue Book notes that a design flaw in this gun resulted in very few surviving.

Starting in 1941 Excellent marked its models number as Roman numerals. Our test gun is a CII, which was made from 1946 to 1966. It came as both a rifle, which is the gun I have and as a carbine, designated by a K after the model number.

The gun

The Swedish Excellent I am testing for you today is a CII, probably made in the 1950s, though there is no way to be certain. The gun has very few markings on it. It is a single-shot multi-pump pneumatic with a mechanism American airgunners are not familiar with, so I will describe it in detail as this report advances.

The gun is lightweight. It weighs just 4 lbs. 10 oz, though it is so slender and compact that it feels like more. The overall length is 38.25-inches and the pull is 13.25-inches. The gun is 100 percent wood and metal. The design will seem odd to most U.S. airgunners, as will several of the operational processes.

Barrel and breech

The barrel is 22.5-inches long, which is great for velocity in a pneumatic. The breech will seem similar to those owners of Remington rolling block rifles, as the breech is pivoted to swing to the left for loading. There is no detent on the breechblock — just push it to the left and the breech is exposed.

Swung to the side, the breechblock opens the breech for loading a lead ball.

Rifling

The barrel is rifled with what the Blue Book listing calls “Paragon” rifling. Generically, this type of rifling is called polygonal rifling. It doesn’t have the sharp edges of conventional land-and-groove rifling and is supposed to deform the bullet less.

But get this — the entire barrel is not rifled. The rifling, which can be seen from looking down the muzzle appears to begin close to the muzzle, not unlike the Smooth Twist barrels found on FX airguns today. The combination of polygonal rifling and a long smoothbore section of the barrel means higher velocity can be achieved for the bullet with lower air pressure.

And the rifling in my rifle is not polygonal, as described in the Blue Book. It is conventional cut rifling with conventional lands and grooves. It just doesn’t start until about 5 inches from the muzzle. I know this because in some early testing I fired an H&N .22 caliber copper-plated lead ball through the gun and it stopped where the rifling began. When I pushed it out of the barrel I saw the impression of the rifling, that I will now show you.

The impressions of rifling lands are unmistakeable on this engraved ball.

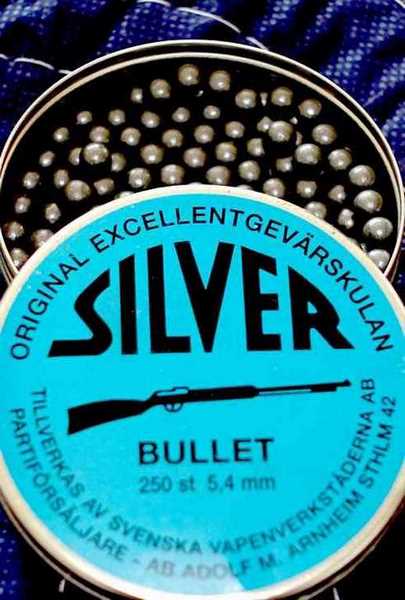

Speaking of bullets, let’s discuss what this strange rifle shoots. It shoots 5.4mm lead balls, though they are not as uncommon as that may sound. When I recently acquired this particular rifle, it came with a tin of Excellent 5.4mm Silver bullets. They are round lead balls. If you are a veteran reader you have read many times that bullets were all round balls until the middle of the 19th century. We only call them balls today to differentiate them from conical bullets.

These balls are made for the Excellent.

I measured these balls and found them to measure 0.213- to 0.2135-inches in diameter. Then I measured some .22-caliber Lobo lead balls from Argentina. They measure 0.214- to 0.2145-inches in diameter. One-thousandth of an inch is close enough to use the Lobo balls in this rifle. They may even be more accurate. The H&N balls that measure 0.217-0.217-inches are too large.

Preparing to fire

To fire the rifle the action is first cocked by pressing forward on the button at the rear of the action. It takes some real force to cock the sear! I normally don’t report cocking efforts for multi pumps, but on this rifle a force of 32 lbs. is needed. That has to come from your thumb, so it’s magnified by the small area. It reminds me of the Gat pistol in this respect.

To cock the action push that button in with 32 lbs. of force!!!

Once the rifle is cocked, it can be pumped. To pump the gun the wooden pump handle is pulled out, away from the action. Compression happens on the return stroke. I was told that the action can withstand up to 10 pumps, but the former owner said he usually only pumped it 4-6 times. Given the age of this gun and my unfamiliarity with the mechanism, I plan to follow that advice.

When the gun has been pumped, swing the breech open, insert a ball and close the breech again. The rifle is now ready to fire.

Sights

The sights are open and simple, but not without some nice features. The front sight is a squared-off post that tapers ever-so-slightly as it rises. It sits in a dovetail and can be drifted side to side for some horizontal correction.

The front sight is plain.

The rear sight is a flat leaf that has been bent at the rear and has a rounded cut for the rear notch. It isn’t dovetailed into the barrel. Instead the base is bent at a sharp angle and slid into a horizontal cut made in the barrel. It is deeply staked on both sides of the cut, but it should be possible to drift the sight. There is a screw in the center of the rear sight for elevation. Both sights are simple, but you can see that some thought has gone into their design.

Rear sight is simple but cleverly designed.

Stock

The CII stock appears to be beech. The butt has a steel plate fastened to it by two screws, in the way things were done back in the 1940s and ’50s. The pump handle seems to be made from a different species of wood, maybe oak or elm? It might need that to stand up to use because it is so small and thin.

The breech and some parts like the button that’s pushed to cock the gun are brass, that has been nickel plated. The rest of the metal parts on the outside of the gun appear to be steel.

Except for the buttplate, the bluing on this rifle is deep, even and nearly all there. The butt seems to have next to no finish remaining.

Value

Swedish Excellents are not common in the U.S. Therefore, I have little data to go on to tell you a value. I do know that a CII like mine sold for $625 on an auction website, and at the Findlay airgun show I was offered one that was not working for $350. That should give you a rough idea of the value.

What’s next?

I plan to test the CII for you just as I do all airguns. I won’t stress the mechanism by over-pumping, but in Part 2 I will give it a thorough test.

You have to push the cocking button towards the valve? I wonder about the valve design. A blow-off valve like the Sharp Innova has no need for a stout spring, while a knock-open valve would require you to pull the button against spring force towards the shooter. Maybe it uses an internal hammer, a bit like the Philippine airguns with similar breech design use?

Mel,

Maybe. I’m not taking it apart to see.

B.B.

I have acquired 3 of these things now, all different. Simpson LTD got a boatload and are blowing them out for as little as $100. None of them work, but are complete.

The check valve on these is just a piece of rubber tubing over a pierced mandrel. The reason the valve spring is so strong is because it has to hold it closed against the pressure. Some models have a trigger guard lever to cock it. I was able to add an O-ring to the pump valve to bring it back, and I just flipped over the flat chamber valve seal. These guns are very easy to work on, and you can make your own seals.

Benjamin .22 round balls worked well for me, but are a little tight in the breach. One of my guns is a repeater with a drum breach. The pumping is similar to a bicycle pump. I can only get 10-12 pumps in them before the chamber valve opens. Velocity is ~500fps.

SwampAngel,

Very nice,… amazing what they can do (try) with a cheaper air gun.

BB,

https://simpsonltd.com/air-guns-1/?sort=featured&page=2

Given your taste,… the site might be of interest if you are not already aware of it.

Chris

SwampAngel,

Welcome to the blog.

B.B.

A simpler mechanism to think of would be a cock on closing type of bolt. But since there is no bolt your thumb has to to do the pushing.

Siraniko,

Good analogy!

B.B.

BB,

As you can tell by Mel’s query, we are going to need to know more about that valve.

From your description it sounds to me like you are closing the valve when you cock it and the spring is pulling it open when you fire. If such is the case, why such a stiff spring? I too am trying to wrap my head around how that action works.

As for your comment that there is no detent on the rotating breechblock, from your pictures of the breech there appears to be at least a guide pin that rides in a slot to limit travel.

Did you think you were going to get away with the five cent tour with this thing?

Most of our Philippine made rotating breechblocks do not have a locking detent to prevent them being opened, relying on friction alone. They do have guides on most to stop them from swinging towards both sides.

Siraniko,

This one has something that limits it to one way, as well.

B.B.

To those of you who have made replies to my comments here in the last few days and I did not reply, I wish to apologize. It seems my email service has been sending the notification emails to the junk folder. I will have to see what I can do the correct that.

Hi BB,

I recently purchased a .22 cal Benjamin Marauder. The tag on the gun says that it’s been factory set to work best when pressurized to 3000psi. I filled it to 3000psi and took 40 shots using JSB jumbo express 14.35gr pellets, and I was kind of underwhelmed with the power numbers. The velocities at 3000psi are lower than the velocities at 2500psi, and the highest velocity the gun achieved all day was 842fps. Out of the box I was expecting somewhere between 870fps and 900fps with a 14 grain pellet.

My numbers were as follows:

3000 -> 2850 shots 1 – 10 ave vel 800fps

2850 -> 2700 shots 11 – 20 ave vel 817fps

2700 -> 2500 shots 21 – 30 ave vel 828fps

2500 -> 2300 shots 31 – 40 ave vel 838fps

The specs listed on the Pyramyd AIR website say max vel is 1000fps. I never expect my results to be the same as the specs listed, because I know they use the lightest pellets possible to achieve those velocities, but don’t these numbers seem a little low for a 14 grain pellet? Also, is it odd that at 3000 psi it shoots 800fps, and at 2500psi it shoots 838fps?

Thank you,

Doug

Doug,

It is clear from the numbers you posted that your rifle IS NOT set up for operation at 3000 psi. It looks more like a max pressure of 2700 psi to me.

Keep shooting until the velocity tails off.

B.B.

Hi BB,

I’m not sure I understand what you mean by keep shooting until the velocity tails off.

Doug

Doug,

Shoot until the velocity starts to drop fast. You want the rifle to shoot at relatively the same velocity, but your first 20 shots don’t show that.

B.B.

Doug,

I am looking at getting an M-rod in .25. I have been doing a lot of research. Aside from the factory adjustments, that should be in you manual, there is mods. that can be done. Another thing I learned is that your .22 may have a different “sweet” range than another. You found out what yours is based on your chrony results. Overfill will result in lower readings, then it will settle in and be consistent and then it will drop off faster. But,…each gun is different depending on how it is adjusted.

I am still learning and not the best person to ask on advice,…..the more you ask,….the more I learn,…. so keep it up! 😉

Gunfun1 and Buldawg76 are 2 people that have played heavily with M-rod mods. (When you are ready), I am sure they would be happy to offer advice. I would say look good at the manual and adjust what you can and keep the chrony work up. You may get less shots,….but more fps. That is what I will do.

Good luck,….I am watching you! 😉 Chris

Doug,

The marauders come set up for a 2500psi fill from the factory or at least they always did in the past). if you want to start from 3000psi, you need to do some adjusting

my mistake. i see now that the gen 2 mrods are in fact supposed to be set up for a 3k fill from the factory

I like the Excellent. Lot of nice features.

But wow 32 pounds to cock the gun and with only your thumb. That’s kind of crazy. Why would it need a spring or whatever that heavy? And while where on the subject of the 32 pound button. Is this one of those pump designs that need more trigger pressure the more pumps it has?

And hmm maybe this gun is where FX got their idea for the smooth twist barrels. After all both guns are from Sweden.

And I had to laugh about what Otho said. But I can relate to his thought. Somtimes you just have to ask why they design things like they do. I hope you get your Hammerli going. You will have to update us on that.

GF1,

No. This trigger is running a striker — not a blow-off valve.

Yes both guns are from Sweden, but I believe it was Ben Taylor who designed the Smooth Twist barrel for FX.

B.B.

Just wondering about the rifling you described- in order to cut regular lands and grooves in just the last few inches of the barrel would the barrel have to be choked to allow for cutting in those grooves? A ball wouldn’t expand to seal like a pellet skirt,would it?

Bruce

Bruce,

No on air it doesn’t.

B.B.

Hey BB, there’s a weird spelling on the description of the rifling ” It is conventional cut rifling with convantional lands and grooves.” Is that correct? I think you just intended to say conventional twice.

Auronotcs,

Fixed.

Thanks

B.B.

What do they say about something as reliable as a Swiss watch? One thing I’ve never understood is that since people have figured out how to make all parts of a gun work efficiently, why do people still market bad designs? Cost is one explanation. But why make a more complicated mechanism that works less well than established designs? I suppose there are a lot of factors involved that are not limited to engineering.

Well, the Swedish Excellent puts it all on the line with that name. One can only wonder whether it will prove to be excellent.

While the rain prevented my shooting over the weekend, it didn’t stop my slinging although I accumulated a lot of mud on my boots. I was determined to try a new slinging method, and you can forget everything I said before about slinging. The new method doubled my distance. My source had said that ancient slingers could exceed 400 yards, more than a bow and arrow. What I was getting before did not come close. Now, taking into consideration, training, length of sling and so on, I could maybe see how that might be possible. Power is a wonderful thing!

Matt61

Matt,

I am quite curios, Maybe you can do a short blog on what you found?

Regards,

August

I assume that you are talking about my slinging discovery. At your service. It all goes back to the Apache Indians. But even before then as a completely ignorant person with my new sling, I could see that there are some basic choices to be made. You can either swing the sling so that it rotates in a horizontal plane over your head, the so-called helicopter hurl. Or you can swing it in a vertical plane to your strong side which would be the right side for most people. The helicopter method is what I thought of with David and Goliath. However, I quickly found out that a missed throw could go all over the place and endanger people. The vertical throw confined the damage to a corridor (which included the top of my head) and it also seemed to be more intrinsically accurate. Throwing in the vertical plane, you can go either underhand like a softball pitcher or overhand like a baseball pitcher. The overhand method had more authority so I settled on that.

Enter the Apache Indians. I read an article somewhere about a guy who met an old Apache Indian who had preserved the tribe’s ancient knowledge of slinging. Using what sounded like my overhand method, he could hit a chosen metal rung on a telephone pole from 35 yards away whenever he wanted. Difficult to do offhand with an airgun. As to number of swings, he said that any more than one just increased your opportunities to miss. Well, I wanted what this guy had, so that settled the question.

I did have some doubts about my lack of power. It seemed that a few additional swings would increase my velocity, but the Apache Indian was pretty explicit. All the same, I tried two revolutions, starting on the weak left side and finishing on the strong right side. But sure enough the accuracy was bad, so I stuck with the Apaches.

But after continually missing my Goliath target and failing to impress, I did a little more research online. It turns out that I had been doing the double swing backward. Rather than starting on the weak side and ending on the strong side, you go the other way and end up releasing with a slight quartering motion, more like a natural pitcher’s throw than straight overhand as I had been doing it. That was what I was determined to test in the rain and mud of yesterday and boy did it work. Those stones really went sailing. And I even managed to hit Goliath once dead center. That shot would have got me kingship, Bathsheba and everything else. So, I had been one small error away from success. It is just like the scene in the movie Young Frankenstein when Gene Wilder, the mad scientist makes his breakthrough: “If you change the pluses to minuses and the minuses to pluses…Grandfather, you’ve done it!” And perhaps this is not inconsistent with the Apaches since I’m not exactly sure what they considered one swing. It could conceivably have meant a single figure movement incorporating two revolutions

Now as to the relation between this and shooting, it can be seen through the Law of Inverse Technological Satisfaction. That is, while superior technology gives better results, it removes you from the process and gives you less satisfaction. You can hit impossible shots with a computerized scope connected to your trigger but so what. And it was observed that while U.S. troops appreciated their M1 Garands, they did not give them a pat when they put them away as they did their Springfield rifles. Can’t get much more primitive than a sling, so the satisfaction is huge, especially when I hit my Goliath shot. Cf. my thesis on the superiority of primitive man.

Matt61

Matt61

For what it’s worth, back when i was playing with slings i found the greatest distance with a length that put the pouch just off my shoe tops with my arm hanging at my side. Then i swung the pouch gently forward until the sling was horizontal, then started my delivery straight overhand like a tennis serve. i could throw 300 yards+ measured with golf balls. Horizontal rotation or underhand throwing were not as powerful or accurate.

The people of the Baleric Islands near Spain were the most famous in ancient Europe, serving in the army of Carthage, then Rome. They were trained from early childhood. Before they could eat they had to hit their lunch on top of a post. They usually carried three slings of different lengths wrapped around their waist. The sling and it’s cousin, the bolas, were used all over the world. When the Spanish fought the Aztecs in Mexico Bernal Diaz, a soldier who wrote a history complained more about the sling stones than any other Aztec weapon.

It’s a fascinating weapon. Hope this is of interest. Have fun

Fido3030

Matt,

Thanks to type that much, it is pretty informative. Make it a blog with pictures, other would appreciate the diversion. And I do agree with you, it is quite satisfactory to train these techniques.

If I understand yo right then you start with the sling in your (for instance) right hand in rest so the stone is hanging near your shoes. Then you rotate forward, make almost one and a half circle and let the stone fly at say 45 degrees (or less depending one the goal you set).

Interesting is that the Romans used pieces of lead which they made by pouring molten lead in a hole in the sand which they made with their thumbs. I have some somewhere and they look like a supersonic boat model bullet also a bit tapered to the end.

I think they stabilized these sling bullets as they can get a rotation by releasing the one end of the sling a little bit slowly. That would make these missiles much more accurate on longer distances. It is only a idea I have, so If you have time you can experiment with that to see whether you can get more accurate with this lead slingshot munition from roman times.

Regards,

August

Matt,

For some pictures, see this site:

http://www.collector-antiquities.com/real-or-fake/roman-lead-slingshot.html

and other in the first sentence needs to be read as others.

Regards,

August

BB,

The first site may contain some info which you can use for the reassembly of your Hammerli. If not, there are enthusiasts which can help you if you send pictures. The other two are informative and maybe of interest for further reference when you are testing.

http://theswissriflesdotcommessageboard.yuku.com/topic/13082#.Vt3l4E32amw

http://theswissriflesdotcommessageboard.yuku.com/topic/10086#.Vt3mq032amw

http://www.milsurpafterhours.com/bb/viewtopic.php?t=4852

Regards,

August

August,

The SECOND BALL!!! That explains it!

Thank you!

B.B.