by Tom Gaylord

Writing as B.B. Pelletier

Air Venturi’s V10 Match pistol.

This report covers:

- Best-laid schemes…

- Straightforward

- How to dry-fire the V10

- Lubrication

- Moly

- Test the trigger

- Put everything back together

- The fix

- Summary

Best-laid schemes…

…o’ mice an’ men gang aft agley! The poet, Robert Burns, was right when he said that. I told you that I was going to show you how to lighten the trigger of the Air Venturi V10 Match pistol today, and I am. But in the past this has always been a simple 15-minute job. It should take me maybe 30 minutes with pictures. I had planned to do the accuracy test today, after finishing with the trigger. Nope! Instead I struggled for some time, and in the struggle I learned something valuable that I will now pass on to all of you.

Straightforward

The job I’m going to show you is straightforward. It should be easy for everybody, as long as you don’t stray past where I’m taking you. In Part 2 we left the trigger at between 2 lbs. 2 oz. and 2 lbs. 9 oz. pull. A 10 meter pistol trigger can be as light as 500 grams, which is 17.64 oz. or 1 lb. 1.64 oz. So, where we left the trigger was more than one pound too heavy.

The first thing I did this time before anything else was to carefully measure the trigger again. It was breaking at around 2 lbs.

The trigger tested at about 2 lbs.

How to dry-fire the V10

To cock the V10 for dry-firing, raise the top cover of the gun as if to cock it, but it only needs to be raised a little — less than halfway. You will be dry-firing the pistol a lot with this procedure, so best learn now how it’s done.

Then I took the grips off and adjusted the trigger pull weight lighter. Now the trigger was breaking at 10.5 ounces, which is 298 grams — way too light! But I would wait to see what would happen with the lube procedure I was about to do, so I stopped adjusting. I had adjusted the pull with the grips off, so I could see how the adjustment screw works.

With the grips off I adjusted the trigger lighter to 10.5 oz.

The grips are off. The left side of the grip has nothing interesting to see.

The right side is where all the action is. That translucent cover hides the trigger parts. Pay attention to those two arrows that point to two pins. Those pins are the axels of parts in the trigger mechanism. When the cover comes off one side of each pin will be unsupported.

Three Phillips screws hold the translucent cover to the grip frame. Remove them and take the cover off. You can now see all the trigger parts.

And there is the trigger. The pistol is not cocked.

You can cock the pistol with the cover off — just take care not to let any trigger parts fall out.

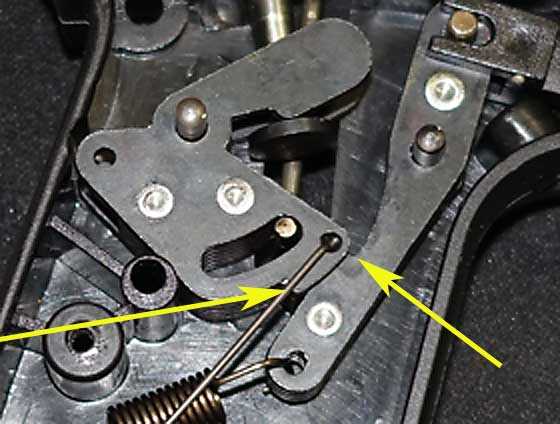

This closeup shows the two parts that connect to form the sear (arrows). In the next picture you will see them together.

Here the gun is cocked. It may not look like it because of some shadows, but those two parts are now in contact. See that brass pin at the upper right of this picture? That is where the trigger (the grooved metal piece next to the pin) will contact the sear to move it.

Lubrication

We have now seen where the lube needs to be applied. The pins you saw earlier don’t need anything. Keep oil out of the trigger because it just attracts dirt. We want to lube the sear contact, only.

This looks at the sear (arrow) from a different angle. That’s where the lube goes. AND ONLY THERE!

Moly

I used moly grease for this job — yes, moly! I know some people feel moly is too slippery for a trigger, and there are triggers that I would recommend not using it on. BSF triggers, for example, are not designed right for moly grease. They become too light. But this trigger has a safe sear engagement and I have been doing this for years to these pistols.

I used a paper clip with a quarter-inch bend at one end to apply the moly grease.

There is the grease on the sear. See how I also applied it to the other part? That was not intended. Use a cotton swab to clean it off. The moly will transfer to the other trigger part when the gun is cocked and fired, so there is no need to lube it now.

Test the trigger

I dry-fired the trigger with the cover still off to see what this lube had done. Remember that it had been breaking at 10.5 oz. before the lube. It now broke at 8.6 oz. (243.8 grams). That’s way too light! So I dialed some weight back into the trigger-pull adjustment screw (the cover is still off the trigger) and tested it again. This time the pull broke at 15.7 oz. (445.1 grams). That’s close enough for me, because the trigger may get heavier when the grips go back on.

That is far too light for a pistol trigger! I need to adjust the pull weight.

With the trigger exposed the pull weight is closing in on one pound. I like that and will close the gun now.

Put everything back together

I put the cover back on, then reinstalled both grips. Now I tested the trigger once more. It was 2 lbs. 1 oz.! Whaaat? This is the special thing that I talked about at the beginning. How could putting the grips back on cause the trigger pull to increase by more than a pound? Only one thing I could think of was the adjustment screw could be binding and that might cause it to tip and throw off the other parts it is connected to. So I pulled off the grips to have a look.

Sure enough — that was it! When the grips were made the hole the adjustment screw passes through was drilled too tight and when the grips are snug the screw has sideways pressure on its head.

Here you see the wood is binding on the adjustment screw head. It was doing this on both sides.

The fix

The fix was quick and simple. I used a sharp pocketknife to ream the extra wood out of both grip panels. I didn’t take off much! Then I installed the grips and tested the pistol again. This time the trigger pull is 1 lb. 1.6 oz or 498.95 grams. I’ll take it! I won’t be competing with this pistol so I’ll never have to go through an official test. If I was going to, I would dial the pull up to 520 grams, just to be sure.

Almost a perfect trigger-pull for a 10-meter pistol.

Best of all, each pull of the trigger is now about the same. None of this 2 lbs. 2 oz. to 2 lbs. 9 oz. business. Job done!

Summary

This turned out to be a way more detailed report than I anticipated. I was going to show you all the steps of the trigger lube, but I have never had a problem with the adjustment screw binding this way. I’m glad it happened, because it gave us all a chance to learn more about this trigger. Now I can test the accuracy of the V10.

B.B.

Who would have thought that 1-2 mm of extra wood would make that big a difference. Poor QC!

Speedy recovery!

-Y

BB

Amazing how little things can make a difference.

Does the trigger still feel crisp when it breaks?

And hope all went well with your operation.

GF1,

I’m home and I’m fine.

Yes the trigger is not much crisper. It’s very much a 10-meter trigger, though not in the same class as the expensive ones.

B.B.

BB

Glad everything went well.

And this really isn’t a match trigger is it. Don’t match triggers pretty well have the 2 stage trigger adjustments and also pull pressure.

I imagine it feels nice. But it just don’t have the adjustability that kind of personalizes the trigger for the shooter like 2 stage triggers have.

B.B.,

Hope all is well. I find this interesting as the adj. screw would be a fixed item. It passes through a tapped hole and attached to a spring. Any slop in the threads would permit some cocking of the screw, but since it attaches to a spring end only, it is hard to believe that made a difference. None the less, it did.

Cool article. I like all of the nice close ups and seeing the trigger mech.. I see they used laminated steel. Interesting. I would think that 2 well made/machined parts would be preferable to multiple pieces of steel stacked to make 2 parts. Less variables.

Good Day to one and all,…. Chris

Chris,

I was wondering about the stacked steel part as well.

In thinking aloud, machining a part is much more expensive that stamping one and those parts of the trigger are quite complex.

If you look at it, that trigger component consists of a side plate (2x) and a core (4x) and two aluminum rivets. The parts could be stamped out by the dozen and assembled in a jig, when the soft aluminum rivets are swagged they would upset and fill the riveting hole fully which would lock the whole collection into one solid unit. Looks like an elegant and economical solution to an expensive machined part 🙂

Due to die slop/wear the sheared edges of stamped parts are not perfectly square (and that is worse the thicker the metal is) so I am guessing that might be part of the reason for stacking the parts.

Arm-chair engineering at it’s best eh?

Hank

Hank,

Notice that reddish brown blush everywhere on the central plates…RUST?!!!

Perhaps caused or increased by galvanic action due to aluminum alloy rivets and inferior quality steel plate? Guess this is not going to be one of the collectables 100 years from now!

shootski

Shootski,

Was looking at that brownish blush, thought it might have been grease.

Aluminum fasteners in steel/iron a base are not a considered problem. I nicked an image (attached) from this website ( http://www.preservationscience.com/materials/metals/PGC.html ) that has a good write-up on the subject.

Hank

Hank,

Maybe I need to do a blog on triggers again. The BSF triggers are all made the same way.

B.B.

B.B.

I would be glad to see that!!

Hank

P.S. Hope you are comfortable!

Chris USA,

While its true that a machined part would be much more expensive than a laminate of stamped panels, I bet sintered metal, which is metal dust formed into a shape under pressure, or lost wax casting, would yield a superior part at a similar price. Both methods are used in the firearms industry all the time to reduce costs over milling, drilling, shaping, reaming, broaching,…

I tend to think that that multi-point engagement at the sear is what caused the broad range of trigger pull weights that BB got with the original screw setting. I don’t care for that quality in a so called target gun, at all.

Half

Half,

Agreed, not preferred the construction but I am going to hold judgment until B.B. has finished his testing!

This one looks to be an awesome plinker and an adequate target pistol for the more casual shooter.

Have to reseal my old FWB 100 – it keeps me happily pistolling.

Hank

Chris,

I can’t figure it out, either, but that is what happened. It’s now a very nice trigger.

B.B.

BB,

Welcome back!

As soon as you get back you start working on us with your Enabler power.

I…must…resist…

R.R.,

One of Edith’s favorite lines to me as I was waffling or drooling over something was,…. “Resistance Is Futile”! 🙂 I am pretty sure that you may remember.

Chris

Chris,

Yep! That was a favorite of her’s 🙂

B.B.

B.B.,

🙂 It is something that I will always remember. Kind of like a “Welcome to the Club” and a “Go For It” all at the same time. Just the push I needed. I may not remember much these day’s,…. but that will always stick with me,… and has.

I am so very glad that I have stuck around to see what is around the next corner. The pace of growth and offerings are/can be daunting.

Chris

Chris,

Yes, I do remember.

This pistol is going to be on my short list, but unfortunately it will likely be there for a long time.

I wish you well on a quick and full recovery. As you recover, you might use this time to think of something current to us all. Many of us just from life get injuries that make enjoying life more difficult, Just getting old results in our bodies not working like they use to. As I have developed carpal tunnel in my fingers and hands, and except for Co2 and PCP air guns the rest are mechanically powered. Perhaps an investigation as to what air guns are best for those who have injuries as well as alerting manufactures of the market they would be ignoring by not doing so is in order. Just a thought.

Waldorf1,

That is a very good suggestion. I need to cogitate on it a bit and if you can think of things that need to be addressed, please tell me.

B.B.

Great blog B.B.!

Love the detailed pictures of the inner workings! Curious minds are happy!

If they can put such a fine trigger on a $270 pistol it makes me wonder why the triggers an many of the rifles are poor. I understand the price-point thing for entry-level stuff but this would be a nice upgrade to be offered on

“deluxe” versions.

Cheers!

Hank

Hank,

A part of the problem is how much force are you holding back. With this pistol it is not much.

The major issue though is litigation. Most triggers on the “lower end” sproingers and even the PCPs are designed to prevent the possibility of an accidental discharge no matter how much they are adjusted. The companies know that their products are likely to be in the hands of the young and/or inexperienced. It takes a good bit of engineering and production modification costs to change from what is now available on their airguns to what it could be.

I am actually amazed that TCFKAC has provided the means to easily modify the trigger assembly on the Discovery/Maximus/Fortitude to a decent trigger.

RR,

It’s your invention, but would you consider changing it to ” The Enterprise Formally Known As Crosman “?

That would leave us with an abbreviation that we can at least pronounce! 😉

Half

Half,

What?! I would no more change that than I would RRHFWA!

Besides, unfortunately I cannot claim credit for that. I merely adopted it into my senseless meanderings.

RR,

OK, then. I’ll just use the acronym INKAVO for Idiots Now Known As Velocity Outdoors.

Half

Half,

That’s great! I love acronyms once I know what they mean. They look so cool all capitalized in sentences and the longer the better.

I’m repeatin’ myself. They say that happens when you get old. They say that happens when you get….Crap!

Half,

The reason for this is that you learn to do this automatically because you are around someone like me who has lost a good bit of hearing over the years and every time you say something, you have to repeat it.

Now it is kind of bad when you start doing it when you type.

RR,

Don’t think that handling the trigger force on a sproinger or powerful hammer-spring on a PCP would be a big problem, there is plenty of contact area on this type of design and you could always throw in a bit of case-hardening.

The litigation to protect themselves from their products being misused by (putting it politely) the hands of young and/or inexperienced people is indeed a major issue. It’s a major issue to those who know better and have to suffer compromised products designed by lawyers instead of engineers.

Seen some of the stuff people do to airguns and it makes me cringe – think that the justice system should recognize when a product is being misused by someone who is terminally stupid and automatically relieve the manufacturer from all blame.

Hope that those lawyers don’t calculate the FPE of a car doing 50 mph… we would all be driving around on bicycles 🙂

Cheers,

Hank

Hank,…. Well said,…… Chris

Hank,

It is most unfortunate that most often the company is held liable even if the said product has been modified by the terminally stupid. The company should have forseen that the product could have been modified and done something about it.

Stupid wins every time.

RR,

Unfortunately, you are correct – stupid wins every time. 🙁

So it seems that the problem is that the justice system can not properly distinguish between a product that is poorly designed and dangerous (company is at fault) and where a product is misused or modified to be dangerous by the owner (owner is at fault) and make a fair and appropriate call. Looks like stupid wins again eh?

My friend missed his chance – his 8 year old daughter got the keys out of his coat pocket, took the family car for a joy ride and crashed it into another vehicle. He could have sued Chrysler and retired! There is no “READ THE MANUAL BEFORE USING THIS PRODUCT” label engraved in the windshield and the product is obviously not safe enough! (…more stupid eh? Sorry about that 🙂 )

Have a good weekend RR!

Hank

BB,

Hope you are back on your feet soon.

Half

waldorf1 I have carpal tunnel in both hands. I am going to have surgery on my left hand next week. Have you had surgery? If so, what are the results ? Are there any other members of this blog who have carpal tunnel ? Ed

No carpal tunnel here yet but yes, basal thumb joint osteoarthritis. The surgery is nasty looking so I’m trying regenerative therapy; you can google Regenexx if interested. I’m not sure if blood platelets and/or stem cells are used for carpal tunnel but I wouldn’t be surprised. Insurance doesn’t pay so cash up front is required. No miraculous results so far in my case. Evaluation of outcomes is hard to find. It’s a gamble. I also adopted a plants-only-no-oil way of eating 5yrs ago and it’s pretty awesome for everything from constipation to cancer including all the degenerative diseases, high blood pressure, hygh cholesterol, etc. Wish I’d discovered this decades ago.

BB-

Hoping for your speedy and full recovery! The morning and the blog seem kinda lacking when you’re not present. Thank you for the work you put in to write this for us before you went in to hospital, it gives us a little taste at least. Your photos and explanation make it easy to understand the workings of this trigger. I can see exactly how each adjustment screw does its job. Simple but effective!

Bruce

Hope you are doing well, BB, and at least perusing the comments section of the blog. Very much enjoyed today’s blog and I think someone said it earlier in this series but this pellet gun looks very much like the Gamo Compact I used to own.

Fred formerly of the DPRoNJ now happily in GA

B.B.,

Hope the prayers of so many are working!

Speedy recovery…think of all the targets yet to come!

shootski

B.B.

Hoping your surgery was successful and you not experiencing too much pain. Wishing you a speedy recovery and get back soon…you are missed, even if only a couple of days. Nice blog today with great illustrations and pictures. I’m not a pistol guy but did enjoy today’s blog. Well done 🙂

“See that brass pin at the upper right of this picture?” That pin appears to be steel with the end exhibiting some rust?

Thank you Pyramyd AIR for the option to edit these posts, it’s awesome 🙂

By way of comparison, the Gamo Compact has a sear spring that just hooks over a peg.

You mention that there is nothing interesting on the left-hand side to see, with the grips removed – not quite true. Notice the steel bar that at its top end is connected to the valve housing, and its lower end sits in the curved slot in the hammer. Opening the gun, the air cylinder naturally pivots up, lifting the valve housing and pulling the hammer into the cocked position.

Regards, Iain

That, by the way, is quite an old gun (not mine, a club gun), notice also the different position of the hammer spring.

Iain – UK,

Welcome to the blog.

And thanks for your insight on the gun.

B.B.

The Gamo Compact’s ambidextrous cousin, the PR-45, sharing the same overlever but with a plain plastic chequered grips, and a crossbolt safety catch.

It’s not actually grips, left and right, attached to a frame, the left hand grip is simply part of the frame and the right hand grip serves as the cover plate.

Regards, Iain

B.B.,

Glad you are back. Take care of yourself and don’t over do it.

Other than the barrel, I think the trigger is the next most important part of a gun. Thanks for the look inside. I am amazed at all the different designs for triggers. The complexity does not always add to the performance from what I have seen.

Don

BB

Nice to see you back and in the flow. Best on your recovery.

Jumpin

Tom,

I was a few days behind on the blog, and just read about you being out of commission to have a procedure. I hope all went well, and you have my prayers for a full and speedy recovery.

God bless

Jim

Jim,

Everything went fine and my surgeon was surprised by how fast I am recovering.

B.B.

Friend Tom,

So relieved to read this. My prayers have been answered. Praise Him.

https://www.youtube.com/watch?v=C1AYKRjoFxs

Always inspires me in so many ways.

Blessings

Kevin,

Thank you. You are on my daily prayer list, too.

B.B.

I’m very glad to hear that! Be well.

Jim