by Tom Gaylord

Writing as B.B. Pelletier

Today’s report is a continuation of reader Vana’s excellent report on stock making.

If you’d like to write a guest post for this blog, please email me.

And now, over to you, Hank.

This is my original 55 year old Slavia 618 in its new “firewood” stock. I made this one in a “camo” style, using cherry and maple blocks in a random arrangement of the pieces.

This report covers:

- Stock Layout

- Let’s get started!

- Putting pencil to paper

- Two approaches to stock making

- Which way to go — subtractive or additive?

- Before we start, tune your tablesaw!

- The forend block

- Machining the receiver mounting points

- Bedding the receiver

- Cutting out the spacer

- About gluing…

- The “spring retention cap” retainer

- Cutting the forend profile

- Summary

Stock Layout

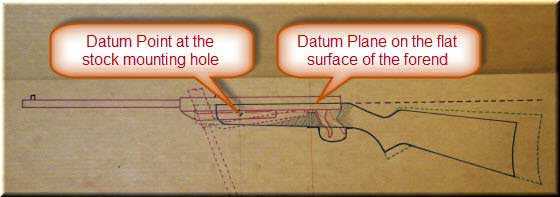

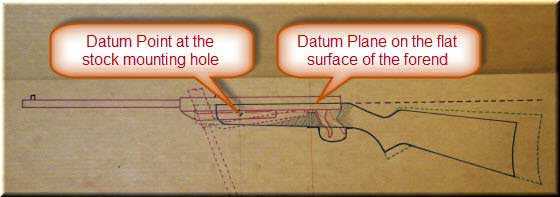

This is the layout for a new Slavia 618 stock with all the important details drawn in.

I will be using datum points and datum planes to work from. These are the reference points and reference surfaces used to measure from, to locate features on our template and our material. All dimensions are taken from the datums. The stock mounting holes are ideal datum points and I will use the top edge of the original stock for my datum plane. In this instance we will use them to relate the features on the receiver to the stock.

Let’s get started!

There are two considerations in laying out the stock — the parts of the stock that contacts the shooter and the interface between stock and the receiver. Good fit for both are important. I’ll be using the original stock as a reference to make a Try-Gun stock. Because it is adjustable I don’t have to worry about getting things “perfect” as the whole benefit of this approach is that it can be made to fit later.

Putting pencil to paper

The outline is not critical but I try to be as accurate as I can while penciling around the perimeter. Then I go over the pencil lines with a straight-edge and felt markers. To keep things clear, I use different colors for the receiver, the original stock and for the new portions of the stock. In the image above, I have added (in the green dotted line) the changes I will be making for the new stock. I prefer ballpoint pens for marking fine accurate lines on the template and on the wood.

To locate the mounting surfaces, clearance cutouts and other features on the stock I’ll take all critical dimensions from the datum point and datum plane on the stock and add them to the cardboard layout. The datum plane (usually the flat top edge of the stock) will be used as a reference for measuring the position of the butt and the height of the cheek-piece as well as the depth of various features to be carved out for the receiver.

Two approaches to stock making

Most commercial stocks are routed out of a specially prepared (laminated or natural) block of wood with a computer controlled router. This machining approach, where all the material that doesn’t look like a stock is removed is often referred to as “hogging it out of solid”.

Which way to go — subtractive or additive?

The subtractive approach — carving a stock from a single block of wood — is possible with hand tools but it is a challenging way to do it, and one little OOPS can ruin the whole show. It’s best to get some experience before going this way. Making a Try-Gun stock and a rough stock out of spruce will give you a good idea if you are ready to use the subtractive approach.

I will be using an additive approach and make the Try-Gun forearm, grip, cheek piece and butt as separate pieces. Working with smaller pieces is easier to do with hand tools and if something doesn’t work out it is quick to make another one. The firewood stock is slightly different, as the blocks are added as the work progresses rather than making the pieces and joining them at the end.

Before we start, tune your tablesaw!

For tight-fitting joints it is important to have a tuned tablesaw. I clean and lubricate the saw blade support structure, wax the table to be sure that everything operates smoothly. The blade-to-table clearance insert needs to be flush and solid, if it is not level, or if it moves around, the accuracy of the cuts will be compromised. Like the pre-flight walk-around on an aircraft, I start every session by confirming that the blade is sharp and undamaged, the fence is parallel to the blade, the blade is perpendicular to the table and all hardware is tightened… don’t like nasty surprises.

The forend block

The forend is the most challenging part of the stock because this is the part that needs to fit the metal receiver closely. Lacking the sophisticated routers that commercial stock makers use I do most of my shaping with my 10 inch table saw. Because I will be using both sides, the top and the bottom of the block to control my cuts I need to take special care that all the faces are square.

Preparing the forend block…

The top image shows the four pieces cut to size and below, shows the block assembled and dressed square.

Because this stock has a slot for the cocking-bar on a breakbarrel I’ll make the forend from four pieces of wood screwed together (they will be glued later). Two thin strips of wood are used as spacers that will create the channel for the cocking-bar and clearance for the trigger. To provide a wide, flat working surface the assembled forend block is a lot wider than necessary – it will be cut to width just before the profile is cut out.

For stress distribution reasons, I’ll match up the boards with the grain orientated “face to face” (like samples #4 & #5 as shown in the “Selecting the wood” section in Part 1) and label them so I can keep track of where they are in the block.

To prepare the wood I’ll dress both sides of the lumber (remove a bit of wood with the tablesaw) to make them flat and smooth.

The next step is to align the four pieces of wood, clamp them together and add screws around the margins to make up the forend block. Some care has to be taken to locate the screws so they don’t interfere with where the holes will be drilled, and low enough to clear the channel to be cut for the receiver. With that done it’s time to redress the edges and ends so that the all faces are aligned, parallel and square.

Machining the receiver mounting points

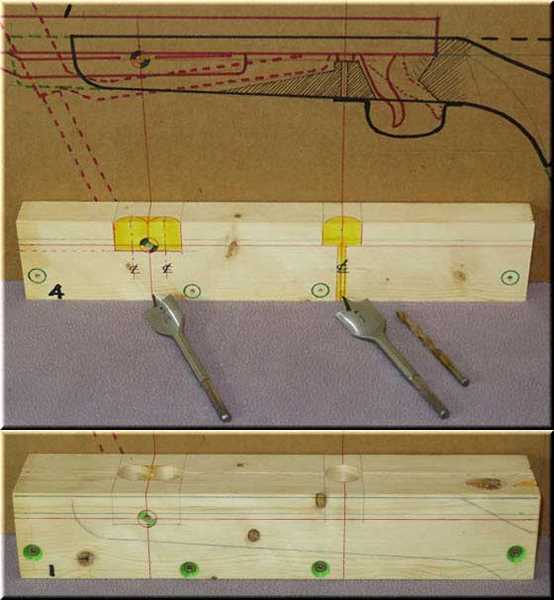

Here the stock mounting holes and clearances have been marked and drilled in the forend block.

Now that the forend block set to go I can start transferring some information from the template to the work piece. I have located the datum plane that represents the top edge of the stock 1/8 inch below the edge of the wood (black line) to allow material for final fitting and cleanup. I add the more important lines (with a red ball-point pen) all around the block and sketched in the stock for reference.

On this rifle the receiver is mounted with three screws. The first step is to locate and machine the areas for the mounting surfaces and drill the mounting holes. With the drawing done, the clearances for the receiver mounting hardware are drilled out with spade bits and the holes for the mounting screws drilled. In order to avoid tolerance conflicts on mounting surfaces, I find it easiest to drill a little deeper than required and fill any gaps with epoxy (thickened with a bit of sawdust) later.

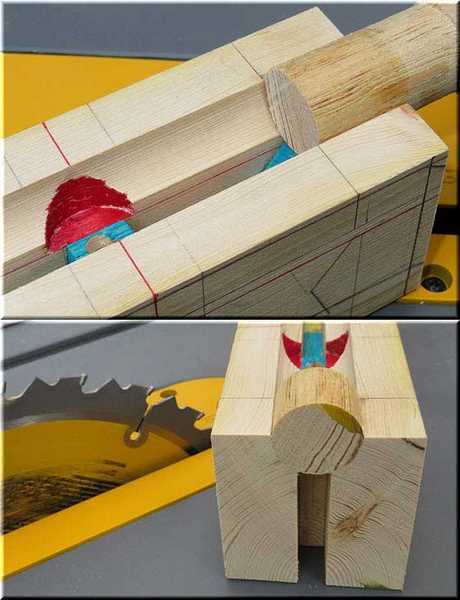

Bedding the receiver

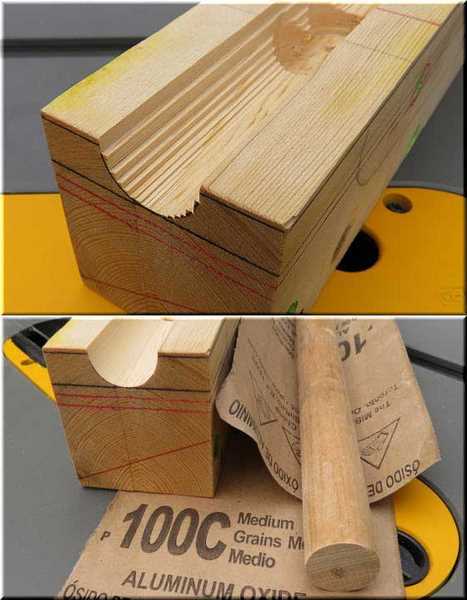

Here the channel for the receiver has been cut on a table saw and sanded smooth.

Here the channel for the receiver has been rough cut on a table saw. I started with the shallow cuts and worked towards the center, adjusting the depth of cut to follow the radius as I went. Because the channel is symmetrical about the center of the block, the cut location and depth can be set for one side of the arc and then flipped around to cut the other half. In spruce, the saw cuts can be over lapped by half a kerf (saw tooth width) and still be easy to sand out. In hardwood it is better to space the cuts closer together.

I use a dowel wrapped with medium grit sandpaper to start bedding the receiver. The dowel is a couple of inches longer than the width of the sandpaper so it guides the stroke and keeps it straight and level. I use a light stroke and clear the sawdust frequently, watching the saw kerf steps to be sure that I am removing the wood evenly. It helps to flip the block around so that the sanding is done from both directions.

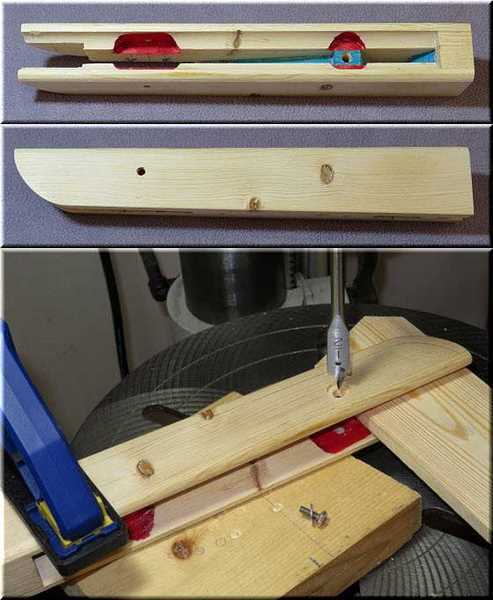

Cutting out the spacer

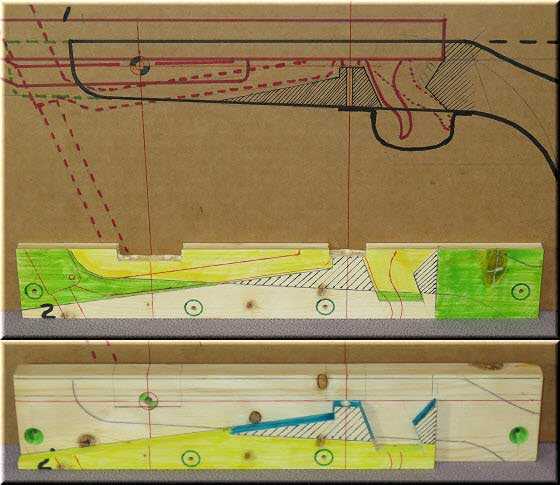

Spacer detail: In the upper image, the hatched areas will be part of the forend, green and yellow areas are cut away and the remaining area with two screw holes will keep everything aligned for gluing. The lower image shows the cut-out spacer (the yellow area is part of the block and will be cut away later).

To save a lot complex chiseling and filing I create the slot for the cocking arm, the channel for the trigger and form the tenon to attach the grip with a spacer made with two thin pieces of wood. Using two pieces has the advantage of creating a “center line” that helps guide the spade bit.

I labeled all the pieces (1 through 4) to keep track of them. In the top image you can see the spacer, pieces 2 & 3 glued together — I used pieces 1 & 4 (protected with some plastic) to clamp everything in alignment. The stock was traced in (using the mounting holes for reference), the cocking arm and trigger drawn (carefully) to show where the clearance is required to allow for full movement. The yellow and green areas of wood will be removed; the hatched area is the actual spacer and the area below the hatched area (with the two remaining holes — “green circles”) is needed to position the spacer when gluing the forend block together.

The lower image shows the spacer cut to shape and ready to be glued in-between pieces 1 & 4. The yellow area is part of the waste that will be removed when the forearm is cut free of the block.

All the coloring is for the sake of my explanations – I usually keep the wood clean and natural.

About gluing…

When gluing two pieces together it is important that the joint is tight, clean, and that all is ready so that it can be quickly clamped and left to set without being disturbed. A glue bond takes place at a molecular level so very little is needed. Glue doesn’t compress, so using too much will result in a poor joint. After the initial bonding, a joint will need adequate time to cure before it is stressed. Made like this the joint will be stronger than the wood and almost invisible.

The “spring retention cap” retainer

Here is the rifle “spring retention cap” dowel being glued in and trimmed. The slot below the dowel is for the tendon used to attach the grip.

The Slavia 618 has a “spring retention cap” at the end of the receiver that requires a dowel to help keep it in place. Here I have added a dowel for that purpose and trimmed the forend to length.

Cutting the forend profile

The rough finished forend.

In these images, you can see the clearance for the cocking arm and trigger, the mounting surfaces for the receiver (red) and the spacer (blue) that created the slot.

To finish up the forend I trimmed it down to the correct height (removing the extra 1/8 inch of wood and the top of the dowel), cut it to the width needed and cut the shape to the profile I wanted. The last step was to counter-bore the mounting hole.

For durability, the mounting holes and counter-bore surfaces are saturated with cyanoacrylate adhesive (“CA” or Super Glue). To avoid blotches in the stock finish, take care not to get any CA on the surface of the stock.

Summary

In this part we have discussed laying out the stock and the steps to make the most challenging parts of the forend. While the forend is the interface to the receiver, the grip is the prime interface to the shooter. We will get to that in the next part.

Vana,

A very interesting lesson in woodworking. I am quite impressed by the amount of meticulous planning which has gone into this and, the patience and the excellent use of simple tools. The writing up is also a joy to read with the clear photographs.

I look forward to the other parts.

Regards,

August.

August,

I am glad that you enjoyed the the blog, makes it worth the effort! …Now if I can get you to make a stock I will have totally succeeded in my intent.

Hank

Hank,

Nicely done. This requires several re-reads to absorb it all. I do see the methodology though. Unfortunately, it is a work day. Looking forwards to reading again and future installments. Nice job on the pics and the color/visuals on the wood.

Good Day to one and all,…….. Chris

Chris,

Yes, there is a lot of information in this part and it can seem a bit overwhelming at first read (especially for people who are not technically inclined as you are).

I used to recommend this approach to my students… My suggestion is that people should skim over the blog (start with the “This report covers” list of contents) and look at all the pictures to orient themselves, then read through the text to get an overall idea of the process then re-read thinking of the steps in detail.

So, when will you be starting you left-hand stock for your Maximus? 🙂

Hank

Hank,

All I can say is WOW! Like Chris said, I am going to have to re-read this several times just to take it all in.

I happen to notice that though I am sure it is not, your equipment looked brand spanking new. Nice job of care and maintenance.

One thing I immediately noticed is your method is ideal for making a laminated type stock.

By the way, how many orders have you received? 😉

RR,

Glad you like it well enough to re-read! Yeah, lots of detail, it is easier to show how to do something than it is to write about it. Part 3 is detailed as well.

The table saw is a recent replacement of the old hand-me-down saw that I have been using – very pleased with it. Considering the price of tools it is well worth taking care of them – I like to apply a spray-wax (like Pledge) to all surfaces before using and regularly after that.

You are right – this is the same way I make my laminated stocks. I glue up strips and pieces following the contours of the receiver, trigger, mounting bosses etc. just like one of those “Contour tools”.

No orders yet LOL! The blog series is to get people to make their own stocks!

Now that we are in a new year and holiday excitement has faded back to routine I have been busy making slingshots. Love all things that shoot projectiles!

Hank

Hank,

On that firewood stock I can well imagine smoothing and sealing those ends must have been fun. Would not running the grain across the thickness of the stock make it fragile or are there two center linear strips as in the try-gun stock?

RR,

An inch and a half of hardwood is pretty strong even when cut cross-grain. You don’t want to use it as a club though.

I made the firewood stock from a solid block and cut the cocking arm and trigger slots on the table saw.

To get the balance right I needed to thin the waist more than I wanted so I re-cut it and installed two screws to reinforce it.

Shaping was not a problem – you just need a good sharp rasp and watch the direction of the stroke around the edges.

Smoothing is good exercise… wax on, wax off LOL! I did cheat and use a power sander though.

Hank

Hank,

You have me wanting to give a stock a try. The only issue I have is I would need to do a laminate stock as I would want to slim it way down and sculpt it out in a few places to make it as light as possible. It can be done with this method. I will just have to see what I can get. That and a table saw. 😉

RR,

You can get 12 inch wide lengths of hardwood veneer (it is used to cover shelves) from Lowes.

You could cut that into strips to to laminate up into the skeleton of your stock like I did on the AR20 stock shown in the first part.

Essentially you would be making very strong custom shaped hardwood “plywood”.

Hank

Hank,

Yes, I have drooled about that stock some time back. What is really neat about it is how you used horizontal lamination instead of vertical.

Hi Hank,

My brain is like sand paper, several passes( reads of this article) to get it right. Perhaps you could post a picture of the gun’s receiver?

Is the table saw your preferred tool, or just the one you have?

Looking forward to future posts to see how this all comes together.

Thanks for taking the time to explain everything in such a detailed manner.

-Yogi

Yogi,

Sorry, I checked through my pictures and don’t have one of the receiver. The receiver is is a tube with a bracket welded to it for the stock left & right mounting screws and a chunk of steel attached just in front of the trigger for the screw that holds the back of the receiver down in place.

I show the mounting points (colored in red) on the rough cut forend in the image above.

I used a 10″ table saw to make this stock as it is the power tool that most people have access to. Wanted to keep things simple. I do a lot of wood and metal working so I have an extensive collection of hand and power tools to support my projects.

Glad you liked the blog!

Hank

Hank,

I have a friend who is a master machinist; your methodology reminds me much of his.

He works in metal; you work in wood; and you are both masters of your craft.

Thank you for an excellent and very nicely-detailed report! =>

May 2019 be awesome for you,

dave

Dave,

I do a lot of metal working as well so I’m not surprised that it shows in my woodworking – the processes are essentially the same. Some of the woods I use (buckthorn, hop-hornbeam) are as hard as many non-ferrous metals.

This part covers the stock to receiver interface – the next part is the stock to shooter interface. More details to come!

Hope that 2019 is great for you to!

Hank

Vana2,

Wow Hank! Part 2 is even better than Part 1.

Funny, as I was reading today’s write-up I was thinking: With some small design and tooling changes this could be an aluminum stock project!

Looking forward to Future posts in this series.

shootski

“Some of the woods I use (buckthorn, hop-hornbeam) are as hard as many non-ferrous metals.”

Pretty cool! =>

Dave,

It has been many years, but when helping my Dad cut wood, we ran across something he called iron wood. It was very tuff to chain saw and very heavy for the length cut compared to other wood types. I do not recall if had thorny branches. It was smooth bark if I recall and had “veins” in the trunk/limbs,… like a very muscular man (or woman these days). This would be in Ohio.

Chris

Chris,

Locally hop-hornbeam is called ironwood – it one of my favorite woods for making bows.

The smooth bark “muscular” wood you are referring to is Blue Beech and is also called ironwood. I have a bit of it on my property. Tough stuff, I have mads carving mallets and wedges from the stuff.

Hank

Chris & Hank,

I’m not sure which “ironwood” this one has on it, but this is a knife my wife bought me from “Bubba” (Warren “Bubba” Glover) at a local fair.

The back 2/3rds of the scales are Georgia boxwood, but the front section towards the pivot is ironwood (you can see more about the woods he uses here: http://bubbaknives.net/ ).

Warren told me he impregnates the boxwood with epoxy to strength it, but that the ironwood is super-tough as it is; the entire knife has proved to be pretty durable in the years I have owned it.

take care all,

dave

P.S. Sallie Mae is over-seeing the pic to ensure that I photograph the correct knife! =>

Dave,

Cool pic. I did look it up on Wikipedia and the tree types listed is quite, QUITE long. It would appear to be a generic name for a heavier/harder wood than what is normally found in a particular part of the world.

Chris

Hank,

You’re very talented. Thanks for allowing this huge group into your shop.

Is pillar bedding and screw cups in our future?

B.B.,

Did I miss the link in this article to part 1 in the series?

Kevin,

Oops! Thanks!

B.B.

B.B.,

Thank you.

kevin

Kevin,

Welcome to my shop! Glad to show you around!

Wasn’t thinking about pillar bedding and screw cups though I have done plenty of them. Lots of iron and brass options to be found in the plumbing department of any good hardware store though I usually custom machine my own from bar stock or bolts.

Hank

Hank,

For a tame springer like the 618 it probably isn’t needed. Your reinforcement of mounting locations with CA will likely be enough. Everyone with a springer in a wood stock should pay attention to your advice about this and do it on their own wood stocks. Well done.

Hi Hank,

Very appreciative of this blog series. I have a couple of blanks in various stages of inletting and I just need to finish them sometime.

I was wondering if we could have a better picture of the firewood stock? Like higher resolution some more angles and closeups? I would really like a closer look =-)

Best regards,

Carel

Hi Carel,

I have this 180 dpi image to offer right now, I will take a couple more if I get a chance.

Cheers,

Hank

Cool, thanks!

Question for you, Hank. When we, us readers, have to take an action out of a wood stock, do you recommend applying super glue to the inner stock screw or bolt holes to make sure they do not deform when re-inserting and tightening the screws or bolts?

Great job on the blog – photos and text. Lots of hard work here.

Fred formerly of the DPRoNJ now happily in GA

Fred,

If the wood is clean, dry and free of oil or grease the regular (thin) CA will soak right in and reinforce the fibers – just be careful about getting it on the surface of the stock as it will damage the finish.

CA is like water and will run everywhere if you try to apply it directly from the bottle – best to put a couple of drops on a plastic lid and transfer it to the hole using a toothpick or needle – its tedious but safe.

Soft woods (like the spruce stock) or damaged areas benefit from the CA treatment. Usually a hardwood stock can handle the screws being torqued properly and don’t need it.

Glad you liked the blog!

Hank

Hank

Nice report 2. Makes me keep thinking back to my dad making his guitars. Waiting for part 3.

GF1.

You had mentioned that before – I thought of you when I got a book on making wood-wind instruments for Christmas – may try a couple of those!

Hank

Hank

Yep that would be cool to make too. I played clarinet when I was in school many moons ago. And my youngest daughter plays the flute.

Interested if you make one. Let me know.

GF1,

Figure that my first instrument will be a pan flute.

Hank

Yep those are cool. Kind of reminds me of a harmonica.

Hank, thank you for sharing your methodology. Enjoying this immensely.

Great series Hank. As I said before, I will wait to see the whole report before starting with my project but I already learned a lot from the first two installments. Thanks for sharing your secrets with us.

Henry

Glad you like it Henry!

Happy to share secrets!

Hank

Hank,

Really can’t tell you how glad I am that you are doing this blog. I have always thought in terms of ” removing everything that doesn’t look like a gun stock” and feared that my chiseling and routing skills wouldn’t be up to the task. It never really crossed my mind to laminate the required slots and pockets into the rough blank. You’ve freed me up enough with that approach to believe I really COULD make my own custom stock. Very liberating!

I’m following your narrative with ease thank’s to your excellent photos, but I do have two questions, if I may. When you transfer the forearm shape and the more critical center spacer to the wood, you say ” very carefully”. Do you use dividers, a contour tool, a template, a tracing or some other technique to transfer it from your cardboard drawing? Also, am I to understand that this is not the stock that will ultimately adorn your airgun? This is a rough copy to tweek from?

Lovin’ this series!

Half

Half,

A good receiver to stock fit is important and is the most challenging part of making the stock. Some dimensions are critical enough that if they are off by too much you may have to remake the piece – best to measure and mark and check carefully!

I use a regular measuring tape or a steel rule most of the time. Vernier calipers and dividers are always handy.

The Try-gun stock is a “fitting tool” but you can finish one up and use it as a stock. You will see that later in the series. Usually the first stock or two is for practice and refining the design.

Most people I have helped make stocks do a couple in spruce and then go to hardwood. Some pallets are made from hardwood and make a very nice stock.

Hank

Hank,

Thanks for egging me on. The stock I made for my 13XX with the Maximus barrel is so much better than the stock pump handle and 1399 stock. It makes shooting so stressles I can’t believe it. It is not much to look at but it sure can dance. I know if I make another one it will be easier and may even look better. I am very happy with it. Now if the gun can live up to the stock I will be very happy.

You actually have me thinking about what wood I want to use for my next project.

Thanks,

Don

Glad to hear that Don!

You going to post a picture of the first one?

Hank

Hank,

I think he already did over here; /blog/2018/12/crosmans-mark-i-target-pistol-part-1/#comment-431836

Excellent blog, do not know if I will try my hand at making a stock but thinking about modifying a 2260 stock to fit a Fortitude, I think it should have a wood stock.

Inside the 2260 stock there is a marking that looks like it will fit the air gauge, would have to look at it and measure to be sure. In the 2260 description it says a hardwood stock but does not say what hardwood, with the action out the wood looks blonde but the stock looks like it was stained walnut or mahogany. The Image on Pyramyd AIR looks identical to my 2260, could your trained eye tell just what this “hardwood” is? /product/sheridan-2260mb-co2-rifle?m=3409

Thanks for your Blog on making a stock it is very good, look forward to the next installment.

Mike

Mike

Remember the Discovery stock should fit a Fortitude. It should be a direct bolt on.

And you bring that up. I was thinking about buying the wood stock that Crosman has on the wood stock version of the 1077 and drilling the hole in it for the pressure gauge and put it on my WildFire. That way I can have a wood stock WildFire.

GF1,

At 92 bucks, I think not /product/benjamin-discovery-stock?a=5456 and it might not exactly fit, I will look at what I have and see what I can come up with, not holding a lot of money at this time.

If that works for you, very cool. I am a fan of wood stocks.

Mike

Mike

Yep that’s a bit expensive for a stock. Nice to have the option though.

And the Discovery stock should be a direct fit on a Fortitude or Maximus.

Mike,

Thanks for the link to Benji-Don’s stock – I had missed that!

I took a look at the hardwood stock on the 2260, difficult to tell from a picture but by the grain pattern I would guess that it is beech.

Hank

Don,

I just read over the thread where you posted the picture of your stock – looks great!

Interesting to see the work that you are doing with the 13XX pistols and parts. I’m not there yet but I can easily see how creating your own custom gun could be very satisfying.

Made your own rocket motors eh? Used to do that as well. A venturi threaded into a Co2 cartridge filled with a powdered zinc fuel made an excellent one.

Hank

In am SO VERY MUCH ENJOYING this post! Thank you. Um. Micarta? Could one make up some micarta slabs and laminate them to a wood core?

Bejezus,

I have no experience with micarta but I am sure that it can be used for a stock. Would think that it would make a stable stock.

Being a resin based material you would have to watch that it did not get too hot (and go soft) if you were using power tools (sanders) for shaping and finishing.

Some micarta contain fiberglass which can dull edged tools very fast.

Hank

Bejezus and Hank,

I have to interrupt. A micarta stock is going to be extremely heavy. It will add several pounds to the weight of a rifle. We don’t notice it on knives because the scales are so small, but micarta is quite dense from the glue that’s in it.

If you plan to use some keep the amount to a minimum.

B.B.

B.B.

Thanks for the comment!

I’m not familiar with the material but suspected it would be on the heavy side. Was thinking that it would be good for a bench-rifle stock.

Hank