by Tom Gaylord

Writing as B.B. Pelletier

Diana model 50 underlever.

This report covers:

- Move the rear sight

- Rear sight move forward

- Change the sight notch

- Rear sight adjustability

- Not finished

- Some disassembly required

- Three stock screws

- Wait a minute!

- Glue the stock

- Dry mainspring

- Assembly

- Velocity check

- JSB Exact RS

- RWS Hobby

- Cocking effort

- Summary

To give you guys a break from the Crosman MAR177 today I started exploring the History of Airguns web page. Have you seen how the History of Airguns is laid out now? It’s now a simple timeline. Clicking on the dates brings up the past historical articles.

In checking to see whether they all made it to the timeline, I discovered this report from 2017, in which I mentioned wanting to shoot the rifle with an open rear sight. I never did that, so today is the day. I thought I’d just have to move the rear sight but you know how little projects sometimes expand? This one sure did! This will be the tale of what happened.

Move the rear sight

I told you in Part 2 that the rear sight can be transformed into a sporting sight by removing the peephole. There is also a forward ramp on the spring tube for the sporter sight, so there is enough distance for the eye to pick up the rear notch.

The Diana 50 has two ramps for the rear sight. The one on the rear is for the target peep and the one in the front is for when the sight is converted into a sporting sight.

The tops of each ramp are serrated with grooves that match the special “foot” that’s on the bottom of the sight. This foot is pressed down into those grooves and makes a mechanical bond that will not slip from recoil.

After removing the rear sight from the rifle, I removed the peephole from the sight, transforming it into a sporting rear sight.

That lone screw on top of the rear sight pushes the foot down into the grooves in the ramp.

The foot that contacts the grooves on the ramps can be seen underneath the rear sight.

Rear sight move forward

To use the rear sight as a sporting sight with a notch, I had to move it forward. I moved it to the front end of the forward sight base ramp. Then I screwed that lone screw back down and the foot meshed with the grooves in that ramp to secure it.

|With the rear sight moved forward the Diana 50 is transformed into a sporter.

Change the sight notch

One more thing needs to be done to complete the change to a sporter. I have dialed up the wide target post front sight element, and the rear notch has to correspond. It had been set on a wide cupped notch when the peep was installed, but the notch plate was rotated to put a square notch in its place.

The Diana 50 has four different front sight elements that can be dialed into place. This is the target post.

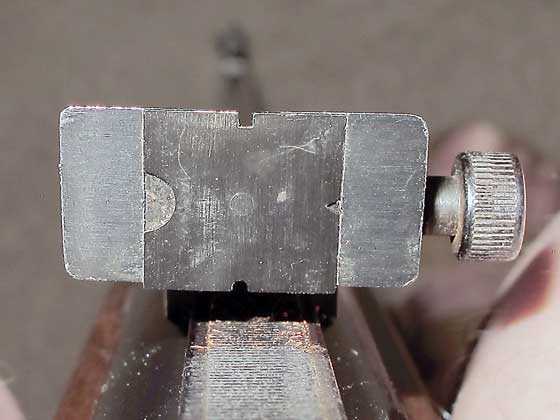

To rotate the square notch plate, the rear sight needs a little elevation so the corners of the plate can clear the sight base on the rifle. That’s how low the rear sight adjusts!

This rear sight notch plate has three notches — a square, a Vee and a U-shaped one. The fourth large U-shaped notch on the left is for visual clearance when the peep sight is clamped on.

Rear sight adjustability

I was surprised to see how much elevation adjustment there is in this particular rear sight.

The rear sight adjusts up very far and the wheel that adjusts it has ten clicks for each step seen on the bottom plate of the sight assembly. The numbers on the top plate tell you which range of elevation the sight is in.

Not finished

Since it’s been so long since the last report, I read Part 4 thoroughly to see how the rifle was performing. I read that the rifle buzzed when it fired in the last test, which is to be expected with these older spring guns. But in this day and age we don’t have to put up with it, do we? I probably know what you are thinking. You think I stripped down the action and gave it a complete lube tune, but this time I didn’t. Instead I did almost exactly what I said I might do at the end of Part 4.

“There is a little bit of buzz when it fires, so it might be necessary to inject some Almagard 3752 grease into the mainspring to quiet down the powerplant. That could only make the shooting experience that much better. I might have a go at the trigger adjustment while the stock is off (for access to the mainspring). Don’t know if I will do any of this, but I’m writing it down as a reminder.”

I thought, “Why not?” The rifle is ready for another accuracy test, so why not do what I thought about last time? Only my tube of Tune in a Tube grease is so low that it no longer injects. I had purchased a 14-ounce grease gun tube of Almagard 3752 grease (same stuff as TIAT), but that can only be applied when the gun is apart and there is access to the parts to apply the grease directly. However, as I was rooting though my lubricant shelf my eye fell on the injector tube of Extreme Weapons Grease.

This tube of Extreme Weapons Grease is nearly full!

I used EWG on my Webley Hurricane we recently tested, and you may remember that it resolved all the problems I had with galling. It’s a thick grease like TIAT, so once more I decided to give it a try.

Some disassembly required

I didn’t want to completely disassemble the Diana 50’s powerplant, but to get to the mainspring I had to at least get the action out of the stock. And that project turned into the rest of my day!

Three stock screws

The action is held in the stock by three screws. The front triggerguard screw threads into the spring tube like we see on most spring guns. The threads are longer than I expected but there were no surprises.

The cross-bolt forearm screw is actually a proprietary two-piece affair, with a threaded bushing that holds the cross-bolt. It’s just as complex as the bolt itself. It came out easily, though the threads were about twice as long as I expected.

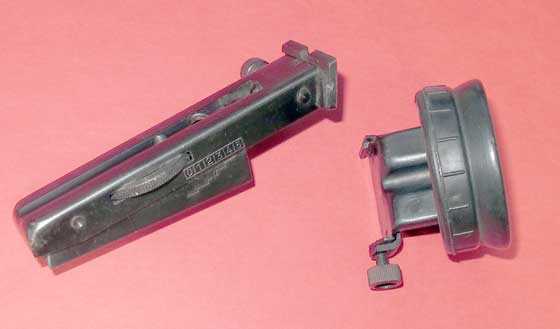

The front triggerguard screw is at the upper right. The stock cross-bolt and bushing are the two lower items. The bushing is actually half of the axel for the underlever during cocking.

With those two screws out I expected to separate the barreled action from the stock. Unfortunately there was one more screw, or nut, to deal with. Diana put a nut and washer on the threaded post that the underlever locks to. It has to come off and I saw the forearm had cracked from some force that could have been applied in the past.

The forearm is also held on by this nut that screws to the post where the underlever latches when closed. The stock has cracked along the grain — probably from someone trying the separate the stock from the barreled action before this nut was removed.

I looked at that nut and thought to myself, “Oh no! I have to make a special spanner to grab that nut!” I then spent the next 20 minutes looking though all my parts and tools to see what I could use to make the spanner. I could sacrifice a small socket from my tool kit and use a Dremel to grind away the sides until there were two short posts to fit into the notches on that nut. I looked and looked, but found nothing. If the socket was large enough to fit the notches it was too wide to fit into the tight channel in the stock. If it was small enough to fit in the channel it wasn’t wide enough to grab the two notches.

Then I thought about a flat piece of steel. That would be even easier to grind to shape, but the only piece I found was the flat tip of my longest screwdriver — the one I use to loosen the long screws in rifle butts that are held to their actions that way. I didn’t want to ruin it, because it took me years of combing though pawnshops to find it!

I decided that after lunch I would go to the hardware store and just buy a piece of steel of the right width. Then I stopped for lunch.

Wait a minute!

After lunch I decided to try one more thing before going to the store. I put the blade of a small screwdriver in one of the notches and tried to unscrew the nut. It was loose and came right off! I had wasted all that time thinking I had to make a special tool when the solution was so simple! Boy, am I glad I checked! The nut came off in less than a minute and the stock could be separated from the barreled action. I now saw that the washer under the nut is actually a spacer.

The nut and washer/spacer are off.

Glue the stock

Now that the stock was separated, I put some wood glue on both sides of the crack and troweled it in with the flat blade of a screwdriver. Then I clamped the stock to hold for several hours while I attended to other things. I left the repair clamped for about three hours and when the clamp was removed the crack was no longer visible.

Dry mainspring

With the action out of the stock and the cocking link removed I could see that the mainspring was bone-dry. No wonder the rifle buzzed a little when it fired!

The mainspring was bone-dry. If ever there was any grease or oil on it, it’s now long gone.

Using the injector on the EWG tube I injected grease everywhere I could reach — including some on the body of the piston. I also lubed the cocking linkage with EWG, as it is under considerable stress when the rifle cocks. And I lubed both the bushing and the cross-bolt that the cocking link pivots on.

The cocking link is in two parts and you can see the pivot hole that the stock cross-bolt fits through.

Assembly

After three hours the glue holding the crack in the stock had set, so I carefully assembled the rifle. When I shot it the first time after assembly, it was smooth. There was no hint of the vibration I formerly felt. As the rifle is fired the grease will slowly spread around the inside and hopefully get to all the parts.

Velocity check

Shooting the rifle was the proof of the job, but I wondered what the EWG had done to the velocity. This was an extremely thin application, so most of the velocity should still be there. I remembered that the Diana 50 was on the hot side for a target rifle, so I tested it with two of the pellets that had been used in the Part 2 velocity test.

JSB Exact RS

In Part 2 the JSB Exact RS pellet averaged 648 f.p.s. It now averages 690 f.p.s. The low was 667 f.p.s. and the high was 701 f.p.s. Only two shots were slower than 690 f.p.s. The only explanation I can offer for the increase is I lubricated the piston seal back in 2017. It must have soaked all through the leather piston seal by now.

In 2017 the RS pellet velocity varied by 136 f.p.s. In this test it varied 34 f.p.s. I think the piston seal is now working as it should.

RWS Hobby

In Part 2 the RWS Hobby pellet averaged 673 f.p.s. with a 45 f.p.s. spread. It now averages 680 f.p.s. with a 20 f.p.s. spread.

Cocking effort

In Part 2 the rifle cocked with 25 lbs. of effort. It still cocks with that much force. It has been so long since I last shot the rifle that I can’t comment on any difference in the feel during cocking.

Summary

This has been a long-delayed Part 5 report on the Diana model 50 underlever. I still have accuracy to test with the sporting sights, so there is more to come. It’s great to be back with this old sweetie!

Hey, I’d like to make a request. Would you be kind enough to compare and contrast the qualities (pros and cons) of triggers among airguns less than approximately $600 in expense.

I limit the cost because i imagine most people do not buy more expensive air guns, and because i know very expensive match guns ($3000+) do have match triggers… Which probably are the’best’.

Although you have written quite a bit about triggers, i don’t recall you comparing them head to head (virtually is fine) and it would be helpful. I would like to know brand vs brand, rifle vs rifle–which has the best trigger. Buyer reviews often state ‘this gun has the best trigger ever’ but i don’t think most buyers really have had the experience to rate triggers in a relative way as you have.

I know you have a lot on your plate but maybe you will recognize this as a needed addition.

Thanks much.

Rco1234,

Let me see what I can do.

B.B.

Best trigger is VERY subjective! In springesr which is better a CD, a Rekord, a T06? Personal preference, they are all pretty good. How about tuned triggers vs untuned triggers, you can always make them better?

Comparing PCP triggers to springer triggers, totally different animals.

Sorry but this is a stupid request!

Which is a prettier state, Montana, New Hampshire, Oregon?

-Y

Yogi,

No, it isn’t a stupd request. Yes, it is very subjective so one of the challenges is to give it some objectivity. But numbers ad graphs are not the way, either. I’m thinking about it.

B.B.

B.B.

To me “the perfect trigger” means a trigger that breaks exactly when the shooter expects it too.

Since each shooter is different, each trigger blade has a different shape, each rifle is different, this is purely subjective. There are good triggers and not good triggers, but perfect is in the eye of the beholder!

-Y

Yogi,

If you carefully re-read Rco1234’s request, you will see he asked Tom to do a report on comparing and contrasting triggers. He did not ask for any info about which is best – he quoted what others typically say about reviews stating that a gun has “the best trigger” and referenced that they probably have no idea what they are talking about. The only time he referenced a potential “best” trigger was in requesting that the report exclude true match guns with their essentially infinitely adjustable triggers, for all the appropriate reasons (most notable the ability to turn one into the best trigger for each individual).

Not only do I think it is a good request (albiet a difficult one), I think it was asked in a very appropriately worded request.

Alan

Alan,

Your 5th grade English teacher and my 5th grade English teacher would disagree!

-Y

Well, I taught 9th Grade English for one year and college English for 31 years.

This is precisely what the OP wrote regarding “best”: “Which probably are the ’best’.

. . . I would like to know brand vs brand, rifle vs rifle–which has the best trigger. Buyer reviews often state ‘this gun has the best trigger ever’ but i don’t think most buyers really have had the experience to rate triggers in a relative way as you have.”

Paring the above down even more we have the following: “I would like to know brand vs brand, rifle vs rifle–which has the best trigger. . . . [you have] the experience to rate triggers in a relative way . . . .”

Michael

Thank you for your understanding.

Yogi,

Agreed!!

“Since each shooter is different, each trigger blade has a different shape, each rifle is different, this is purely subjective. There are good triggers and not good triggers, but perfect is in the eye of the beholder!”

Over the years I have shot rifles with a wide variety of quality of triggers and once you get used to them you can do pretty well as long as they are consistent.

In most cases, you are stuck with what there is. But “bad” triggers can often be improved by tightening tolerances (on pivot-points), removing burrs, careful stoning and some proper lubrication.

The simple mod to the cheap plastic Maximus trigger have made a huge difference and while I wouldn’t call it a “match trigger” it is very serviceable.

While I prefer a nice light & crisp match trigger (like my FWB 603 has – I’m spoiled!) I don’t get too worried about the triggers and accept them as part of the rifle’s character.

Cheers!

Hank

Hank,

As I mentioned, a good trigger is one that breaks when you expect it to.

The OP says, ” I would like to know brand vs brand, rifle vs rifle–which has the best trigger.”

What would you call that request?

-Y

Yogi,

In addition, “among airguns less than approximately $600 in expense.”

Michael

So the answer is any HW that will accept the V-Mach tuned Rekord Trigger?

-Y

Along with the TX200 MkIII and HC.

Yogi,

It is challenging to report on a subjective subject. The OP is requesting a comparison with comments by B.B. who has a lot of expertise in this area.

Given a comparison report, the OP could try a couple of the rifles mentioned to synchronize what he is feeling with what Tom is describing so that would be of value.

It might be easier to report on the triggers that should be avoided and allow that the others were acceptable to excellent.

The OP didn’t mention what he would be using the rifle for but comments in the report should shed light on that

Think what trigger is “best” depends on what you (really) need. My (centerfire) deer hunting buddies freak-out at the triggers on my 10 meter rifles but good as they are they would be useless on a deer rifle because they are way too sensitive to use with gloves or cold hands.

My comments above were a reply to you but also a general comment that there is a wide range of quality and that there are thing you can do to improve a so-so trigger if the rest of the rifle is to your liking. My Maximus is a prime example of that – (after the mod) I enjoy shooting it as much as I do my PCPs costing 10 times as much.

IMHO, unless it is really bad, the trigger is well down my list of other considerations in choosing a rifle.

Hank

Yogi,

I’m 95-98% with you on all of this. A trigger which is always the same and which always lets you know when it is about to go is a trigger one can learn to shoot, right? Some might be harder to master, but a good shooter can master it regardless.

I’ll bet that among predictable and consistent triggers, one which is also crisp would be just a hair better in your estimation, not necessary, but nice.

Michael

Hank,

A really good shooter (I’m not) can overcome less-than-fine triggers, “fine” being smooth, crisp, light, and predictable.

A mediocre shooter like me benefits from a nice trigger because a poor one throws off my aim because of MY inadequacies. I shoot much better with my FWB 601 than I do with my Gamo youth rifle, and it’s not just the barrels and sights. The trigger on the Gamo is crummy. It is especially too heavy, and I have not developed the ability to squeeze hard without affecting my POA.

BTW, in every other respect the Gamo is delightful, cocking-to-power ratio, ergonomics for me, loudness, weight, etc.

Michael

Hey B.B.,

Yeah, thanks for not discounting my request altogether. As you know, I’ve been reading your blog for many years-although i rarely comment as i used to do.

Of course, i realize that almost any trigger that your are accustomed to will become serviceable, but we can probably agree that there are some triggers that are objectively better than others. I have quite a few airguns. My favorite triggers are on my Crosman 2300s and my Daisy 499. My Walther Terrus has a ‘good’ trigger. All three of these airguns have very very different trigger feels, and yet i get good groups from all three of these guns. On the other hand, i get amazing groups from my Walther LGU–but i hate its trigger! So, triggers don’t always predict the group. That i know. Yet, some triggers are sweet. What makes them so? I would agree that they break when you expect them to break and they are relatively light–but what else? And specifically, what is the feeling of a t06 vs cd vs rekord vs other name brand triggers?

I am looking to buy another spriger or gas piston rifle (probably not a pistol) in the 300 to 600 dollar range and i want to be satisfied with my purchase. Groupings are not everything! I want a soft smooth trigger, and of course i know there are some few available but what separates them? I don’t know. That is what I’m hoping to discover. I don’t have the incredible experience that you have… Probably none of us does outside of PA testers.

Anyway, thanks much for your future review if you’re able, and for trying to run a pleasant forum.

Rco1234,

Hopefully you live relatively close to a full service airgun store with a range. Most of them will let you shoot before you buy if you are a serious about it. I doubt you will really get the feel of the trigger from B.B.s effort. For one thing how a trigger works has more to it than the trigger group. Much of what people think is the trigger is actually all the dimensions relative to the grip/stock girth, distance, and angle! What do your hands/fingers have to do with that? If B.B. has short stubby fingers and little hands with little or no grip strength and you have long fingers and XXXL hand size and the grip strength of an Orangutan; your mileage will differ as they say! Go to a airgun club and see if anyone wants to shoot yours and you shoot theirs! Buy the airguns your interested in and if you don’t like it sell it on line, at an airgun show/swap, or return it to the retailer.

I don’t think you will find a better way.

shootski

BB you can get an adapter to fit a standard grease gun. it is like a needle valve and I use it to grease the chain saw sprocket. You can put your almaguard grease tube in a grease gun and lube a springer just like the injector

mildot52,

I have the adaptor. LAZY! 🙁

B.B.

Yogi,

First of all, I am NO trigger Nazi!

I agree with most of what you said about the subjectiveness of the trigger debate. I would have added Ohio (almost totally flat) to keep it from being a list of states all of which have mountains!

I also keep seeing lots of shooters agree with your concept of: …“the perfect trigger” means a trigger that breaks exactly when the shooter expects it too. I was taught the perfect Target Trigger is one that never lets you know exactly when it will let off; but when it does it breaks like a glass rod. The concept is that as you wobble you press when the sight is moving toward the perfect aim and stop increasing the pressure when you are moving away from the target center and THEN without the shooter knowing exactly when the round is launched to the X! But only on the move toward the perfect sight picture! NEVER when moving away. The science of it is that what you think you are seeing, right this millisecond, is already gone from what the sight is actually “seeing.” Granted that is three position target shooting but it works for hunting for me. I have dealt with near hair triggers as well as multi pound triggers; if they break like a glass rod with repeatable take-up and press, NO Creep, that is a great trigger…if it has no over travel that is an added plus.

Just my opinion ;^)

shootski

Well then maybe B.B. should do a series on “how to tame the wobble”?

-Y

PS the only glass rods that I have broken have been very thin pipettes. After they begin to bend you know exactly when they will break!

Yogi,

Wobble is never tamed…it is only reduced or dealt with say a sling or by increasing our fitness and learning bone on bone position technique; of course you can join most folks on the bench or bipod to kill off most of the wobble. I prefer to not be shooting with a Ransom Rest or a rifle vise!

Yea! Glass pipets usually bend first that’s why i used the glass rod in the analogy.

Be well!

shootski

Rco1234,

A top $600 price tag allows MANY fine-triggered air rifles. Any spring air rifle by Weihrauch except for the HW90 (above $600 anyway), which includes the HW30S, HW50S, HW57, will have the Rekord trigger, which is smooth, crisp, light, predictable, and has a wide range of adjustment. Also, the Air Arms TX200 MKIII and TX200 HC have excellent triggers modeled after and every bit as fine as the Rekord.

You might edit your request to have a lower price requirement.

Michael

Michael,

No, no no! Leave me that wiggle room.

B.B.

B.B., Heh, heh, heh. The challenge is what makes it fun. Too easy is too dull. You know that. :^)

The following is FUN: “Hmmm. Well, Gamo has that one trigger that is pretty crisp and adjustable, which rifles have that again, and this budget Diana has the TO6, and . . . among price-point PCPs there is the . . .” :^D

Michael

Rco1234

If I understand your question correctly, I believe you want BB to compare tiggers found in medium priced airguns. I agree, it would be interesting to see how a Diana TO6 trigger compares to a Weihrauch Rekord trigger, or a Hatsan Quatro trigger. Having owned a number of Weihrauch airguns, I must admit I am bias toward the Rekord, but I don’t know how much better. Do they break cleaner, adjust easier, and more reliably? How about how much cost or work would be involved to make an average trigger a better shooting trigger?

Ciao

Titus

Thanks Titus. Those are excellent additional specifics. Weight counts but so does reliability. Smooth is better than gritty. How much adjustment is available? How easy are they to adjust? I know some rifles require taking them apart to adjust the trigger–that seems a bother. And like i said i just don’t know the pros and cons of the infinite number of triggers out there.

B.B.,

This article perfectly illustrates how much of a backlog you have on your plates. It is a good thing you wrote that note for yourself. I wonder how many more round tuits are lying in wait among the past articles buried by the cavalcade of airguns to be reviewed.

Siraniko

LOL! I found him a couple the other day. If everybody starts looking around he may never get to a “new” airgun.

Siraniko,

Oh, please! Let’s not even go there!

B.B.

B.B.

Great report, waiting for more…..

Is there a way that you can have links to all the parts. In this report you have links to all the earlier reports. Would it be possible in the earlier reports to have links to subsequent reports?

Also, why did you need to move the rear sight forward? As a peep sight it is very rearward, near the shooters eye. As a notch sight it needs to move forward? Why?

-Y

Yogi,

Hopefully the master will add more and do a better job, but with the rear notch sight close to the eye, it will “disappear” as it is too close to be focused on, similar to a ghost ring sight. With it more forward the eye can focus on it better, allowing you to use the notch to line up the front post and target.

Why is this different than with a peep sight? In both cases you are focusing on the front sight. The rear just goes along to line everything up. Plus, a longer site radius surely would help with accuracy.

-Y

Yogi,

It’s true that you eventually focus on the front sight on the blurred target, but with peep sights one is naturally lining up the front and rear sights just by looking “through” the tunnel created by rear peep sight. With open sights one must first ensure alignment of the rear and front sight before concentrating on the front sight. A longer sight radius is helpful but with open sights you must be able to see the trough of the rear and align it to the post of the front. Too close to the eye and you will definitely have difficulty keeping it aligned along with the target.

Siraniko

Yogi,

That’s not entirely the case. With a notch sight you do need to align both the rear and front sights.

Instead of questioning, why don’t you try it yourself? Try to hold a notch sight close to your eye and aim that way. You will see immediately why it doesn’t work.

B.B.

Yogi,

One of the problems this blog has experienced is by other people trying to put links in the earlier articles to the later parts. That stripped away a lot of the formatting. Let’s leave things as they are.

Why did I more the rear sight forward? Because the rear sight is now a notch that is impossible to see when it’s close to your eye. A notch needs to be far enough away that you can see both the notch and the front post.

Crosman made the mistake of putrting a notch on one of their pistols and giving it a buttstock. That made it impossible to sight with. If the rear sight is close to the eye it has to be a peep, because you cannot focus on something so close and see anything else.

B.B.

B.B.,

Especially as I have aged, even with reading glasses, an open rear sight too close to my eye would be a shapeless blur, and alignment with the front would be impossible. I need to have a reasonably clear peripheral rear sight image as I focus on the front sight, just as I need a reasonably clear image of the bull behind the front post. Only the front post needs to be sharp, but the other images have to be there.

Michael

BB,

I was pleasantly surprised to see this report on an older lady this morning. I do so like the ingenious arrangements that were used with these old gals, such as this sight. I am also glad the stock repair was easy. I would hate for you to have to send it off to be fixed by a “pro”.

RR,

The crack was very straightforward and took no great skill to repair — a perfect woodworking job for BB. 😉

B.B.

B.B.,

Given its location you are of course correct about the cause of the crack, but after it first formed, I suspect dry air had a hand in widening it. It looks exactly like cracks I see in wood instruments that have been stored in arid conditions, even if only temporarily. Wood instruments like at least 35-65% humidity, but ideally 45-55%. Quick swings are not great for cured wood, either.

Every guitar collector has a good hygrometer in his instrument storage area. My guitar and air gun storage spaces are one, so I have one excellent hygrometer for both. I know one world-class vintage guitar collector who not only has a very high-end hygrometer, but he also compares it to readings from a sling psychrometer regularly! (He is pretty obsessive, but he does have more than a few million dollars worth of vintage guitars.)

Michael

Michael,

Someone should make a humidor for guitars.

B.B.

B.B.,

Over the past 15 or so years many different designs of guitar humidifiers have been invented and marketed, some quite good. There are humidifiers that are integral to guitar cases, humidifiers that mount into the soundhole of an acoustic guitar, humidifiers to place in the storage compartment of a guitar case, and so on. It is especially of importance for acoustic guitars, which nearly always have raw wood surfaces on the inside. Be careful not to over-humidify, however, because that can warp wood or cause mold problems inside the grain of the wood.

Personally, I like the old trick of taking a film cannister (find someone under 35 who knows what THAT is), drilling or punching two holes in the cap, placing a damp sponge in it, and tossing that in the storage pocket in the guitar case. Also, dry air is a good reason for not leaving a particular guitar on a stand, out of its case, for a prolonged period of time.

Too dry or too humid air is on the mind of every orchestra string player in a desert city or a tropical city. Live in Miami or Seattle and play fiddle? Better have a hygrometer and (a moderate, like baking soda) desiccant ready it gets so muggy you can see the water just hanging in the air. Tucson? Same thing but the opposite.

50% humidity is the perfect number for most woods.

Michael

After I read RR’s comment about your having to “send it off to be fixed by a pro”, I thought it was a bit of sarcasm on his part, as he has been known for from time to time. When I then began to read your comment to him I thought my view was confirmed when you started off with “The crack was straightforward and took no great skill”.

Sometime what is read between the lines isn’t really there.

edlee,

This time I would say that it was! 😉

B.B.

BB

Is it okay to believe Extreme Weapons Grease is similar to Almagard 3752? Guess I’m back to the subject of which lubes to use and which lubes to avoid for specific jobs. Maybe I’m making this subject harder than necessary. Still, your lubricants shelf would be of interest to some of us.

Enjoyed this report and looking forward to more.

Deck

Deck,

I’m still learning about EWG. As of now I would say it seems equivalent to TIAT for dampening vibration. And it is a good tough lubricant.

B.B./

BB,

I have picked up a tube of Almagard 3752 and it is my intention to reload my TIAT syringe. You should be able to use a small spatula and do such.

RR,

Yes, I can. I have known that for a long time. But I have misplaced my round tuit.

B.B.

B.B.,

Oh man. I feel very silly. I just now wondered what kind of tool a tuit was, perhaps a special sort of caulk gun for fine work. So I looked up “round tuit” and, well, you know. ;^)

Michael

Michael,

I’m glad that happens to someone besides me! 🙂

B.B.

Michael,

LOL! Awesome! You are now an official member!

:^)

Morning all,

One of the versions of the old B3 underlever has a notched rear sight with a dovetail mount that attaches to the scope rail. This position is too close to the eye to be useful, even while mounted as far forward as possible. Other versions of the B3 have two mounting holes at the end of the compression tube for a more typical rear sight position. Will

Will,

I remember that! Also the Chinese TS45 had a rear sight that was too close.

B.B.

Will,

I believe that’s an early one. They moved the rear sight down a bit later as you noted. Yours probably is early enough that it also has no anti-beartrap mechanism. As you probably know, but in case you don’t, be careful you don’t chop your thumb off by holding that lever firmly when you load a pellet.

Michael

BB,

I have come to the conclusion that when you finish this report you will need to send this lady on a vacation to RidgeRunner’s Home For Wayward Airguns. The other ladies would greatly enjoy her company and there are no other lady named Diana living here at the moment.

BB ,

The viscosity of EWG is almost as thick as TIAT . The main difference being if I lived in a hot climate and it never froze outside I would use TIAT . If I used my gun in a cold climate I would go with EWG as it is a synthetic based grease and it will not lock up a action in the cold . I have seen AR pattern rifles shooting in 20 degrees range days and run flawlessly with EWG . My 2 cents for today , hopefully this helps out .

Gene Salvino

Gene,

Thanks, as always.

B.B.

Gene,

Thank you! I have been using SIG SAUER SPEC1 line and i just now found out the SPEC1 line of lubricants are made by the EWG maker – SLIP 2000 outfit. I agree on the low temperature operation for AR and other auto platforms down to temperatures that only a dry lube “worked” in the past. They claim -100°F to +750°F Works well on Anschutz Fortner action in subzero Fahrenheit temperatures.

shootski

B.B.,

I was glad to see you were able to fix the cracked stock on this lovely old gal. You did not mention the type of wood glue used, but you mentioned a 3-hour cure time before use. Re-reading the report, and looking at the area in which it is being used, that should hold fine for this rifle’s future use. I would just offer the recommendation that I generally use Titebond III Ultimate Wood Glue for gun stock repairs; but in almost every case I had to use it (about a dozen times), the crack was in the wrist of an old shotgun, an area that really takes a beating from recoil, especially on the 12-gauge guns. Titebond III Ultimate Wood Glue has a minimum recommended cure time of 30 minutes, but due to the nature of the repairs, I left it clamped for 24 hours (their recommended time prior to stressing the bond) prior to test-firing the repaired shotguns, and it worked great! Hence, if you ever get a crack in a high-stress area on a springer, you may wish to give that glue a try.

I used to get it at Home Depot…back in the days when one could just walk in to the local Home Depot! =)~

Looking forward to your trigger report for Rco1234 (he picked the right guy! LOL =>),

dave

Dave,

I used Titebond II. Set up is 30 minutes, but I gave it longer.

B.B.

“I used Titebond II.”

B.B.,

Awesome!…OK…sorry…I should have known…I’m just “preachin’ to the choir”, hahaha!

I should have figured you already knew about that stuff; it’s all I’ve been using for the past 5 or 6 years; and I can’t say enough good things about it. =>

Happy to see this rifle back up to snuff,

dave

I have a Winchester 450 similar to this, it has the same crack in it I noticed. I now wonder if this is a common issue on these rifles for some reason. I also noticed the wood is being pressed out of shape, by recoil I assume, in the shoulder of the latch screw hole, towards the muzzle. I have been contemplating stock removal and a try at barrel bending as it shoots 2 inches high at 20 yards with the rear sight bottomed out and the tallest front sight I can find. I have the same screw issue you mentioned, I tried removal, I am not as lucky, the latch screw isn’t giving up that easy. Looks like ingenuity/fabrication will be required.

MMCM13,

Oh, phooey! I guess I lucked out.

I think a flat piece of steel with the center cut out to make two projections to go into the notches will be easiest. Grab that with vise-grips and I think you’re home.

B.B.

I am going to look at using a needle nose with fine points, or a snap ring pliers prior to fabrication. It has been like peeling an onion on this rifle, first find sights, then a diopter sight, then the shooting high, now the challenge, stock removal And barrel bending, I hope it is a shooter after all this…

I have a Thomson Center Hawken black powder percussion rifle with a double set trigger. It is my all time favorite target trigger. Once the rear trigger sets the front trigger can be adjusted to a hair trigger. I have mine set so all you do is touch your finger to the front trigger and it fires.

I took the Hawken pig hunting one day. The front trigger can be pulled without setting it with the back trigger. It then breaks at about 4 pounds. I came upon a pig at around 200 pounds that looked very tasty. It was about 60 yards away so not a difficult shot. I drew a good bead on that pig and touched the front trigger. Nothing happened. I kept my aim because a hang fire happens once in a great while with a percussion gun. It took me another moment to realize the hammer was still cocked. I refined my aim again and touched the trigger again nothing happened except the pig ran off. You probably have guessed what was going on. I had shot the gun in three position competition in my black powder club for a few years. When I took it hunting I figured it would be safer to not set the trigger but I had not shot the gun that way. Habit took over and my thinking only got as far as not setting the trigger. My finger had pulled that trigger thousands of times. Muscle memory was just too ingrained with that gun. I would not have had a problem with Not setting that trigger on a different gun. It is a good hunting trigger when not set.

No bacon

Don

“I refined my aim again and touched the trigger again nothing happened except the pig ran off.”

Don, that is frustrating! I, too, love a Hawken replica for a hog rifle. And I used to get hang fires in competition till my wife fixed it for me (note: she is also the one who got me the rifle, after growing up watching her Granddad should an actual Hawken on a daily basis); she gave me a tiny pin cushion to put in my possibles bag and a couple of long pins with a 3/16″ diameter ball on the non-pointy end. Right before I cap the rifle, I use the pin to dig down through the nipple and into the powder (like no left over paper from the last cap), and I push till I hit the far side of the drum in which the nipple sits. Since, I started following her advice, I haven’t had any hang fires…her Granddad taught her well. =>

Take care & good shooting to you,

dave

Dave,

You have a great wife. I used acetylene torch tip cleaners on my nipples. After a while they would get the office too big and that was hard on the hammer and my face Lol. My worst hang fire was Deer hunting on a horse in the snow it took so long I almost shot the horse. It must have been at least 10 seconds. I was swinging the rifle around to put it in the scabbard when it went off. Lucky for me the horse and I were ok.

I really enjoy black powder but hate the gun cleaning. I haven’t tried some of the new black powder substitutes. I hear they are not corrosive and do not clog up the barrel.

Don

Dave,

I have not tried it but hear the Jim Shockey’s Gold black powder substitute is one of the best.

Don

B.B.,

This is a tool you should look for: https://www.thorlabs.com/thorproduct.cfm?partnumber=SPW801

shootski