by Tom Gaylord

Writing as B.B. Pelletier

Diana model 50 underlever.

This report covers:

- Loading tap

- Rear sight

- Pre-test preparation

- Fastest way

- Velocity RWS Superpoints

- JSB Exact RS

- RWS Hobby

- Cocking effort

- Trigger pull

- Evaluation so far

Today we will learn the velocity of my new/old .177 caliber Diana model 50. But there are several things I need to clear up before we get to that. Let’s start with the loading tap.

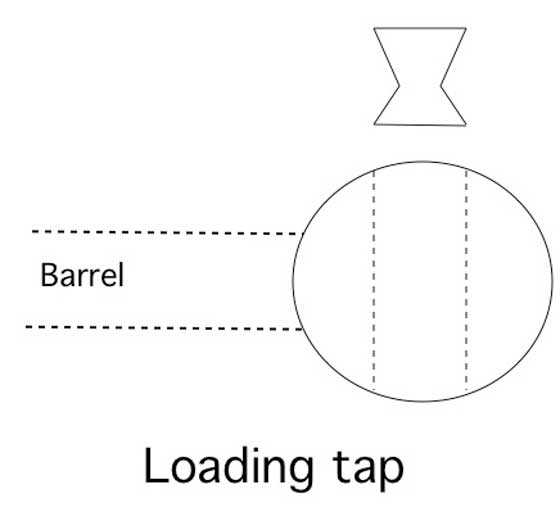

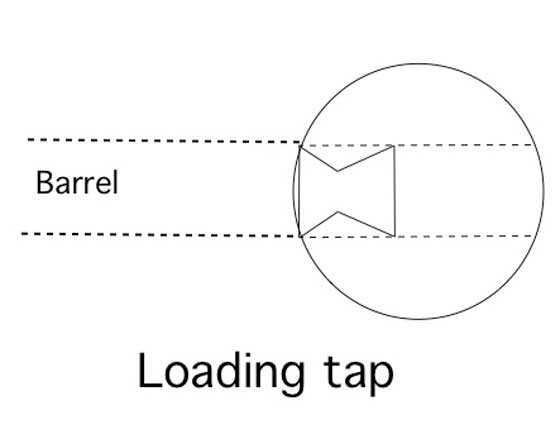

Loading tap

The Diana model 50 is an underlever spring-piston air rifle. That means the barrel doesn’t open like a breakbarrel, so there has to be another way to load a pellet. On some underlevers the entire compression chamber slides back, exposing the breech, but others like the model 50 use a loading tap. A tap sits behind the barrel and rotates open to load the pellet and closed to align the pellet with the breech.

Drop a pellet into the open loading tap, nose-first.

Rotate the tap closed and the pellet aligns with the breech, ready to be blown through the barrel with the shot.

Push the loading tap lever forward (to the left) to open for loading.

Rear sight

I said in Part 1 that I thought the peep sight was dedicated and didn’t convert to a sporting open rear sight, but reader Mike Driskill showed me different. So, for this report I have removed the peep disk to show you.

The peep disc has been removed and the spring-loaded rear sight plate, with three different sighting notches and the large groove, is rotated to show the notches more clearly. Any notch can be selected.

This feature turns the model 50 into a sporting rifle. The entire rear sight is moved forward to a different sight base on the spring tube for the best eye relief.

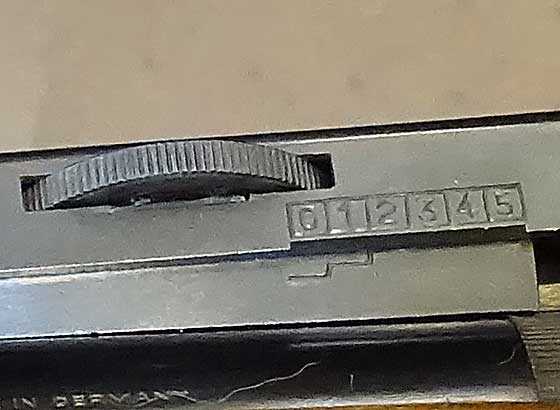

I was also asked what the numbers on the left of the rear sight mean. They are elevation reference numbers that an index mark aligns with as the rear sight is elevated.

The index line on the bottom aligns with the elevation numbers as the sight goes up and down.

Pre-test preparation

Pop quiz — the Diana 50 was made from 1952 to 1965. What is the piston seal most likely made of? Answer — leather.

What should we do to a leather piston seal before shooting it? Answer — oil it.

Extra credit — how do you oil the piston seal of a taploader?

There are two ways. The first takes the longest. Stand the rifle on its butt with the tap closed and drop 10 drops of oil down the muzzle. The oil will run down through the barrel, through the loading tap and into the compression chamber, where the piston seal will soak it up.

Fastest way

Here is the quicker way. Open the loading tap. Fill it with oil, close it and stand the rifle on its butt for an hour. The same thing happens without the barrel getting in the way.

More extra credit — what kind of oil should be used? That depends on the power of the gun which we don’t yet know. But we can guess pretty close. A spring-piston rifle made between 1952 and 1965 rifle will probably generate less than 12 foot-pounds at the muzzle. Velocities with be slow, so regular household oil can be used. I used Crosman Pellgunoil.

Velocity RWS Superpoints

Since this is a taploader I want to use pellets that will fill the tap when the gun fires. The RWS Superpoint is my favorite pellet for this, because it has such a thin skirt.

This string was both interesting and instructive. I will show you every shot from start to finish, because I want to discuss it. Remember — this was fired 60 minutes after oiling.

Shot………Velocity

1…………….522

2…………….369

3…………….420

4…………….437

5…………….453

6…………….455

7…………….506

8…………….516

9…………….589

10……………606

11……………638

12……………646

13……………685

14……………669

15……………671

16……………650

17……………670

18……………671

19……………652

20……………618

21……………670

Wow! That string is a classic illustration of why a chronograph is so important to airgunners. The rifle was full of oil because I over-oiled it. So, all the extra oil shot out with the first several pellets. I’ve seen this before, so I just kept shooting and watching the numbers on the chronograph screen. When they stopped increasing, the rifle would be in its power band.

It’s arguable where they stopped but I am calling it at shot 12, which was 646 f.p.s. That one and the next 9 will be the string. So, for this pellet the low was 618 and the high was 685 f.p.s. That’s a large spread of 67 f.p.s. That much variation is probably due to the extra oil in the barrel. No doubt the velocity spread will tighten a little with more shooting.

The average for the string I selected is 660 f.p.s. I think that’s probably about where this pellet will be when the rifle settles down. At the average velocity an RWS Superpoint generates 7.93 foot pounds at the muzzle. That is about what I expected.

JSB Exact RS

Next I tested the JSB Exact RS dome. They are lighter than the 8.2-grain Superpoints. They weigh 7.33 grains. They averaged 648 f.p.s. in the model 50, with a spread from 572 to 708 f.p.s. That is 136 f.p.s., which is too much to expect any accuracy. Since the rifle had started to settle in, I think this shows that the RS pellet isn’t right for this rifle. I won’t test this pellet for accuracy. At the average velocity this pellet generated 6.84 foot-pounds.

The results of this pellet are another reason to have a chronograph. They clearly show when a rifle doesn’t like a pellet.

RWS Hobby

For the final pellet I chose the RWS Hobby. Since the rifle is a target rifle I wanted to try at least one target/wadcutter pellet, but I selected Hobbys for one additional reason. They have wide skirts that work well in loading taps.

Hobbys averaged 673 f.p.s. in the 50. The spread went from 640 to 685 f.p.s., so a difference of 45 f.p.s. See how much tighter that is? At the average velocity, the Hobby generated 7.04 foot-pounds at the muzzle.

Cocking effort

The rifle cocks with 25 lbs. of effort. It feels like a little more than that to me, but I think that’s because I can feel the coils of the mainspring compressing as it is cocked. The rifle cocks with a crunch.

Trigger pull

The trigger is set up to release with a single-stage pull that breaks at 1 lb. 8 oz. That’s on the light side, but it’s the single stage pull that throws me. It’s not breaking crisply like a good two-stage trigger would. Since this is a ball bearing trigger I thought I should be able to adjust it to a good two stages with a clean break on stage two.

The front screw locks the setting and the rear screw is the adjustment screw. The previous owner has either Locktited the locking screw to make a permanent bond or he glued it with Epoxy. It isn’t moving! If I want to adjust it I will need to put it in a press to hold tension on the screw as it is turned. Or I will have to drill it out and replace it. I don’t like it when I encounter things like this, but at least the trigger isn’t too bad where it is right now.

Evaluation so far

This model 50 is a fine classic airgun. It cocks easy, has a light trigger, decent power and intriguing sights. I can’t wait to test the accuracy!

Very nice. Those sights are incredible. The fact that the rear sight can be moved forwards as well is amazing too. They were really thinking when they chose the sight set up on this one. Looking forwards to the next report.

Good Day to one and all,…. Chris

BB,

A most interesting air rifle I must say. I would have to do my best to find a front sight hood for it. The long stock also gives it a military look. Underlever with tap loader. This is certainly worthy of an eclectic collector. I do hope you can get that screw loose without damaging it.

Would I be correct in my assumption that the large rear sight groove is best suited for when the rear peep hood is mounted on it?

RR,

That’s right about the groove.

B.B.

Off topic.

If you didn’t go to the Texas Airgun Show this past weekend, you missed a good show. Attendance appeared to be down a little from 2016, probably due to the weather.

I have talked myself out of buying a TX200 three times in the past, but I gave in this time and found a Mark III .22 with a Hawke 3-9 x 50 AO mil dot scope for what I considered a fair price and walked out with it. The seller told me it had a Vortec kit installed, but I have to take his word for it since I’m not taking it apart right now. Chronographed it in the shop with seven different pellets and then battled the rain and wind and found the best of the seven for accuracy. The JSB 15.89 at 686.7 fps and 16.6 fpe. Ten shots at 22 yards, best I could get due to rain and wind, went into .779”. Two shots were flyers, I called one but the other may have been wind or who knows what. Eight of the ten were in .529” covered by a dime (take note BB). I believe it will do better once I get better with the trigger. All shots were over a rest. H&N FTT and JSB RS both went 710 fps, but couldn’t match the JSB 15.89 for group. I may try them again later. The H&N did look promising. By the way, Hobby’s clocked 814 fps.

BB had brought his TX in .177 for me to try, but I found the .22 first. I prefer .22 caliper guns to the .177. Thanks again BB.

Jonah,

As I told you at the show, I considered buying that rifle myself. You got a real bargain, plus its a beauty.

B.B.

Jonah,

I saw that rifle and thought it was a good deal. Your chrony results confirm it was. I have one in .22 and really like it. Enjoy shooting your new rifle!

I agree with you — attendance was affected by the weather. Some vendors didn’t show as well.

Jim M.

B.B.,

Just wanted to compliment your close-up photography with this piece. Looks great, with minimum glare and maximum detail and contrast! I can see everything.

Hope the weather isn’t causing problems for you.

Walt

Walt,

I have to give the credit to digital photography. I used to take three exposures for each shot I wanted when I used film. And I knew my camera inside and out.

With a digital camera I can see the results immediately in stead of waiting three days, and I can adjust the exposure as needed. The camera does all the hard stuff now.

B.B.

B.B.,

The photos do look very good indeed. The glare is completely under control and the tones still look natural.

Are you using a gray card now? It looks so good I have to ask.

Michael

Michael,

No gray card. I guess I’m just paying more attention, plus I adjusted the software to help me more in that area.

B.B.

Your a man of many talents B.B. The photography is awesome. For anyone looking to lmprove their photograph skills check out the last three issues of Muzzleloder magazine they have been doing a wonderful series on photographing firearms.

B.B.

You may be able to break the locktite or epoxy joint by applying heat to the screw – I use a soldering iron as a heat source. Thermal cycling the joint will also help free up threads bound by rust. Rapping the back of the screwdriver can help “break” the joint as well.

Could be that the screw is cross-threaded or has been stripped/glued so some repair work may be needed.

I prefer modern guns but this one looks like it would be fun to shoot. I’m impressed with the sight – nice feature to be able to select the notch you prefer.

Happy Monday all!!

Hank

Hank,

Good tip on the soldering iron. I think I can find Edie’s soldering gun for that. Thanks,

B.B.

BB

Edith’s soldering iron. What did she solder if you’re u don’t mind me asking?

GF1,

Edith was an independent woman. She had a hand drill, a soldering gun and a toolkit.She knew how to do basic large-wire soldering,

B.B.

BB

From her comments on the blog I thought she was like that.

Morning BB,That is a very cool rifle!I liked everything.I watched some footage of the Texas air gun show,on Joe Reas YouTube channel.I just recently became aware of him there.I saw you met him(guy w/patch eye)He seems knowledgable/air guns.I met,commented, he answered me!He has quite a sense of humor!I like him.Thanks to everyone for welcoming me here!-Dan

B.B.,

When it is accuracy time, please consider trying RWS Superdomes. They are thin-skirted in .177, unlike the .22 ones, which are thick-skirted. In my 50, also a .177, they do well in the backyard at 20 yards, although I do not have any Superpoints to compare them to.

Michael

Michael,

Superdomes , eh? The .22a have thicker skirts that don’t usually do well in taploaders, but just for you I’ll try ’em. To be honest, I don’t think I know the .177 Superdome that well.

B.B.

B.B.

B.B. and Jim,

In .177 they are a different animal than in .22 in my opinion. Check out the photos of the individual pellets in .177: /product/rws-superdome-177-cal-8-3-grains-domed-300ct?p=227

And then look at the thick skirts on the .22 ones: /product/rws-superdome-22-cal-14-5-grains-domed-200ct?p=790

Michael

Michael,

I see that now. Good lesson!

B.B.

Such a shame that RWS Superfields don’t seem to be exported to the states, the superdomes are, sort of, the plinking pellet in the range, a bit how the Hobby is to the more expensive wadcutters.

That’s good info about the .177s. I have tried the .22s in several of my rifles without getting the good results others claim out of Superdomes. I’ll have to get some in .177.

Jim M.

BB,

I see that Houston is really getting hammered. I hope anyone you know there is safe.

Ditto on the photo kudos. The one of the sight is so good it raised a question. Does the elevation jump to each of those little stairstep graghics ( that I can plainly see in the aforementioned stunningly clear photo) as the wheel is turned or is it a gradual adjustment as you back out the wheel?

B.B.,

Off-topic, but I reread a bunch of your older reports over the weekend, and in one you commented that red dots are especially useful for those with older eyes versus open sights.

I’d like to try a cheap red dot (not a pricey firearm one) on a couple CO2 blowback pistols, but I was wondering how they behave with blowback airguns, both in terms of holding zero and longevity.

Michael

Michael,

I have several cheap red dots and they have quite a bit of mass so they could impact how well the action cycles. I have a co2 blow back ( the name escapes me at the moment) that has a rail that extends over the slide for mounting optics. I think any of the sights that I have will work on that one ,when I get around to mounting one.

Michael,

I would like to know that. too. Why don’t you test one and tell us? I have never mounted a dot sight on a pistol with blowback. I have mounted one (a good one) on the Beeman P1 and it held up okay.

B.B.

Michael,

None of my blowbacks have a rail on the slide.( If I am remembering correctly. They don’t have adjustable sights either ,unfortunately ) If you end up having to mount a rail to the slide that will add even more mass.

I have an Umarex Desert Eagle. I’ll try one on that and report back.

Michael

Michael,

I have a couple of Electro DOT Field sights on Umarex Browning Buck Marks that I like a lot. They don’t recoil much, of course, so I can’t speak to that, but they seem to be made really well for their $18.00 price point. I looked at some video of the Desert Eagle and saw that the sight would be mounted on the frame rather than the slide, so that removes the concern about not cycling properly. My best guess is that this sight will hold up OK and you’ll only be out 18 bucks if it doesn’t. My Buck Marks are springers after all, all be it low power springers. The sight is the open type, as opposed to the kind in a cylinder, making it lighter and the dot that I use is the plain red dot. I can tell you that it dims down enough to be more that acceptable indoors and bright enough to use in full daylight outdoors. I think the dot is 3 MOA but I’m not sure. I know that it looks small enough to be very precise at 12 – 23 yards. That’s the distance that I use them and they work great. When I bought them I was worried that the dot would be too big. I believe that you will find these way more serviceable than the Daisy or Centerpoint ilk. And it has a Pic and Weaver mount ( 20 mm with only one crossbolt) which I think is what your gun requires. That’s my two cents. Hope it is of some help.

BB,

Just took a good look at the breech photo. Is it open or closed and how difficult is it to seat the pellet below the point where it might shear the skirt. Are there any modern pellets that might present a problem loading? Is the port deep enough ( or long enough) that the pellets that sometimes give problems in mag fed PCPs could get rolled over in the bottom of the port such that the breech won’t close and the pellet won’t come back out?

Halfstep,

The tap is closed in that picture. I will show you what it looks like open and with a pellet in it in the next report. The pellets usually drop all the way to the bottom. Only bent skirts prevent that.

B.B.

B.B.,

Could you possibly show how the sight converts from one mode to another? You had a difficult time seeing it the first time. How does that big hood fit onto the rear sight?

Siraniko

Siraniko,

Sure, I will try to show that next time.

B.B.

B.B.,

Thank you kind sir.

Siraniko

B.B.,

I should comment that you mentioned the one thing I wish were not the case with my Model 50. It cocks hard for its power because that lever is so short. At least it is positioned high; if you cock it with the muzzle pointed up, which helps in the leverage department.

Some people complain about its heavy weight for its low power, but that is one of the things that calms the Model 50s shooting behavior.

Michael

Just a PSA, but try to send the American Red Cross a check today or tomorrow, in any amount. No donation is too small. If you’d like, write “For Harvey Victims” on the memo blank.

Off to work how. I’m going to listen to SRV’s “Texas Flood” on the way.

Michael

Michael,

Can you even imagine the music we’d have today if Stevie Ray hadn’t been taken so early?

Halfstep,

I live in northern Illinois, only about 60 miles from East Troy, WI, where Alpine Valley Music Theater used to be. I wasn’t there that night, but I had a few friends who were and saw SRV play only an hour or so before he died.

I did see SRV in concert, though, years before his death. Taken too young.

Michael

Michael,

I got to see him perform long ago as well. It was while he was at the peak of his addiction so he wasn’t at his best, but he was still well above the rest. His playing was spot on( I think he must have been able to do that in his sleep, play that fast and keep it clean) but his vocals were not too good and, to me , those are as iconic as his playing. Lot of good players just can’t deliver with the pipes, ya know. As a matter of fact, the sound man had his mic so low you had to strain to hear. At the time, I was a little disappointed, but I sure wish I could do it over again now.

Half

admin

Is anyone else having an issue with the comments RSS feed?

Normally I read the comment and then click on the date / time to mark the comment as read. Then the comments just drop down and I read the next comment and so on. But today every time I click on the date, the page reloads and then I don’t come back to the same place I was at before clicking and I have to search for the next comment.

I made a comment about this on Saturday but maybe the admin has not addressed it yet.

Gravitars not showing up either. If I called it the right name. The picture that is by your user name. It’s like it doesn’t load when the comments load.

GF1,

Must be your browser, because the system is running fine. Dump you cache and start over.

B.B.

BB

I strictly use my phone all the time. Haven’t used my laptop for I bet a year now. But I did wipe the cache on my phone just now.

No luck. This all started the other day when I couldn’t get logged on and when I couldn’t reset my password. Back when you had IT send me a new password reset link because the first one they sent wouldn’t work.

I am not seeing those as well…and having a lot of difficulty following the comments sequentially. The page reloads and jumps to earlier comments.

On my laptop, using Yahoo, everything is normal except a pop up that says “Only secure content is displayed”,… which goes away shortly after I start scrolling. It does this on NO other site. That is my 2 cents on the topic.

Chris

Which browser do you use? I am using Firefox. It was working perfectly until late last week. Now it is very difficult to navigate as I have described. Still the same issue tonight. I cleared my browser cache out but that made no difference.

Geo,

Explorer. Edge seems to be the newer version, but I am use to the Explorer layout. My computer is an HP. Unless I got it wrong, you work on computers, no? If so, you are probably way ahead of many here.

Edge is the Windows 10 browser by default. I think of it as a dumbed down version of Internet Explorer. It may be a little faster but it’s very plain appearing with no color. I am using Windows 7 with Firefox as my browser. I’ve used FF for many years. I like the many extensions available for it and the customization. Nice colored tabs and icons.

Yes, I do repair computers…it’s easier than shooting groups with my Diana 34 🙂

The comments are still not working like they were. When I click on the date/time above the comment, the page reloads, and sometimes it comes back to the comment I was on, and sometimes it goes back up to the blog somewhere. This makes it very difficult to follow new comments using the comments RSS feed. Someone who just browses through the comments wouldn’t see a problem. It’s when you click on the date that things go wacky.

BB, Just want to say how good it was to see you finally at the airgun show. I am delighted with the HW35 Luxus you sold to me. Its super sweet to shoot. I was also able to pick up a super nice FWB126, and I got to meet Chad and Erik from Iraqvetran 8888, so the drive in the rain was way worth it!

Rob,

I hope you enjoy that rifle!

B.B.

Aha! So that’s where that HW35 disappeared to. I hesitated at the wrong time!

Jim M.

Finally got to crony my R1 and found out that it is shooting H&N FTT 8.64 at about 800 fps making it a 12 fps gun right on the money after some spring dampening compound was added. It’s turning into a really sweet-shooting gun. I shot a 27/60 in a HFT match Saturday and I still haven’t figured the holdover for all the ranges yet. I also added a bubble level for the scope which I’m hoping will help improve my scores also.

Brent

I know your thoughts and prayers are with folks here in Houston and South Texas and it is appreciated. I have lived here all my 60 years and never seen anything like it. I have been blessed with a high spot and electricity. Half of our yearly rainfall in two days. People with boats are rescuing people. I have Coast Guard and National Guard helicopters flying on either side of my home rescuing folks.

BB, another great article on this classic! That’s actually very strong velocity for a model 50. They tend to be more sedate than their barrel-cocking cousin the model 35, due to the amount of “lost volume” behind the pellet in the long transfer port, and loading tap.

I second the motion to try Superdomes, they are often nice performers in older Dianas. In .177 they have a large-diameter skirt which seals well against the tapered hole in the tap.

The pictures are lovely! I never get tired of looking at this elegant rifle. Dennis Hiller, in his “Collector’s Guide to Air Rifles” had one of the all-time great lines in describing the 50’s styling as having “sexual overtones,” LOL.

Mike,

I will try Superdomes. I promise!

B.B.

B.B.,

The Umarex Desert Eagle has both blowback and a mounting rail, but as Halfstep mentioned above, the entire action does not blow back, just the rear segment, so a red dot would not move.

Just looking about the web, I see that most if not all CO2 blowback pistols that one can mount a red dot sight on have a mounting frame,

a la the Tangfolio race guns: /product/tanfoglio-gold-custom-co2-metal-pistol-kit?m=3240

That suggests to me that airgun red dots might not be well suited to recoil.

Hmmm.

Michael