by Tom Gaylord

Writing as B.B. Pelletier

Walther’s LGV Challenger breakbarrel was a short-run success in 2013.

This report covers:

- Tune in a Tube

- LGV improperly greased by factory

- Moly used improperly

- Cocking effort

- Firing behavior

- Summary

Today I test the velocity of the Walther LGV Challenger. This modern classic breakbarrel has a lot to recommend it, but it does shudder with mainspring vibration. I will see if I can fix that today and what it will cost in terms of performance.

Tune in a Tube

Out comes the Tune in a Tube applicator. Mine was almost empty, so I refilled it from a 14-oz. cartridge of Almagard 3752 grease, which is what it is. But when the pistol was pushed the grease would not come out of the spout. The grease was migrating back around its internal piston and coming backwards, so it was clear this applicator was shot.

I used a cotton swab to spread the grease around the mainspring, but before we get to that I have some other things to tell you.

LGV improperly greased by factory

To grease the mainspring I had to remove the barreled action from the stock. When I did that I discovered two interesting things. First, there is a spring-loaded plate in the bottom of the stock to keep the articulated cocking link aligned. The end of the link passes through the cocking slot to connect with the piston, but it isn’t retained inside the spring tube.

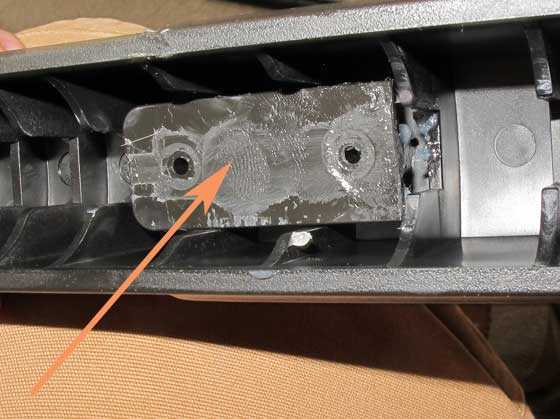

The spring-loaded plate inside the stock channel keeps the two-piece cocking link aligned.

The spring-loaded plate (arrow) holds the cocking link against the piston.

Moly used improperly

The factory greased the mainspring with moly. That was the last thing I expected to see in this powerplant. Moly does nothing to dampen vibration and should only be used for friction reduction. It isn’t correct for this powerplant that has some looseness.

Moly grease does nothing to dampen vibration. It is incorrect for this application.

As I said I used a cotton swab to apply some TIAT to the mainspring. Then I assembled the rifle and test-fired it. It was better but still not what I wanted. So out of the stock came the barreled action once more and I put in more TIAT. This time I was successful.

Velocity

Back in 2013 the LGV shot RWS Hobbys at an average 664 f.p.s. Today after applying the TIAT grease the average wa 631 f.p.s., but I want to show you the string, so you can see what I saw.

Shot……..Average

1…………..628

2…………..625

4…………..623

5…………..632

6…………..626

7…………..644

8…………..631

9…………..650

10…………625

The velocity spread went from a low of 623 to a high of 650 f.p.s. That’s a difference of 27 f.p.s. In 2013 the spread for Hobbys was 21 f.p.s.

What I see in the string is the velocity is increasing the more the rifle is shot. It may not return to 664 f.p.s. with Hobbys but an average of 650 might be possible.

Cocking effort

In 2013 it took 33 lbs. to cock the LGV. Today it takes 32. That’s too close to call. I’d like to add that the barrel lock means you don’t have to slap the muzzle to break the barrel down for cocking.

Firing behavior

The rifle is relatively calm now. It isn’t the best I have shot but it’s ahead of where it was. It should feel good when I shoot for accuracy.

Summary

As far as I’m concerned, the LGV Challenger hasn’t changed that much since I last tested it. Therefore I plan to bypass the 10 meter test and go straight to 25 yards

B.B.,

Didn’t you need to wipe off that improperly applied moly grease first?

Siraniko

PS: Check the header: This report covers: done twice.

Siraniko,

Yes, I wiped the moly off.

Fixed the other thing.

B.B.

Hi folks,

I got the Weihrauch HW75 (also known as Beeman P2) yesterday.

My impressions so far:

– It is just as well-made as the HW45/P1 (not a big surprise, given that they are almost identical on the outside).

-Thankfully no fiberoptic nonsense, just nice and clean iron sights

-The HW75 grip gives my hand support where the standard “Colt 1911 style” HW45 grip is a bit lacking for me.

-The cocking stroke was *hard* in the beginning, harder to cock than the HW45 in fact. It seems to be breaking in and getting a lot easier, though.

-The trigger feels great but not as great as the one on my HW45 (which has seen a lot of use and I have also lubed it). I guess it’ll get there. I couldn’t resist looking inside and I noticed the trigger mechanism is very similar but not identical to the HW45.

-The shot cycle feels very calm. Some people have worried that the hammer hitting the valve might introduce unwanted movement, but I think that’s pretty unlikely.

I can’t say much about the accuracy yet as I’m still adjusting the sights and getting used to the gun. But given that I can even shoot the HW45 with its heavy recoil accurately (if I do my thing), I’m sure this one won’t disappoint.

So far, I like this pistol a lot. It’ll be a lot of fun seeing what kind of scores I can achieve with it. So far, the record is 91/100 for 10 shots at 10 meters on a standard air pistol target (achieved with both the FWB LP80 and the Diana LP 5)

Kind regards,

Stephan

Stephan,

An HW45 and an HW75? Then throw a FWB LP80 in the mix? A Diana LP 5? Would I be correct in my assumption that is an old Diana LP 5?

Dude, you have some serious air pistols.

RidgeRunner,

of course I didn’t buy them all at once but rather over a period of several years 🙂

My advantage is that I live in Germany where these pistols are made. Weihrauch guns are not quite as expensive as they are in the USA (the opposite is true of US products in Germany, of course).

The Diana 5 is actually not that sought after. You can get one for under € 100 (~ US$ 120). Perhaps because it’s not a super-duper-Magnum. I *really* like this one, especially the “G” version that has a nicer looking and more ergonomic grip. I think it looks fantastic, feels great, has a very good trigger and is accurate. I suspect the only thing the current LP 8 does better is power.

The LP80 and LP65 are pretty sought after. But the good thing about them is that if you service them (new seals and springs), they will be good for another few decades.The customer service at FWB is absolutely outstanding by the way, even if you are just asking questions and ordering parts for old guns like mine. Highly recommended!

I have indeed had experience with FWB customer service. I have owned two FWB 300S’s and a FWB 601. I would greatly like to have a FWB 100 series decide to come live at RRHFWA, but I do not think that is likely going to happen. Maybe a Diana 10 will come wandering in though.

Although I do have a couple of air rifles that are fairly powerful, my pursuit has always been for accuracy. Many people are usually shocked at how well some of these old gals can shoot.

I myself have learned that if you want something accurate, it usually can be found in Europe and if you want power, it is here in the U.S. That is starting to change though. Some have figured out what good is all that power if you cannot hit your target?

Stephan,

That is a good report. Congratulations!

B.B.

BB,

Like Siranko, I would have been tempted to go inside and wipe out the moly. It is a shame your applicator has gone south. Maybe you should consider one of these.

https://www.amazon.com/Injector-Plastic-Marinade-Syringe-Download/dp/B081JQH89T/ref=sr_1_9?crid=2A2WHUT30LGAZ&dchild=1&keywords=basting+syringe&qid=1598606961&sprefix=basting+syrin%2Caps%2C224&sr=8-9

Cocking effort

… the muzzle to break the barrel dow (down) for cocking.

RidgeRunner,

Never knew those things existed. Then again I just manually filled a standard plastic 10cc syringe with the grease equivalent to Almagard 3752 and used the tip with small plastic tube press fitted to apply the grease in my case.

Siraniko

Siraniko,

I have seen all types of variations of these, some totally metal.

I still have my original TIAT applicator. I also have a cartridge of Almagard to refill it until it wears out, but I have already used some of it with a Q-Tip as an applicator.

When my TIAT applicator finally wears out, I will find something to replace it.

Siraniko,

Another thing about syringes is they can be quite difficult to get in the U.S. It is like in many countries around the world, they encourage you to have a silencer for your firearm or air arm. In the U.S., owning a silencer of any sort can be quite tricky.

RR,

I have seen some pretty big ones at TSC or one of the other big box farm related stores. Quality Farm + Fleet or Rural King. Probably for horses or some other big critter.

Chris

BB,

Looking forwards to what it will do.

“Cocking effort” section,….. barrel dow(n)……

Chris

Since you already have the 14 oz. cartridge, just get a regular grease gun. For most applications, I prefer a pistol grip operated one with an 18”-24” flex hose.

Paco,

Yeah, but when you are greasing up an airgun, one of those big honkers can be quite tricky.

Quite to the contrary. My grease gun resides in a holder in front of me at the workbench. If I need grease, I place the hose end on the intended spot and operate the pistol lever. A little or a lot depending on how much I squeeze the lever. If I need a minute amount, I have a needle attachment that is really just a large hypodermic needle.

Hi Tom,

Wishing you the Happiest of Birthdays today. Surprise & Delight Always!

—Joe

Hope your birthday tomorrow is even better! And next year, etc. etc.

Jerry

BB

Is it possible to use more TIAT than you should? I noticed you said you added more cause it wasn’t to your liking.

Thanks

Ray

Ray,

I’m sure it is possible.

B.B.

Ray,

It is very possible to use more TIAT than you should. You would be surprised how much room there is in the spring section of the compression tube.

BB

Enjoy your birthday!

I prefer a locking lever on any break barrel that otherwise requires bumping to cock. I believe a perfect break barrel should include this feature.

I think either you or some reader suggested tuning down a HW50S to get an ideal springer that is not only accurate but easier to cock, nicer shooting cycle, etc. That may require a different spring or cutting off the existing one. But your trip back inside the LGV to apply a second TIAT application has me wondering about another TIAT application to my HW50S.

Deck

Deck,

I shot it for accuracy today. It is now dead smooth.

B.B.

BB

This report convinced me to do another TIAT job on my HW50S. I forgot to put a sheet under the Weihrauch so had a wonderful time hunting a lock washer and spacer with a flashlight. The first TIAT application was 1-2 years ago and looked meager. Looking for the smoothest shot cycle and not concerned with some power loss I applied more than before. The upshot is no loss of accuracy and almost no piston sound. I may now have a detuned HW50S. I shot one AA 16 grain 10 pellet group into .60” at 25 yards rested. This is encouraging because I didn’t use an artillery hold.

Thanks.

Deck

B.B.,

Hmmm. What we now know is that the LGV Challenger produces 10.5 foot-pounds, weighs well over 8 pounds, is harder-cocking than most other 10 foot-pound break barrels, has a so-so trigger, is subject to rookie errors in its assembly, and it cost about as much as a Beeman R9.

I suppose one could gut its entire powerplant and replace it with an aftermarket one that is both smoother and more powerful, and it would still have the nice lock-up and accuracy.

Given Walther’s craftsmanship inside the LGV Challenger, I’m surprised James Bond wasn’t killed in “Dr. No” after he switched to a PPK from his preferred Beretta mouse gun.

Michael

Michael,

I think the ‘old Bond’ was killed off by the latest version of him. They finally got it right.

I think he likes a full sized P226 now? Yes on new internals for the LGV, but find one with a wood stock,

for a much better price used. The P1 is so light and handy with a carbine stock, about the same power,as this LGV but a shorter stroke piston. Its just more fun to use it than a bigger heavier rifle.

R

R,

The LGV I have has a synthetic stock.

And as for Bond, the P226 is not a Walther but a Sig, right? Well, so long as James doesn’t drop it . . .

Michael

Michael,

What?! Someone else is not that impressed with a Sig?

RidgeRunner,

Heh, heh. :^)

I really don’t know much about them, but it seems to me one learns an awful lot about a manufacturer from how they deal with defects in their products and take care of their customers. The little I read about Sig and their response to the drop issue reminded me of my warranty experience with Umarex. But my buzzy Challenger wasn’t capable of killing anyone because of its problems. That is about as serious an issue as can be.

Then again, to me most modern auto-loading firearms look like super-soakers spray painted black. ;^)

Michael

Michael,

I understand. I am kind of partial to John Browning’s designs myself.

Michael,

I have owned several different Walther pistols over the years and must say I have been impressed with the quality I have seen and the ruggedness and simplicity is great. The ones I have had were well designed and well made.

RR,

Obviously the PPK and P38 are rightly legendary. But I’d bet the farm that the designers involved in their development had nothing to do with the design and production of the Walther LGV Challenger. ;^)

Michael

Michael,

No, probably not. I am not sure when the PPK came to be, but as I am sure you are aware the P38 was designed before WWII. I am certain there is a considerable generational gap there.

There is, in fact, an airgun connection to the designer of the P38.

http://record-firearms.de/en/geschichte/

Looking at what they still produce, the models 1/2/3 have a common design and differ in sights and grips, and are similar in some respects to the Umarex Browning Buck Mark. The 77 is about the size of a HW70, but simpler, although the grip is in some ways better in that it is not ambidextrous but has a nice palm swell and thumbrest.

The 68 (a large break-barrel), Jumbo (compact overlever) and Champion (sidelever, magazine fed pellet firer) are discontinued. I’m sure I’ve read mention of a fire at the factory at some point, perhaps that destroyed some of the tooling.

Iain

Michael,

I think you depend on internet reports a little too much! Or do you have first-hand knowledge to share about a SIG SAUER P226? When the US Military switched from the 1911 to the Baretta the Navy SEAL Teams ignored the economy of the 92FS and went with the superior weapon.

I think i will go with that group’s implied recommendations.

shootski

shootski,

I have no knowledge about Sig Sauer other than what I have read, from authoritative “internet reports.” I have no opinion about them at all, good or bad. As for the Pentagon, their selecting something to adopt is faint praise. You might think twice about using the U.S. military as a sole endorsement for anything. Was the P226 the right weapon, the wrong weapon, or the army weapon? (Again, I have no opinion or idea, and frankly, as an air gunner, I don’t care too much.)

My allusion was inspired by a different Sig, and since you seem eager for information, I would be happy “to share” some, not from me, and not about the P226 but the P320, from Wikipedia (https://en.wikipedia.org/wiki/SIG_Sauer_P320):

“In late July 2017, the Dallas Police Department in Texas instructed all personnel to stop carrying the P320 pending an investigation.[21] There were concerns that the firearm may discharge when it is dropped and the back of the slide hits the ground at a 33-degree angle. The problem was thought to be related to the trigger weight; some triggers were heavy enough that they essentially continued to move due to inertia after the gun hit the ground. Internet publications, such as TheTruthAboutGuns.com, conducted independent tests that appeared to confirm potential drop firings (at a 40% rate).[22]

“On 8 August 2017, SIG Sauer issued a notice that they would upgrade all P320s to address the issue.[23] The upgrade is described on the company’s website as: “This will include an alternate design that reduces the physical weight of the trigger, sear, and striker while additionally adding a mechanical disconnector.”[24] The P320 upgrade program is detailed on the SIG Sauer website at: P320 Voluntary Upgrade Program.

“David Hartley, et al. v. Sig Sauer, Inc.

A lawsuit related to the above noted drop firing problem and filed in April 2018 in the United States District Court for the Western District of Missouri led to a class action settlement in February 2020.[28][29][30] Elements of the agreement include:[29]

“Communication that the mechanical disconnector added via the P320 voluntary upgrade program “provides an additional level of safety,” to be advised via the SIG Sauer website and direct customer communication

“Extension of the voluntary upgrade program for 24 months past the settlement date

“For anyone who submitted their P320 to the voluntary upgrade program and was told it was unrepairable, a refund of the purchase price or a new P320

“For anyone who submitted their P320 to the voluntary upgrade program and was charged for repairs, a refund of such charges

“A class action settlement form is available on the SIG Sauer website.[31]

“Derick Ortiz v. Sig Sauer, Inc.

In September 2019, an Arizona gun owner who purchased a P320 in September 2016 initiated a class action lawsuit.[32] It claims that SIG Sauer “continued to sell the flawed gun to the public”,[32] and that the upgrade offered “would still not fully compensate him for the significantly diminished resale value of his pistol.”[33] In March 2020, judge Joseph N. Laplante denied SIG Sauer’s motion to dismiss the case.[34][33]

The documentation for the above Wikipedia quotation is below:

“BREAKING: P320 Recall Issued By Dallas Police – Prohibited From Duty Till Repaired – The Firearm Blog”. 2 August 2017.

“BREAKING: TTAG Test Shows P320 Striker-Fired Pistols Are Not Drop-Safe – The Truth About Guns”. 8 August 2017.

“SIG SAUER Issues Voluntary Upgrade of P320 Pistol – Sig Sauer”.

“P320 Voluntary Upgrade Program – U.S. Consumers”. sigsauer.com. Retrieved 12 March 2020.

“Hartley et al v. Sig Sauer, Inc. et al”. pacermonitor.com. Missouri Western District Court. Retrieved 16 March 2020.

“Settlement Agreement” (PDF). sigsauer.com. January 2020. Retrieved 16 March 2020.

“Hartley v. Sig Sauer, Inc. Class Action Agreement”. sigsauer.com. Retrieved 16 March 2020.

“SIG Sauer P320 Class Action Settlement Claim Form” (PDF). sigsauer.com. March 2020. Retrieved 16 March 2020.

“Bookman, Todd (30 September 2019). “SIG Sauer Sued Again Over Potential ‘Drop Fire’ Defect with P320 Pistol”. NHPR.org. Retrieved 26 March 2020.

“Laplante, Joseph N. (23 March 2020). “Opinion No. 2020 DNH 036” (PDF). United States District Court for the District of New Hampshire. Retrieved 26 March 2020 – via govinfo.gov.

“Judge Declines to Dismiss Proposed SIG Class-Action Suit”. U.S. News & World Report. AP. 25 March 2020. Retrieved 26 March 2020.

So, shootski, I know nothing about the P226, sorry, but I was glad to be able to teach you something about the Sig Sauer P320. Thanks for giving me the opportunity. :^)

Michael

Mike, Mike, Mike…,

Your post:

“And as for Bond, the P226 is not a Walther but a Sig, right? Well, so long as James doesn’t drop it . .”

No mention of the SIG P320! I am not eager for information about the P320 since i have owned an X5 P320 for a number of years and have no need of your extensive internet research. No compensation for your labors will be forthcoming…you will just need to find some other source to cover your trip to Bali. Lol!

I doubt the Navy SEAL teams ever pay much attention to the Pentagon bean counters when they select a weapon. If you understood my post it would have been clearer to you that the SEAL Teams in fact rejected the Pentagon’s choice of the Baretta 92FS

Although you are right about the SIG P320 and reported issues with drop discharges SIG very quickly made modifications and no reports are currently attributed to the P320 and its safe operation. I won’t probably be dropping my X5 or any other weapon so im not worried…it seems the X5 was built different than the standard P320 so i lucked out.

Oh, unsolicited but…Bali was wonderful 50+ years ago but the Hippies changed all that and it is no longer the paradise it was for centuries before there arrival, smh!

shootski

shootski,

As I wrote above, I can’t help you with info about the P226.

Michael

Shootski,

I would have kept the 1911A1.

RidgeRunner,

You aren’t alone there! The 1911 is still one of the most desired auto-loading handguns being made, and that from a 110 year old design. Now that’s longevity, which in this day and age is getting to be a more impressive trait every day.

Michael

RidgeRunner,

I LOVE the 1911 and have the hand size, the training, and strength to shoot it well. I looked at the P220 (my son owns that) carried the M11 (P228) But I must say that after shooting modern Glocks, S&W, H&K, and SIG pistols that i understand the new direction and actually get that the faster cycling slides, quick reset triggers, large capacity Magazines, better personal ammo load logistics, and inherent resistance to salt fog (and perspiration) have much to offer. 9 millimeter can get the job done with proper shot placement (as airgun pesters and hunters know better than any of our fellow shooters) makes for a very fast on multiple targets weapon. When you face Few on Many engagements like Navy SEALS and other Special Operations types that speed advantage is a big plus over the typical 1911 as designed and currently manufactured.

I LOVE MY 1911 and carry a full size when i might expect I’ll only be called on to engage a few if unlucky. I do carry a SIG P239 and spare magazine on my ankle. I used to carry a P238 but it made sense to switch to common ammo when carrying the 9mm.

shootski

Shootski,

Now my thinking is a bit different. Why take two or three shots when one will do. If you feel the need to carry a lot of ready ammo, there are large capacity frames that are no wider.

Also, when the fan is spinning, proper shot placement can be quite difficult. After some practical field experience, one of the local Sheriff’s Departments turned in their 9mm for .45 ACP.

I’ll take a rattly old 1911 any day. In fact, it had better rattle.

RidgeRunner,

Like i said I love my 1911 and do not fault your local Sheriff’s choice. I’m certain that they have the same realization of nothing is perfect and almost everything is a compromise.

I will say that one additional reason to go 9mm is that IF you run out of ammo on an operation in most countries the SEAL Teams will likely be able to find some more 9mm; NOT the case with .45ACP!

Remember im on board on the1911 as long as it is one of the really good builds and not a piece of junk all too many are these days.

shootski

B.B. and Readership,

A really great FREE, FREE, FREE, Balistics Calculator and a great source of education: https://www.jbmballistics.com/ballistics/calculators/calculators.shtml

H.B. B.B.!

shootski

“Balistics.” A study of Bali? ;^)

Mike,

Need to keep you on your toes! How else will you ever get your faculties back to full strength?

shootski

My wife and I loved Bali oh, 18 or so years ago. 50 years ago I was in third grade. :^)

Mike,

By the time you and your spouse were in Bali enjoying yourselves my wife and I had worn out Ibiza and moved on to Madeira for a second go round. It is funny how things seem to always change and yet never really for very long! It might be time to try Bermuda once again for our island fix.

shootski

shootski,

Madeira would be nice, but just thinking about going to Ibiza makes me want a shot of Penicillin!

Michael

shootski,

Thanks for the link. I also found this to be helpful:

https://www.everydaymarksman.co/equipment/rifling-twist-rate/

What do you think of his comments? – Don

Don425,

“What do you think of his comments?”

He is accurate and polite to his commenting readers…some of whom need to reread a few times and then get out a pencil and paper.

The article is basic but accurate and informative. I think he is a little doubtful on the bullet deformation issue; he probably shoots solids (copper) or Lead core with good jacket construction. Shooting cast Dead Soft Lead solids or worse still hollow points or hollow based bullets quickly gets to deformation issues with too high of a spin.

I think (theorize) thin skirted pellets may be a large part of the reason for accuracy issues for pellets at velocities above 950 FPS and not because of transonic/supersonic aerodynamics. It would take high speed photography or video to show if pellet designs that were accurate at breakbarrel velocities are just not staying symmetrical driven to PCP spin rates by faster barrel twist rates and compounded by much greater MVs!

He struggled to beat back his readers comments about barrel length being NO factor by not just saying clearly that barrel length has no direct effect on spin rate! Twist and muzzle velocity are clearly the only operators on spin rate in all of the formula he uses.

shootski

shootski,

Thanks for taking the time for your comprehensive reply. Your guidance is appreciated. – Don (this comment was initially posted in the wrong place, since deleted)

Happy Birthday B.B.! Have a great day. Looks like you won’t get relief from the heat today, but should by mid-week.

Jim M.

Jim,

Thank you very much!

B.B.

B.B.,

Maligayang Kaarawan! Happy Birthday Tom!

Siraniko

Siraniko,

Salamat!

B.B.

B.B.

Happy Birthday! Hoping you are able to do something special today, and enjoy yourself. 😉

Geo

George,

I took a 2-hour nap! My neighbor used his spare key to come in an see if zI was okay bedcasuse my phone was turned off.

B.B.

BB.,

It’s Sunday already. A Belated Happy Birthday!

Boy can I relate. A nap is one of my favorite gifts to myself. I’m reminded of this story……

The pope is travelling through Canada…

…watching the wonderful landscape flying by as his chauffeur drives him across the seemingly endless roads through the wilderness.

Eventually though, he grows bored and asks his chauffeur if he can drive for a bit.

“Listen”, the pope says, “I’ll drive for an hour, nobody will see. You can take a nap in the back, enjoy yourself, and nobody will ever know.”

After a bit of pondering, the chauffeur accepts, gives the pope a quick rundown how to operate the car and gets some shut-eye on the backseat.

The pope, meanwhile, puts the pedal to the metal. The car has the muscle to go over 70mph easily and as luck wills it, he gets stopped by a police officer, probably the only one around for miles.

The officer approaches the car and looks at the pope. He shakes his head, looks again, then tells the pope to kindly wait as he calls his superior.

“Chief, there’s… uhm… A bit of a tough situation…”

“Oh, come on, you’re on traffic duty, how hard can it be?”

“I just stopped a very, VERY famous and important person, so I don’t know if I can give him a ticket for speeding.”

“For god’s sake, even if it’s the Prime Minister himself, he has to obey the law. Who is the person you’re talking about, anyway?”

“Frankly, I’ve got no idea, but he’s got the pope as his chauffeur.”

BB,

Happy Birthday! Here is some candles for ya’,…….. !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

🙂 Chris

B.B.,

Enjoy your day!

Our age is just a number!

Wishing you a year of good heath and happiness!

shootski

Happy birthday BB from BB!

Brent B

BB,

Belatedly, for your birthday I will sing you the “Happy Happy Joy Joy” song.

Happy Happy Joy Joy!

Happy Happy Joy Joy!

Happy Happy Joy Joy!

Happy Happy Joy Joy!

Happy Happy Joy Joy!

Happy Happy Joy Joy!

Happy Happy Joy Joy!

Happy Happy Joy Joy!

https://www.youtube.com/watch?v=eVM1nUmDHHc

🙂

B.B.,

Happy Birthday, have a great day!

Thanks for all your 24/7 work. Take today off and have fun.

Don

Happy Birthday BB!!!