Reader Michael’s Walther LGV.

This report covers:

- The test

- Pondered a long time

- Today’s work

- The mainspring was lubricated

- Tune in a Tube

- The secret

- Application

- Button up the rifle

- First shot

- The cost

- Discussion

- Message to Michael

Wow! Do I have a report for you today. Unfortunately you can only read the numbers and not feel the rifle when it fires. If things were reversed you would be the ones saying wow.

The test

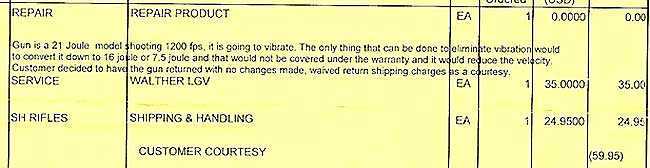

In Part One you learned all about reader Michael’s Walther LGV. When he got it it squeaked every time it was cocked. So he returned it to Umarex USA for servicing and they put on a good tune that eliminated the squeaking problem. They also either adjusted the trigger, or it came that way — Michael will have to tell us — and then sent it back with a note. I want you to read the note, because it means everything to this report.

Michael shared the note with us in his comments to Part 1. I enlarged it and printed it here for you to read.

The note that came back with Michael’s LGV.

Well, I’ll telling you today that note is incorrect. I have shot 26 foot-pound air rifles that didn’t vibrate. It’s all a matter of the tune. Umarex did several things exactly right, but on one account they missed it, and today I will tell you what can be done when you have the same problem.

Pondered a long time

Before I set my hand to the work I spent a long time thinking about what should be done. I have tuned spring-piston air rifles in this blog and have used every trick in the book to quiet them. Perhaps the one where I did the most was Johnny Hill’s Diana 45 that was a real buzzer. It was nowhere near as bad as this one, but until I saw this rifle I didn’t know they ever got this bad! To see what I did read Part 6 of that 10-part report. I buttoned the piston, made a new tighter mainspring guide and lubricated the heck out of the moving parts. And with all that that rifle went from being a buzzer to smooth.

Today’s work

All I did today was remove the barreled action from the stock. That exposed the cocking slot which was what I needed access to. To remove the action I removed two stock screws from the forearm and two screws from the area of the triggerguard. I say “the area of the triggerguard” because this triggerguard is one piece with the stock. The rear screw is behind the guard, and it also has to be removed to separate the action from the stock.

Two Allen screws in the forearm and two at the triggerguard.

The mainspring was lubricated

Once the stock was off I could look through the cocking slot and see that whoever tuned this rifle did put moly grease on the mainspring. For a gun with a tight powerplant this would probably enough, but this LGV isn’t such a rifle.

The LGV mainspring is lubricated with moly grease.

The moly was a good job, and under other circumstances it would be fine. But this rifle is the poster child for buzzy spring guns! It was time for my secret, which isn’t a secret at all.

Tune in a Tube

About seven years ago Gene Salvino who worked at Pyramyd AIR at the time told me about Almagard 3752 sticky red grease. He said he was getting results with it on every spring gun he touched. I listened to be polite, but then life took over and I promptly forgot what he told me.

Then I saw something online called Tune in a Tube and I called Gene to ask whether the stuff was any good. He said it was great and he thought he had already told me about Almagard 3752 grease. Well, he had, but Tune in a Tube came in an applicator that assisted in greasing the deep internals of a spring gun. I bought one, tried it and became the product’s biggest fan. And as you guys know I tune a lot of spring guns, so I went through the first tube quickly.

Tune in a Tube really works!

Then I bought a 14-ounce grease gun cartridge and refilled the TIAT applicator from that many times. But that applicator is not made to last and finally it gave up the ghost. After that I resorted to either disassembling the guns and applying it directly to the mainsprings or I used cotton swabs to insert it through the cocking slots. And I have been doing this for several years.

However, applying TIAT this way is sloppy. I wanted something better. And that is my secret for you today.

The secret

And now for my secret tool. It’s a grease gun with a short hose that ends in a sharp applicator needle. Michael’s LGV is the first time I have used it this way. My original grease cartridge was almost used up, but there was enough for this one job.

This was the first use of the grease gun with needle applicator.

The grease gun needle applicator puts TIAT deep into the places you want.

Application

Two of us were involved. My neighbor, Denny, was over so he moved the applicator needle along the mainspring and I pumped the grease. One person could do it with no problem. We were very thorough because this rifle vibrates so much! The applicator needle allowed us to get grease on both side of the spring, as well as all the way inside.

I have never seen a rifle that vibrates as much as this LGV and I wondered if TIAT was up to the task. If not I would have to take the powerplant apart and possibly make some new parts.

Button up the rifle

After the application I put the barreled action back into the stock and the job was done. All that remained was to test it.

First shot

I did this work in my garage, so I was there with a bullet trap. I got some H&N Field Target Trophy pellets because I wanted some weight in the pellet when I shot it the first time. When I fired the rifle it went “thuck.” Huh?

This rifle went from being the worst-vibrating spring-piston rifle I have ever seen to one of the smoothest air rifles I have ever shot!

Remember I told you that now that the trigger on the HW 30S I am testing is adjusted properly the gun seems to fire more harshly? Well, that wasn’t the whole story. This LGV is another reason why I feel the HW 30S is a little harsh. Because this one is now so SMOOOOOOTH! That’s right, Michael, your LGV is now much smoother than an out-of-the-box HW 30S. Think about that!

In fact, this LGV is even smoother than my TX200 Mark III. It is just as smooth as my HW 85 (which is a version of the Beeman R10) that was tuned by reader David Enoch’s brother. He essentially did all the things to that rifle that I did to the Diana 45, so you’re talking about a tune that would cost many hundreds of dollars — if you could find anyone to do it. Except I did it on this LGV in 15 minutes with about 50 cents worth of grease.

I shot the rifle again and again and simply could not believe that it was as smooth as it is. Even with lightweight pellets it just goes “thuck.” Not even “thunk” which would be a tiny bit of vibration. The rifle no longer lunges forward, either. It just sits in the hand and pulses when it fires.

The cost

Michael and I agreed when this project began that a smooth-shooting air rifle was the goal. To heck with what the chronograph says. Now it was time to test it to find out.

Seven-grain RWS Basic pellets that averaged 945 f.p.s. before the TIAT and had a 16 f.p.s. velocity spread now averaged 811 f.p.s, with a 35 f.p.s. spread. Wow! I had thought a drop of perhaps 40 f.p.s. was a lot, but this pellet has shed 134 f.p.s. No need to point out that is a lot!

The muzzle energy was 13.88 foot-pounds. It is now 10.23 foot pounds. That’s a big change.

RWS Meisterkugeln Rifle pellets that weigh 8.2 grains previously averaged 882 f.p.s. with a 14 F.P.S spread. After the application of TIAT they average 730 f.p.s. with a velocity spread of 26 f.p.s. That is a 152 f.p.s velocity drop.

The muzzle energy was 14.17 foot pounds. It is now 9.71 foot-pounds. Cowabunga!

JSB Exact Heavy domes weigh 10.34 grains. Previously they averaged 755 f.p.s. with a spread of 15 f.p.s. Now they average 646 f.p.s. with a 9 f.p.s. spread.

Previouslyhe muzzle energy was 13.09 foot-pounds. It is now 9.58 foot pounds

Discussion

I see the velocity spread is tightening up. What I think is happening is the TIAT is spreading around inside the spring tube as it is shot. The more the rifle is shot the faster it will shoot and the tighter the velocity spread will become.

But the way the rifle shoots right now has to be experienced to be appreciated. So, before you guys start telling me what has to be done, I’m sending this rifle back to Michael as it is to let him decide. If it were my rifle I would leave it exactly this way and just shoot it. But if he decides he does want more velocity he can send it back and I will take it apart to remove the TIAT. Then I’ll apply it in smaller stages until I have it shooting smooth again.

I have learned a couple valuable lessons in this short series. First, no matter how bad a spring gun vibrates, TIAT can always fix it. And second, if a lot of TIAT is used, the velocity will decrease by a lot. That’s two things I didn’t know before.

Should Umarex USA do this? Probably not. Many of their customers open a returned airgun box and run to the chronograph to see whether they should like what has been done. But if they are discerning shooters, there might be a small subset that like this performance at lot! It’s a tough call for a commercial venture.

Message to Michael

When you get your rifle back, put it together and shoot it with any pellet you like. After you see what I’m talking about I think you’ll want to explore this rifle a little before making up your mind what to do. I think this is exactly what you wanted from the beginning. I won’t say that your LGV is as smooth as your Winchester 427, but it’s pretty close. And that nice trigger makes it an airgun you want to shoot a lot.

If you then want to send it back to me I will do what I discussed above and we’ll see what can be done.

B.B.,

That TIAT application seems to have been able to hush up the spring. Here’s to hoping that the fix lasts for quite some time. Then again if Michael experiences the same problem again he now knows that a re-application of TIAT will stop the twang and vibration.

Siraniko

PS: Last illustration blurb: “The grease gun needle applicator puts TIAT dewep (deep) into the places you want.”

Siraniko,

Fixed. Thanks,

BB

if I had a rifle that shot tiny groups I would not care if it sang Dixie after the shot. no need to get anal over a stupid buzz.

I had a LGU it was very smooth and the most accurate air gun I ever saw. 3/4 inch groups at 50 yds. a lot of PCP rifles would struggle to do that.

mildot52,

If one could live with the buzz I’d leave it alone. But, since it spoils the enjoyment and the fix is not so arduous why not? I do agree that to go in deeper might not be worth it for some people but not for all.

Siraniko

well you can always wear ear muffs lol. some guys like working on a gun more then shooting it. I respect their skills. I like shooting more. the guy sent his rifle back was deprived of shooting for for who knows how long all for a silly buzz that would not affect accuracy. the LVG and LGU were sold as tuned rifles from the factory and guys took them apart and you could see it. so one of those rifles buzzing would mean to me the guy took it apart and might have broken one or more of the buttons on the piston putting it back together. I had both rifles and they shot like custom tuned rifles

Mildot

I had the last of the wood stock LGU’s. It was a very accurate springer. It was very smooth and solid feeling. Chris USA ended up with it. I think he will say the same about it.

And yep if a gun buzzes I will live with it if its accurate.

Accuracy over rides a guns other issues with me. If it rang like a bell when it shot but was accurate I would be ok with it. As time goes on I have found that accurate guns are keepers. Even if they don’t look good either.

mildot52,

I don’t understand. Now that I think about it, why would you part with the most accurate airgun you ever saw? I still own the handful of the most accurate air guns I’ve ever had and doubt I’ll ever sell any of them.

Michael

after getting in position and set in the bags to shoot the rifle and it was not hold sensitive you have to totally break up your hold stand up cock the gun then get all rested up again. My FWB was as accurate at a little over 40 yds and if it was set on the bags good I could cock it slowly load and be almost on the target without even standing up. if I knew they were to stop making them I would not have sold it

mildot52,

Why would you have to stand up to cock a breakbarrel? The sitting and kneeling positions are the easiest for cocking, much easier than standing as you can place the butt on the ground. And Prone is only a slight challenge, but not terribly difficult if you follow the below instructions, which I believe I learned as a Boy Scout:

1st, Lift your left elbow off the ground, moving even more weight to your right side.

2nd, Sllide the butt down to your left knee (already pulled up in the Prone).

3rd, Using your right hand as a fulcrum, with your left hand slap the muzzle snd pull it downward to cock it.

4th, Load as usual with your right hand.

Milldot52, I’m confident if you follow those simple instructions, you’ll be cocking a breakbarrel in all four positions in no time! :^)

Michael

the rifle was an LGU which is underlever. it could be cocked sitting down as well as a break barrel but I would fire 2-300 shots a session. so I put the LGU recoil pod on the floor grab the lever pushing down to cock it. there was no strain cause I used my weight. try that with the method you outlined 2-300 times and tell me how you make out lol and if you can hold it on thee target steady

mildot,

I shoot Sitting mostly now because of my knee and hip issues, but I could’ve cocked it 300 times back when I shot Prone. Those models are only 32-36 pounds. (And if you’re Prone, your heart works much less anyway.) If you shoot like that a few times a week or more, you can’t help but toughen up very quickly.

You’ve got to eat your Wheaties, LOL.

Michael

What’s interesting to me about the note is that the pre-TIAT Walther was making just a touch over 16J, and post-TIAT, it drops down to about 13J, so in a way the comment isn’t that far off (aside from the pre-TIAT energy being well short of the 21J mentioned!

Nathan

B.B.

I wish you had posted a video or at least sound clip of “the buzziest airgun ever”.

I believe that the Walther LGV, at least the new one, was designed to be a 12 fpe airgun.

Are you not now worried that something else is wrong? Maybe a canted/broken spring from all the vibration or perhaps a chipped piston seal.

It is now shooting too slow!

-Y

Yogi,

I knew seeing the numbers was going to put people off. The way this rifle now shoots I want Michael to experience it before anything else is done.

As for a sound clip. you have seen nuclear explosions on film and they weren’t bad. Yet it is the sound (moving as compressed air) that blows those buildings apart. Sound clips tell very little.

BB

On a side note, Almagard 3752 is another fine product of Lubrication Engineers, providers of Crosman Pellgun oil.

Paco,

Now I didn’t know that. Thanks!

BB

BB,

Over time Michael will see an increase in speed/power and the spread tighten up. That stuff is sticky and takes a bit of time to spread out and disperse evenly. I used geegobs of it on my Webley/Hatsan Tomahawk. It was a horror story to shoot also. It is still a real solid THUK, but the N is gone. Now I am seriously thinking of taking it down to a Thuk.

I congratulate Michael for getting one of these. I considered it, but for me Walther never put the right sights on the right stock. Yes, I could have bought the correct sights and put them with the correct stock, but at the price this was I had too much Scottish blood in my veins.

I was interested in one also. However, I was hoping for a 14-16 fpe gun.

I was then told it is a 12 fpe gun. I had no idea it is really a 9 fpe gun.

So a 9 lbs gun shoots at 9pfe, is that some kind of magic number like pellet weight and pfe generated is?

Maybe Umerex is on to something…that a gun that shoots at 1200 fps should weight 12 lbs!!! lol!!! lol!!!

-Y

Yogi,

Mass is how many companies tame sproingers. That is why Gamos are so hard to shoot well. They are light. I wonder how much a Whiscombe weighs?

BB,

Glad it all worked out.

In the picture of the spring, is that a metal inner spring guide or is it plastic (like a Vortek kit)? It looks white-ish in the pic.

Chris

Chris,

The spring guide in this rifle is plastic, just like most spring guide are today, including those in guns made by Weihrauch.

BB

If it were FM’s rifle, would leave it alone and just “choot” it with gusto – suspect it will only get better the more it is enjoyed.

Good article for those, like FM, who have entered the realm of spring-piston rifle-ing. This is a reminder to myself to also get a good, suitable tool kit for when the time comes – as it will – to at least be able to carry out basic maintenance and minor repairs without buggerin’ things up. Hopefully.

BB,

A friend dropped by to show off his new springer. The rifle had a bit of a buzz and I suggested that re-lubing it would probably help.

I didn’t have much time so it got a “quickly tune”. I took off the stock, flushed out (dissolved) the factory grease with varsol and re-lubed the chamber/spring with red tacky grease that I had thinned (enough to pour and flow) with naphtha.

I had my friend reinstall the stock the next day (after the naphtha had evaporated) and try the rifle. He said that it was shooting much better/quieter so the “quicky” approach seems to work fine.

Sorry that I didn’t get before/after numbers or a more substantial report but it was (literally) a 20 minute job.

Hank

Hank,

That red tacky and naphtha trick might work real well with one of those big turkey basting syringes.

R.R,

The baster is a good idea.

I just thinned the grease to the consistency of thick syrup, poured it in, “sloshed” it around to coat everything and drained the excess out.

I didn’t see the end result but my friend said that everything he could see had a layer of grease on it.

By next morning the thinned grease in the mixing bowl had returned to normal and appeared to be fine.

Hank

“I had a [sic] LGU it was very smooth . . . . The LVG and LGU were sold as tuned rifles from the factory . . . I had both rifles and they shot like custom tuned rifles.” –Mildot52

“I had the last of the wood stock LGU’s. . . It was very smooth.” –Gunfun1

B.B.,

My LGV has the same powerplant as Mildot52’s LGV and LGU, which “shot like custom tuned rifles.” And Mildot52’s LGU and LGV and Gunfun1’s LGV, were all “very smooth.”

The mystery still unsolved is why my LGV, unlike theirs, had to lose 30 percent of its power to be similarly smooth. What inside mine (which in 2013 retailed for $566.10), which I purchased new, is inferior to what was inside theirs? Just how did Walther botch mine on the assembly line so that the mainspring had to be slathered in TIAT?

Michael

Michael,

I don’t have a clue about that. But I can tell that you won’t be satisfied with the rifle as it is now. I will not send it back. I will disassemble it and see what I find.

BB

B.B.,

Thank you. :^)

Michael

Michael

I should of never let that wood LGU get away. It really was a nice gun.

And I’m wondering if the cylinder is out of round somewhere and the air is just blowing by the piston seal. If I owned the gun it is something I would check.

Gunfun1,

Are you a mind-reader? As I woke up this morning, I wondered if the compression tube was out-of-round. If that were the case, it would explain everything.

Michael

Michael

Curious to see what BB finds.

BB,

The first comment on this blog was by Siraniko, then you and mildot 52 replied to Siraniko, then Siraniko replied to mildot 52, then mildot 52 replied back and then it was Gunfun’s turn to reply to mildot. With me so far? I want to make a reply to Gunfun, but there is just a drawing of a pencil after Gunfun’s comment and the word reply is missing. Does that mean that his comment was the last one allowed in that thread?

My second question is about this “Message” box. Can you request that it be constructed in a way that allows for stretching it bigger so we can see all of our comment when we go back to proof it? If you find you want to add/edit something to your comment, THAT box DOES stretch, so it seems the same needs to be done on the original box, like the old page allowed.

Half

Halfstep and BB,

The resizable window for replies ( the little handle at the bottom right of the box ).

We need this for longer replies. So we can see as much as we can on our screens. Anyone who likes writing does not want to look at their creation through a letter slot. : – ) Robert.

PS I see that the RETURN key works as in real life ( end line, got to next line ) and does not make a new island of text. GREAT !!!!! let me just check.

and I am still in the same paragraph after pressing RETURN. : – )

Half,

It seems that they have gone from a thread with 9 levels to 4 levels.

you may have to scroll up to see the start, Ridge Runner says “Over the thirteen years….” then Gunfun1 replies, RidgeRunner replies, Michael replies, RidgeRunner replies, Gunfun1 replies, RidgeRunner replies, Gunfun1 replies and then the reply to is gone, note that this started off at level 2 making 9 levels of the thread.

Contrast that exchange to the new way of doing things, on the new blog it looks like this,

/blog/2020/12/does-seating-pellets-extremely-deep-help/#comment-467828

After RidgeRunner’s 2nd comment the comments go vertical, do not know if they can or will re-expand to 9 levels but it is what it is.

As for the comment box if you are making a long post it may be wise to use a text editor and once you have it right copy and paste it into the message box.

In the past folks have lost comments into the void after hitting send, I guess it will still happen with the new format as well.

Mike

Mike in Atl ,

Thanks for taking the time to tell me how to find the wooden stocked Avenger. I had actually found it on my own, although in yet a different way than you laid out. My purpose in the comment to BB was to point out the shortcomings of the MENU box in the NEW AND IMPROVED website. If I owned a company that designed/

marketed a brand of air gun under the name of say, Air Venturi and sold it in an online store like Pyramyd AIR, that I also owned and I then paid someone to build me an improved website to sell my airguns on and they didn’t make sure that a customer was directed to my Air Venturi brand at least as easily as they were directed to Air Arms and AirForce guns, I would be concerned and would wonder what orifice their heads were in. Now on the other hand, if I was trying to direct my customers to Air Arms and AirForce products because they were more expensive and had higher profit margins, then I would appreciate the fact that they didn’t include the lower priced and lower margined Air Venturi in the only three brands that start with an “A”.

As for the thread length question, are you saying that the pencil without the word “reply” DOES indicate the end of that thread?

halfstep,

Yes, no matter how much I click the pencil without the word “Reply” beside it that is the end of the thread.

Siraniko

BB,

I wanted to point out that earlier today I was looking for the new wood stocked version of the Avenger PCP Rifle. I started at the MENU symbol at the top of this blog. Then I went to Pellet Rifles and was directed to a page that let me select Pre-Charged Pneumatic and at that page I selected Brands and at the top of the list is Air Arms and AirForce but no Air Venturi. Is that an oversight? The list seems to run in alphabetical order from there.

Half

Half,

Searching from the menu is not always great, if you go to the top of the Pyramyd AIR site on the right is a search button go there and put in Avenger and you will get this.

/search-results-ext?Ntt=Avenger&sid=1375A617A415&N=0&Ntk=primary&q=Avenger&cx=002970863286801882398:jlcminxfwdw&cof=FORID:11;NB:1&saSearch

The price has gone up a bit, the original was 300 bucks I think.

Mike

Mike,

Of course it has gone up. Everyone wants one so the price will rise to the level at which it stops selling. Then they can have a SALE and still make as much money as they did before.

Mike in Atl

For your information and for what it’s worth.

You are the only person on the blog that I can not read all you post on my telephone. Your lines of text run off the page and I can not scroll to the right to see them.

Interesting.

Pete,

I think it is because of the links in my posts, lets try this, here is the text from the post higher up on the blog to halfstep with the links removed.

Half,

It seems that they have gone from a thread with 9 levels to 4 levels. Here is an example,

Link removed

you may have to scroll up to see the start, Ridge Runner says “Over the thirteen years….” then Gunfun1 replies, RidgeRunner replies, Michael replies, RidgeRunner replies, Gunfun1 replies, RidgeRunner replies, Gunfun1 replies and then the reply to is gone, note that this started off at level 2 making 9 levels of the thread.

Contrast that exchange to the new way of doing things, on the new blog it looks like this,

Link removed.

After RidgeRunner’s 2nd comment the comments go vertical, do not know if they can or will re-expand to 9 levels but it is what it is.

As for the comment box if you are making a long post it may be wise to use a text editor and once you have it right copy and paste it into the message box.

In the past folks have lost comments into the void after hitting send, I guess it will still happen with the new format as well.

And here is the text of my post that you are replying to with the link removed.

Half,

Searching from the menu is not always great, if you go to the top of the Pyramyd AIR site on the right is a search button go there and put in Avenger and you will get this.

Link removed.

The price has gone up a bit, the original was 300 bucks I think.

I think it is the links that are allowing the text to spread out making the text run off the right side on smart phones and some tablets.

Mike

Pete,

Yes, having links does seem to be a problem, with only the text I can now read the posts on my smartphone.

Mike

Thanks that could be it.

Pete,

Let me try one other thing, embedding the link this way I think I can include links without the text running off the screen.

Half,

It seems that they have gone from a thread with 9 levels to 4 levels. Here is an example, you may have to scroll up to see the start, Ridge Runner says “Over the thirteen years….” then Gunfun1 replies, RidgeRunner replies, Michael replies, RidgeRunner replies, Gunfun1 replies, RidgeRunner replies, Gunfun1 replies and then the reply to is gone, note that this started off at level 2 making 9 levels of the thread.

Contrast that exchange to the new way of doing things, on the new blog it looks like this.

After RidgeRunner’s 2nd comment the comments go vertical, do not know if they can or will re-expand to 9 levels but it is what it is.

As for the comment box if you are making a long post it may be wise to use a text editor and once you have it right copy and paste it into the message box.

In the past folks have lost comments into the void after hitting send, I guess it will still happen with the new format as well.

And here is the text of my post that you are replying to with the link embedded.

Half,

Searching from the menu is not always great, if you go to the top of the Pyramyd AIR site on the right is a search button go there and put in Avenger and you will get this.

The price has gone up a bit, the original was 300 bucks I think.

Lets see if that works, my html is a little rusty.

Mike

It seems that the web archive has removed the content I linked to. Oh well, at least it seems that in the future I should use embedded links for the phone users.

halfstep

When you drop the brand menu, at the bottom is a link that says “see more”. Click that and Air Venturi will appear.

Seems like I have to use the see more link a lot.

Pete,

Thanks, I knew that before I posted my comment, but I also noticed it only added one more “A” Brand. I was trying to gently suggest that dropping down the whole list to begin with might save some missed sales and if you are only going to list 2 of the 3 brands that start with “A”, why not make sure your house brand is one of them.

Half

BB et al.

I am ruminating: The grease is dampening. It introduces friction. ( this might sound weird for a lubricant…)

If you have two parts that move very closely together but do not touch very much then you could say they are frictionless. ( Lightly slide a flat surface over another flat surface for an example ) if you introduce grease between these two surfaces….. you have introduced a friction coefficient. They are now “touching”. and so the friction has increased. and friction is interesting as it goes down the faster you move ( maximum friction at rest ). Any lubricant in a system will produce energy losses IF it increasing friction ( the lubricant is preventing the parts from touching …) . The classic example of this is the oil additive promotional geared gadget that shows you how their product makes engine oil sticky ( decreases fling off etc ) BUT the interesting thing is the different amounts of energy you need to turn both gears one full turn. It is obvious the tacky oil is harder to turn, no question. This is all interesting stuff.

Any kind of dampener is trying to take energy out of a system. A hydraulic dampener gets hot, this is energy bled out of a system. It is doing work. ( and yes brakes do do work ! ) How do you make a high power spring gun stop buzzing without essentially choking the spring with grease? Reduce the spring to inside wall gap? Is the spring too long? ( right now I am using the slider on the right to look at my text….not good .)

At the moment I have my FEG Telly relums on the bench and am having fun with PRELOAD. I have never done this before. With the stock off I can clearly see how close the coils are getting when cocked. Using washers in the piston I can adjust this spacing ( fun with springs! ). The results are good. It clearly shows that the spring needs to be “coil bound” to get max power ( which will wear the spring etc out faster ). The trigger weight goes up proportionally. By adjusting the preload I can balance power, recoil and trigger weight to what I consider good for my indoor range. If I take out 20mm of washers I drop my POI quite a bit and trigger pull is not so heavy. As I am not leaving the rifle cocked for too long the spring life will not be toooooo compromised ( imho ). And yes I slather the spring in grease, it is wheel bearing grease and medium tacky, maybe NLGI 1. Your TIAT is NLGI 2 ( if I am correct ) and specially tacky etc.

What we need to do is take a spring into zero gravity, compress it then let it go and high speed video what it does. I bet my money on it “waggling” it’s ends and/or it bounces coils along itself reflecting off the ends. and even spinning…. all of these would cause buzz… and if you try to stop this buzz then you are going to lose power. Do we really understand what springs do? Why do arrows waggle in flight? Would a cross bow hybrid air rifle be a better quieter system? ( compressed gas versus bent steel… ).

Or even two stage springs…. one to get it rolling slowly and the second to launch it ? Ruminating over ! : – ) Robert.

PS the resize window corner handle comes up when you EDIT your post. Can we have that when we write our posts too please! ( may help reduce my post length in the future…. wink. )

PPS the grey font colour when editing a post is … hard to see. It’s like looking for a greyish rabbit in fog.

RobertA,

Ok,………….. no more coffee for you! 😉

Chris

RobertA,

Ok,… you make some good points. Lube the spring with TIAT (and) increase tolerances,… and you have less slow down. I’ll buy that. It is my understanding that the grease (only) reduces the duration of vibrations. Sliding and lubrication is secondary. Too tight of tolerances and fps suffers.

Chris

RobertA,

On tuning, shimming, etc.,……… you need to get a chrony. I have seen some touted lately as low as $20. Sure,… it may not be the best and not have all the bells and whistles,…. but it will give you a number from which you can collect hard (measurable) data.

Chris

RobertA,

Nice try but it takes a whole bunch of mathematics to figure out why Michael’s Buzzer goes off when other folks rifles go THUK: https://roymech.org/Useful_Tables/Springs/Springs_Surge.html

I think it is actually a case of SURGING well explained by Ray.

I’m glad my break-barrel are both gas-spring and most all the rest of my airguns are PCPs, CO2, or Pneumatics! I have found that my aversion was toward coil springs and not break-barrels!

shootski

Shootski,

“If a spring which is subject to a vibratory motion which is close to its natural frequency the spring can start to surge. ”

Bad grammar. What is this “natural frequency” and “surging” ? Not enjoying this whole paragraph. Does not look applicable.

What would be cool to read is what happens when you unload a compression spring inside two end stops, such as in our air rifle spring tubes. I can imagine that a particular spring will resonate in the tube. Reflections of compression waves bounce back and forth in the tube. and hey guess what?

The TIAT dampens than out , and it also slows the spring down ( all that tacky grease to wade through ). I am no scientist that likes to mathematically model physical science ( though I did read some stuff on a guy who modelled physics using electronics… it was intense ) but doing practical experiments is cool, change the spring properties etc and retest. High speed video…. etc. FUN !!! Really good science starts with observations ( it’s when you can’t observe that things get weird….like bacteria and viri before microscopes….).

I bet you $10 that when you let a compression spring go in free space it will oscillate. It may be to do with the compressed spring length, the resonant frequency of the spring, the diameter of the wire, the coil frequency etc.

We need to go into space to test this out. The sproingers get some space time on the space station to test out springs. We need a budget, some space air gunners and a selection of springs and some really neat video cameras. no biggie. We can beat the buzz!!! and keep the FPS !!! Robert.

RobertA,

I Savvy.

My son wanted to be a Mechanical Engineer (ME) back in the early’90s. He visited the school’s Lab and talked with the head of the lab and drooled over all of the tools and machines that were State-of-the Art. But after that visit he went for Finance/Economics; seems the ME Lab was closing in two years because all work in ME was forecast to be done virtually in the near future. He is happy he isn’t an ME sitting in a dark room reviewing/approving the work of Off-Shore workers like some of his friends who stuck with engineering.

Tinkering is fun for sure but that train left the station long ago…for that matter where are the train stations?

shootski

PS: You don’t need to go into Space to get that zero G! Just by a ticket for you and your Slinky on the Vomit Comet!

Shootski

We need to need to make new train stations. Innovation and risk taking and tenacity is key to widening the knowledge of science and it’s applications.

There are no stupid questions. Why does the spring buzz? Why does this spring not buzz? How do radios work? Why do arrows waggle in flight? How do magnets work?

People who look down at others who are discovering things for themselves ( even on well trodden paths ) are the problem. Everyone should build a crystal radio out of bits of coal and tin cans and copper wire. We still have all we need. Everyone should understand how simple springs are and that they have interesting properties. A charged capacitor? A saturated inductor? Potential energy that can be released at once or slowly released… it’s what our trains stations are made of. Steam! Expansion! Pressure! Compressed Co2! Compressed Hydrocarbons! Hydro dynamics! Friction! all great stuff and wait there is more! The dull virtual engineering program that surgically creates “new” solutions that are worse than the old ones. The factory that made metallic alloys to create electrical shunts closed down. Those alloys were a trade secret, they spent decades developing them, hands on. Now where are they? In your virtual lab you will specify a shunt that is xyz but in the real world you can’t make it! Why? Because we let that information slip through our fingers. It is very very hard to make a perfect shunt. In the virtual you just dial it up. too easy! But then the “engineers” who have to make it are scratching their heads because things do not add up.

Can you make a transistor at home? What about an X ray machine? A laser ? and how do they work? Is it really that hard to understand?

Re build the train stations at once! Wind your own springs! Do you want a fancy kitchen or a fancy work shop? There is so much science, sooooo much. What is cavitation? are the bubbles in my soda cavitating? Why is some steel soft and other is hard? How do springs even work ? Is glass really a fluid ? he he he.

We need fascinating trains stations ! and they are available to everyone. ( all this on one cup of coffee…) Robert.

Shootski

That’s my favorite thing about roller coasters.

The zero G’s.

I dont like heights but I could do a fighter jet.

Love acceleration and zero G’s.

Shootski,

I’m standing on the opposite side of the holler. I have a fair collection of coil sproingers, but I do not have any gassers. I myself would rather deal with the metal coils than the average gas tube.

I am not saying I cannot be won over. I can see many of the benefits of these things. The major problems with them that I have are the majority are not adjustable and are not rebuildable.

Theoben had an adjustable one. Alas, they are no longer. Was it easily rebuildable, I do not know. For a time Hatsan offered an adjustable one. Do they still offer such, I do not know.

It would be nice to see an airgun company step up with adjustable and rebuildable pistons, but that costs money. I would pay it, but how many others would?

RidgeRunner,

I’m certain the shooting and hunting on your side of the holler is just as much fun as on mine. I was one holler over for a long time with no break-barrel (serious ones) at all! Now I’m shooting these newfangled break-barrels and having some fun. I still have my Aversion to the coil Thingies but this IS STILL the Land o the FREE so I’m certain we will see eye to eye on the FUN of airgunning.

Different strokes for different folks!

shootski

RobertA,

If you cannot find Almagard 3752 here is a list of equivalent greases I found on the internet. The Royal Purple version I was able to find worked a treat taming my Webley and my Father’s Hatsan. Look around your local automotive store and you find one of these:

Castrol 4020/220-2™

Castrol 8060/220-2™

Chevron Delo® EP 2

Chevron RPM Automotive

LC Grease EP-2™

Citgo Lithoplex MP2™

Citgo Premium

Lithium EP 2™

Conoco Super-STA® 2

Exxon Ronex MP™

Exxon Unirex EP 2™

FAG LOAD220™

Fuchs (Century) Uniwrl 2™

Lubrication Engineers

Almagard® 3752

Lubriplate® 1552

Mobilgrease® XHP 222

Pennzoil® Pennlith® EP 712

Pennzoil® Premium

Lithium Complex 2

Petro-Canada

Multipurpose EP 2™

Royal Purple® UltraPerformance® 2

Shell Albida® LC 2

Shell Retinax® LC 2

SKF LGWA2™

SKF LGEP2™

Texaco Starplex® 2

Unical 76 Multiplex Red™

Siraniko

Siraniko,

I have now a tube of Mobil xhp 222 which is NLGI 2. Not very tacky. Blue. Seems fine. Will be on the look out for super tacky. We have a pretty good industrial part of town here. Not all grease is the same! Thank you for the list! Robert.

Siraniko

Thanks for posting that list. Did you by any chance get it from the Timken Bearing grease interchange list? I found the same greases on the Timken list, once you inspired me to start looking. I further investigated many of those listed and it looks to me as if the primary feature of the grease, for the purposes of taking the buzz out of an airgun, is to have a consistency of peanut butter, rather than tomato paste, margarine, fudge or chedder cheese. That is the significance of the NLGI Grade 2 rating. I personally don’t think things like the drop point, temperature range and many of the other criteria used to describe greases really matter in the context of de-buzzing a spring piston airgun.

I have a tube of grease called Sta-Lube Extreme Pressure Sta-Plex Premium Red Grease that isn’t on that Timken interchange list but it is a NLGI 2 grease. It lacks some of the other features of the greases that made the list, but I’d bet it doesn’t matter and this grease would quiet a buzzing springer just fine.

Maybe there’s a blog topic to be fleshed out from this discussion. Will any NLGI 2 grease calm a buzzy springer?

Half

halfstep,

Yes I did get it from the Timken Bearing grease interchange list. Knowing the mindset of most lazy people your question of will any NLGI 2 grease calm a buzzy springer? It will probably take some time before it can be answered as others experiment with alternative greases only if Almagard 3752 is not available to them. Like in my case and RobertA.

Siraniko

Siraniko,

We know what’s in the next blog. 😉

Grease.

In my humble opinion, the industry is not seeing eye to eye about what properties greases will have.

Frankly they don’t want to agree ( see Beta vs VHS, RCA vs DIN etc).

NLGI is a spec made for a particular reason. It may not address the reason you might need grease!

For example: two NLGI greases will not be the same IF they have features outside of the NLGI scope such as “tackiness”. ( I am picking that tackiness is not in the NLGI scope )

Can one NLGI 2 spec grease have more “tackiness” that another NLGI 2 grease?

and I am pretty certain the answer is YES. So not all NLGI 2 greases are the same…. darn.

well well here we go:

https://en.wikipedia.org/wiki/NLGI_consistency_number

Yep, they are not testing for “tackiness”. So there you go. Not all greases are the same. Not all beer is the same, not all pellets are the same and not all small furry creatures from Alpha Centauri are the same ( see Douglas Admas on this ) ….

End result being that my TIAT is not the same and BB’s et al TIAT even though they have the same NLGI number. heck. We need to test all the greases and have a tackiness index and a data base. and free samples for all ! I will now shut up. : – ) Robert.

Dilema,

My Diana 6M needs to be resealed. I would like to send my vintage HW 50S to be tunned. I am trying to finance these two items by selling some of my vintage pellets. Would like you guys’ opinions. Are these vintage pellets someting that cannot be replaced as far as accuracy and fit ( most of my rifles and pistols are Diana, Weihrauch and Feinwerkbau ) or are they someting that can be replaced by offerings by H&N or JBS?

Items include

Beeman silver arrow pointed .22

Beeman laser pellets .177

Beeman laser .22

Beeman silver arrow pointed .20

RWS Hobby .22

Beeman crow magnum .22

Beeman ram jet .20

Beeman perfect rounds .177

RWS superpoint .177

Containers are sealed. Colors have faded some a few have scratches and dents.

Alex,

Worth aside, I would take new pellets over old pellets any day. If any old designs were “magic”,… they would still be around. You might find someone (collector) that would buy the whole lot.

Chris

Alex,

A few years ago I gave my friend that has a airgun shop and a reloding shop, same store, a box of paper shotgun shells in most all calibers under 10 gage. I had hoped he could make a little off of them. I was in his store a couple weeks ago and he still had most of them and the price was down to a dollar or two apiece.

So I would not expect too much on the pellets.

You seem to have a DIY attitude, with some study and safety in mind think about doing the reseal yourself. And maybe some TIAT for the tune.

Don

BB

Off topic question.

I have seen people here on the blog say they add a drop or two of silicone oil when they are airing up their pcp’s, but I don’t recall hearing you say that.

Is it something you would recommend?

Pete,

If it is silicone chamber oil, then I do recommend it. But not with every fill. Maybe once every 6 months or so.

BB

BB,

Can the Almaguard be used to reduce hammer/striker bounce in my 2240 and my Avenger? My 2240 has a boss max valve and the force is too much for a simple plastic hammer debounce device. Would I coat the striker lightly with it? I could sacrifice a little fps/fpe. In the Avenger, it might give me smoother shots at high regulator pressure.

R. Scott,

I don’t have a clue, but it’s worth a try.

BB