This report covers

- BB is no grease expert

- Moly grease

- Moly that’s not good

- Petroleum-based grease

- When to use grease

- BB greased the train tracks!

- Lithium grease

- Tune in a Tube

- Summary

Today we will talk about grease and how it relates to airguns. Reader CptKlotz, who is Stephan from Germany, asked about the grease I used on the Benjamin 397 trigger parts and I said I would write a report on it. I told my neighbor, Denny (Sawdust), and he said he would be interested in learning more about grease, too.

BB is no grease expert

I’m learning this stuff as I write this one. I know a little about grease, as it applies to things like wheel bearings and airguns, but I am far from being an expert. My research for this report taught me a few things.

First off — don’t Google Grease or you will get page after page of references to the movie that starred John Travolta and Olivia Newton-John. You have to put the word lubrication next to grease to get anywhere.

Grease is a solid or semisolid lubricant made from a liquid lubricant and thickening agents. It has high viscosity until shear (pressure) breaks it down to form an oil-like substance. I said when I lubed the hammer of my 397 that I wanted the oil-like part of the lithium grease that I used because I didn’t want the semisolid grease to slow the hammer down.

The most common type of grease consists of soap used with something like mineral or vegetable oil mixed to make an emulsion (two liquids mixed to form something called a colloidal suspension). But sometimes the mixture is a liquid and a solid. Let’s start there with something called molybdenum disulphide.

Moly grease

Moly grease is a mixture of a dry solid particle, called molybdenum disulphide, suspended in a grease (yes — that is another emulsion) “vehicle.” In this instance the term “vehicle” means something that the moly particles are mixed in that helps to spread the solid particles around. You see — not all moly comes as a grease.

Moly by itself is a dark gray powder that can be spread directly on metal parts to which it bonds and forms a super-slick surface. Several decades ago I went in with the Springman, Jim Maccari, and we split an order of moly powder. I ended up with a 10 ounce jar of this dark gray powder that works just as I have explained and am about to show you.

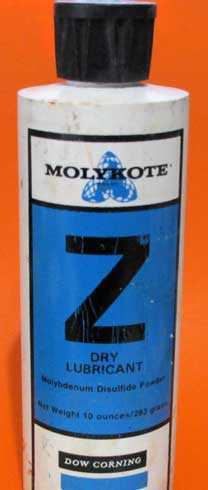

Moly powder bottle.

Moly powder.

A cotton swab is rolled in the moly powder and picks up just the right amount.

My steel back scratcher will serve as the metal surface.

0

The dark spot in the center is where the moly powder was burnished in with the cotton swab.

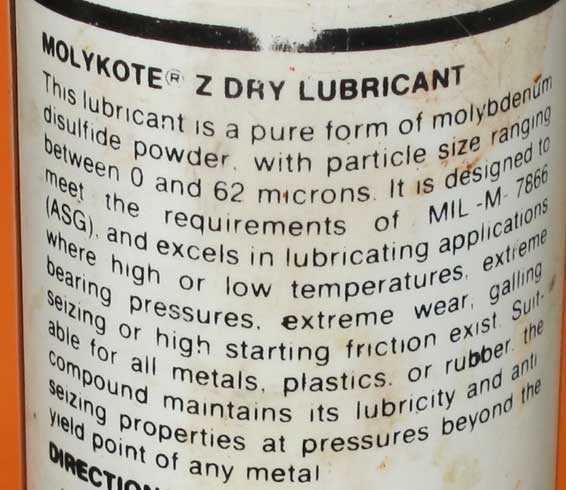

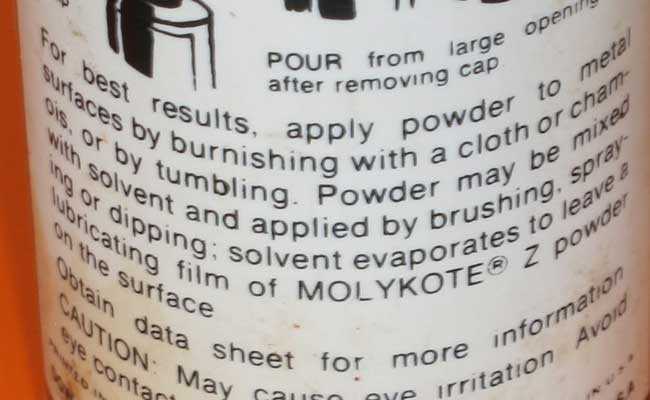

Let’s read the directions.

That’s what moly is and that’s what it can do.

And that is how it is applied.

So the moly grease we buy is moly powder mixed with grease so it will apply easier. The more moly particles in the grease, the better. I bought the powder in case “they” ever stop selling moly grease. I’ll make my own by mixing the powder with white lithium grease.

Moly that’s not good

Years ago Beeman sold a moly that was suspended in a solvent vehicle. It was called Dri-Slide. The solvent removed all lubrication from metal surfaces and promoted rust. I rusted several airguns with the stuff before learning not to use it.

Petroleum-based grease

The most common type of grease is petroleum-based. Most shops have this kind of grease on hand because it is used so widely. What is used to thicken it determines what it is to be used for. While these greases may have started as oil, their thickeners turn them into the products they become and they no longer act like the oil that’s in them.

When to use grease

Oil works well for lubrication. Why would you use grease instead of oil? One word comes to mind — viscosity. Grease stays put for many years, where oil eventually runs off, leaving the metal parts without lubrication. So you grease parts that are never or infrequently oiled. I’ll give you an example.

Greases labeled EP are for applications where extreme pressure is anticipated. And the center bearing of a train’s freight car truck (where the train’s car wheels are held together under the freight car) comes to mind as one of the hardest applications for grease. It’s not a place that gets greased that often and the pressure must be enormous!

The center plate of a rail car truck (arrow) connects the wheels to the car. It doesn’t get greased very often and it bears a lot of weight.

Several special dry “packages” consisting of a steel ring inside a grease-inpregnated plastic envelope are tossed into the center plate when the car is lifted off the truck. Imagine just how often that happens! Probably only when they need to change the graffiti on the side of the car.

The steel ring inside the envelope is a softer steel than the center plates of the truck and the car, and it wears away over time. The grease is there to do its greasy thing, but without that steel ring the truck would have to be greased a lot more frequently.

BB greased the train tracks!

When I worked at Frontier Village amusement park in San Jose, California in the late 1960s, I was Casey Jones for a time. That meant I was the engineer who ran the railroad. We had about a 1.2-mile track and the train hauled up to 80 people around the park on each trip.

Every morning my first job was to polish all the brass poles on the merry-go-round and after that I had to grease the rails for the train. On the curves I applied a thick grease to the inside rail of the curve — the part where the wheel flange stopped the wheel from leaving the track. That was every morning. It kept the wheels from squeaking as they rubbed against the track.

I remember one day it was misting (it doesn’t rain in California) and after I greased the tracks I couldn’t stop the train. I applied the brakes at about 2-3 m.p.h and instead of stopping in 100 feet it took 500 feet to stop. I slid right through the station when I arrived after a trip. When it happened old BB said some bad words and he forgot that he had the push-to-talk button on his microphone pressed! Bad BB! Potty-mouth BB!

Lithium grease

Now that you know what grease is — a colloidal suspension of two liquids — what of it? Well, if the place we want to grease won’t be under extreme friction or subjected to water, other greases work best. Lithium is the basis of many greases and white lithium grease is a favorite for airgunners. You can get it at any automotive store or hardware store and it isn’t expensive. It won’t handle the same shear force (pressure) that moly will, but for many applications it is good enough. Most imporantly its lower viscosity doesn’t rob any motion, which to us means velocity.

For springers like lower-powered Dianas (the 25 and 27 come to mind) lithium grease is great for almost everything. It does soak up some vibration that moly grease doesn’t, and it lasts for a long time. Remember, grease is just a way of getting oil to remain in place.

Tune in a Tube

Wheel bearing greases have improved over the years and we are reaping the benefits. Almagard 3752, which we know as Tune in a Tube, is one example of a very high-viscosity wheel bearing (and many other bearings) grease. It is water-resistant (something lithium greases are not), and resistant to heat, pounding and slinging, plus it doesn’t harden over time. And it reduces vibration like no other grease I know of.

It contains Almasol, a solid wear-reducing additive that handles heavy loads, resists chemical attacks and can handle heat up to 1,900 degrees F. It forms a microscopic layer on metal but does not build on itself, so tolerances are maintained.

It also contains Quinplex that resists impacts, has high tackiness and is water-resistant. It helps forming a barrier against corrosion.

Yes, you can buy Almagard in 14-ounce grease-gun tubes, but Tune in a Tube is a little cheaper, plus it comes with its own applicator. For the hobbyist it’s the best deal.

Summary

I have touched lightly on greases today. I haven’t even addressed things like medical-grade greases or food-grade greases. Nor have I mentioned petroleum jelly like Vaseline, which, strictly speaking, isn’t grease at all. I’ve tried to stick with the greases that airgunners might use.

B.B.

Da Grease, the degrees….

-Y

B.B.,

Channel Grease; aka Ocean Grease!

https://infinitychannelswimming.com/product-category/ocean-grease-anti-chafing-lubricant-for-open-water-swimmers/

A light touch is required for application and you better not get any on your goggles!

Made with Lanolin (Wool Fat) Titanium or Zink Oxide and a base of various types.

shootski

B.B.,

Great intro into greases. You may still have to touch upon silicone grease for the PCP users. I’m sure it was an old hand that told you to grease the tracks. I can’t imagine you coming up with the idea of greasing the rails unless you were wearing your Bad Bart hat!

Siraniko

PS: Section Petroleum-based grease 1st paragraph 2nd sentence, “Most shops have this kind of grease on hand because iot (it) is used so widely. ”

Section When to use grease 3rd paragraph 1st sentence, “Several special dry “packages” consisting of a steel ring inside a grease-inpregnated (impregnated) plastic envelope are tossed into the center plate when the car is lifted off the truck.”

Section Tune in a Tube 2nd paragraph 1st sentence, “It contains Almasol, a soild (solid) wear-reducing additive that handles heavy loads, resists chemical attacks and can handle heat up to 1,900 degrees F.”

Siraniko,

Fixed them. Several corrections I made after scheduling were not made by WordPress. But I fixed them.

BB

BB,

thanks for the report. CptKlotz agrease.

So comparing “moly grease” with “lithium grease” is really a category error as a product could well be both.

I have Liqui Moly LM-47 “long life grease” (with MoS2) here which seems to work well enough for many things. I checked the datasheet but I think it only says that there’s MoS2 and graphite in it, not what the base grease is.

BTW, isn’t it funny how every job, no matter how crummy, teaches you *something* if you pay attention? The same goes for almost every hobby, too.

Kind regards,

Stephan

Stephan,

I have learned sooo much from messing with airguns and learn something more every day. Spring mechanics, pneumatics, lubricants, yadayadayada. This is one of the reasons I enjoy this hobby. With this I am able to enjoy shooting and learn something new every day, which is one of my favorite things.

Stephan,

Making a subtle joke in a second language is a real talent! I agrease with you! 🙂

BB

BB,

There is quite a difference of opinions concerning what is the best grease for sproingers. The “recent discovery” of Almagard 3752 or TIAT has been working wonders over white lithium grease in the airgun community, but there are some who have stated it has a low flash point and emits toxic fumes. These others would recommend Krytox or Ultimox 226 for sproingers.

I have one of those cartridges of Almagard. It was a lot cheaper than TIAT and I can reload the TIAT tube until it gives up the ghost. Then I have some large syringes to take its place.

I also have a small container of food grade open bearing grease. Talk about some thick stuff. I have not tried it on a sproinger yet, but I might get brave one of these days.

RidgeRunner,

I believe every grease/lubricant has its place and purpose. There is no such thing as an all purpose lubricant despite what the Snake Oil salesman says. Almagard type greases were mainly developed to be tacky to dampen vibrations. Lithium grease is mainly for long term lubrication. Oils are to be applied to bearing surfaces for maximum slipperiness. I don’t believe oils should be applied to polished sear surfaces of triggers. Am I wrong in what i believe?

Siraniko

Siraniko,

For polished surfaces you need something that lasts. That’s where mol;y comes in handy.

BB

I couldn’t find any specific data but I believe that the pressure on the trigger and particularly the sear acting surfaces must be very high, particularly in a springer. The force is considerable and the contact areas are very small. I suspect that any grease would soon be displaced from those places which is why a dry lubricant like moly works best.

Henry

B.B.,

That’s one slick back scratcher!

(Sorry.)

Michael

Very interesting, Tom. I think my Polaris Ranger and Sportsman use a “Polaris” red waterproof grease that is likely Almagard. I wish someone would clue me in on the type of grease gun (or fitting) that will release easily from the zerk. It is frustrating to struggle while laying on your back and contorting to get the gun in place and pumping. I don’t think the ones with “releases” will get to all my fittings.

BB

I have been asking you to share more of what you know about lubricants and here it is!

Seems the bonding agent mixed with the lubricant is a key component. As an example there is a well known skin product that contains only half the amount of petrolatum found in vaseline type products but it adheres to the skin much longer than 100% petrolatum.

Deck

Deck,

I was going to mention that “personal” lubricant, but I deferred. It ranks as a medical lubricant.

BB

B.B.,

Why do I find myself visualizing Bad Bart trying to stop the train to rob it after he greased the rails and the train bypassing him entirely?

Siraniko

Siraniko,

Bad Bart’s name was Dakota, and he did rob the train in the badlands and made BB walk back to the station barefoot, while he drove the train back.

BB

All this train talk reminded me of my favorite “growing-up days” train adventure movie.

Thanks BB, an interesting read!

Moly powder would be useful to have. On parts where I want low friction but free movement I burnish Moly grease on to (in to) the metal then wipe/polish off the excess (to imbed the Moly) before applying an oil film. Powder would be easier but I haven’t found it for sale.

I heard of a test where they brushed Moly on to the engine parts (one application before assembly) of half of the giant earth moving machines used for the James Bay dam project. After the dam was completed the engines were disassembled and the wear measured. The untreated engines showed the expected amount of wear from heavy use and Moly treated didn’t – for the most part the treated engines were still within “factory new” specifications.

Hank

Hank-

Moly powder is pretty widely available. Search ‘molybdenum disulfide powder’.

Thanks pacoinohio!

Did a search and found some in Canada.

Cheers!

Hank

BB, Since airguns dont work in space, what are we gonna do for fun?

More importantly, what grease do we use for up there?

Surely, they must have a grease for there.

They’ll need maintenance guys for the space casino too.

Rob

That is a question for Marvin The Martian.

Fawlty, I wonder if he puts moly powder on his back scratcher.

It’s ok, whatever works. Pretty much anything works in a low powered airgun like mine.

Rob

Wouldn’t a CO2 gun work in space? Just sayin’.

Roamin Greco,

As would PCPs

shootski

I thought 1stblue was talking about shooting an airgun in space, like on a spacewalk, not inside a spaceship where there is air to pump into the PCP. But I guess you could use up some of your limited air supply to pump into your PCP before going out on a spacewalk to plink at stuff whizzing by. That’s dedication to the sport!

Roamin,

I would think that PCP’s and co2 guns would work fine in space, you would get a boost for not having to push the air column out of the barrel but there may be a lack of accuracy due to the lack of air that would help stabilize the pellet on earth.

An interesting thought, accurate or not the pellet shot would travel forever, well until it found a star planet or something else to crash into.

Mike

Well, you would not need to worry about wind drift or gravity…the trajectory would be more or less a straight line.

Roamin Greco,

Getting picky!

Are we talking Near Space (for billionaires) Space (within the Solar System) or Outer Space?

Near space is pure near earth orbital mechanics so not even close to straight(ish) flight without attaining escape velocity and accounting for Solar Winds. Next you deal with Orbital Mechanics flight which aren’t all that straight either due to Solar Winds, ever changing Planetary and Solar Gravity. And finally, in outer space you will be buffeted by Cosmic Winds…you just can never win!

Airguns just don’t shoot straight! LOL!

shootski

Even more slick than moly is tungsten disulfide. It goes on the same as moly, but works better.

I do not know if it works better, but it is a whole lot easier to say.

Mobilehomer,

Yup!

shootski

B.B.,

Great post; it brought back some memories, for sure; besides working at the SAAB plant, I also worked a part-time (teenager) job running a machine to pack “anti-seize” into small containers.

https://www.manufacturing.net/home/article/13216826/understanding-the-true-value-of-antiseize

At that place, everyone who worked there was allowed a small can, for free, for personal use. =>

Take care & God bless,

dave

Been thinking about 100% synthetic motor oil. What does everybody think? It’s good enough for $10,000 engines.

Jumbo

Several years ago there was a shortage of compression chamber lube for medium/high powered springers. A technician with a well known airgun manufacturer told me to use it if the recommended product was not available. I used it perhaps twice with no ill results. I hope others will comment as I am curious to know their opinions.

Deck

Jimbo

Sorry, spell checker got me!

Deck

Jim,

For a light oil,… I use the Mobile 1 full synthetic 0-20 which is the same thing my ’11 Rav. takes. I suppose desired viscosity is the ruling factor. I would still be hesitant to use it in a PCP or maybe even a springer. I use it in applications like pivot pins and such. Like you said, if it is good for engines,.. it ought to fine for air guns.

Chris

B.B.,

I remember Dry-Slide being sold by ARH – the original. But it seems about the same time I was learning that it was being discouraged to use in air rifle chambers due to possibility of combustion.

Can you tell me anything about dry powder Graphite Lube? I picked up a tube of it somewhere along the way and keep wondering what I could use it for – outside of locks. Do you suppose it would work as an additive to another type of lube?

LMo

LMo,

https://www.nanoslicklubricants.com/services/tungsten-disulfide-powder/

Graphite works but when it is really COLD or HOT and the pressure is out of sight nothing beats Tungsten DiSulfide…not as messy either!

shootski

Shootski,

I noted, with interest, the previous mention of Tungsten Di-sulfide. I brought up the dry graphite powder only because I’ve had it for years and never seem to use it – even for locks. For most everything else, including my firearms, I still have a good supply of RIG products I bought in the ’80s and have supplemented them with a couple of modern products to fill in the gaps. Working on an air gun or fire arm is pretty much a gut call for me as to what viscosity I choose to use. RIG Universal is pretty good all around stuff and I also have the +P Stainless Steel Lube. Remember when stainless steel guns had the problem of galling?

All of my airguns are less than magnum so ARH’s Euro Tar fills the bill for springs. If I need more, for any buzzing, I did get a tube of TIAT. Then I top off any specifics with a small jar of Air Venturi’s Moly Paste. I’m pretty well covered but it does leave that graphite out in the cold.

LMo

LMO,

I have used powdered graphiute on some lube applications, but when moly powder came out I never used it again. I really don’t know how it compares. I do know that it is recommended for keyed locks.

BB

BB

Thank you. Pretty much what I figured. Being somewhat of a cheapskate, I haven’t had the courage to invest in the moly powder. That Air Venturi stuff seems pretty good, tho.

LMo

LMo,

I use the Air Venturi moly grease most of the time.

BB

From the world of firearms, I recall the advice of most gun writers was to simply hose down the action and trigger with something like Birchwood-Casey Gun Scrubber, followed by lighter fluid and then leave the trigger mechanism otherwise unlubricated. In looking for a cite to that advice, I found the following from my second favorite gun (firearm) writer;

“And take care to get nothing at all on the trigger. With an AR, be liberal, and make sure that you do lubricate the trigger with grease, not oil. Geissele recommends ALG Go-Juice 0000 Very Thin Grease, and who am I to argue with Geissele?”

https://www.fieldandstream.com/story/guns/how-to-clean-a-rifle/

My point is, if firearm triggers require very little to no lubrication (essentially a rust preventing film of lighter fluid), with the exception of ARs, whose triggers require very thin grease, what should airgun triggers be lubricated with, if at all? After all, doesn’t a trigger need a certain amount of friction so it does not move when it shouldn’t? Do different airgun triggers need different types of lubrication or maintenance? Dors it matter if the airgun will be used in very cold temperatures? No disrespect to B.B. or anyone else’s views, but I wonder what would an airgunsmith recommend?

Roamin,

As Siraniko pointed out, there are thousands of types of special lube and I (and other writers) cannot possibly know them all. Take a manufacturer’s recommendation, unless you know they are just trying to sell you their own product over other equivalent products.

BB

I’ve had some semi auto firearms that worked better with a little grease on the slide than oil did.