This report covers:

- Specificity

- Edge-latched

- The point

- Crossbow trigger

- Ball-bearing trigger — a different arrangement

- Summary

I had a question about triggers from reader Roamin Greco yesterday. Here is what he asked.

“For some reason, I have been seeing a few of these 45s offered on ebay lately. I ended up with a Diana 35 (Actually a Winchester 435) with two adjustment screws in front of the trigger. How are the 35 and the 45 different, and how are they similar? As I commented before, I fear mine has a broken spring.”

And here is my answer to him, “Roamin, They are as un-alike as two airgun triggers can be. This one is modular. Yours is pieces held together by an outer assembly shell — the spring tube. The only similarity is both of them release the piston.

Today I will explore that with you. It’s been a while since we discussed airgun triggers, so this should be interesting.

Specificity

To have this discussion we need to be specific. I will therefore address the triggers in spring-piston airguns — and, yes, SPRING piston means both coiled steel spring and gas spring. They are both spring-piston guns.

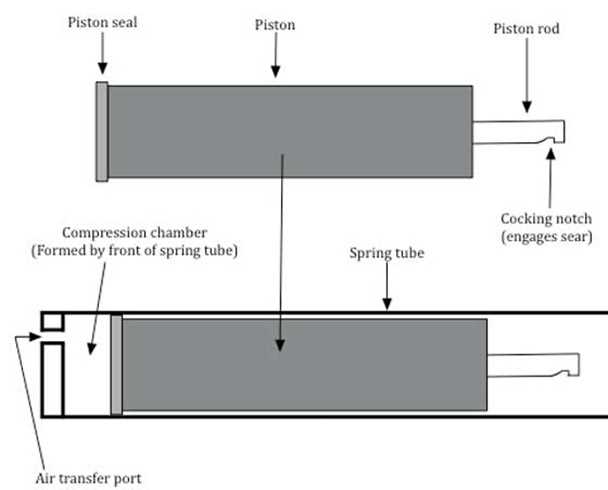

Most airgun triggers work by restraining the piston at the rearward limit of its travel, where the spring, whether coiled steel or pressurized gas, is at its most compressed state and the piston has the longest way to travel. Actually Roamin Greco asked about the difference between the Diana 45 trigger in the airgun I reviewed yesterday and the trigger in his Diana 35 that’s labeled a Winchester 435. I will start with the type of trigger that goes in most spring-piston rifles.

The pistons in spring guns are latched or “caught” by their sears ways that dictate what types of triggers will work with them. Until you understand the differences in piston types, you can’t appreciate why certain triggers such as the Rekord won’t work with certain types of pistons.

A center-latched piston has a rod in its center that in some way gets latched or “caught” by the sear. When it’s latched, the sear restrains the full force of the mainspring. That can be well over 100 lbs. of force in the case of a coiled steel spring, or several hundred psi of gas pressure in the 2-piece expanding cylinder of a gas spring. The sear prevents the piston from moving until it’s released by the action of the trigger.

The center-latched piston grabs the sear with its central piston rod.

A BSA Meteor piston with a center-latched piston rod (arrow).

Don’t think that the piston has to stay in the same orientation for the central latch to work. The piston in a TX200 Mark III is free to rotate on its longitudinal axis, yet still latches on the center of the piston rod.

The piston in a TX200 Mark III latches on the center rod but is free to rotate around its long axis.

Edge-latched

An edge-latched piston latches on the piston’s edge. Well — duh! It just means the surface of the piston that catches the sear is located on the edge of the piston’s skirt and there may not even be a central rod. There can be, but it isn’t used for cocking the airgun. Do I really need to show a picture?

The point

The point of this discussion is that guns with pistons like this have triggers that interact with the pistons in specific ways. And most airguns have triggers that do it this way. For example the trigger of the Diana 45 is one that does.

This is the Diana 45 trigger assembly out of the rifle. The tubular part on top aligns the assembly when it’s inside the spring tube and the two holes on that tubular part are for the two crosspins that hold the trigger assembly in the spring tube against the pressure of the mainspring.

Crossbow trigger

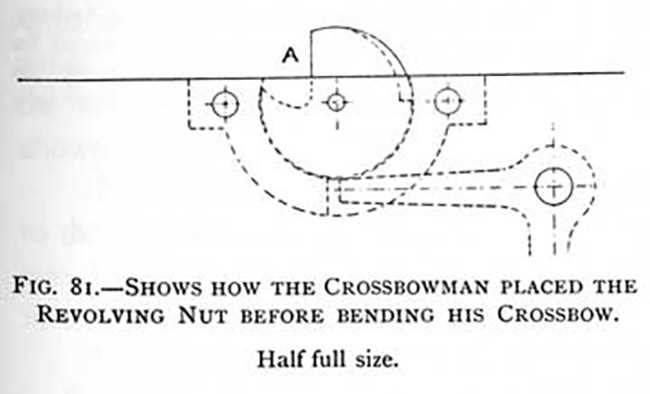

The crossbow of legend — not the ones being sold today, but ones made in the 14th or 15th century, had a trigger made of steel and horn that restrained a force of several hundreds of pounds — sometimes as much as 700 pounds! The bows were made of steel or of laminated animal horn and were extremely stiff. On these powerful crossbows that are often called warbows the archers used winches to draw the bowstring back to the sear that held it.

From Sir Ralph Payne-Gallwey’s famous crossbow book, this illustration of the trigger nut that is the sear illustrates how a vintage crossbow trigger works. That nut is made from animal horn, and the trigger from iron.

Ball-bearing trigger — a different arrangement

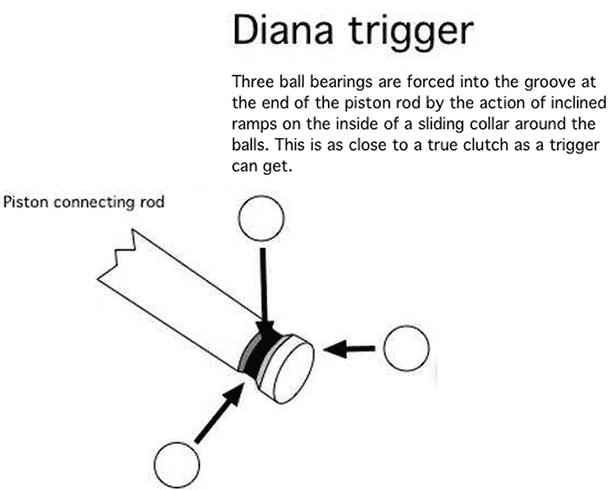

Now we come to the trigger that’s in Roamin Greco’s Diana 35. I call it a ball-bearing trigger because ball bearings are what hold the piston — though they need other parts in order to do so.

These are the principal parts of the Diana ball-bearing trigger. The balls fit inside the black tube through slanted holes, one of which is shown to the left of the long slot. The small spring below fits in that slot and also presses against an edge of the large silver tube at the top left when the black tube sits inside. When the rifle is cocked the piston rod comes back and goes through the center of the black tube, pushing the three balls up out of its way. The dimples seen in the silver tube are ramps that allow the balls to press down on the piston rod and catch it. The trigger releases the silver tube, in turn acting on the ball bearings to release the piston rod to spring forward under tension of the mainspring.

Summary

Whew! I wrote all that in almost four hours of study and reflection. I wrote it just to demonstrate why a trigger like a Rekord cannot be installed in every spring gun.

Then Roamin Greco told me that wasn’t really his question. I read “trigger” into the question when it wasn’t really there. Oh, well. I answered a question no one asked. Silly me.

Next week I hope to answer his actual question that he explained after most of today’s report was written. Here’s hoping I got it right this time!

BB,

Is there any mechanical advantage when the manufacturer chooses the edge latch instead of the center latched trigger? Is one better than the other?

Siraniko

Siraniko,

Edge latching is more of a necessity rather than an advantage. You see it on gas spring guns a lot.

BB

I think that you’ve just convinced me never to disassemble the trigger on my TX200, or on any airgun for that matter. Hey . . . I’m good with Ballistol and a rag. Orv.

Thanks, B.B. I find this fascinating.

Hi everybody,

very interesting topic, whether it was the original question or not 🙂

If you don’t know a lot about guns, you probably wonder what’s the big deal about triggers. They are glorified door handles, aren’t they? 🙂

When you shoot a few guns and look at how triggers work, you start to realise why they make a difference and how much knowledge and skill goes into them:

https://www.youtube.com/watch?v=_BlQRRciXMQ

(animation of the Rekord trigger)

I’m not a mechanical engineer and also weak at math, but it’s obvious how much care has gone into finely tuning different springs and levers to get a device that can a) securely hold a piston with a powerful spring in place and b) release with a light and crisp action.

Given how long the “Rekord” has been around, they also probably did it without computer simulation. But it can still hold its own today…

I think it’s also pretty interesting how different triggers can be (even in spring piston airguns) given that they all have the same purpose.

Stephan

BB

Makes me wonder which came first, the ball bearing trigger or the MG42 machine gun?

Deck

Deck,

Likely the ball bearing trigger. That is probably where the engineers figured out how to lock the chamber and bolt together. Having said that, I could have it backwards. Like you said, which came first?

Many of today’s triggers are considered two-stage triggers. The trigger acts upon a “lever” which is restraining the sear, which is restraining the piston. I think I got that right.

Many of the triggers around here at RidgeRunner’s Home For Wayward Airguns are single stage direct sear triggers. The trigger itself is the sear. Some of these are very nice. It depends on the angle of the engagement and the amount of engagement. Some of the older gals around here have adjustment screws where you can set the amount of engagement. There are some single stage triggers around here that are absolutely horrible. They have miles of jerky, creepy engagement and no real way to adjust them. They are in need of a lot of work.

The Webleys around here have a unique trigger I consider a single stage, but work different from most. The pistons come toward you when released, so the sear holds the piston forward and the trigger pushes up on a lever which is part of the sear, moving the sear point down, releasing the piston.

WARNING! The contact points of the trigger assembly are hardened. Any filing/sanding/polishing can remove the hardened layer, exposing soft metal which WILL fail to hold the other parts in place, which WILL allow premature firing. Believe me, you do not want that. I recently acquired a Webley Junior which had a brand new unhardened sear. It only took a few shots for it to wear out totally and now will not restrain the piston. I have another brand new sear which I will harden before installation.

RR, how do you harden a sear, and if one would polish or stone a sear, in order to reduce the creep found in a cheaply made airgun, would one not need to re-harden the remaining metal?

Roamin,

The short answer is yes, you would need to restore the hardness.

Two possibilities (the long answer 🙂 )…

If the part is made from “tool steel” it has sufficient carbon that it can be annealed (softened for easy shaping); hardened (full hard and brittle) or tempered (the full hard state modified to be less hard/brittle and more usable) restoring the hardness is easy.

Many parts are stamped out of (inexpensive) low carbon sheet metal then treated (“case hardened”) to form a hardened layer on the surface. Any grinding will remove the thin hardened layer exposing the soft metal underneath.

In the first instance, you can harden and temper a tool steel part if you have a propane torch and a can of water (for hardening) and a can of oil (for tempering). Lots of info on the web.

Case hardening is a bit more involved. Basically the part is coated with carbon, packed in an airtight container and “baked” to transfer the carbon to the metal. It’s not rocket science, I’ve case hardened parts using wood charcoal, a ceramic flower pot and my wood stove.

Cheers,

Hank

Thanks, Hank. It is so interesting that our hobby packs in so much science. From fluid dynamics to metallurgy!

Roamin Greco,

As. a kid growing up in Philadelphia my best friends dad was a salesman for a foundry selling their forging services to the military and heavy industries manufacturers. He often took us along to places to learn about new things. You caused me to remember one of them with your post:

https://www.metlabheattreat.com/metal-hardening-metal-quenching-metal-tempering.html

This place has been in the business for a long time and has a resource page about your topic of interest. I was surprised that they were still in business; looks like new owners.

From what I remember of our visit it is a combination of Art, Science and skills way beyond my ken; I would leave it to professionals with the equipment and experience on something as vital as a safe/functional trigger.

shootski

Everyone,

When I worked at AirForce I interacted with the heat treater for case-hardening the trigger parts. After heat treatment I would spray on a molycoat film on all the parts and then bake it on in an autoclave set to low temperature..

The minimum depth specification for the case was 0.015-inches. That’s why stoning the parts doesn’t work. And filing doesn’t work either because the parts are harder than a file.

BB

Agreed. Certainly not the parts to dabble or tinker with, without a level of expertise.

RG,

I would recommend using moly grease first. It will not take much, just coat the contact points. The moly will infuse itself into the “rough” spots and smooth things out a bit.

Many of the modern “cheap” airguns utilize quick and dirty engineering in their design, most especially the trigger assemblies. With the “old gals” they used machined steel and a good bit of engineering. Some of the single stage triggers around here put many modern two stage triggers to shame.

These old gals were quite expensive in their day. My 1906 BSA is a prime example. People used to form shooting clubs, usually about ten people, pool their money and buy ONE of these BSAs to share. The average working stiff could not afford it. I picked this thing up for almost nothing. It would cost thousands to make this air rifle today.

You can only do so much with a sow’s ear.

There is a perpetual search for the friction less trigger. The usual route is the use of rollers and or ball bearings but almost always this leads to trouble. The Canjar trigger used a ball bearing to trip the sear and it was very popular among Powder burning bench rest shooters in the seventies . I had one in a Winchester Model Seventy “Bullgun” set up for NRA Across the Course shooting. Seems that after a while wear on the ball bearing and sear would induce a situation where the sear would release when closing the bolt . I loved the trigger but the company went under and parts were not available. I have had similar experiences with triggesr that utilize rollers and ball bearings and vowed never again. Triggertech is the hot hand now in PB but they use rollers, I wish them well. Ball baring release aids for bows will create a flat spot on your bowstring that will not allow the release to hold and will launch your arrow at about 3/4 draw. At the point of releasing the sear just give me two flats slipping on one another thank you.

SSC, my Winchester 435 made in 1971 has a sweet trigger release. It’s older than me. But I take your point. My Beeman R7 with the Rekord trigger is still sweeter!

RG,

That R7/HW30 is a sweet air rifle! Not only is that Rekord trigger nice, but the air rifle itself is very interesting (accurate). You would be hard pressed to find a better shooter for short ranges, even in PCP. You would have to go way up in price. That Rekord trigger makes me want to expand my Weihrauch collection.

I know what you mean.

😉

There is another spring piston airgun that has an entirely different trigger action. The Daisy 1894 Spittin’ Image Lever Action copy of the Winchester Rifle.

All the trigger did was slide out from under the hammer releasing it to strike the cocking linkage that held back the piston assembly. Literally knocking the lever down and out from under the spring plunger and releasing it. Totally simple operation.

A hook on the cocking lever engaged the spring piston and pulled it back half way then another spring loaded lever attached to that cocking lever popped up under the piston assembly and continued the rearward piston movement and held it back like a sear as the cocking lever was returned to its stowed position.

By the way , that is not an original Daisy 1894. It’s a highly modified Winchester (Daisy) version that came out much later with a wood stock. I converted it to operate the same as the original. They changed everything and the new trigger actually held back the piston and had to be pulled out from under it. Super hard to pull.

Bob M,

That trigger is in the zone between the single stage and dual stage triggers. It is initially a single stage trigger, but having the hammer strike the sear sorta kinda moves it into the dual stage triggers. It sounds like the engineers took an existing trigger assembly for a lever action PB rifle and modified it to work on an airgun.

RR

I see where you are going with this. The hammer just replaces other linkage to release the sear…. or ? holding link ?

Unfortunately hammers are not included in the trigger mechanism. Part of the firing mechanism, yes. They are released by the trigger to allow the hammer to perform its job, independent of the trigger once released.

In this case the trigger is totally removed from sear movement and is just the first step in a series of events.

I would call it a two stage ‘firing or piston release mechanism’ consisting of a single stage trigger that releases the hammer and a hammer that strikes the cocking / sear link that holds the piston assembly.

Otherwise a Flintlock would also be considered a two stage trigger….perhaps a three stage trigger, adding the creation of a spark.

Heck how about a four stage adding the trigger set.

But yes I see your line of thought. Another stage could be removing the rifle from the safe and putting it in your hand. Necessary to pull the trigger… Properly 😉

“Oh, well. I answered a question no one asked. Silly me.”

B.B.,

This is not silly at all; I predict it will be a great reference for future airgunners. 🙂

Take care & God bless,

dave

Definitely not a silly walk thru the subject – FM even learned a couple of things, one of them being to leave triggers alone except when pulling them to fire.

B.B.

Bummer I am traveling and can not devote the proper attention that this topic deserves. I sure hope it is a multi-parter?

Next to barrels, maybe even more so, I believe shooting enjoyment comes from having a terrific trigger. When you say, “I can work with it”. I hear fingernails on a caulk board.(remember that?). What you are saying in that the trigger is poor, just not horrible.

Have a great weekend,

-Yogi

Yogi,

I have to agree with you on both the chalk board and the trigger. I have pulled too many nice triggers to waste time getting used to a poor one. Having said that, I have pulled some like BB describes this way. Many new sproingers have triggers that would disqualify the airgun from living at RRHFWA, but many newbies think they cannot afford airguns with nice triggers. Many of these newbies do not realize what a nice trigger is. If they can get a sproinger trigger that is not hurdy, gurdy, jerky and is predictable in its release, they are quite happy and can do fairly decently.

You and I are spoiled. Hi, my name is RidgeRunner and I am a trigger snob.

BB,

I was hoping that you would address my question about the Model 45’s two screws and their purpose in this report. Will you be addressing that when you return to the 45? I’m especially curious about the one that is painted to prevent/detect? adjustment.

Half

Half

Half,

I don’t know the purpose of that second screw — for certain. But I believe that is adjusts the amount of contact the trigger has with the sear. Why else would Diana have made it impossible to adjust?

And now that I have taken a lot of ten sion off the trigger spring adjustment, the second stage breaks as crisp as glass. So Diana adjusted this one correctly.

BB

BB,

I am catching up with your blogs after a pause mandated by travel/family/work duties. Although late, I want to thank you for this great article on triggers. I learned a good many years ago the difference between a good one – generally machined from tool steel – and a jerky and heavy bad one – stamped metal mostly. These are not absolutes, there are exceptions.

Looking forward towards the next installment.

Henry