This report covers:

- Mr. Jelly Chuck

- Point one

- Point two

- The Original Buegelspanner

- The parts

- Learned a lot

- Other stuff

- Summary

Today I am cleaning my blog house. I find myself with a bunch of lemons and it’s time to make lemonade.

Mr. Jelly Chuck

Mr. Jelly Chuck

I wrote about this two times. The first was in the report titled, BB needs your help. I couldn’t think of a reason to buy a target like Mr. Jelly Chuck and was hoping some of you could. But you all thought it was sillier than I did.

The second time I wrote about it was in a report I called Mr. Jelly Chuck: Part One. Well, there ain’t gonna be a Part Two, because when I returned from the Pyramyd Air Cup in August, Mr. Jelly Chuck was taking a permanent nap. The daily temperature where I live in Texas ranged from 108 to 113 degrees F (42.22 to 45 degrees C) and for the week I was traveling I set my house air conditioning to 95 degrees F (35 C), to save on electricity. That did happen but it put Mr. Jelly Chuck to sleep.

A week at 95 degrees put Mr. Jelly Chuck to sleep — permanently!

In the photo above the flat bottom Mr. Chuck used to stand on has widened into his bottom right side that melted. When I returned home Mr. Chuck’s head on the right was stuck to the wall next to the table he was standing/sleeping on.

Point one

Mr. Jelly Chuck was never a good idea. He was a $19.95 target that sold for the bargain price of $73. But at least he didn’t last very long! Not in the Texas heat anyway.

Point two

There were very few good ideas of how to use Mr. Chuck — assuming he lasted. His outside was uneven so he wasn’t the best for penetration testing. You could see the pellets inside him, but because of the rough outside you couldn’t see them clearly. So, as ballistic gel, Mr. Chuck needed to be melted down and cast as a brick with smooth sides. You know, I believe such things are even being made and sold as ballistics gel blocks today! They sell for less than $70 and do more than the Jelly Chuck does.

The Original Bugelspanner

I’m BB Pelletier — I can fix anything. That was what I told myself when I took my Tyrolean Bugelspanner (triggerguard cocker) dart gun apart. It turns out I can fix anything — except the stuff I can’t fix!

My Tyrolean Bugelspanner dart gun. This is the last time I saw it together, which was sometime in 2013.

This Bugelspanner is a .25-caliber dart gun. It was made between the turn of the 20th century and about 1940. It’s a breakbarrel single shot.

The mainsprings are cocked by a single downward stroke of the triggerguard. Then a lever on the side is pushed and the barrel tilts forward for loading.

The triggerguard is up when the gun fires.

The triggerguard is the end of the cocking lever. Here the gun is cocked.

The parts

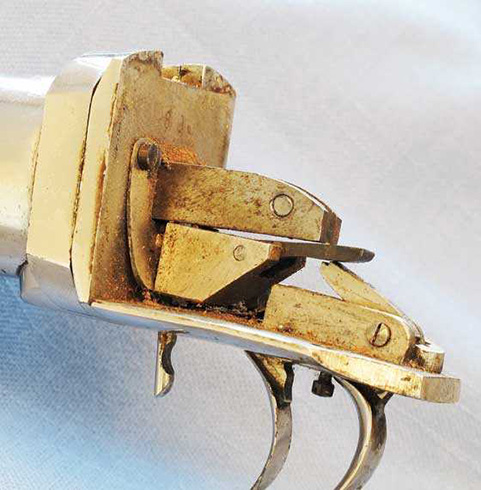

Inside the Bugelspanner there are a lot of parts. The double set trigger alone has plenty of them.

The double set triggers may look simple, but they are scary complex!

The trigger plate has a dovetail at its front that grabs the rear of the cylinder and holds the powerplant together. The cylinder back plate (left in the photo) is held between the 2 parts. The black part that’s flopping down on the back plate is the sear.

The leather piston seal has deteriorated. It looks okay, but it’s crumbling and flaking off.

Double volute springs attached to a central guide for the mainsprings of the Bugelspanner. They’re in good condition but very dirty and dry

Learned a lot

Disassembling the Bugelspanner taught me several things. For instance I know to never do it again. I know to recognize when I’m over my head and to not take on the project. And I know how to store disassembled airgun parts for years until I find someone who can do something with them. Yep — I learned a lot!

Other stuff

I have other projects laying around. The HW 54EL that I showed you the other day now has its Rekord trigger removed and I discovered why the trigger blade was broken. Some hotshot “airgunsmith” got into that trigger and “gunsmithed” it — by which I mean he destroyed it by stoning the parts and lubricating them so the trigger may never work again. To get the 54EL working I will install another Record from a donor gun until I can either correct the damage to this Rekord or buy a replacement trigger.

Summary

What I have shown you today is what’s behind the curtain and in little piles everywhere in my house. When a gas spring rifle decides to bleed down it becomes a new pile somewhere. I usually show you the stuff that works. Today you saw some of the stuff that doesn’t.

“Some hotshot ‘airgunsmith’ got into that trigger and ‘gunsmithed’ it — by which I mean he destroyed it by stoning the parts and lubricating them so the trigger may never work again.”

BB,

That is just plain sad! But it’ll be really cool if you can get that ol’ gal shootin’ again.

Thanks for the look “behind the curtain.” 😉

Blessings to you,

dave

BB,

Since I tune everything I buy and help to do so for friends I have sometimes similar said moments. It is just like this – something won’t work, and it will break first against all logic, to not work at all.

Good news at the end: I decided to replace everything in my FWB300s. I did it! Everything is brand new inside now. It is sooo smooth and just beautiful now! I’m delighted. I communicated directly to my wife: “look babe, I save at least 3k EUR at the weekend! No need to buy a new match airrifle anymore”. She told me directly like a ricochet: “you are not alone, I saved at least 500EUR today. I did not buy this brand new dress”. Yes… she is a hard opponent.

Tomek,

Good job repairing the FWB300S! Glad it worked out. They are a most splendid air rifle and a wonder to shoot. It’s clear to see why everyone loves them.

I took shootski’s advice and shot all of my air guns to keep the gremlins from settling into the lesser-used ones and the 300S was gorgeous.

Have fun,

Will

Thank you Will 🙂

I thought it is much harder to dismantle it. To be honest with some tutorial where you can see some tricky moments there is actually zero stress about it at all. Now I’m really happy and there is a difference also on the target grouping. At the end it seems to be that Tomek is not the worse shooter you can imagine 🙂

My lessons learned: belive in your skills and do it. Without overthinking.

Will S.,

shootski has NO cloths!

I hadn’t shot my Benjamin Discovery (№28) in way to long as well as my 1st Generation Marauder (№9) so now i get reseal my Discovery and already replaced the O-Ring on my Foster fill fitting on the Marauder.

I blame it on the kayaks, DAQ Big Bore airguns and the SIG ASP20s; but in my heart I know it was all my own DERN fault!

I will do better in the future all my air pistols are happy after this weekend ;^)

shootski

Shootski,

You really have me worried now. I may have lots of great looking useless airguns in my collection.

Most of my free time is at night and I hate putting off high priority projects to have fun.

Considering exercising one or two airguns a day instead of starting an overwhelming project.

Perhaps a new ritual with my morning coffee.

Bob M,

It doesn’t need to take all that long ;^)

Just bring out more than one or two in the same caliber and powerplant type/power level at a time.

That’s my plan from now on…LOL!

you got this!

shootski

Tomek,

Well done. Your wife will just have to not buy 5 more 500EUR dresses to match your 3k saving!

By the way, where did you source the spare parts for your FWB 300s?

The breech seal is starting to crumble in mine, so the old gal is due a makeover.

Bob,

There is a possibility to buy directly from Feinwerkbau, you have to visit the homepage and check the explosion schematics for part numbers which you need to order. They are still produced and there are also many manufactured seals you can buy. I would suggest sticking to the original Feinwerkbau parts (green color seal) as they match and the quality is superb.

I bought the complete set in one of the airgun online shops:

https://www.waffencenter-gotha.de/shop/ERSATZTEILE-Spare-Parts/LUFTDRUCKWAFFEN/HERSTELLER-MODELL/FEINWERKBAU/Feinwerkbau-Modell-300-300S/-Verschleissteile-Reparatur-Set-2-Standard-F-unter-7-5-Joule-FEINWERKBAU-300-300S::3589.html

I don’t know if this link will work…

https://www.waffencenter-gotha.de/shop/ERSATZTEILE-Spare-Parts/LUFTDRUCKWAFFEN/HERSTELLER-MODELL/FEINWERKBAU/Feinwerkbau-Modell-300-300S:::11_12_614_88_115.html

It is original Feinwerkbau part set. The steel ring for the piston actually you probably don’t need to change, only wash and put a little bit fine grease. But to be honest – once you do all the job to dismantle and wash it clean you can also purchase the steel ring and after that you are sure it will last the next 15 years daily shooting.

The mainspring set was original 46 years old in my 300s, was only few mm shorter than original new. My point is – when you do the job just put all new parts inside, it is not so expensive. There is not much difference in the velocity now, but the working point is superb. This I cannot describe, actually unbelievable.

The system may work without almost any grease, but I don’t like it that way. You would need to make a custom mainspring guide (at the bottom) and cut out the steel original one (which is smaller in diameter than it should be). To avoid any system working noise (I hate mainspring buzz noise) I put some grease on it and the effect is this time like a hammer. The system is so quiet that it makes you wonder if it is working at all!

Hi BB, wanted to drop you an email about one of your old posts. Is it possible to get an email where I can get in touch? Thanks!

Chris,

Write to

blogger@pyramydair.com

BB

LOL! I do believe all of us have such “piles” about. I am presently having a little trouble with a Webley Junior. Hopefully I will get it worked out.

If you were to send me that Buglespanner, I would see if I can get it put back together.

B.B.

Now I know why when I ask about reviewing dart guns, you never respond!

You have bad Karma relating to dart guns….

-Yogi

PS “Wild Kingdom” is making a comeback, time to fix up your dart gun.

Yogi,

… or bad karma about me and dart guns! 😉

BB

BB

Is that Chris above who used to be a veteran enabler on this forum?

Deck

BB

I am curious to know why leaking gas springers are so hard to fix. I’m not aware of any reader that does it either. I don’t fix much of anything but I like to read about how it’s done.

Deck

Deck,

There is a lot of technology involved. Vortek may look at my ASP20 soon.

BB

BB

Hope Vortek can get yours repaired. Somebody out there can do it. My ASP20 in .177 suffered a 50% drop in velocity and Sig paid for shipping and returned it good as new in a few days. I have brought this up before but think there is an opportunity for some current or former Sig technician to service these wonderful break barrel rifles. I then switched to a different pellet and weight that may or may not have anything to do with it.

I tend to stay away from purchasing air/gas springers even though they seem to be slightly less hold sensitive than steel coil springers all else being equal.

Deck

So has the gas ram in the ASP 20 bitten the dust?

-Y

Yogi,

The rifle has definitely slowed down some. I talked to Tom Gore and he said he would take a look at it if I can send him the gas piston.

BB

B.B.,

I look forward to that as future insurance.

Could you ask someone you know at SIG who supplied the OEM gas spring for the ASP20?

shootski

shootski,

I know because I already asked in 2018. Sig built their own gas piston.

BB

B.B.,

You wrote:

” B.B. Pelletier

August 2, 2018 at 9:17 am

Everyone,

This just in from Ed at Sig.

The Whiskey3 scope reticle is a mill dot and the turret is also stepped in mils to keep the match simple. It’s made by Sig’s Electro-Optic division, headquartered in Oregon, and has an infinite warrantee. In other words, for the life of the scope, regardless of the owner.

Sig buys the gas spring. They feel that technology is best left to the experts, so they can concentrate on the things they do best.

B.B.”

Okay! It cannot be both ways so which of you is right? Ed worked there back then. If i was a betting man i would need to bet against you Tom.

shootski

shootski,

I was there but I made a mistake in my answer today.

If you could find that why did you ask me?

BB

B.B.,

I may be a big jerk from time to time but…

I’m not trying to point out errors.

Since i own two of the SIG break barrel gas springers, and as a PCP early adopter who owns no other springer no less, enjoyed shooting them.

Having a source for the most likely to fail part in them is important to me and probably many others.

It took me quite a bit of time to find your comment because i was not certain my memory was correct on your posting of Ed’s answer.

Sorry if it upset you;

just trying to keep information flowing.

I wish Ed or someone else could provide a Part Number.

SIG ASP20 owners would make a joyful noise and give thanks later this month.

shootski

There is an online video of a test/demonstration that is designed to simulate the occupants of the JFK limo and the single bullet theory. The models of JFK and JBC were made of ballistic gel. I seem to remember that they had to keep the models refrigerated and only had a limited time to complete the test once they were brought out into the ambient temperature. What happened to your Mr. Jelly Chuck reminded me of that aspect of the video. And yes, the single bullet theory was demonstrated to be viable in the test.

BB,

Those basket cases you have there are such interesting guns! The ether-assist HW35 is a rare R&D oddball and the beautiful old dart gun with the Tyrolean stock is so intricate inside. They both light up my imagination. Good luck in getting them to work. When you find your round tuit, it will be fun to ride along while you sort them out. It’ll be fine, you’ll see.

I’ve been working on making my IZH MP-61 more accurate and it’s been hit and miss. The spring speed is critical for useful fps, and spring lube can slow it down too much, as you discussed previously. However, it’s fun to experiment. After cleaning the barrel and some careful crown work (eeek!), it can group, which is promising. Chrony testing ahead to check fps stability. Such a goofy air rifle! I really want it to be better than a ten meter can plinker, but I’ll take any improvement that will make the rifle just interesting enough to want to use.

Regards,

Will

Will,

What size groups (5 shot, ctc) are you currently getting with your MP-61 at 10m and 25yd, or whichever distance you normally shoot it at?

Will,

I have the IZ61 too. Since many years without special tuning it is pretty stable. What I did is just put some additional grease on the mainspring and sometimes I put few drops silicone oil into the compression chamber…

What I should do is much more. It has been accurate and stable enough to not motivate me so far – my boys (10 and 6 yo) both love it.

This may help you, please translate in the browser, should be enough to understand the main points to do.

https://zwiatremwlufie.pl/tuning/baikal-izh-61-tuning-po-rosyjsku/

Without “doing nothing” to improve the accuracy what you can do in 2 minutes time: please unscrew the plastic barrel cover (barrel end, on the muzzle) and make the diameter bigger than it is (it helps, the influence of it is gone and accuracy was better after this action).

Rob and Tomek,

Thanks for the input, gentlemen. Rob, I’m shooting groups of 5 shots at ten meters, standing, using a forearm rest, as usual. My average of six sets was .64″ center to center. The smallest group was 1/2″ and the largest, .85″. I’m using a peep sight, with the original front post. The trigger is a joy to use.

Tomek, I was daydreaming of being able to drill out the conical bore at end of the muzzle. I found a shiny high spot in that conical bore that I believe the pellets were hitting after exiting the rifled bore. So I ground it down with a small round stone in my Dremel tool, and I think that improved accuracy a lot. The groups at 10m shrunk from about 2″ to just over a half inch. The bore is visibly off center at the muzzle end, while the conical bore is concentric with the barrel, so things aren’t lined up. I want to give the barrel to my machinist friend to mill a nice, wide, vertical hole with a flat, polished bottom at the muzzle, and see if that will help. Did you drill yours out? I’m afraid to do that.

It was a dark day with light rain yesterday, so I didn’t use the Chrony to determine pellet speed. But I will come back to this post and put up the results soon.

I cleaned the compression chamber and rubbed some moly paste into the walls of the chamber and used just a little white Lithium grease on the spring and the body of the piston, so it’s almost dry. This would hopefully maximize the piston speed and it might give me close to 450 fps at the muzzle.

Right now, I can just about take a sip of coffee after the shot and before the pellet strikes the target at ten meters. Just kidding, but it shoots slow.

The piston seal fits the chamber fairly easily; it’s not a tight fit. I think it’s a correct fit. The parachute seal is pliable and not hard, so it should seal well. If the pellet speed is stable, then the seal is good. We’ll see!

Regards,

Will

Regarding the IZH status, the Chrony tells the tale:

269.3

261.7

266.3

232.3

226.2

The gun is shooting at about half the speed it should and has a falling velocity trend.

The piston seal leaks…well! It leaks well! Maybe it’s too dry. Some pellgun oil might help. Else I need a new seal. Thanks for your interest.

Regards,

Will

Will,

I only made a bigger bore in the barrel-end-stop plastic cap. The barrel itself I left alone as it seems to be pretty good crowned. The accuracy is better after this action because the bore in the plastic end-cap was not made central and was a bit too small (it casued some turbulences at the muzzle). I found the effect to be enought to do nothing else. The velocity after I put some silicone oil into the compression chamber stays pretty stable at the level of approx. 460FPS with 7.5grain pellet. I found it stable enough, accurate enough and fast enough for the purpose of general plinking. It is a very robust airgun (survived many dry shots, fall down the stairs etc.). I did not say the last word yet, the time to dismantle and tuning will come 🙂 But it is just good as it is now, gained my respect because of its durability so far. It is not buzzling and that is the mean reason why it was not dismantled so far 🙂 Tomek does not like the buzz.

BB,

Your experience brings my old proverb to mind:

If it’s not broke, fix it till it is.

jumpin

jumpin,

That’s a proverb I have down pat! 😉

BB

BB,

Fortunately, I don’t have too many boxes of parts pending reassembly. 😉

It’s satisfying to do your own maintenance and modding can be fun if you’re into that kinda thing but I always think about the sign posted in the local repair shop…

$50/hour – standard rate

$100/hour – if you fixed it and it doesn’t work

$200/hour – if you tried to fix it and all the parts are in a box

Cheers!

Hank, I love it; that’s hilarious! 😉

Not entirely off topic. I’m looking at an old FX T12 FT in a pawn shop. They claim it shoots,, but I don’t know for sure yet. It has an adjustable cheek piece and appears to be walnut, if that would help date it. Does anyone have any experience with this rifle. Looks like there are seal kits available, if it should need resealing. I don’t want to get it and find that it ends up in my pile of unfinished projects. If anyone has one or has had any experience , I would appreciate any advice or warnings. Thanks

I read a few of the reviews of that rifle. There was one for sale at AoA some time back IIRC. Considered a simple and reliable rifle. Early ones had a peening problem on the valve. I would buy one at a good price in a pawn shop, they had a good reputation for being accurate.

Thanks, I appreciate the information.

FM has his little pile to work on but has not found the required Round Toit to get started. It’s a combination of fear of failure, inertia, procrastination and buzzing honeydoos.

Good morning

Should WordPress be added to the list of the stuff that didn’t work out?

Bill,

That Word Press falls under the:

If it’s not broke, fix it till it is.

Rule!

shootski

I don’t know why I’m still awake, but I’m glad I was to read your comment. Ha-ha!