by Tom Gaylord, a.k.a. B.B. Pelletier

This report was requested by blog reader Rob 8T2 and seconded by a number of others. I reported on the spring piston forward spring guide that’s known as a top hat, and he wondered if I was also going to talk about the AirForce top hat. Though they share the same name, the two items aren’t connected in any way. One is a spring guide, and the other is an adjustable valve stem for a pneumatic valve. The adjustable valve stem draws its name because, like the forward spring guide, it also looks like a gentleman’s top hat in profile.

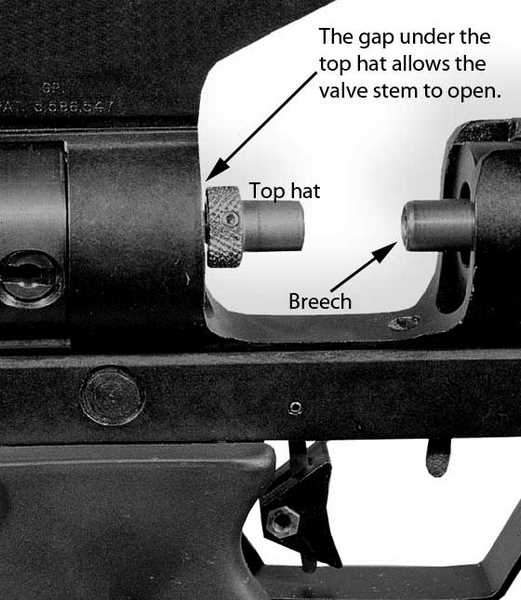

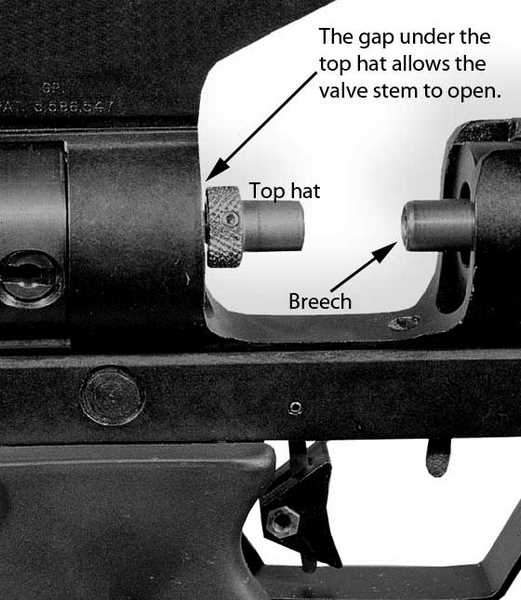

The sliding breech cover has been pushed forward, cocking the striker and revealing the breech for loading. This is the original valve from a first-generation AirForce Talon without a power adjustment wheel.

To understand the AirForce top hat, we have to go back in time to before AirForce Airguns air rifles had power adjustment wheels on the left side. In January 2000, I reported on the new AirForce Talon, the first air rifle to be offered to the U.S. market by the new AirForce company. But I’d already owned the rifle I tested for two years. I bought it from the UK company, GunPower, in 1998, when it was configured differently and sold as their Stealth rifle. In late 1999, AirForce Airguns sent the parts to reconfigure my rifle to their new Talon specification, with an 18-inch .22-caliber barrel.

By that time, I already had many hours of testing and shooting on the rifle in its original Stealth configuration with its 12-inch barrel. It was during that time, by talking to AirForce owner and creator John McCaslin, that I learned how to adjust the top hat of my rifle to change the power.

You may find it amazing to learn that I could adjust that rifle to fire from 65 f.p.s. all the way up to 950 f.p.s. with 14.5-grain Eley Wasps. In truth, any velocity below about 400 f.p.s. was just a parlor trick. The rifle could do it, but all consistency was lost. From 400 to 950, though, it was fairly consistent.

How the top hat power adjustment worked

Power was adjusted by screwing in the top hat to shorten the valve stroke and the valve dwell time (the time the valve stayed open). The valve stroke became shorter because the wide flange at the base of the top hat contacted the top of the valve body and stopped moving. Then, the valve return spring started pushing the valve stem closed again, aided by the high-pressure air inside the reservoir.

Conversely, a longer valve stroke meant more dwell time and more air flowing out. At some point, however, the pellet left the 18-inch barrel, and the longer valve stroke stopped having any additional influence. Once the pellet’s out of the barrel, no amount of additional air can push it any faster.

To loosen the top hat for adjustment, unscrew a tiny 0.050″ Allen screw in the large knurled bottom flange of the hat, allowing it to turn on its threads. Once the desired clearance was reached, the small screw was tightened again. This screw caused problems because enthusiastic owners were over-tightening it, causing it to put dents in the hollow valve stem it contacted. In later years, AirForce started putting two screws in this flange to increase the locking pressure and hopefully reduce the damage to the valve stem.

The o-ring secret

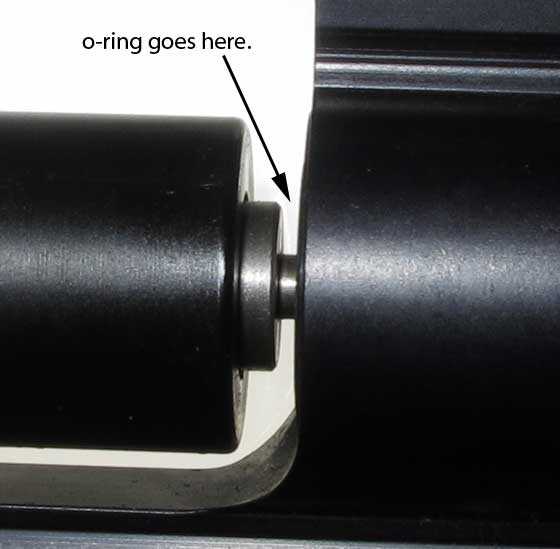

Adjusting the top hat was a chore. One day, airgunsmith Tim McMurray told me about an easier, more convenient way. He said to slip a rubber o-ring around the top hat flange, so it rode in the space beneath the flange. It very effectively limited the amount of valve stem travel. Once I found out how good it was, I left it in place all the time. I wasn’t interested in sheer velocity. I wanted good accuracy at a reasonable level of power. Nothing has changed in 14 years, has it?

The closed breech of this very early Talon shows where the o-ring goes.

Here you see the breech open for loading.

Talon SS puts an end to top hat adjustment

In November 2000, I wrote about the new Talon SS, which was the first AirForce rifle to have a power adjuster on the left side of the gun. My own SS was a pre-production prototype that didn’t have the power scale engraved on the side of the rifle; but after 14 years of continuous use, it’s still working fine and the air tank has never leaked.

All AirForce sporting PCPs now have this power adjustment wheel.

The Talon was also updated with the power adjustment wheel at the same time. Now all AirForce sporting PCPs have power wheels and the top hats no longer need adjustment.

John thought that the power-adjustment mechanism would put an end to the fiddly top-hat adjustment, but it didn’t! By the time the power adjuster came on the market, there was a lot of interest in AirForce Airguns…and the internet was abuzz with homebrew ideas of how they should be set up and operated. People did use the new adjustment, but they also continued adjusting their top hats. Top hats continue to be adjusted and discussed right down to today!

The truth about the top hat

The truth is that the top hat is still a very influential part of the AirForce system. It does have tremendous impact on the rifle’s operation, though not always in the ways you read on the internet. Now that the rifles have the power adjustment wheel, the top hat has become more of a starting point or a setting that gives each rifle a potential range of power. The power adjustment wheel is what fine-tunes that range. The top hat is a set-and-forget kind of adjustment, only people are not leaving it alone.

Some valve stems are very thin, such as those found on the Hi-Flo valves. When the screws are over-tightened on these valves, they dimple all too easily. That’s one reason I advise owners not to adjust their top hats.

Top hats are set at the factory with feeler gauges. I’ve told several people I once discovered that an American quarter coin was exactly the right thickness to set the top hat for a Condor Hi-Flo valve. I’ve actually done that more than once. A difference of one or two thousandths of an inch from the factory spec usually isn’t critical. But when the difference grows larger than that, it does start to become critical. It depends on which rifle you’re talking about to determine if the difference is critical.

For the record, I left AirForce Airguns in 2005, and a lot of things have changed since then. I’m not qualified to give out factory specs on anything they make today. I don’t adjust my top hats at all. I use the power adjuster 100 percent of the time when I adjust, and most of the time I leave each gun set at the position that gives me the greatest accuracy.

You wanted to know about the AirForce top hat — there you go.

I did the o-ring behind the top hat trick within the first 3 days of getting my .177 cal. Talon SS.

Some times its just too hard to leave these airguns alone if you know what I mean. 😉

Then out came the .177 barrel and in went the .25 cal. barrel. And I remember I said I was going to leave this gun alone; no mods, just shoot and enjoy it. Yea right. I ain’t never left anything alone in my life. 🙂

Well, nothing’s ever perfect! this means there’s always room for improvement.When I started working in an auto repair shop, with other techs, I marveled at some of the simple solutions some were using to address both age old problems and new ones! “Javier” might not be able to tie his shoes, but he fills tubing with sand before applying heat to bend it, this may not stop the pipe from kinking, but makes it much easier to control, While “Ed” cuts a tab out from under someone’s dash to aid heater core replacement, saving himself 1.5 hours-that’s $30 in his pocket! ” It was just there for the assembly line robot to hold it by during installation.”

Once again, I find myself in a sea of knowledge.

Thank you all!

Reb

Or that tab was there so the dash would behave in a certain way when the airbag fired.

I am not saying it was in the case, but unless you know exactly what all the outcomes of that kind of modification are don’t do it. Obviously the risks in some fields are higher than in others.

B.B is right with sometimes things should just be left alone.

Or on a 1970’s Buick Skylark with a V-8, drilling a hole in the fender well enabled one to access the rear spark plug fairly easily. I originally used 18″ of extensions and two universals on my socket for that little bugger. I found that no one had ever replaced it and the electrodes had eroded down to “safety pin” sized pieces of metal.

Yep, a true mechanic that’s been around awhile does tend to learn these shortcuts that us shadetree guys don’t know.

Fred DPRoNJ

Howdy alla ya’ll, ain’t the brightest bulb in the chandelier, truth is my “base” iz a little larger than it useta be & it won’t even fit inta the socket no more!?! Don’t know nuttin’ ’bout top hats, o-rings or any kinda mechanicin’ that can’t be dun with a hammer or duct tape, but I can help ya with a shoe tyin’ thing I dun learned from my Uncle Red Neckerson. Only buy shoes with velcro. You’re welcome. Have a great weekend. Shoot/ride safe.

Beaz

LOL (laughing out loud – interpretation for those of you without young-uns). There used to be a TV commercial with former Speaker of the House Sam Irvin for American Express cards. He ended the commercial by saying he was just “a little, ole Country lawyer”. That’s what I think of you, Beaz. You just want everyone to think your a little, ole backwards character. We know better! Have a good weekend.

Hey, just heard that Senator Yee of California, a Democrat and rabid gun control advocate similar to Diane Feinstein, just got arrested for gun trafficing. What irony! The Gun Control nutters are going, well nuts!

Fred DPRoNJ

Wonder if that’s the same one that married someone named Hawes. Saw the headline in the paper, Yee-Hawes wedding. I’ll check on that & keep ya posted.

Beaz

Yes, Fred! I found some of the modifications Caroll Shelby did, to be some of the most ingeniously simple ways of addressing problems!.. With some very old technology! Just goes to show how differently we all think!

After I looked online, this was a universally accepted, yet little known “trade secret” modification on this model.

Reb

You wouldn’t believe how big that book would be if somebody wrote about the tricks used in the muscle car days. Engines, suspension and so on. I’m not only talking about everyday maintenance or repairs. I’m talking performance tricks also.

Its a shame that alot of those tricks wont get to be learned by generations to come. You know the tricks of the day could still be applied to the new vehicles that will becoming out.

I actually would like to see what the hybrid cars will bring in terms of performance. How about a 60 mpg turbocharged 4 cyl. with electric assist that runs the 1/4 mile in the 12’s. Maybe I’m dream’n. But maybe not.

That’s exactly what my plan was with my last car! A ’97 Probe. It was slow off the line so I figured a couple of 5-10hp dc motors, one for each rear wheel and battery pack under the hatch. Naturally aspirated, that car would do 130mph all day!

Alas, it disappeared while in storage, along with my beloved slavia 618.

Sure do miss that lil’ gun!

I know it’s been a long time since you posted this, but did the o-ring behind the tophat work? Would you recommend it?

It is real difficult to not fiddle with these things. Right now I am wanting to get an 18″ .25 barrel for my TSS and machine it to 16″. I was going to go .30, but I decided to wait until larger selection of pellets are available.

I’m going to put a 12″ reservoir on my Edge also. That will probably increase the shot count significantly.

Tinker, tinker, tinker, tinker…

RR,

By cutting back your barrel you will be cutting off the choke, unless you work from the breech end.

B.B.

B.B.,

Is a choked barrel really more accurate than a non-choke barrel?

Joe,

You have asked a question that shooters have been asking for more than a century. No one knows for sure. Most shooters believe that a choked barrel is more accurate, but they give many different reasons.

What I can tell you is that the great barrel maker, Harry Pope, always choked his barrels by about a half-thousandth. And the interesting thing is, many of them were muzzleloaders!

There are intentional chokes and incidental chokes.

Maybe I ought to write a blog about choked barrels and what people think they do?

B.B.

When you think about it, FX’s “Smooth-Twist” barrel takes the choking idea and adds one more element by adding the “rifling” at the end of the barrel too.

David H

When I was contemplating cutting a springer barrel down I researched about the chokes and found a few things- Springers and PCPs behave differently in regards to barrel length, spring guns use a fast burst of air and use all the pressure in approximately the first thirteen inches, I ended up cutting it at about fourteen inches where there was another tight spot but did lose the choke, the spot I cut at had a slight choke just smaller , its a good idea to find the tight spots. I have not lost any accuracy and since the gun actually broke in with the shorter barrel it is very accurate. PCPs need all the barrel length because the pressure is slow and continues to speed up the pellet all the way up. I went under but think its good ti get a full rotation in the rifling and since ags have a one in16″ twist, but experiments of cutting an inch at a time with a chrony is the best way to find the “sweet spot” and a good crown job after is essential. Hope this helps.

On the choked barrel, I’m a believer and I’ll tell you why.

It seems that somewhere back in the eighties I ran across a colt python with a 3″ barrel on it and, having learned a 2″ is a great deal more difficult (but far from impossible) to hit with, and the aesthetic balance was far better than the box stock 2.5 inch item…well, soon it was mine.

But there were a few oddities; notably, the serial number look-up seemed to indicate not only an 8″ barrel, but it was supposed to be in .38 special only caliber as opposed to the .357/.38 caliber that most Pythons have come in since time immemorial.

Hmmm, mysterious.

To make a longish story marginally shorter, and belatedly noticing there was no engraving on the barrel indicating caliber, Colt address, or anything, I realized my lovely 3″ Python was not only a cut-down 8″ barrel, but the cylinder had been reamed out for .357. And, of course the shortening of the barrel (VERY nicely done, by the way) had neatly removed the choked portion of the barrel.

Oh well, I thought, It’s still a nice 3″ and I was far from convinced about the choke thing Colt flogged.

Well, I had that barrel on the Python for a couple of years and it consistently shot…okay. But never great. It was a disappointment and finally I gave it one more chance and sent it off to Colt and replaced the cut-down 3″ with a new, choked 3″.

The difference was not quite night & day, but close. All the sudden I could take a snub-nose .38 to the range and make money from the illiterate who really believed a snub-nosed .38 was only accurate at elevator-interior distances.

That’s what the choke did for this particular revolver. Pope was right.

But we still need the literary device of the epilogue.

Somewhere not so long ago, I acquired a 6″ Smith K-frame. As lovely a piece of sculpture as we’ll ever see outside a museum…and achievable for we, the pre-millionaires.

But here’s the funny thing, that 3″ choked barrel will still out-shoot the un-choked 6″. Not by much, but still, the difference is there, And it’s there every time.

Go figure.

I do have to point out that he was asking the risk of losing choke for an airgun, not a magnum pistol cartridge coming out of a 3″ barrel, uh big difference. I can understand how much difference that would make there, such high pressure and short length for the bullet to stabilize. I have found chopping barrels in .177 springers to decrease variations in poi between different pellets every time. I have to conclude the crown is far more important then a choke. Think of a slight variation in the crown of that magnum pistol, it will have far less of an impact on bullet flight then the same variation in crown on pellet flight. They are apples and oranges.

Just goes to show though because he also was asking about pcp barrel shortening and I talked about springers! There is a huge difference there too. Springers tend to benefit more with barrel shortening then pcps do.

Sure, I was convinced by the choked barrels since the logic seems so sound and because the Benjamin Marauder is choked.

Matt61

I look forward to reading such article.

B.B.,

I look forward to reading your article.

A blog on barrel choking would be a most interesting read!

It is my understanding that the purpose of choking the barrel is to resize the pellets to a consistent size as they leave the muzzle. If you open a tin of pellets and measure each one, you will find they will vary in diameter, sometimes quite a bit. By choking the barrel you supposedly eliminate one of the many variables you have to contend with to achieve anal accuracy.

I happen to have a 12″ .22 barrel for my TSS that was made from a Eun Jin barrel. I do not think that it is choked. When I get my TSS back up and running, I may have to try it out and see how it does unchoked and then choked.

I thought re-sizing a pellet via a choke in the barrel, distort the shape of the pellet, and if the distortion is not uniform, the pellet will not fly true. I assume this is less true of a bullet from a firearm because even a lead bullet is much less prone to distortion from a choke. Unlike a bullet, a pellet is NOT a solid core projectile and also it has a filmsy skirt.

Well, a LW barrel is choked and they are some of the most accurate air rifle barrels made, so there just might be something to it.

Sorry,

Those Lothar Walther (LW) are not that accurate from my experience. The better ones are the old BSA, HW and Anschutz, and of the three the old BSA barrels (Daystate used to have in their old air rifles) are the most accurate.

With your tool we can actually test this!

I think I just peed a lil’, I’m so excited!

It is my intention to remachine the breach end. I am wanting the benefit of the longer barrel, but do not want to lengthen the air rifle and want a little room for some baffling.

My results of increased consistency with the 77 springers could also be from reducing the range of barrel vibrations with the shorter barrel and full harmonic dampeners. There’s a whole nother issue to think about.

I dreamt a prototype barrel choking tool up the other night- a pipe cutter with the cutting wheel replaced with another set of rollers and some plasti guage? Your thoughts?

I feel this could be redemption for many an over zealous barrel lopper!

I’ve heard of guys doing that but that it takes a LOT of pressure so it is better done with larger fixtures – they were saying some kinda lathe press I think.

Yes, a lathe would be ideal, however, how many of them used a lathe to lop it down, do you suppose?

That is very true. Better get a good quality pipe cutter, make that two so you can match the roller. How big do you think you would need? Going to need plenty of leverage and a good clamp on the barrel so its not torqued out of wack.

Lord knows I’ve done that a couple times! Twisting tight brakes on and off.

This is where just a little heat comes in handy.

We used an old school 6″ cutter for up to 3.5″. plenty of leverage there, and No, don’t try this with the barrel mounted in your gun! Unless you’re in desperate need of toothpicks!

A higher thread count could lessen the amount of force required, so it could be done by hand.

Reb,

Dennis Quackenbush made up one of those for me in the late ’90s.

B.B.

So it does work?! Awesome!

Reb

BB said they made one but he didnt say what the out come was.

NowI would like to know what the results were.

Me too but something tells me we’ll be waiting for the choking blog on that one!

I don’t see Dennis Quackenbush sending it to B.B if it didn’t work.

RDNA and Reb

You guys need to slow down. I don’t know if you guys read any of the blogs and caught that I’m a machinist. Been doing it since 1982.

I have cut a few barrels down and re crowned them over time. And have even straightened barrels. And I’m actually doing something similar like Ridge runner is doing but a little differently. I just took and machined the breech end of a .22 cal. Discovery barrel and I’m making some new barrel collars for that barrel diameter to put in my Talon SS.

I’m making it for some longer range shooting. BB and a few people commented about different things using that barrel and different choices of what caliber to use. But I chose this barrel for a very simple reason. I already have it. And It’s just like another day at work for me and I actually enjoy doing this stuff. So I should be able to get back to finishing the collars in a few days. We been real busy at work so I ain’t had extra time to get anything done.

And then about the choked or unchoked barrel thing I have heard alot of different things about that also. So to me that would be a excellent blog for BB to do. Matter of fact the sooner the better.

Aw, We’re just tossin’ around ideas before they get forgotten. Like the Tippman 98c I picked up yesterday. I’m considering converting it to .22! I have a few questions for you pcp guys, so be prepared for all those regular questions from newcomer’s, and some totally off the wall stuff too!

Reb

You just can’t imagine the conversations that have came up overtime.

I have noticed that BB has to do a lot of repeating throughout time. But I think its great that he does answer when them times happen. It kind of gets overwhelming when you try to go back through the archives to find info about something.

And also maybe some new trick has been learned about a subject that was discussed in the past and wasn’t even thought about yet. So yep I’m always interested in new info about a old subject.

GF1,

I repeat things for exactly the reason you mentioned. I know it’s been done before, and maybe this time I can do it better.

B.B.

And I Thank You very much, Sir for sharing your time, knowledge and patience with us and allowing free, open, and civilized discussion and of the passion we all share!

Reb

I have no clue what you mean by we need to slow down… did we offend you? Anyway, I just did a test with my chopped .177 with ten shots from five different pellets,center to center was .30 at ten yards. So that ones good. When I figure out how to get pictures up this stuff will be on my site. Im eventually going to cut the new NP down but want to keep the shroud so I’ll need to retap threads for the new end. Getting used to the grip a little better but still finding a legacy stock, the only other on that will fit. Would love to whittle a nice maple one all custom like but boy would that be a lot of work. Be a heck of a reward though.

RDNA

Not offended at all. More like confused about what your were talking about with making a choked barrel. How was you going to do that?

Or was you talking about cutting a barrels length shorter and then re crowning?

Oh, well first it was about cutting barrels down then subsequently the benefits or negligibilities of chokes, then how could you add a choke to the chokeless chopped barrel, I had heard it suggested to modify a pipe cutter before elsewhere but don’t think it’d work very much, but that people do use some sort of press that incorporates with a lathe, I don’t have a lathe and that pellet test was just to show why I don’t worry about choke, at least not on springers.

RDNA

Ok more clear now. Barrel cutting and re crowning on a lathe yes. Choking a barrel I would think that would be more difficult to do. I myself would like to know the correct way to do it. But I guess on the other hand I really never looked into choking a barrel because I have had good luck by just cutting and re crowning barrels.

Go to the home page for the FX barrels and watch their video’s about how they make their smooth twist barrel. And if you watch their video of their factory tour it shows how each barrel they make is hand straightened by the owner of the company before its released for production. Also some cool tests they do on their guns also.

Back in the day, at least some barrels, were choked by what I consider step lapping, which actually removes metal from the barrel, requiring a larger projectile to fit the bore. I was just thinking of an easy way to choke one without removing any metal.

Reb

To me that sounds like it would defeat the purpose. That would be taking the material away from the lands of the rifling in the barrel.

That’s the art of it! they worked from the breech end so this was the larger part of the bore, from constant abrasion while the muzzle end was only minimally worked, therefore having the smaller diameter,or choke.

Reb

Sounds like more trouble than its worth.

Think about how much more accurate any barrel would be with a finely tuned choke.

This is the reason for the tool, and, if it worked and was done correctly would allow you to “fine tune” your choke.

Reb

Thats the qestion Joe asked.

I dont know if a choked barrel would or wouldnt be better.

One way would be to try is the best I can say.

Probably requires annealing the barrel to make the metal “soft” enough to flow under pressure, then cranking a tapered set of rollers around the muzzle end (that referenced pipe-cutter, with the cutting blade replaced with a flat wheel), followed by heat-treating the barrel back to original hardness.

Genius! I don’t know if annealing would be required, but Yes, you understand the concept.

Thanks, I thought i’d gone rogue!

Yeah, I think the chokes don’t really make much sense, I mean they sound good in theory, size the pellet, but the pellet was already sized with the skirt blowing out and engaging right from the get go. It seems realistically like it just increases friction, maybe in pcps will help give a last ditch pressure boost, but springers have already lost all their pressure. I think chokes have their place but its on shotguns mostly.

I think you just hit the nail on the head!

in a high power springer the blast of air is so intense that the skirt is forced into the rifling, creating a leak free seal, for more power and accuracy, however with other power plants, the blast of air is much slower and with less heat, making it inadequate for creating such a seal. I hereby postulate that these other power plants will benefit far more from a choke.

Or I could be wrong. 😉

I forgot to say Ive been meaning to check out the fx smooth twist, I wonder why no one makes the micro groove barrels like the Marlin .22s? Think that would work mint for pellets. Maybe too much friction but they look cool.

RDNA

LW 12 groove ? All four of my PCPs have them.

twotalon

Ooh ok, cool, hadn’t really looked for em, just remember the old 60s had it, did lother walther make the barrels for marlin in the 70s? Or today even? How do you like the 12 groove over standard rifling?

My 953’s rifling is reminiscent of this,I’ve never counted the grooves but you can tell it is high quality. I saw a buncha used ones the other day, from a shooting club for $50-$75. There’s no telling how much work went into those guns!

RDNA

I doubt that LW made them for Marlin.

I don’t think the number of grooves matters much. It’s more the quality of the barrel.

twotalon

I actually saved a 5X2′ round of Pecan for this purpose, it’s been dead for 3 years from a lightning strike.

What’s good with pecan? Good hardwood? Nice grain pattern? I’ve never seen any that I know of. That would be so satisfying to say “I handmade the stock.” What kinds of wood that are commercially available would be good for that?

It’s the largest member of the Hickory family, including all Walnuts.

Good for smoking too!

You can buy pre seasoned blanks in various states of finish, seasoning is of the utmost importance, to prevent cracking twisting and warping. Be prepared! They ain’t cheap!

But yes very worth it!

I would like to add here that my father spent about a year building a thumbhole stock for a 25.06 from one of these blanks, back when that’s what he did for a living. That thing looked like it had 1/4″ of Tru Oil on it!

Very rewarding!

Yup . That’s what they look like . Uh Huh . Fo Sure . Sho ’nuff . You betcha . Ya hey .

twotalon

If both AirForce and GunPower are selling airguns made from the same parts, who makes the parts?

Are there even more companies selling air rifles made from the same parts?

I see this all the time in my field, but I was totally unaware it was common in this one.

StevenG,

AirForce makes all the parts.

B.B.

B.B.,

Again, great article. I like to know why some PCP airguns such as the HW100 don’t allow a user to adjust the gun’s pellet velocity?

Joe,

I’m not B.B. and I don’t play him on TV but………

You can adjust the velocity on a HW100. I fiddled with mine. The fac versions are easier to adjust than the 12fpe versions.

You should adjust both the reg and the hammer spring preload when adjusting the power on a HW100. This keeps everything in balance.

Here’s a decent video on adjusting the HW100.

https://www.youtube.com/watch?v=OEb7Oeif-C4

Here’s a good analysis on the workings of a HW100:

http://www.airgunforum.ca/forums/topic266.html

kevin

Thanks, but let me re-phrase my question, and this is what I intented to ask: Why can’t we externally and easily adjust some PCP airguns, like the HW100?

Joe,

I think one of the reasons is cost. I think another reason is because the majority of airgunners adjust the power for their needs and leave it there even if it has an external power adjuster. I have pcp’s with external power adjustments and rarely use them. Verifying trajectory at one power with one pellet is enough for me. Too many variables and the gun becomes ineffective for me.

Seems like most of the airgunners I know and shoot with treat their variable power scopes the same way for similar reasons. They set their scope on one power and leave it there.

Just my opinion.

kevin

Thanks Kevin, BUT again I ask my original question, why don’t some airguns like the HW100 allow a user to adjust it power externally and easily???????????????????????????????

Assume you don’t like my answers??????????????????????????????????????????????????

We may never get a straight forward answer and if you did get a answer from Weihrauch for example it would be one that you didn’t want to hear. So lets just say that it would add extra cost to the end of a rifle then what if the gurus out there say that the adjustment looks hideous and criticise and comment how it would work better if they did x.y,z like some other company did on their guns. PCP is one of the first design in air gun history but yet the modern versions are very new to air gun world so who knows it may be a standard in the near future. I don’t like were we are going with air gun prices good 177 ammo is close to 22lr ammo we are going backward where only the wealthy can afford these 1700-1800 kinda like when cars came on the scene only the rich had them, but now who can afford a horse, not me.

Joe,

Here is what I believe. Weihrauch is not a company of airgunners. They were 40 years ago, but those days are past. They still make great spring rifles, but I don’t see any innovation coming from them anymore.

They built the HW 100 is a conservative, conventional way.It is a fine air rifle, butt it’s not in tune with what is happening in 2014.

I would liken Weihrauch to the Checker corporation. They continued to make a fine 1958 automobile well into the 1980s, even long after the market had moved on.

That is just my opinion.

B.B.

B.B.,

I was hoping that your answer is that companies like HW doesn’t want users to easily adjust the velocity because it would lead to a less consistent velocity, or looses accuracy, or waste of air, or maybe even damages an airgun. I do however agreed with you that HW is conservative in their airgun design, but HW was never a very innovative company to begin with even 40 years ago. After saying all that, HW does have one air rifle that I thought is innovative, and that is the HW57. How come PyramdyAir doesn’t have the HW57 in stock?

Joe,

I’m going to disagree with you. HW is the company that invented the Rekord trigger — the most copied airgun trigger ever.

HW created the HW77, the most copied underlever design.

HW created the HW 55, the recoiling spring rifle that won a gold medal in 1969, shooting against recoilless target rifles.

HW created the HW 52, a target .22 rimfire that at one time was the best in the world.

HW was a very innovative company, in my opinion. You can’t just judge them by the last 20 years. Ypu have to look at the entire 20th century.

B.B.

B.B.,

What do you think of the HW57 ???

Since none U.S. retailer sells this airgun, I assumed it is not good.

Joe,

Every airgun Weihrauch makes is good. I have never tested the 57 so I can’t comment on it but I do believe it is good.

B.B.

Joe,

There are US retailers that sell the HW57.

kevin

Kevin,

Which U.S. retailer sells the HW57 ?

Hey BB,

I know you’ve talked a lot (a lot!) about trigger mechanisms before, but i don’t remember you going into depth in a single (series of?) article(s) explaining the intention and movement of each piece and how they work together. If you have, would you point me to them. If you haven’t, would you mind writing about this. I can see how much of it works, but then I get confused by the ups and downs and pulls and pushes and springs of the whole thing working in concert. Or maybe there is great variation between models where explanation is difficult and doesn’t carry over between brands? Again, if you’ve already done this, then I’d be glad just to read those articles if you could direct me to them.

Thanks for your hard and revealing work.

Rob

Rob,

Kevin has bookmarked a site where you can see a trigger in motion

Kevin?

By the way, each trigger is potentially different.

B.B.

Thanks much. I will definitely have a look.

Rob,

Here’s a link to lots of demo’s that are relevant to airguns including how a trigger works. Click on the demo and it will actually move through first and second stage:

http://www.arld1.com/

kevin

Excellent. Thank you.

I should have said that I own only pumpers if that makes any difference.

Sorry, also that the macro photos and directional arrows help a great deal.

Hey ya”ll! I just stumbled across a few paintball guns, one of which is a Tippman 98 custom. It’s missing the barrel, which gives me an idea. I’ve seen video of this gun shooting gravity fed steel BB’s and wonder if anyone’s heard of someone modifying it to accept .22 pellets.

Anyone?

I remember a blog posting about such a gun, and it was made by the people who started Tippmann. It’s been a few years since B.B. wrote about it. I remember it functioned flawlessly, and it didn’t freeze up when using full-auto.

Edith

Beautiful! Thank you so much, Edith! I’ll check it out!

Reb,

I did a feature article for Shotgun News about the Air Ordnance SMG 22

https://air-ordnance.com/smg-22-p-938.html

It’s belt-fed and it does work well.

B.B.

It looks almost exactly like the AO SMG2, I guess they’re brothers, or sisters, whichever you prefer.

I looked but couldn’t find any conversion kits for sale.

Someone’s selling one, right?

Just got off the phone with Bob Tippmann. No kits:( , Guess it’s all up to me, and my friends 😉

HELP!

Hey B.B., I’ve started a blog of my own, and wondered if it would be ok to share the link with everyone here? Don’t worry I’ll try not to put you out of business! Lol, jk

RDNA,

Pyramyd AIR is very sensitive about any links that get posted on this site. Edith will have to make the call.

B.B.

Of course, that’s why I wanted to ask, should I send the link for you and Edith to survey first?

RDNA,

Post a link, and I’ll look at it. If I feel it conflicts with Pyramyd AIR or their standards, I’ll remove the link.

Edith

Was it the language exception? Cause I’ll adapt that to conform if necessary

RDNA,

I’ve sent you an email.

Edith

Ok, I haven’t received it yet but I did change the language clause, hindsight proves it is better without that allowance.

I’m guessing they reruoted the co2 so more goes behind the pellet and less is used for the blowback action. sound right?

Ahe-e-e-m; “Rich 8T2”. Thanks B.B., I appreciate it!

Oooops ~ I goofed!

BB,

Can you explain the relation between AirForce company and GunPower?

You aren’t Ton as in Ton Jones the progenitor of the new Escape rifles are you? Anyhow I am also curious as to the origins of AirForce and remember well reading about the GunPower rifles before AirForce guns were a thing here in America. Also I’d like to say this is my first comment on the blog despite having been reading it voraciously since around 2006 or so whenever the airgun bug bites me. I have to give my deepest gratitude to Mr. Gaylord first and foremost and everyone else who contributes all the information that makes this one of the greatest airgun resources on the internet that I know of. More often than not anytime I have had a question or an idea pop up, someone with much more knowledge than me has likely tried the idea and/or the airgun in question and posted their results here. This blog here has saved me countless hours of futile experiments and alot of money in the process and has allowed me to refine my tastes down to the pure essentials of marksmanship which is the foundation my hobby is built upon. Especially these days with the burgeoning growth of the hobby it can be all too easy to get lost in the swarm of marketing fluff and over-hyped velocity numbers, and I truly thank you all for sharing your experiences on here day in and day out.

Mitchell in Dayton,

Welcome! Thanks for your post. Best I’ve read in a long time. Thanks!

Kevin

Thanks Kevin. I’m hoping to contribute a little here and there wherever I can no matter how little. I’m really looking forward to warmer weather and also hoping to expand my pitiful little collection of airguns at the same time, and I felt the time was right to drop in and add a little to the conversation.

Mitchell, What kinda guns you got?

Right now I’ve got a Gamo 440 tuned by CDT back in the day, an IZH 46M, a Crosman 1377, a Diana 45 (the older kind) and my number one favorite backyard plinker, a CZ Slavia 631 Lux. I used to own a RWS M34, and a M54 Air King that I miss tremendously. I sitck to .177 unless I hit the lottery and get into PCPs. I’m currently saving up to finally add a FWB 300S that I’ve lusted after for 10+ years, and hoping to attend the Flag City Toys That Shoot show in April since I’m only 2 hours away. I went last year for the first time and made the decision right then and there I was going to bring a whole heck of alot more money this year if I can help it. It was my first airgun show and it was amazing finally getting to see airguns I’d only read about in person and many others I didn’t even know existed.

I’d say you’re doing fine. And, if you’re just punching paper or plinking you’re already well on your way to that FWB, by sticking with .177!

Mitch…

I went to the show a few years ago . Some of the P.A. gang were there.

I didn’t take along any extra money….just wanted to have a look. Got there right at opening time. Very crowded.

twotalon

Right you are. Without this blog, I never would have gotten into airgunning. And that was 8 years and tens of thousands of pellets ago.

Matt61

Mitchell,

Welcome to the blog. Are you planning on attending the Toys That Shoot airgun show in Findley April 12? If so, look me up. I’ll have a table there.

B.B.

I’ll be sure and stop by your table and say hello BB. If its anything like it was last year, it’ll be packed wall to wall with excellent airguns and even better people. Really hoping I’ll score some nice german equipment for backyard 10M work without breaking the bank. Once again thanks everyone for the kind words.

Ton,

GunPower is a business partner with AirForce, who builds the guns.

B.B.

I’m totally vindicated! So there is a top hat in a pcp as well as in a springer!

Matt61

BB.,

Unfortunately Talon SS does not put an end to top hat adjustment. When I bought Talon SS last year the power wheel was the main advantage that made me choose it over the Marauder. However to my disappointment the PW gave almost no control on the pellet speed. Barely a difference of 20 fps between level 0 and level 10. Nearly a constant speed independent of the setting. Nothing close to the 400-800 fps range AF claim. I called AF and PA and the only answer I got was that each gun is different. I then learnt about the O-ring trick. It did the job and I was able to control speed down to 400 fps or less even. By the way, where do you get a good selection of o-ring for such jab. I got mine from home depot which, despite doing the trick, are a bit lose for the placement and I wish I can find tighter one that would give more consistent positioning of the ring during shooting.

Awny

Is it a .177 by any chance ? Mine acts completely different between the .177 and .22 barrels. The .177 is kinda squirrely .

twotalon

TT

You sure are right about the different caliber barrels having their own personality’s in them AirForce guns. Well not only the Air Force brand either. My Marauders act different also when comparing calibers.

GF1

So you finally got out of bed ??

twotalon

TT

Ha Ha, maybe so.

GF1

Bit more S55 info for you…

In spite of a lack of good outdoor weather for shooting , I have found that I should treat it like I would treat my other PCP guns…

When shooting on the higher power settings, it needs to be shot once to settle the valve and prevent a weak first shot.

When leaving it sit for 3 days (let’s just call it “overnight”) it will need to be shot once for the same reason.

twotalon

TT

You are right again. If I shoot my PCP guns after they sit over night or longer my first shot will always go low.

No matter how bad I want to make a shot out of the back door at a pest. I dry fire the gun before I load a pellet and open the door to make the shot.

GF1

I always shoot a pellet to make sure the power plant sees the right conditions. If a “blank” works for you, then you can save a tin of pellets over time.

twotalon

TT

Never thought about it that way. Just always done it like that. It ain’t like taking a chance on a firearm and messing up the firing mechanism.

Could this be exhaust valve extrusion?

Reb…

Maybe in the case of letting it sit too long without shooting, but the part about needing to shoot after a fill is probably due to a change of conditions caused by a different pressure and a need to self settle at the new pressure to get back into the curve right.

The valve bounces then settles depending on pressure and back pressure from every shot . Normally there is a gradual change as you shoot off the fill, but things get out of wack when a sudden change happens. If you only adjust the power setting on a Talon, the next shot will not come up right. Needs to waste a shot to get on the new curve.

Common PCP problems. Get to know the individual gun and live by it’s rules.

twotalon

Sounds a lot like adjusting a scope.

Reb

Yeah, adjusting scopes can be a bit funny too. They can be O.K. if you get them figured out and they can work well, but if you try to adjust them the way most people THINK they should work, then they will cause you nothing but trouble . On top of that , a lot of people will not even recognize that the source of their problem is the scope. Lots of hair pulling and maybe a lot of time and expense wasted on the rifle, or maybe selling a perfectly good rifle.

Your equipment likes to trick you. You gotta be smarter than your hardware is.

twotalon

So the valve can find it’s proper seating location for it’s new pressure? If that makes sense then I’ve got it.

Reb

Seems right to me. Some guns may not do this , but you should expect this and watch for it just in case.

twotalon

OOPS

That’s S500.

twotalon

OOPS again..

Should have added “after a fill” to the first sentence.

The boring movie on TV has me half asleep this afternoon.

twotalon

TT

And sorry but I would rather be shooting out in that not so good weather over watching a movie. Come on TT you know you want to go out and shoot.

Heck look at me sitting here on this computer talking right now. It’s supposed to be around 60 today but rain is in the forecast. So I’m getting ready to go out and do some shooting here in a minute. It will be Monday before I know it and then back to good old work again.

GF1

In my younger days I would have been out shooting, but it is cold, windy and snowing at the moment. I am not going to get any good data in that. And I don’t feel like trying to dry off a gun afterwards.

Maybe a day next week I hope.

twotalon

TT

Snowing! I hope we are through with that stuff in or area. Come on spring time.

GF1

Look at Ohio on the weather radar map. That’s what I got today.

twotalon

Edith

I have thought about moving to Texas. My wifes family lives there already. May happen when the kids finnish school.

TT

Right next door to you in Illinois. I’m glad we ain’t getting that stuff. I know I have had enough for this year.

Ummm…move to Texas 🙂 The season for air conditioning arrived last week. Tom’s wearing shorts and is now mowing the lawn. You guys are living in the wrong states!

Edith

GF1

Me too. Weather gets kinda bouncy this time of year..a few “teaser” days mixed in with the crap.

twotalon

Awny,

Welcome to the blog!

McMaster-Carr is the place to source an o-ring assortment.

B.B.

I’ve found TSC to be an invaluable resource, for many things, from repairs to pellet traps to ammo.

Off topic; Has anyone built a speargun from the tubing used in the expanding water hoses yet?

Let me add slingshots also. This stuff is Tough!

It says my username is already taken, which I highly doubt. Maybe I’ll try another later.

WordPress is kind of a pain, there’s .com and .org which apparently are completely separate. I guess the .org profiles which are the basic ones for just posting on here and then the .com I had to do a whole new registration to make the blog site. I don’t know if it requires a .com profile to use the .com blogs but might be.

Making a .com profile is how you get the cool little profile avatar and its then attached to your email address and will show up anywhere you web post with any account with that email… cool!

I’ve got an idea for an Avatar but it will take some doing to set up. Can I change usernames later? Or would that still not work?

Reb,

You can change avatars. Just upload it to your current profile. User names cannot be changed. If you want a different user name, you’ll have to create a new account.

Edith

Thank you Edith!

Good info on today’s blog. Thanks! It’s nice to have info on the tophat from someone who actually worked at AF.

/Dave

/Dave

I just remembered something when I seen your reply. How is that hop up going on that 760 barrel. Any luck?

Huh?

Reb

I will let /Dave explain if he see’s my response. It got started when we were talking about airsoft guns. It was his idea. And he has been doing the experiment so he will be able to answer better than me.

Gf1,

I haven’t really gotten any good results to post yet. I tried different amounts of protrusion into the barrel but all that happened was it spread out the groups even farther than without. I didn’t get the barrel drilled and tapped closer to the receiver yet. If you recall, I had the hop-up set close to the muzzle for this round and eventually will try it close to the receiver when I get some time.

/Dave

/Dave

Yep I remembered that was the results you had. And that your were going to try it by the receiver. That is what I was thinking about if you got to test it after you drilled by the receiver.

Maybe that will work out better that way. Might give the bb more time to stabilize I’m guessing before it leaves the barrel. Well like I said still interested in the outcome of the experiment. So post when you get some info if you will please.

Will do! I’m still dinking with the LG55 too. I changed grease in it and that didn’t help with the velocity so my next stop is to play with the piston seal some more. It’s a bit tight. I could wait for it to break in after a thousand or so shots, but since I also play with my other toys that might take a while….

/Dave

/Dave

I forgot about your LG55. Your going to try a different lube?

And I knoow what you mean about the other toys. The old R/C airplane bug is starting kick in again. I use to fly in the winter all the time. But the old fingers dont work as good in the cold anymore.

/Dave,

Setting velocity aside for a moment…how’s the accuracy in your LG55? What pellet has proven most accurate? Thanks.

Kevin

Accuracy is nice, Kevin! H&N Finale Match Pistol seem to do the trick for now. Meisters are next. If after the next round of fitting it’s still misbehaving, I might want to come see you about the original factory spring (if you still have one). That might be a little stronger than this JM spring. I don’t really mind the lower velocity, but it’s giving too wide of an extreme spread even with the new seal. Enough to where you can hear it and see the vertical poi’s change..

/Dave

B.B,

Why don’t some airguns like the HW100 allow a user to adjust its power externally and easily?

BB

I guess this as good of time as any to ask. What happened with that blog you were going to continue about the airsoft guns?

GF1,

OBE, I guess!

I’ll make a note to myself to update it.

B.B.

BB

Ok Im slow today. What does OBE mean?

GF1,

Tom says it means overcome by events. (I didn’t know either & had to ask him)

Edith

Ok thanks Edith.

Just don’t stutter on the keyboard…

OOBE was the common acronym for “out of body event”

(What the… 9 + 7 = [] twice in a row…, or was the previous post 7 + 9)

I did the registration they were talking about, I couldn’t figure out the picture thing yet but it sure is nice not being reminded how bad my math can be, all the time.

Edith…

You got Tom to mow the lawn ? Is that his punishment for the last hole that he shot in the wall ??

Does he have to mow the lawn with a pair of scissors if he shoots the new sofa ??

twotalon

TT,

I don’t ask him to mow the lawn. He insists on doing it. I’ve offered to have a service do it for him, but he says that doing chores is a good way to remain active and independent in his senior years. He’s right, and I’m of the same opinion.

We have a relative who just wants to sit and wait for old age to force him to move to an assisted living facility. Nuts to that!

Edith

Edith…

You keep going as long as you can. Particularly if you feel up to it. Otherwise you are just giving up. Some people would gladly take away your last good years if they could. Maybe the shoe will be on the other foot some day. See how they like it then.

twotalon

Edith

I like mowing the grass also.

But I got a riding mower. 🙂

I hate mowing grass. I would rather plant trees and shrubs and such. I don’t have a cow, so I don’t need the pasture.

O.K.,I finally got a second shot outta the 392! After 25 pumps I stuck a .22CPHPthrough an aluminun tag an 1/4″ deep in an old telephone pole, the second shot was a Gamo .22 round ball, again 1/4″ deep. Wow! I actually feel slight recoil from this gun @ 8 pumps.

I don’t expect I’ll be using this knowledge very often, but it’s nice to know I have the option. 😉

Reb

You are going to beat your gun to death doing that. That’s a lot of wear and strain. Take it easy if you want it to last for a long time.

twotalon

That’s what I meant! It will do it but not for long. at least not without some parts from Mac1. I was prepared with another pump cup, or for valve lock, just in case, and now I know the intricacies of going that far with one.

I can’t wait to get the 3120 going again! It’s just a much more solid gun, That’s why they require less modification.

Reb…

Have fun with it. People have turned pumpers into short shot count PCPs. Decide if you think it’s worth it.

I am not much into mods, unless there is a particular need to do so. I tend to try cleaning up original glitches if I can without much trouble and then live happily ever after. Just about every gun I have gotten hold of had at least one sore spot that needed cleaning up.

twotalon

I just like the idea of having a follow up shot. Them squirrels is tough!

Reb

No kidding. When in doubt, use more power !

twotalon

Just wait til I put a .25 barrel on my 760!

I really want a decent 10 fpe sidearm. That’s gonna take some work!

Reb

Sounds like too much work.

twotalon

It would be totally worth it to me! But I’d settle for a Tippman 98 slingin’ 15.3grain .22 balls @ 500 fps.

Totally doable, look at the Air Ordinance SMG22, and I’d settle for semi only.

Reb

Not familiar with these guns, but do what ever turns your crank.

twotalon

The only mod i’m considering for the 3120 is a debouncer, and only if it needs it.

I’ll probably see what the valve looks like next month and go from there.

Reb

Do what you think needs to be done, and if any gains are going to be worth the trouble.

Need to go to bed. Maybe I can shut up then.

twotalon

Mitchell in Dayton,

No Mitch, I am not that Ton. I am privileged to be the person to draw you out to start commenting on this wonderful blog! I wish you many more posts!

Way up yonder y’all talked about how in a sproinger it was not necessary to choke because the skirt flared out. My CFX would shoot dime size groups with 4.52mm FTTs, but quarter size with 4.51mm. It may not be a good idea to choke a sproinger because of the low volume of air, but with a PCP you have more air.

I spit out a buncha stuff right around there. I can’t remember it all. I’m glad it’s gonna be in the archives though!

I think I ran Two Talon off with some of it, for which I offer my apologies.

Reb

I put a good dent in my beer supply last night and was pretty well burned out when I pulled the plug for the night. If there had been anything decent to watch on TV, I would have stayed away from the keyboard.

Who knows…maybe B.B. will get a few dozen ideas for new blogs after all the stuff last night.

twotalon

I was out or I would’ve been in bed by 10;00.

That’s another thing.

I find it difficult to focus with alcohol in my system.Since I’ve started shooting on a daily basis, I no longer drink if I want to shoot. I have gone from a 6 pack a day to one maybe 2 beers a night, saving myself about $5 per week! This money goes toward my shooting budget and coupled with all that pumping I’m in much better shape than a year ago.

Once again, I would like to express my gratitude to everyone here.Thank You!

Reb

Yes IMO they may create excessive friction depending on placement in a springer.

Go to the post where I started with “I think you just hit the nail on the head”.

4.51 is apparently too small for your bore. Have you tried a 4.53 or is it even available?

It is not the skirt diameter, but the head diameter. As to whether they offer 4.53, I do not know. If you go through a tin of pellets, you may be surprised how much variation there is. When you get into the “match” pellets, supposedly the manufacturer has sorted through them by size and weight and they are more uniform. That is where you start seeing the 4.50, 4.51, etc. on a label on the tins.

Which may demonstrate where a choked muzzle comes into play …

Centering the head of the pellet so it is not tilted as it leaves the muzzle.

Wow! I feel like my brain is gonna explode!

Most excellent blog,Gentlemen OOps and Ladies!

B.B., Does anyone offer a Mini Ball style pellet?

H & N does, in both .177 and .22.

/product/h-n-rabbit-magnum-ii-177-cal-15-74-grains-cylindrical-with-round-nose?p=754

Be advised. Read the reviews before you order any. No one, including myself, recommends them. they are a waste of good lead. I have some in .177. They will not even load in most barrels. One guy tried them in a Condor and they were horrible, so power is not the answer for these things.

Try the H&N Baracudas. If you need more power than they give, you need more air rifle.

Just remember this basic rule: What good is 500+FPE if you can’t hit what you are shooting at?

The fact that I’ve never heard of anyone getting anything better than terrible results with those things always surprised me. In all my airguns so far H&N pellets have worked as good or better than the other brands I’ve tried (JSB, RWS, Crosman Premier). Even their non-lead pellets turn in accuracy in my HW-77 and FWB 602 not too far off what I get with the Finale Match! And yet there they are, the Rabbit Magnums which can be put through a rifle which is a normally a tackdriver and have trouble hitting anything smaller than a garage door! It’s baffling. Are all the sales to shooters who buy them once to try them out?

Very likely. I keep pulling them out when I pick up a different air rifle, but the results are always the same, ugh.

a Mini Ball has a recess in it’s base, much like a pellet. I don’t think the rabbit magnum has one.

Actually, it does have one with a thin skirt. It just does not shoot worth doodly out of anything I have tried.

I won’t be buying any and never have considered them for purchase. They are too heavy for anything I have, and I remember my black powder results with conical bullets.

However, I am luvvin’ the round balls in airguns!

They probably require a much faster twist rate to stabilize due to their length, size and shape.

Reb,

I have never heard of one. There isn’t enough explosive force in an airgun to0 obturate the skirt. Diabolo pellets are the closet thing airguns have to real Minie balls.

B.B.

Thanks, B.B.not even a springer?

Reb,

You are talking about 2,000 psi against 15,000 psi. Big difference!

B.B.

Justa thought.

Somehow I see this choking blog as a history lesson on the civil war era and advancements in technology that came from it.

It sounds like H&N should swage all those rabbit magnums to include a hollow base. It couldn’t hurtany more than marketing a bullet for an airgun. I have had very good results from all H&N pellets I’ve ever used, even the rebranded ones, which are the best deals I’ve run across.

As I just posted a little higher up a few minutes ago, it does have a hollow base with a thin skirt. It does not seem to help any though.

B.B.,

I am a UK resident and have been following the blog for some time now and it is truly fantastic. Apologies for changing the subject but I really wonder when Umarex will release some more pellet pistol replicas. Might you know why they seem so hesitant to release new ones this year? Is it the R&D involved which makes it prohibitively expensive when compared to BB action shooters. I have scouted a great number of blogs, particularly in the UK and there seems to be a far greater demand for new pellet pistols than for BB replicas so can’t see why Umarex is disinclined to release new models for 2014. Would you be able to shed any light on this?

Regards,

Oli

Oliver,

They aren’t being reluctant. I am reporting on the Colt Python revolver starting tomorrow.

What you are experiencing is the time distortion that results from my reporting on a trade show on the internet. You find out months before these guns arrive for sale. It has always been this way, but reporters were not able to get the word out as fast when there were only magazines in which to report.

Umarex is pushing replica airguns just as fast as they can.

B.B.

Consider how many of us are still waiting for Crosman’s “butterfly” cantilevered air pump — which was first shown in 2012…

Or the Paradigm! can anyone say what’s happening there?

I will have to say after I did the o-ring behind the top hat trick. That I did have to re-adjust my power wheel and fill pressure of the gun. I was able to go to a lower fill pressure.

I just wish I knew why. 🙂

I have no idea but that sounds like a good thing and you’d get more shots from your tank, or have to do less pumping with a hand pump, so Good Job!

Maybe the O ring is assisting the valve return spring?

Reb

Its moore like a balance of the componants working together.

B.B., I’m between jobs right now and have considered this for some time.

How do you suppose one would go about getting into airgun manufacture?

I would be interested in just about any aspect I can think of.

Is there anyone that may need help out there?

Reb,

I’m going to do you a big favor now and tell you that asking the question like that means that this is something you definitely DO NOT want to do.

You do it only when you cannot stop yourself from doing it and it takes over your life. Ask Lloyd.

B.B.

I think I’m already there, but I will take your advice and just have to settle with tinkerin’ around here.

Thank You, Sir

Reb

Reb,

Tinkering is the way to go. Tinkering leads to innovation. You never know what big ideas will spring from small things we do.

Edith

Edith, I suppose I do have a few projects I could keep myself busy with. Right now I’m trying to figure out where to start with this Tippman.

RDNA, I just found an OK. Nova for sale, that looks just like the gun you picked up the other day, same lever and all.

OK, here we go! I’m assuming that co2 can be used in a hpa tank however not the other way around?

I’m also considering a vortex block for the feeding mechanism, running .22 round balls or possibly a forced feed like the Crosman 2100. Any thoughts? If anyone has any ideas concerning the valve work, just spit ’em out, I’m all ears!

Thanks for your considerations!

Reb