by B.B. Pelletier

Testing and photos by Earl “Mac” Mcdonald

Well, Mac finished his test of the .22 caliber Beeman R1, and he learned a lot in the accuracy portion. As promised, I’ll tell you what he learned that he could not believe until he demonstrated it for himself.

First things first, though. The first thing Mac learned was that he had trouble seeing through the Bushnell 4-12×40 scope to the point that he became disturbed about it, so he removed it and mounted the Leapers Accushot 4-16x56AO scope he used in the test of the HW50S rifle. Once that scope was on board, he was satisfied and got to work testing accuracy.

No accuracy?

Only there wasn’t much to speak of! He was surprised that the best the rifle would do at 30 yards was groups of more than one inch. He called and asked my advice. He wondered if the R1 is a hold-sensitive rifle, and I told him it’s very hold-sensitive since it’s a breakbarrel. Most breakbarrels are. They require the utmost skill with the artillery hold to shoot their best.

I told him my special technique of laying the rifle on the backs of my fingers, with my off hand touching the triggerguard. This makes the rifle muzzle heavy, and the R1 is already a very heavy rifle, so this influence is magnified. Mac shot this way and noted that the rifle dug into his fingers quickly due to the weight.

But that wasn’t the end of it. I also told him to clean the barrel with JB Non-Embedding Bore Cleaning Compound on a brass or wire brush. You veteran readers know the drill by now, but for the new readers among us, it works like this.

Cleaning the barrel

Using a solid cleaning rod and a brass or bronze wire brush, you load the brush with J-B Bore Paste and then clean from the breech to the muzzle with 20 strokes in each direction. Push the brush up from the breech until it exits the bore, then pull it straight back again until it completely exits the breech. Do this 20 times in both directions, then remove all residue from the bore until it’s clean.

Mac balked at this procedure, because it didn’t make sense to him. It took us a week to get the necessary cleaning supplies to him, during which we discussed this procedure several times. How could this possibly help, he wondered, when the bore was already clean? He had run cleaning patches through it until they came out clean. I told him that the bore may look shiny and clean, but that it really was loaded with sharp burrs on the lands that needed to be removed. He would discover this when he cleaned the barrel himself.

The day finally came when he was able to clean the bore as described here, and he was shocked at what he found. The brush was extremely difficult to run through the bore for the first three passes in both directions. Then it became noticeably easier and he finished the cleaning with ease. This is normal. I’ve had barrels fight me with as many as 11 passes of the brush before they became smooth, but the transition always happens and the barrel is easy to clean from that point on. You can feel that the major obstructions have been removed.

After cleaning, Mac tested the rifle a second time and was shocked at the first groups that measured smaller than one-half inch! That’s 10-shot groups of .22 caliber Crosman Premiers going into less than one-half inch at 30 yards! Try to do that sometime with any spring rifle you own if you think it’s easy.

The half-inch groups did not last, though. He was shooting them intermittently while he was chronographing the gun for the velocity test, and before long they began to enlarge. They soon exceeded an inch in size. Mac called me asking what to do and I advised him to clean the barrel again. The Crosman Premier pellet is made from lead hardened with antimony; because of that, it deposits lead on a rough barrel very fast.

So, he cleaned the bore for the second time, and this time the accuracy seemed to return to stay. There were no more half-inch 10-shot groups, but they did cluster around three-quarters of an inch. Below is what Mac wants to show you — before cleaning and after. He’s discarded the half-inch groups as unrepresentative of the real accuracy potential and will show groups before cleaning and after two cleanings.

10 JSB Exact Jumbo domes before cleaning.

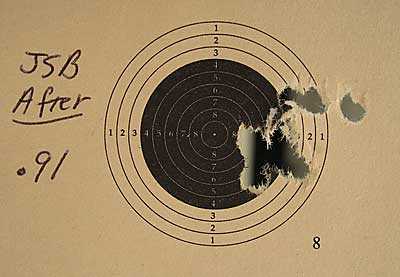

10 JSB Exact Jumbo domes after two cleanings.

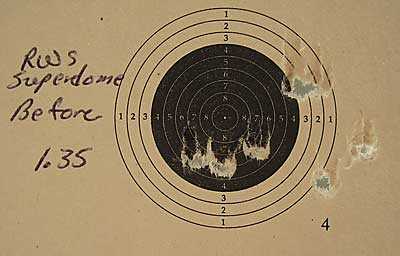

10 RWS Superdomes before cleaning.

10 RWS Superdomes after two cleanings.

10 Crosman Premiers before cleaning.

10 Crosman premiers after two cleanings.

Effects of cleaning with J-B Paste shown for the first time!

Mac was surprised at the outcome of the cleaning. This was the first time he had seen what J-B Paste can do to a new airgun barrel. I’ve been preaching this remedy for many years — ever since Ben Taylor of Theoben told me about it and I tried it for the first time. But this blog report is the first time I believe that the results of cleaning a new barrel have been shown so dramatically. And that’s the surprise I promised you. Some of you already know this from your own experiments, but far too many airgunners simply do not believe this treatment works. And here are the graphic results that prove that it does.

Mac’s assessment of the R1 is that it’s a nice air rifle, but a touch too twitchy for his tastes. He says that if he owned one, he would detune it for better consistency, which is exactly what I did with my personal R1. If you want crushing power in a spring-piston air rifle, get an RWS 54 that delivers it without the hold sensitivity of a breakbarrel. If you own an R1, it’s best to either learn how to shoot it with the proper artillery hold or else tune it back to softer power and recoil.

Mac also commented on the Rekord trigger in his test rifle. He says it broke cleanly at 54 oz., which is not light by anyone’s calculation. But he felt that the weight of the rifle, plus the glass-rod crispness of the trigger more than offset the pull weight.

His final observation was that once the Leapers 4-16x56AO SWAT scope was mounted on the rifle, everything seemed fine.

Wow, after hearing/reading about how the R1 has been a legendary, I am surprised that its accuracy (at 30 yards) is not as good was the recently tested R9, HW50S, and HW97, even after cleanings. Is it because of the R1 being too powerful, and/or too hold sensitive? Thanks.

tdung,

There are a couple of things working here. First, as a breakbarrel, the R1 is hold-sensitive. Second, as powerful as it is, it is ESPECIALLY hold-sensitive. Third, this particular rifle has a rough bore that will lead up fast. It will eventually smooth out from shooting and cleaning, but until it does, you will be cleaning it a lot to get the best accuracy.

Remember that Mac did get 10-shot groups that were smaller than a half-inch at 30 yards. But he then leaded the bore and had to clean it again. After that he didn’t get ant ultra-small groups again. I believe that with time he would have found what his test rifle wanted and would have been able to shoot the tight groups once more, because he shot many of them when he shot them. They weren’t just flukes.

But the R1 is a sensitive rifle that needs a careful hand to get the best results.

I guess that is the whole story.

B.B.

Morning B.B.,

Was shooting my Diana 350 Magnum yesterday with Crosman Premiers and wasn’t having much luck with it’s groups. Will get out the J-B Paste tonight and give the barrel a good cleaning!

Bruce

Mr B.

Watch shooting CP in that thing. I leaded the crap out of my TSS shooting dry CP in less than 50 shots.

Cp need some kind of lube to hold the leading down, but oil or other easily flammable substance is not a good idea. Must be used VERY sparingly.

Been shooting waxed CP and dry Exact with my 48 without any problems.

Once you get it clean and dry, push a few dry pellets through the bore to see how it feels. If accuracy drops off later after a bunch of pellets, push another dry pellet through the bore. If you feel some badly rough spots that were not there before you know that it is leading badly. You may also see lead coating the bore (particularly the lands) at the muzzle…if you dont have a brake or cocking handle to obscure your view.

twotalon

twotalon,

Thanks for the heads up on the leading with the CP’s. I’ve got 4 barrels to clean. What’s the best way to do a Discovery? Anybody!

Bruce

Bruce,

How about a report after the cleaning?

B.B.

B.B.,

You’ve got it, but first I need to get a one piece cleaning rod.

Bruce

B.B.

I had trouble with my first Talon barrel leading up. AF told me to use JB paste so I got some from Brownells. Trouble is Brownells sells the the cleaning paste and the polishing paste. I didn’t know which to get so I got the polish. The stuff helped some and the bore felt better and took about twice as long to lead up with pellets that were lubed or not lubed, but the barrel was still beyond help. The last half of the barrel was very rough (from center to muzzle end).

I have cleaned most of my other barrels with the polish and it has slicked them up pretty good.

The 48 is another story, as the only way to clean or polish from the breech is to tear the whole rifle down. The only cleaning it has got was to cock it to expose the breech end, shoot some break free in the bore, then let it stand vertically (muzzle down)for a few minutes before pulling a brush through from breech to muzzle a few times. Then another shot of break free followed by several patches. All this pretty much just removed the dirt. Barrel is very good and does not lead easily.

twotalon

twotalon,

There is only one JB Non-Embedding Bore Cleaning Compound. You want the cleaner, not the polisher, though that may work, too.

AirForce recommended it to you because that was how I used to “fix” most of the “inaccurate” barrels that were sent in to the company. One of my jobs was to test all rifles before they were sent back to their owners, and almost invariably a cleaning with JB Paste did the job. In fact, I can only remember one barrel out of all those I cleaned that didn’t shoot right afterwards, and we discovered that it hadn’t been choked. That one barrel was swapped for a new one.

I made believers out of everyone there (as well as myself) with what this stuff can do.

B.B.

B.B.

No doubt that getting the dirt and the fuzzies out of the barrel helps.

AF only told me ‘JB paste’. At the moment I did not know that there were two different JB pastes.

I cleaned my barrels with the polish this way…

Breech through muzzle one way only a half dozen times. Then stand muzzle on a folded paper towl or rag on the floor. Tight fitting patch with polish rubbed in…shoved up and down the bore 20 or 30 times. Repeat a couple more times with another patch and more polish. Then follow with clean patches. Bore sure looks and feels nice after that. That’s also what I did to that purple 24″ AF barrrel that looked like trash. The bore was not bad at all after a few patches, but after polishing it up it has the best bore of any of my rifles or spare barrels.

twotalon

BB; What would you recommend when using the JB compound on a RWS 52? You can’t clean from the breach unless a pull through is used. Or, perhaps a rod that is inserted first then the brush attached?

Thanks.

Mike

Mike,

I cleaned a diana rws 54 several times which is a kissing cousin to the 52.

You can clean the barrel from the bore to breech but must be extra careful not to touch the crown/end of the barrel. Attach the brush to the rod first. Before you begin be careful. If you create a burr or foul the end of the barrel you’ve cost yourself untold accuracy. Use a crown saver or at least put a properly sized drinking straw at the end of the barrel to insure that the rod does not contact the lands and grooves of your barrel.

In the breech end strategically place a rag or paper towels to completely capture any jb bore paste that is cast into the breech. You don’t want this to migrate into the internals of the gun. Wipe off any excess bore paste and compound used to treat your barrel in the final pass from your breech seal.

kevin

BB,

In my experience, my RWS 54 was hold sensitive like most other springers I have shot. I found it capable of really good accuracy once I found the exact spot it liked to be rested, and the right amount of grip and cheek weld. At 40 yards, groups before I got the hold down were about 1 1/2″ and after I got it figured out, groups were small enough to be covered by a nickle. That was just my experience with one attuned 22 caliber 54. Others have said their 54s were not hold sensitive.

David Enoch

BB: I’m glad you did this blog and showed the before and after pictures. The worst one I had a similar problem with, was with my RWS 320 . That is, until I cleaned the bore with JB and lubed the CPLs . Another was a Daisy SG. Many of the airgun god’s over on the forums, especially one in particular, will flame you if you mention cleaning a airgun with a rod and bore paste. They only recomend a piece of weed wacker line and goo gone. Sad thing is, goo gone will damage seals if even a little of it runs into the transferport and sets there awhile. Especially the chinese chewing gum like material seals. Also, if you leave a barrel completely de-greased with simple green or goo gone, and do not lightly oil the bore after, it will rust. Rust will damage the delicate rifling more than anything. Airgun barrels do need cleaning sometimes and you need to buy the materials to do a good job. Some folks can’t get past that and won’t buy a good rod and learn to use it.

Although a different type of gun , I have found that leading and wad fouling in my shotguns to affect accuracy. We have to use shotguns with slugs to hunt deer here. Before the advent of rifled slug barrels , I found that accuracy suffered even in the smooth barreled guns. Groups would be twice as large from a fouled barrel. I used to brush and clean after every five rounds. Five round groups are a lot for slugs, you shouldn’t need shoot more than once or twice at a deer, Robert.

Yeah. Some people have misconceptions and pet procedures. They can’t stand to think of anything else. I doubt that googone on a patch will get rid of lead or the fuzzies.

twotalon

They jumped on me pretty good when I used to post on that forum ( I don’t post on any forums any more) for questioning that myth and a couple others. Of course, the guy who owns that forum, by his own admission, didn’t even own an airgun or any type of gun five or six years ago. He even tuned guns for a year or so ,then “retired”. Being around guns of all types for a very along time it is hard to accept advice from folks like that.

I use goo gone and oops to clean up paint and construction adhesive in my work. Both are solvents, and contain hyrocarbons. If they will disolve dried on PL 400 in carpet , they will harm a seal used in an airgun if allowed to remain for some time. They will not disolve lead or can they be used to polish bores. You can use them to clean the greasy gook that comes in the chinese guns out of the barrel first. Then you need the JB and the brush. After that a lightly oiled felt cleaning pellet to lightly coat the barrel is good. Just don’t let the cleaning product run into the compression chamber.

Robert,

Those other forums also try to scare the crap out of you for using a metal cleaning rod. I have also heard B.B. caution during use, but not discourage from use. What is the truth in the matter? I’m not sure because when you use the rod and there is resistance in the barrel, the rod flexes and so may rub the barrel. According to those on other forums this is disasterous.

Fused , Use common sense. The JB lubricates the brush , which should be soft brass. If the rod flexes badly , then use a smaller brush ,or squash it a bit . Problems from rods arise when folks saw them back and forth without caution , use to tight of patch, and /or brush, no lube, and bend the rod. If you have to force ,STOP!, and regroup. Use a crown saver if possible and necessary, with both rods and pull throughs. Also, using jointed rods and poor (soft material) quality rods to clean with is bad. You have to buy the right stuff if you are serious about maintaining your gear. This also includes a good gun vise to hold your gun while cleaning it. If you stick a pellet inthe barrel of your gun , how would you remove it if you had no rod? How would the tuners and forum jockeys remove it? Robert

Fused that is “use a crown saver “, disregard the” not” part. Little typo there, I’m a hunt and peck typer, with two fat arthitic fingers,Robert.

Robert,

You have some good info here. Do you think you could ask Edith to help you correct your original comment about the crown protector to avoid confusion? Probably involve deleting your original comment and re-adding it. Save the original in ms notebook or whatever wordprocessor you have before correcting it.

-CJr

Edith or whoever repaired my typo above ,thank-you, Robert

BB, while it’s good that MAC found bore cleaning to be effective, isn’t it a little bothersome that an $800 air rifle needed this step? I would think that the roughness he found indicates a sub-par barrel bordering on a factory defect.

Well, bench rest shooters have used JB bore paste to clean guns before they even fire them for the first time. Those barrels and guns ,cost several times what a simple HW barrel would cost,Robert.

The cost of $800 is in line with the quality IMO. The barrel is not defective it just has minute burrs left from the tooling . It would cost maybe $1500 if it came lapped. What you get with a good quality barrel ,like from HW is excellent quality steel suited to the application, machined with excellent tooling , by skilled tradesmen who were motivated to produce a good barrel. What you get with the chinese barrel may well be what borders on defective. When you polish a good bore ,you are making it a little better, if it was good to begin with. The problem with many shooters today is that they won’t use the right materials to maintain their gear, and they equate perfect with money ,based on comparrasions with crap.

It’s not that cleaning helped at all, it’s that the cleaning helped so much. And it appeared that two cleanings were necessary to get what still seem to be less than stellar groups (again, considering the fact that it’s an $800 rifle). If I’m not mistaken, BB’s tested a number of lesser rifles that left the factory without benefiting nearly as much from the procedure as this rifle did (or not at all) … and delivered what I believe to be comparable accuracy in the end. Look up his tests of the Gamo Big Cat and the MP513.

This does indeed speak to the tooling and machining. As for the specialty steel, air gun barrels are typically mild – I don’t believe any exotic alloys are called for or used.

Lastly, if the factory did take the trouble to do essentially what Mac had to do, I hardly think it would’ve added $700 to the price of the gun. If it did, I’d sure like to have that job… must work out to over $1000 an hour!

Vince,

What can I say? We just reported what happened. Yes it does seem a bother, but I’ve seen similar results with other Weihrauch barrels.

My own R1 is extremely twitchy, but I learned how to shoot springers because of it. And a detuning does improve performance in many cases.

B.B.

Vince,

I have had to clean brand new Lothar Walther barrels for the same reasons. So nobody is perfect.

B.B.

Good points all. Like always Vince brings everything back into perspective. Before we get too carried away with HW model guns – make sure you realize what you’re paying for. Fit and finish (barrel excepted) are worth something, it’s up to the buyer. But we shouldn’t pretend that there is nothing else that can compare on performance, perhaps at a more reasonable price.

You know, looking at Mac’s targets, I’ll bet those “fliers”, the pellet holes that are outside his main poi, would disappear if he took the trouble to sort the pellets. I know, it’s really not worth it here as it would just take that much more time to test and report on the rifle but I think it’s something the Blog readers should keep in mind. As for lubrication, if you don’t want flammable liquids or petroleum based combustible liquids on your pellets – such as BB’s touted Whiscombe Honey, remember Wayne and his coconut cooking oil. He swears by the stuff and I think it was Alan L. who was happy with the way his eggs fried up 🙂 with it. So you get two birds with one oil (sorry).

Fred PRoNJ

At this juncture, I think it would be a good idea if Wacky Wayne would give us his process on using coconut oil. I have a jar waiting to be used but I’m not sure what to do.

-CJr

Anybody know if Crosman’s customer service number listed on their website is any good?

I am having trouble contacting them.

twotalon

I have been blessed by the Air Rifle Gods this week end. Neighbor had thrown away 2 Daisy BB guns, a Model 25 and a Red Rider. The RR is in very bad shape, plastic stock and made in Arkansas. The 25 is also made in Arkansas, but is in pretty good shape, some rust but a good shooter. Both for free.

Went to an antique sale and bought a .177 under lever springer for 40 bucks. It has no wording on it and will probably be hard to ID. I will get some pics soon. I have never held an under lever springer. When I cock it, the chamber will slide to the rear, exposing the breech. The breech is not flat like my break barrels, it is “cone” shaped. Not trying to be cute here, but the cone is a “male”. The chamber has a “female” cone with a plastic seal inside. My first question, is this common for an under lever, the cone shaped breech?

Something else it has is an adjustable front sight. It is shrouded, but it has no blade, it has a pin on top of a threaded bolt. The top of the shroud has a hole to insert a tool to raise or lower the pin. The rear sight has not windage but it too will lower/raise. Is the front sight common to any certain rifle manufacturer or time period?

I am hoping the breech and or the front sight will help me get a name to this rifle. It shoots great btw

That sounds like that cheap Chinese piece of crap I got at the cummins sale. Cone shaped breech and a funky cone shaped plastic seal in the face of the sliding chamber.

twotalon

Did I mention the stock looks like it was painted?? lol Either painted of some kinda stain. Orange is the best color I can come up with. The screws are all slotted head screws/bolts. If that helps any.

Yep.

twotalon

Gene,

Does it look like the gun in this article?

/blog/2010/08/industry-brand-b3-1-part-1/

kevin

OK, 2 out 3 Gods were smiling at me this w/e. lol

Yes, it looks alot like the B3. The shroud is different, mine has that hole on the top, and a pin, can’t see what your pic has. My rear sight is way back on the receiver, the rear sight and a rail is all the same piece of metal. The lever handle is almost the same, mine has thin grooves, not the “diamonds” your pic has. Trigger and guard looks 100% the same, no safety.

So much for my reading skills, it was only a month ago when BB wrote this.

Gene

That sounds a lot more like mine than the pic of the one in B.B.’s blog .

Mine also has the rear sight in the dovetail at the back, and a plastic butt plate. Sling swivels on one side.

twotalon

Yes, and the forward swivel on the right is also the stock screw, one is any way.

Was yours called a B3?

Just says cummins industrial tools on top.

Cost $20 a few years back.

twotalon

Gene,

Just a reminder…………it was free.

kevin

Actually the 2 BB guns were free, the B3 was 40 bucks, but to have another Model 25, priceless.

Thanks guys.

Wow,

Some one made out on the B-3. You can pick those up all the time for $20 or less if you find some one with one that wants to get rid of it.

Keep in mind that Cummins warranties them and I have bought several non-working ones or ones missing parts and taken them back to Cummins and exchanged them for new working guns. Then sold them for $20.

Keep your fingers out of that breech after cocking!

Gene, I don’t think you got a genuine B3. What you got, I believe, is a crossbreed that was actually based on the now-discontinued B4-2 rifle. The B4-2 bore a strong resemblence to the B3 but had a larger powerplant and is generally made better. Cummins sold these a while back as “B3’s”, even though they weren’t. The adjustable front sight is the giveaway, I think.

“Real” B4-2’s have a rear sight that’s adjustable for elevation only with a pushbutton slider. It also had a scope rail that was so badly secured that it was worthless until it was glued down. And it had a trigger-blocking safety. The Cummins variant had no safety, a rear sight adjustable for windage AND elevation, and the scope groves were cut directly into the main tube. The rear sight, BTW, was not permanently mounted to the gun – it was clamped onto the scope rails. Really, it was a better gun in my opinion.

That front sight is adjustable, BTW, with an AK47 front sight adjuster tool. I believe you’ll find that it adjusts for windage, too.

To make sure – pull the action out of the stock sometime (keeping the gun upright), and check the pins holding the trigger pieces in place. If they can slide right out it’s a B3. If they’re peened over so that they cannot come out it’s the B4-2 variant.

Frankly, $40 for a B4-2 really isn’t that bad…

Vince,

You’re one of the main reasons I keep checking back here. Your hands on knowledge, which I know of first hand, is what I count on. So many other forums have posters that spew forth opinions and arrogantly claim those opinions to be gospel when in fact they misquote and have little, if any, first hand knowledge of what they speak.

I think you’re too humble and speak too infrequently.

The hidden power of this blog is in knowledgable

kevin

GLITCH caused by me.

Vince,

The power of this blog is in knowledgeable airgunners like you. Please don’t be a stranger.

kevin

This article is a wonderful primer on shooting magnum springers accurately.

Once upon a time I spent a lot of time shooting a variety of magnum springers (break barrels, sidelevers and underlevers) for power and accuracy. Here’s my two cents to be added to the checklist to wring out ultimate accuracy:

1-I clean the barrel of every new/used gun I acquire. Right or wrong it eliminates an accuracy variable in my mind. Use a one piece COATED cleaning rod with brass brush loaded with JB Non-Embedding Bore Cleaning Compound (as already described). Hold the handle of the rod not the rod itself when making the passes through the barrel (from breech to muzzle if possible). I like dewey one piece cleaning rods.

2-Check stock screws, trigger guard screws, mount screws, pivot bolts, scope ring screws before shooting and during shooting.

3-If you’re shooting hard pellets, like crosman premiers and rws superdomes, lube the pellets. I like krytech wax lubricant but many others, like coconut oil, fp10, whiscombe honey, etc. since they purportedly work as well. Whatever lube you choose use it sparingly.

4-Put at least 1,000 pellets through a new gun to break it in. Dieseling and velocity variation are common in this break in period and ruin accuracy. Don’t expect much from your gun in this break in period.

5-Experiment with a large variety of pellets.

6-Experiment with a large variety of holds.

7-Lighten the trigger pull. I’m a terrible shot and I couldn’t be very accurate with a 54 ounce trigger.

8-For the longer distance accuracy these guns are capable of get a good scope that is rated for magnum SPRINGER recoil.

9-If you need a pellet to go faster than 850 fps buy a pcp, hpa or msp.

kevin

Kevin,

Thanks, as always, for sharing your great wealth of experience and knowledge. Now I know what to get, and thanks to B.B. and you, how to do it.

AlanL

AlanL,

Thanks for the kind words. Not sure I would describe it as much as a “great wealth of experience and knowledge” as much as a bushel basket of frustration but with B.B.’s guidance many AHA! moments at the end.

Always happy to assist others in investing lots of time and money in this hobby LOL!

kevin

You see?! This is what I’m talking about. You HAVE to read every comment because there is so much information hidden in the bunch that is valuable and would be missed otherwise. (now who wants to go through all the blogs and pick out all these jewels and put them in one blog?)

-CJr

CJr,

As often mentioned, that’s exactly why I wish the search function on the blog would also include all the comments. Of all the improvements that could still be made to the blog, that’s by far the highest priority one, in my humble op.

-AlanL

You nailed it Kevin , very well put. Still, you know it’s hard to convince folks who get all their air gun cleaning supplies from the lawn and garden section of Wamart. Otherwise, the forums wouldn’t be full of posts asking why isn’t there a cheap subsitute for pellgun oil that you could buy there,Robert.

Robert from Arcade,

Amen. Invest $500 + in a gun then spend an inordinate amount of time saving a total of $30.00 on maintenance supplies that will last you for years.

kevin

Applying Pellet Wax

Use an old pellet tin, like a .22 cal screw-on Crosman type, shake the KryTech well, put a thin coating all over the inside of the lid. Pour about 75-100 pellets into the bottom of the tin, screw the lid on, then roll the tin around on its edges and flop it around in the manner of turning a coin over and over. Alternate directions and rotations so the pellets get a good chance at rubbing each other and contacting the underside of the lid. Open the lid, pour another hundred in with the first batch, close up and do the rolling and flopping again for another 15 seconds or more. Let dry with the lid off for at least 10 minutes.

Another proven method is to take a fresh paper towel and wet a strip 1″ wide strip down the middle. Roll a half tin of ammo thru the wet spot and then transfer to a dry towel to let the volatile carrier evaporate. This procedure was suggested by Steve Schulz (2002 National PCP Champion) and has been used by numerous champions since.

A Little Does a Lot

The pellet wax is thick, and if sprayed directly into the back of a pellet cavity, it can dry and make the pellet heavier, which will hurt long range accuracy and promote dieseling in Springers. It doesn’t need to be applied in great volumes, according to LD who did extensive testing of KryTech in spring guns. Even if it is applied lightly every fourth pellet it still has the desired effect of eliminating lead fouling and extending barrel cleaning intervals.

WARNING! KryTech contains PTFE and when burnt by smokers can cause health problems. Never smoke anything before you have thoroughly washed your hands of the pellet Wax.

Shoot More/Clean Less

A thin layer of the KryTech product extends barrel cleaning intervals by reducing the amount of friction between pellet and bore. The wax gets burnished into the pores of the steel and leaves a shiny finish like a waxed car with all the irregularities of the surface smoothed over. Like a waxed car, the cleaning chore is much easier. You never have to pull more than 5 patches through a conditioned barrel to have it spotless and ready to kick butt again. Lubes will not only condition the bore, but protect it from corrosion, and the wax will let your gun shoot a few FPS more as well. The KryTech dries on the pellet leaving only a waxy film that will not attract dirt and won’t attack your breech seals or leave a mess on your shirt or pants from wiping your wet fingers.

Makes Guns More Accurate

If you treat your equipment with care its performance will reflect it. LD did exhaustive research to find this lube that will work in Springers without dieseling excessively. Since he owns hundreds of airguns he wanted to use a single lube on all of the pellets used in them. Since I’m his bud, he came to me to market it and it has taken some top guys to another level. Shake well before use and keep in a cool dark place.

Wacky Wayne swears by coconut oil instead…

It might work better. I’ve never tried coconut oil.

kevin

I do something similar with pellets in a tin.

A shot or two of teflon/wax lube (Dupont). Add some pellets and roll the tin around as you described. Then open the tin and pour the pellets into the lid. Wipe the excess lube out of the bottom, then pour the pellets back in. Then wipe the excess out of the top. I only put enough pellets in to just cover the bottom of the tin (large tins). Shake the tin around enough to get the pellets in one even layer and let dry. Have to work pretty fast before the carrier evaporates too much and the lube gets thick.

For oil, sometimes a few drops in the tin, pour in some pellets, roll around. How many pellets and how many drops has to be worked out. I have sometimes poured out the pellets then wiped out the excess oil before returning the pellets.

Another way…Cut a couple layers of paper towl to fit the bottom of the tin (you could use the foam pad if the tin came with one) . Add a few drops of oil and roll the tin around. Surprising how much dirt gets picked up on paper towl.

Lots of other ways too. These are just what I use.

Then there is pledge in a baggie. But if you ask these guys which kind of pledge the don’t answer. They must want to look like experts, but have never really done it themselves.

twotalon

What a treat this article is. I never expected a seminar on barrel cleaning on top of the R1 accuracy report. This shows how necessary it is to read every word BB’s blog contains as well as the ensuing comments. This one article drives home all the other barrel cleaning tips mentioned on this blog. Since repetition is the key to learning for me, BB, you can’t repeat too often any of the valuable tips and techniques you offer us on this blog.

-CJr

B.B.,

Being the ham handed trembling duffer that I am, it is next to impossible for me to get 1/2″ groups at 25 yards (let alone 30) with my RWS 350 and RWS 54 (both .22). So my question is, is there a sure fire way for scatterblasters like me to determine that a bore (new or otherwise) has burrs on the lands or requires a cleaning? I remember much earlier in the blog that you basically advised Against cleaning bores unless absolutely necessary. You also mentioned that simply shooting 300-500 pellets through a gun would wear away any burrs just as effectively as wire brushing it. On a related note, you mentioned that Crosman Premiers also tended to lead the barrel (which I take to mean that they eventually fill up the grooves with lead and thereby eliminate the benefits of a rifled bore.) It was this latter concern that seemed to be the primary reason for cleaning a bore, is that right? Anyway, the main question is, how to tell that a bore has burrs, other than accuracy problems?

-AlanL

The top of the lands and the edges of the lands at the top get loaded first. Where the contact is heaviest is where it rubs off first.

twotalon

Alan,

You are asking the equivalent of, “If I whisper during a hurricane, why can’t anyone hear me?” If you are truly ham-handed (and I doubt that you are) there is no way you could ever notice the small effect of a dirty bore.

What you lack sounds more like experience. You are not applying the artillery hold correctly.

I used to teach people to shoot using the artillery hold at the old Winston-Salem airgun Expo (before Roanoke). By the time I was done instructing them they invariably said, “Oh, if I had done THAT all along, I would have shot much better. I didn’t realize that when you said to hold the gun loosely you really meant it!”

So let’s concentrate on the artillery hold first and foremost. Watch the video embedded in this article:

/article/The_artillery_hold_June_2009/63

As for whether your barrel is clean or not, assume nothing. If you think it’s dirty, just clean it. It’s the only way to be sure.

B.B.

Thanks B.B. I’ve been a dedicated student of your artillery hold since day one. I have no problems getting tight groups with my HW30. It’s just the heavier rifles that seem to be more squirrely.

-AlanL

BB Have you ever campaigned the spring gun makers to enlighten their customers re Artillery Hold?

Every time I go to Cabelas and look in the “bargain cave” I see dozens of RWS and Gamo rifle returns on the sale rack. I have to believe that many of those returns are due to accuracy as the neophyte shooters view it? (have never bought one a) they don’t discount the price neough and b) more importantly, I’m the only one I trust to have never dry-fired a springer

Even a co-worker of mine could not get his Gamo to shoot accurately until… well you know what I showed him and lo and behold, he gets 2″ groups off-hand at 30 yards.

Seems to me that the makers would be doing themselves a GREAT BIG favor with sharing this info and likely insuring return customers instead of product returns?

PS most of the rifles at Cabelas were so-called “magnums”, so that makes it even worse!

Brian,

My experience is that most shooters who object to magnum springers are shocked by how hard they are to cock.

B.B.

For those of you who have IE8 and have complained that the print in the blog is too small, our programmer has provided this info:

Hold down the “Ctrl” key; then using the scroll knob on your mouse (the thing inbetween the buttons used for scrolling up and down), roll it forward one click. This will zoom in the webpage. You can do it more then one click, but if you’re not careful and roll it too far, it will zoom in too far. To zoom out, hold down the “Ctrl” key and scroll backwards on the mouse.

Hope this works for you. My browser (on a Mac) is Safari, and I hold down the command key & the + key to quickly enlarge print…or the command key and the – key to reduce print. I always use the + button on the blog, so I can sympathize with those who think the print is too small 🙂

Edith

Edith,

I use IE8 and your technique of using the ctl key and scroll knob works for me. Thanks for that.

-CJr

Also holding the “Ctrl” button and pressing the + or – buttons will have the same effect. helpful for those who maybe are using a laptop w/out a mouse

CTRL+Shift+(+) [plus sign, no parentheses] will magnify in Firefox too, great if you don’t have a scrolling mouse.

CTRL+Shift – will make smaller.

CTRL+0 [zero] returns everything to the normal view. Great for blowing up pictures then quickly returning to normal.

-AlanL

Am now a wholehearted convert to ChairGun.

We usually head to the range Saturday mornings for a bit of R&R. Debated whether or not to go because there was a stiff 35km (22mph) wind that was blowing across the range.

Packed up the laptop and decided to try to shoot anyway.

Fed in the pellet, wind, fps info and came up with a 12″ adjustment at 30 yds.

So, picked a point to the right of the target…about 3″ off the paper and let fly.

Holy crap…within an inch of dead centre on the first try!

The wind was definitely playing havoc all round as it was gusting…but still, managed 10 shots in a 3″ circle with open sights, all hovering around the centre of the target.

Very impressed.

Now…does anyone know if they make a Chairgun app (or something like it) for the i-Phone. Packing an expensive labtop into the field is not something I relish.

CowboyStar Dad, I’ve got a question for you about your car-racing days. In one of the Bob Lee Swagger books (Night of Thunder), he switches gears to hunt a new kind of assassin. This guy doesn’t pursue his target with guns but with cars. He’s a renegade NASCAR driver who has been banned from competition who steals Dodge Chargers, soups them up, then runs people off the road with them. In the course of tracking him, the book gets into the details of driving including professional-level cornering which is supposed to be a very big deal. Ordinary drivers know to slow down once you go into a turn. However, for race drivers, this reduction in speed is unacceptable, so the solution is supposed to be juggling between the brake and accelerator pedals around the turns–“playing left foot right foot” as they call it. Is this true? Unfortunately, the controls on my rc car do not permit this, but it sounds interesting.

On a more mundane note, do race car drivers actually use a manual shift with a clutch at the high speeds they drive it? This is amazing to me as I am quite mesmerized to watch a shift driver even at normal driving speeds.

Matt61

Matt61,

I did a little racing with the pantera on can am tracks. In general, the answer is that you either go into a hard corner slow and come out fast or go in fast and come out slow.

kevin

Matt, in reality a race car set up for proper cornering allows you to ‘heel and toe’ for both shifting and cornering. The accelerator and brake pedals are positioned close enough that you have the ball of your foot on the accelerator while braking with the heel, though in fact once you are commited to the corner braking is for the most part a no-no.

What’s better is to get all your braking done before you hit the apex of the corner and than accelerate smoothing around the corner. If you have enough power you also want to create a situation in which you break the rear wheels loose and start a drift before you exit the corner. The reason for this is that when properly placed in the drift the car is ‘straight’ a little earlier than if you just drive around the corner…allowing you to accelerate out of the corner a bit earlier…it may only amount to getting on the gas 1/10 of a second quicker…but if you add those 10ths up over 10 or 15 corners on a road course you end up cutting 1-2 seconds off your lap time.

All of this is the reason that most race and performance cars still favor rear wheel drive.

Front wheel drive is more forgiving of a lot of different road conditions…but in the hands of an experienced driver rear wheel drive is much more capable of all out speed.

Gee…much like a magnum springer.

Matt,

Any driver trying to alternate between gas and brake during a turn would soon find himself into the outside wall. Think of what your tires are being asked to do: they can accelerate the car; steer the car; or slow the car. Any one thing will decrease their ability to perform the other two tasks.

Also, consider the effect of weight transfer resulting from acceleration/deceleration. Braking will bias the weight to the front end, thus unloading the rear and losing adhesion. Acceleration will unload the front end.

Any car will go faster in a straight line than in a curve. Weight transfer to the rear will lessen front tire grip, but if the car is going straight, that won’t matter. So, you would want to do your braking in a straight line entering the turn, then turn your car before the apex of the track’s curve (early apex).

This will allow you to line up your nose, more or less, with the next straightaway early in the turn. Roll into the throttle as you unwind your steering lock, and you’ve effectively extended the straightaway back into the turn you are leaving.

Driving a race car is a bit like driving on ice: you want to make all your control inputs as smooth as possible. The goober who tries to drive too deeply into the turn before slowing and turning will commit himself to a late apex. He might get ahead of you going in, but you will pass him coming out when you are accelerating in a straight line while he is still trying to turn his car.

CSD’s comments about front wheel drive are true, but some front-drive cars are still very quick and can outrun many big-engined rear-wheel drive cars on a tight course. The major problem with front-drivers is that the front wheels are being asked to propel the car as well as steer and brake it. They will hold a tight line until the front tires lose adhesion, then it’s head-first off the course. Rear drivers tend to exit the course rear-end first.

While my own racing career wasn’t as extensive as CSD’s, it did span dirt track stockcars and SCCA sportscars. It is the same laws of physics we all deal with. My little 2-liter Neon ACR could and did outrun a variety of big-engined rear-wheel drive cars on tight courses, especially 5-liter Mustangs, and, on occassion, even more powerful cars.

I just hope readers don’t take this guy’s book too seriously and get themselves hurt trying his “expert” advice.

Les

Matt,

Sorry. I forgot your question about shifting gears.

All piston engines have a rpm range in which they develop the most power. The idea is to get into a gear that will allow your engine to be in that range when you need to accelerate off the turn. If the corner is a fast one, you may not need to shift at all. You can figure on losing about a car length on every shift, but if you can stay in the power band, you will be able to quickly recover that.

Like doing your braking before you turn your car, you need to do your downshifting on the way in, too. A slow corner may require more than one downshift. It is NOT reccommended that you skip gears when shifting!

It is important to walk the track before driving it, to mentally note what you expect your car to be doing at any particular place. This includes where you will make gear changes and braking points.

My Neon has a 7,000 rpm redline. Before I reach 7,400, a limiter starts cutting out ignition power to the cylinders. If I would ignore that, it will simply shut the engine down completely.

My engine seemed to make the most power at about 6,800 rpm. So that was my shift point for upshifting. I mounted a big, bright shift light on the steering column that flashes at 6,800 rpm. This saves me from having to watch the tach when my eyes have more important tasks at hand.

The ACR has no engine speed limiter, just an rpm limiter. Here are the speed ranges I used:

First gear: 0-35mph. Second gear: 35-55mph. Third gear: 55-80mph. Fourth gear: 80-110mph Fifth gear: 110-130mph. Going by gearing, the car would in theory be capable of 150mph, but aero drag prevents speed above 130mph. The ACR has a closer ratio transmission than normal production Neons. Fourth gear is slightly underdriven; fifth gear is slightly overdriven.

Again, you always have to consider what you are asking your tires to do. A downshift at speed can cause enough deceleration to take a lot of adhesion away from your front tires, while unloading your rear tires (on a front driver). It is worse on a rear driver.

Les

AlanL,

This is for you:

https://www.youtube.com/watch?v=1VVOH7Ep_8w&NR=1&feature=fvwp

WARNING-Turn your speakers OFF

kevin

Kevin,

Gee thanks! First Slinging Lead and now you too! ‘Tis recoil I want… but in gentle moderation (like the kiss of a loved one- thanks CJr) lest B.B. get mad! 😀

-AlanL

So, the old JB Bore ploy worked eh? Mac should read the blog more. 🙂 I like the idea of what this cleaning can do very much, but I’m so paranoid about damaging the muzzle of my guns that the jar of JB that I bought has been sitting around unused. But Mike Melick used JB on my IZH 61 when I sent it in, so maybe I am reaping the benefits.

Matt61

Hooooray!!!

Finally got hold of Crosman. After many tries on my part with no success, my wife tries and they pick up on the first ring. How did the blond do it?

Two new seals for the Titan, and a new barrel for the 2300 in 7-10 days.

twotalon

twotalon,

The blonde did it because she called the phone they were answering next.

Duh!

B.B.

Rats!!!

At least I don’t have to get any more moly on my hands for a week. I put the Titan back together and have been shooting it with the bad seal to rub the moly in.

Getting low on moly so it’s about time to order a lube kit from Macarri.

By the way, that 97K is still itching me very bad. Even though I really don’t need another gun.

I saw Paul shooting one on American Airgunner and noticed the rings appeared to be high mount. May have been because of the scope objective size. Forgetting the objective size, what would be a good height for this gun if you know?

twotalon

Medium mounts for 40 or 42mm objective bells and scope length about 13″ to 13.5″. Get a scope length that does not cover or interfere with loading pellets into the breech.

Thanks. I was going to tailor the scope to ring heigth for the best position for sighting. Particularly after trying a scope on the 48 which fits the best with open sights ( what I really wanted in the first place).

Was looking at a BSA scope with sidewheel on PA 1″ sccope listings.

twotalon

The Hawke brand is nice and reasonable pricing too. I have the 4-12X x 40mm illuminated reticle on my 97K.

I also have two BSA scopes and they are better now than I remember them back a few years ago, also put a $39 BSA red dot on my Crosman 2240 this past weekend… didn’t expect much out of it and was pleasantly surprised with workmanship. It’s a red, green, blue dot model depending on lighting, and all 3 colors have 3 brightness settings. Knocking down 2 inch square metal plates at 30 yards with two hand hold. I was happy!

I have a TX 200 and it has a definite buzz that seems to continue after the shot. It seems to shoot fine and accuracy is good with the recommended JSBs. I wouldn’t have thought much of it but everything I read about the rifle is that is NOT buzzy. I got it new and it sounded like this out of the box, now I have about 2000 pellets through it and seems to have gotten no better, no worse. Any Ideas on what my problem is, or if i even have a problem. I have another RWS springer that sounds tighter and seems like that shouldn’t be the case.

I figured if there was an answer to be had about a TX this is the place… Thanks for any help. ~Brian

Brian,

You may have a mainspring with a slight bend to it. The TX 200 is easy to disassemble as it requires no mainspring compressor. The spring is under about 1/2″ of preload.

Let me know if you want to take a look. I’ll advise you of the reports that instruct how to disassemble.

B.B.

Thanks BB, yes please let me know.

Do you think this is causing any issues, long or short term, other than the noise?

Brian,

There are no issues, either long-term or short that can arise from a slightly bent spring. It’s not going to hurt your gun in any way, and chances are the bend isn’t going to get any worse.

But you will probably want to look at the powerplant yourself to confirm my diagnosis. If the bend is more than just slight it could affect the spring guide a little.

But enough supposition! Nothing to do but to find out where the buzzing is coming from.

There are numerous blog reports on how to disassemble a TX 200, but mine is quick and to the point:

/blog/2010/2/disassembling-and-assembling-a-tx200/

If this is still not enough information for you, let us know and we’ll find something that will work.

B.B.

I often have the temptation to go to work cleaning; it just seems something that belongs to the sport. But FWB gives strict instructions that the only thing to do to keep the barrels of my C-20 pistol and C-62 rifle is to shoot cleaning pellets, one or two per few hundred rounds. At most 3 pellets keeps the barrels awfully accurate. I didn’t clean either gun thoroughly for most of ten years, then last spring while recuperating decided to do a patch pull-through. It took no more than 5 dry patches (after one wet) to have the patches coming out absolutely white. This is about the usual pattern with both guns.

FWB also supplies some special lubricant, and I suppose I’ve greased maybe 1 pivot point per gun in all these years.

So I have no useful experience in barrel cleaning to improve accuracy. I suppose the most obvious conclusion is that’s what doubling the price of the R-1 bought in terms of manufacturing and finishing precision. Shine a light down the barrel and it’s like looking into a metal mirror.

I should have added that at the third cleaning pellet, there is no trace of lead or other dirt on the felt pellet.

I have a barrel cleaning question and it’s NOT what I can use instead of the JB paste 😉

After reading this I’d like to clean a few of my airgun barrels but I’m puzzled by the shrouded barrel of my Benjamin Trail NP, won’t debris, gunk or junk coming out of the barrel plug the shroud?

I went looking trough old blogs and you did mention that you cleaned the Benjamin Trail XP barrel but didn’t mention (or maybe I missed it) if you let the shroud on it or not or if you used something to keep the junk out of the shrouded part and if I do have to remove the shroud could someone please tell me how? I know there’s a ring at the tip but I can’t seem to make it move and I don’t want to damage it so I didn’t try too hard either.

J-F

J-F,

Cleaning a shrouded barrel is the same as cleaning a plain one. It’s the baffled barrel that causes problems, but you still clean them the same way. Go in through the breech if possible and try to keep the brush from touching the baffles, if there are any.

On some rifles such as the Benjamin Marauder, you can remove the barrel from the rifle. Then, just clean it in the way I’ve described.

But don’t clean any airgun barrel unless accuracy has fallen off. They don’t need to be cleaned like firearm barrels do.

If you want to shoot Crosman Premiers in a barrel that leads up, I recommend coating the pellets with Whiscombe Honey. That’s a mixture of two parts Hoppe’s Gun Oil (from a good gun store or online) and one part STP Engine Treatment. Drop 20 drops into a foam base in a pellet tin and put down one layer of pellets to be oiled. Then just let the pellets roll around on the foam. Normal handling with coat them. This does not diesel and helps keep the bore clean.

B.B.

Hi Fellow-shooters–

I just won a Beeman R-1 at an auction in upstate NY….days after one of those mass-killings. They had in the doorway a pile of “BB guns” laying there…I was the only one who showed any interest at all in this mixed collection of air rifles…[this beeman, 1 daisy, and 3 benjimens ]. Then I overheard the auctioneer say that he wanted to sell off the BB guns 1st and to put the hi-powered rifles away in the office. You couldn’t have thrown a dead cat in the room without hitting a gun-hater! Well, no surprise that I won the beeman, although 3 other guys put bids in…the thing is: I need to get more info on this air gun…and I still have a few other questions–

MY BEEMAN:

made in W. Germany

Has a stock with hand-checkering and white spacers*

Has sights…open sights and really good ones to boot!

Came with a Bushnell Banner scope [2.5 X something, it’s covered by the ring]

the guys at Pyramyd said mine is a std. model [I took the scope off for shipping]

So, what do you guys think? Do I have some weird vintage model that’s like a crossover or missing link?

Have I mentioned that I am blind in my shooting eye [right]? And, that I may have to sell this air-rifle to get that very eye fixed???** So, I have a R-1…std or not, gorgeous beech hand-checkered stock*, made in W. Germany, just completely re-done at the factory ready and able for sale–

e-mail me at: mulefool13@verizon.net

* honestly, my R-1 is better looking than any I have seen on this site…there are no dings, nicks or gouges–just signs of light use…if it was a coin, I’d grade it AU-55

** ironic ain’t it!?

thanks and happy hollardaze,

Steve R

Ravenstalin,

Welcome to the blog. Your rifle is dead-stock normal for a Beeman R1 from the 1980s and ’90s.

Here is another huge R1 report, with links to all the other parts:

/blog/2006/08/spring-gun-tune-part-13-range-testing-the-r1-we-tuned/

B.B.