by B.B. Pelletier

Vince is back with 2-part blog about another gun he’s repaired. I get a lot out of Vince’s guest blogs because he gets to play with and repair guns that I don’t have! I learn a lot and I’m glad to see that there’s someone who can do such fine work and be incredibly resourceful at the same time. He sets the standard high. For those of us who don’t work on airguns, it’s just nice to know that there’s someone this good who does.

If you’d like to write a guest post for this blog, please email us.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them), and they must use proper English. We’ll edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

by Vince

Guys know the type. Pretty to look at, but not overly flashy. Demure, faithfully consistent, does just about everything she promises to do, never lets you down, very forgiving and seems to be just about the perfect partner for a lifelong commitment.

Then it happens. One small misstep — one slight slip of the mind, an apparently insignificant momentary lapse in judgment or prudence, and BAM! It’s all over. The relationship lies in pieces, the damage is done, and the joy of newfound attraction is gone forever. IF ONLY YOU HAD KNOWN!

Well, after this article YOU WILL KNOW! And, fortunately, it doesn’t have to end this way. One can, indeed, live quite happily with the Diana 300R repeating underlever.

Repeater… the “holy grail,” in a sense, of better air rifles. A repeater that takes all pellets. A repeater that sacrifices nothing in accuracy. A repeater that’s easy to load and doesn’t misfeed and doesn’t mangle pellets. A repeater that…well, you get the idea.

The RWS/Diana 300R hit the market a few years ago as an upper-tier gun in the Diana line. I’m not sure what it cost, but it I believe it was in the range of $400. Whatever it got, it didn’t get for long, as the rifle disappeared from the catalogs after a relatively short run. All due to that hypersensitivity to even the slightest mishandling — if it was the wrong kind of mishandling.

The 300R is a fairly heavy underlever springer with a T05 trigger and a 7-shot .177 rotary mag. It’s equipped with Diana’s standard iron sights — open blade front and a rear adjustable for windage and elevation. As expected for a Diana underlever, it’s on the hefty side, with a weight of around 8 lbs. All that’s pretty standard in the way of specs.

Nice wood!

The real trick to this rifle is in the magazine that loads from the top.

See where my finger is in the above photo? It’s pushing back on the top cover of the magazine, which is how the mag is released so that it can be removed from the gun. But wait! If you wanna mess things up real bad, this is the time you’re going to do it.

Notice where the cocking lever is. Yes, it’s in the cocked position (fully rearward). The position of that lever is very important when removing or replacing the mag. Don’t do either when the lever’s in the forward position. Sounds rather strange, doesn’t it? Let’s see why that is. First, take a look at the mag.

Correctly loading the mag is crucial to proper operation.

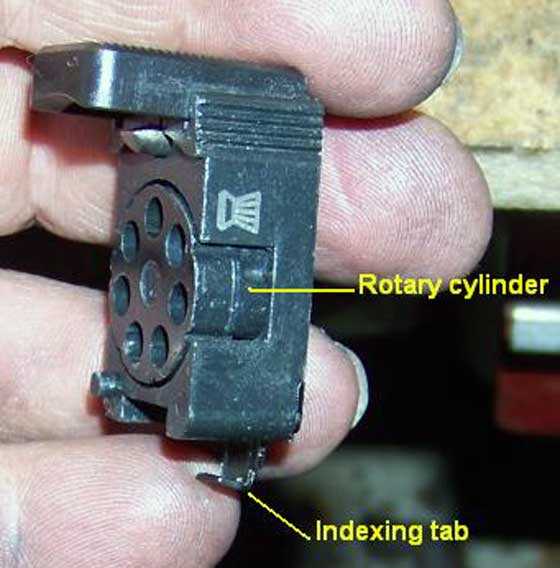

Shown above, the pellet carrier is actually a revolving cylinder similar to the Crosman 1077 and several Umarex pistols.

The magazine well with the mag removed and with the lever in the stowed position.

That thin (and hardened and, thus, brittle) metal rod running through the well is the feeder pin. Obviously, this pin runs through the mag when the lever is forward, which is why you can’t remove the mag when the lever is up. What does the pin do?

As you pull back the cocking lever, the pin retracts.

As you can see, as the cocking lever is pulled back the pin starts to retract into the rear of the action. Note the position of the lever. Also notice how the tip of the pin is this nice, rounded, bulbous shape. There are a couple of reasons for that, which I’ll get into later.

With the lever all the way back the pin is completely retracted, and the mag can be removed without incident.

Don’t remove the mag before the cocking lever is all the way back.

Likewise, the pin moves forward again as the lever is returned to the stowed position. This pushes the pellet out of the mag and into the breech of the rifle, from where it’s fired. That’s why the tip of the pin is rounded, so it doesn’t damage the pellet as it pushes it forward. Since the pin stays in place while the gun is fired, air has to flow around that pin to get to the pellet. That’s reason No. 2 for the nice, rounded tip — less drag on the airstream.

Go back to the picture of the magazine. See the indexing tab? As that tab is pushed upward, the cylinder rotates (indexes) to the next pellet. That happens at the very end of the cocking stroke, after the trigger sear latches. Which is important to know, as I’ll explain in a minute.

The mag itself is loaded with pellets in the usual way:

The cylinder is placed back into the carrier:

Make sure it’s seated all the way. You might have to rotate or wiggle the cylinder a bit to get it to seat properly. The entire magazine is then reinserted into the gun — AGAIN, with the lever pulled back!

Stay tuned for the rest of this story in tomorrow’s blog!

Very good writing as usual Vince, congrats.

This would have pretty much been the only underlever I would have considered buying…

I know they have anti-finger chopping safety’s and all but I just can’t convince myself of putting one of my precious little chubby finger in that little open slot. Even a great quality rifle like the TX200, I don’t think I could do it. This one would have appeal to me when it came out.

Totally off topic.

Does anyone know how hard it would be for Crosman to put out a detuned version of the Discovery for the Canadian market?

Since it’s a 2000psi it’s easy to fill with the pump that you can buy with it and since the valve would use less air to shoot at lower velocities the shot count would end up being higher wouldn’t it? It would be the cheapest detuned PCP we can get at 450$ (the current price for the full power version with the pump) the next available sub 500 fps PCP is the AA S200 at 600$ without any kind of recharging equipment… Come one Crosman make a little effort for the northern neighbors.

J-F

Cutting the power on a Disco could probably be done by cutting the size of the transfer port or by reworking the valve. The problem would be that there may be something in your laws about how easy it would be to boost the power back up.

twotalon

There is nothing in the law about modification as long the adjustment (let’s say) screw isn’t already there. Otherwise we wouldn’t have all the 2240, 2289, 1377 etc. As the parts for them are plentyfull and very easy to get and somewhat easy to install. The 2289 pumper is very popular here for that very reason, there’s a small bleed hole that everyone knows about and that lots of people just epoxy shut, some work harder and drill, tap and close it by placing a small screw in there.

It’s your responsability to tell “the man” if you’ve modified your gun and made a firearm with it.

The 1700P silhouette PCP pistol from Crosman was sold then it was discovered that it could be adjusted to shoot just a little bit faster, as far as I know it wasn’t made into a firearm but big sellers stopped importing it, just to be on the safe side I guess.

The Webley Alecto is pretty much the easiest to turn to firearm specs yet it’s very legal to own (and a dream to shoot).

I’m wondering if Crosman doesn’t want to do it could an importer order a bunch and have them modified with a smaller valve for the market here?

I’m sure it would sell pretty well.

JF

two talon,

It can also be easily done by putting in a weaker hammer spring. Simple! Did some experimenting with hammer springs and got as low as 350 fps. And as high as 975 fps.

Settled on a spring gives me 750 fps to 975 fps with a power adjusting screw. But you can set that range almost anywhere with the right spring!

If it’s really that easy it’s really a shame they haven’t tougth about make it. Less power should also equal to less noise right?

JF

Just found some info (along with a few pics) of the new Crosman Rogue… that thing his HUGE.

The rifle is a repeater and has a marauder like mag and… and… I’ll just stop the chating and give you the link :

https://www.americanairgunhunter.com/rouge.html

J-F

J-F Thanks for the link… Now, that’s an AIR RIFLE!

It would be great to see what that platform could do in a .223 version. Given the physical size, the mag could be 15 rounds and the shot count (quick math) could be 30-35 at 1100 fps!!!

Can you recommend a good second mortgage company? I’ll be needing one very soon!

Also go to http://www.ammoland.com/2011/01/18/crosman-benjamin-rogue-357-big-bore-epcp-air-rifle/ to see more announcements and on their other pages, more new products from Crosamn including a .177 ca AR15 upper receiver air gun modification.

J-F:

Hear that thump? That’s my jaw hitting the ground.lol

DaveUK

Dave UK…and just think, with the Rogue de-tuned to UK 12 ft lb rules, you will get “6000” shots from one fill!

Not to worry though, the VAT tax of 300 quid will keep it off the shelves at Sainsburys!

Cheers!

Brian in Idaho:

lol,

We will have to just dream of the ‘Rogue’ over here I’m afraid.

20% VAT(Value added tax)on luxury items like PETROL!!

I suppose the thousands of ‘5 a day community outreach social workers’ have to be paid for somehow. lol

DaveUK

Workin on the dole mate, workin on the dole…

Hi Vince,

Great article.. again..

I really did like those 300r Diana’s… you fixed em up great Vince!.. even with that issue you describe so well… One just has to be careful, with what one is doing.. other wise a real nice spring gun.. when your done with it anyway:-)

The Diana 46 Stutzen might also suit your needs JF… with the flip up loading port.. if I remember right.. Vince??

Anyway..

I just got back from Larry Durham’s (LD) place in Temecula in S. Calif. I picked up the new 30fpe bench rest USFT Tim built, and he tuned for me. After about 10 sight in shots with the new gun, to get the new scope on paper… (I had about 2 mins:-))… the match started. It was shooting two cards of ten, 3 shot groups at 50 yards. There was nine shooters that included LD & Tim .. I think six were shooting USFTs, and maybe 4 of them with the new USA made barrels…. mine the newest one..

LD said that first card I shot is the third best, at his bench rest shoots, a .303 center to center average on the 30 shots… and the winning card for the day… my second card was good enough (.463 average) to not bring my total down too far… and I won the 50 yard match too. In the 20fpe contest at 25 yards, I used USFT#6 and took 4th, but got the most… (24/75).. “X” (that’s taking out the very center of the bull).. Larry didn’t seem to mind me beating him too much.. since he had just built the gun.. and I’m such a newbie.. the credit for sure goes to him 🙂 …. and his skills as a designer and gunsmith!

but still.. all in all… a good day for Oregon 🙂 … here are the results LD posted on his forum…

By Larry Durham..

We had some nice Warm weather, around 75F, mild breezes, though shifting as is usual here, Good turnout, with nine shooters, one coming all the way down from Oregon.

We shot the new for us International Type target at 25M as well as our

regular A36 target at fifty yards, firing three cards of 25 shots each at the short range and two cards of 10 three shot groups each on the fifty yard ones.

Long distance traveler Wayne Burns, using a brand new gun I had just finished tuning for him the night before the match won the Long fifty yard leg with a fine showing for sure. While old-timer Roger Lovett took the marbles in the International match, using his 20fpe USFT.

I kinda fell apart myself, forgetting my .177 pellets in the garage and, being too lazy to run up and get them, the attempting to use some borrowed ones of a type I’d never even tried before, and later, once I had retrieved my “good pellets”, I ended up using someone elses’ front and rear rest that just didn’t work well for me, all on a hastily put together 20fpe rifle. But, all those thing were avoidable and just show how things can go if you are a scatter-brain.

Here are the stats:

20fpe class – International Match:

Name tgt1 tgt2 tgt3 >total “X”s

Roger Lovett 240/8x 243/6x 242/5x >725/19x

Matt Kellerman 240/7x 245/5x 238/4x >723/18x

Tim McMurray 245/10x 245/11x 232/2x >722/23x

Wayne Burns 234/10x 239/7x 243/7x >718/24x

Larry Durham 212/0x 237/6x 225/6x >674/11x

Richard Woods 212/2x 209/1x 217/2x >4/5x

Tim Donaldson 190/0x 202/2x 217/2x >609/4x

12fe class:

Larry Pirrone 222/2x 230/1x 232/5x >684/8x

OPEN CLASS- Fifty Yards for groups of three:

Name Tgt1 tgt2 aggregate of 20 groups

Wayne Burns .303″ .434″ >.368″

Roger Lovett .408″ .349″ >.378″

Matt Saenz .380″ .420″ >.400″

Larry Durham .418″ .427: >.422″

Matt Kellerman .649″ .576″ >.612″

Rich Woods .740″ .686″ >.713”

LD,

Match director

BTW….

Larry let ME, use his rest, and was helping ME get stuff together, so that’s most likely why he forgot his pellets.. SUPER nice guy.. and a SUPER great air gun wizard! …. Maybe even greater than Vince.. but the jury is still out:-)

Wacky Wayne,

Match Director,

Ashland Air Rifle Range

Wayne,

That is some excellent shooting. I wonder if a USFT in .25 wouldn’t be even better, if you could get decent pellets. On to 100 yards and beyond! What are the rules, bags or rests, etc.?

Wayne, yes, the Stutzen is perfectly safe. It’s also something of an underperformer – luck to get 800fps out of them. And it can be a pain to get BOTH o-rings to seal properly.

Vince…

I can see that someone who does not know the right way would break it very quickly.

How many breech seals does it have ? I would guess three? Does it make it hard to remove and replace the mag?

twotalon

Hi Tom,

When will the new Benjamin Rogue be available for purchase. Also, what is the expected price for the rifle?

Thanks,

Jeff

Jeff,

Crosman says they hope to have the rifle ready for market in the first quarter of 2011. I would estimate more like the third quarter.

Look for the price to be around $800.

B.B.

BB looks like Jim Chapman had some fun with that new Rogue out at Boulder? Did you have a chance to shoot or even see the prototype over the past few months? From the photos on the Ammoland site, I would comment on one aesthetic change for Crosman, make the LCD screen area and controls blend or harmonize with the colors/texture of the gun. As of now, it reminds me of the control panel found on a piece of medical equipment. Visually a “deal killer”. Also, the LCD should be back-lit when prompted.

PS how’s the o’l body feelin this morning?

Brian,

I have spent the past few months in and out of the hospital, so no contact with the prototype. I did participate in its development, but at the advisory level.

At the moment I’m concentrating on not allowing the hernia to poke through my abdominal wall. I have to start exercising to build the muscle that will repair the tear. In the beginning, that will just be a daily walk and lots of protein.

B.B.

OK on the daily walks, those are good for you regardless.

Keep up the good fight Tom, the remainder of 2011 has to be the hospital-free year!

Thanks Tom for the quick response!

I thought of one other follow up question.

Will there be any type of sound suppression on the Rogue?

Thanks again,

Jeff

Jeff, go back and read the first article link posted by Brian In ID. Yes, this rifle does have a shrouded barrel! It is going to be something else!

Vince, quick question – I noticed that Diana has a wadcutter drawing or etching on the barrel – is that the type of pellet they recommend or can domed pellets be used as well? I ask because the CO2 level action Crosman I acquired last year also has a wadcutter etched onto the barrel but I’ve had good success with domed pellets.

Fred PRoNJ

That’s just to indicate ‘pellet’ (as opposed to ‘BB’, I guess). Just about anything will work.

Jeff,

Yes, it has a shrouded barrel.

B.B.

Have to hand it to Crosman, they been on the ball this year bring affordably priced high end offerings to market. Today with the announcement of another exciting product the Crosman MAR177 competition air rifle. The $900 price seems high at first, but no other gun of this type is even close to that level, plus it’s a pcp gun.

Bub see my link to Ammoland in above post. Looks like tha MAR17 is just the upper receiver and PCP parts that mate to your own AR15?

Brian, thanks for the heads up. It looks like you are right and it’s just the upper receiver. Does make the price look a lot higher…Bub

Vince:

Wow! what a cool rifle.

A lovely example of a repeating springer,even if it is a little finicky.

Do you guys remember the tube type magazine you could retro fit to tap loading air rifles?

They seemed to be all the rage in the 80’s but I haven’t seen them around since.

DaveUK

Vince,

Once again you’ve impressed us with your technical, illustrative and writing skills. So far this looks like an under lever for me, but I’ll have to wait and see how she shoots.

I wonder how many of those pellet seating pins got replaced before the gun disappeared from the market?

Bruce

PS Thanks to J-F and Brian in Idaho for the links to the Rogue.

Wayne,

It’s nice to hear from you! Congratulations on your showing in S. Calif at LD’s. We’d sure like to hear a lot more about your USFT built by Tim and tuned by Larry. Do you possibly have the time to do a guest blog?

When I watch the show on the guys mining for gold in Alaska, I can’t help but think about you and your mining claim.

Mr. B.

I’ve been traveling a lot lately.. Whenever we have some raised garden bed orders in the direction of a shoot… I’m off:-) … within reason.. like 800 miles one way:-) .. not much time for writing anything.. or even to check in on the forums… BUT…

I do have lots of neat info to share about USFTs now that I get to play with Tim and LD so often… Tim actually let me hang out in his shop the day he put my gun together.. and let me help a little.. and let me take pics! Nothing like watching a master at work, and seeing how all the parts make the gun operate… I learned a whole lot that day!! .. Maybe..

I could pick out a few pics to share, but wouldn’t want to share most of them.. to protect Tim’s products privacy… and tell what I learned of the story, of how the USFT bench rest guns were born…

Tim has a conversion kit for any USFT to become a bench rest gun.. but LD makes a custom solid Alum. forearm that really makes it a TRUE bench rest rig… Then if you add one of the new USA made barrels, that LD designed, you’ve got a world class air bench rest rig… we shall see how “world class” this coming July/Aug. at the world air gun bench rest contest, in South Carolina.

HHHMMMM… to practice shooting and keep traveling to contests… or to write a blog story..

I’ll have to think on it:-).. It’s darn tough at this moment not shooting my new gun… It’s sitting next to me in a bench rest, pointed at the indoor target.. drawing me.. as I type.. gotta go now:-)

Wacky Wayne,

Match Director,

Ashland Air Rifle Range

Vince,

Nice job. Great photos of an even greater rifle. I somehow missed this one while searching for a good under-lever a couple years ago. 7 shot repeater should have jumped out at me. I eagerly await the rest of your report!

ka

Vince,

Great article. You definitely have a knack for holding a readers’ interest.

Thanks to your suggestion i was able to purchase a 300r off of yellow classifieds. I asked the guy if it had a broken pin and he claimed it was like new so i bought it. When i received it. it had half a bent pin only. Dont ask how you can break half and not the whole thing off, but the rest of the gun was immaculate so it didn’t phase me. I took it apart and drilled the back of the pin holder out with a .045 drill and pressed out the bad pin. The original pin measured to be about .043, so i drilled it out to .051 and inserted a .052 hardened gauge pin as a replacement. its a bit beefier and it doesnt has a bull nose at the end, but i rounded the end and it seems to press pellets in to the breech just fine.

I really enjoy shooting this gun. it would be nice if another attempt was made by RWS to build a repeater with perhaps a more rugged design.

Im looking forward to the next article on this

rick r

Sorry,Off Topic BB,

Not wanting to go up the route of scoping my HW,I decided maybe just to add some TruGlo fibre optic sights to the 99s.

TruGlo sights made specifically for HW breakbarrels (bar the HW90) do exist,just no one imports them to the UK as an accessory.

Not enough demand apparently,in fact I am the first fella to enquire according to ‘Hull Cartridge’.

As an off the shelf add on I would give them a go but with all the hassle and cost of importing one myself,I need to ask what you folk think of fibre optic sights on a break barrel springer.

Many thanks.

DaveUK

Dave UK, the good fiber optic sights are just fine, they use luminescent materials. The cheap ones are just colored plastic tubes and leave a lot to be desired.

If your eyes (or eyeglasses) are up to the task, I think you will find the F.O. sights work very well outdoors or in bright interior light, especially if the target is a darker color or black outline type.

Cheers Brian,

If I do go to the trouble of importing and fitting the TruGlo Sights,one thing is for sure.

My HW99 will be pretty darn unique round these parts.Maybe reason enough to go for it 🙂

DaveUK

Dave UK…BTW, where are you finding airgun specific Truglo sights? On line?

The Truglo website in the U.S. only has the front globe insert type, not full front & rear sets nor any others specific to airguns that I have found.

Brian in Idaho:

That is what I found.TruGlo sights are fitted to air rifles as we know but don’t appear to be sold as after market accessories.

The TruGlo Sights for the HW break barrel range are featured on the Weirauch web site.

Click on products-air rifles and then scroll to the bottom of the page.

DaveUK

RWS 350 experts!

Do any of you own an RWS 350 and have taken one apart? I just bought an RWS 350 Feuerkraft and noticed that it had an unusual sound when cocking. It sounded like a there was interference on the spring as it moved. It just didnt sound like the rest of my guns. Even though it shot fine i still had to know what it was, so i took it apart and found this weird thin sheet-metal sleeve that the spring fits into. ive never seen this before. The sleeve had a dent on the end as if to retain the spring somehow.

When i put it together the spring sounded worse than before as if each coil now slips along this dent in the sleeve and rakes as it passes by while compressing(cocking)

So the question is: is the thin sleeve supposed to retain the spring? if so i need to create a deeper dent, or is the spring supposed to slide freely in this sleeve and the dent was never supposed to be there. Thanks

rick r

Rick,

First, did you shoot 1,000 shots before disassembly? That’s the rule, unless there is a major concern. Minor noises are a part of the break-in period.

Second, was the thin sleeve inside the piston body? It is a way to take up space, so the spring doesn’t rattle around inside the piston. The dent is probably a means of keeping the sleeve inside the piston body.

Strip the rifle and lubricate the spring with moly. Shove the sleeve inside the piston body and see if you can get it to stay there. It should have a lip bent over on the innermost end of the sleeve, which the spring bears against and therefore keeps it inside the piston.

Or remove it from the gun, but prepare to hear even more noise when you cock, unless you coat the spring with sound-deadening material like black tar.

B.B.

BB

Thanks for the response. No i didnt have the patients to wait for 1000 rounds. I was just curious to see what the noise was( a weakness i need to work on).These springers aren’t typically hard for me to disassemble and I havnt had any issues in the past with reassembly except in this case with the odd sleeve problem.

The sleeve was inside the piston body as you assumed. So your saying that the dent in the sleeve might be to keep it inside of the piston body rather than the spring inside the sleeve. ok that definitely makes sense to me.. So i will look at adjusting the dent so that it will allow the spring to move freely but retain its self in the piston.I must have damaged it while pulling it out. lesson learned.

I did try removing the sleeve altogether and reassembling ; and though it was quieter while cocking it seemed to vibrate a bit more when firing, so I would like to return the gun to its intended design now that i know that the noise when cocking was the spring sliding against the sleeve.

The only other alternative i would consider might be replacing the sleeve with that Delrin insert you wrote about awhile back, though im not sure of its compatibility on an rws 350.

Youve been a huge help.

thanks again BB

rick r

rick,

Derrick over at Another Airgun Blog, has a great post showing how he manufactured a sleeve for a loose piston.

http://anotherairgunblog.blogspot.com/2009_04_19_archive.html

Hopefully, it will answer any questions you have about what and why some pistons have sleeves inside them. Essentially, they are shims to tighten the fit between the spring and the piston itself.

That guy has some skills with sheet-metal forming!, and that does look like my sleeve in my 350. After i fixed the dent that i made in the sleeve I added a coat of moly grease to the spring( the thing was bone dry and sounded like it scraped, which is why i took it apart in the first place). it sounds wonderful now while cocking and feels great when the piston hits; like areal solid thump.

Rick R.,

Now you know something valuable about tuning a sp[ring gun. Ain’t life wonderful?

B.B.

Vince, this touches on one of my fascinations which is repeating springers. One of the great joys I take in the IZH 61 is the clip which allows me to reliably bang off shots. The only other repeating springer is a the Mendoza and what I’ve heard about its mechanism is not promising. I may have missed where you evaluated the quality of this repeating mechanism. Does it work well?

I forgot yesterday that even if the federal government took a holiday , the blog did not. B.B. sorry to hear about the hernia, but that really and thankfully is a trifle compared to the rest of your ordeal, and I expect that you’ll be better before you know it. What a great story about Lloyd and Crosman. That’s what America is all about! I’ll look forward to hearing about this rifle. This sort of easy and precise power regulation is just my style. I would have guessed that the problem lies in the computer technology that is sufficiently reliable, light, and cheap but from the suggested retail of the gun, I’m guessing those problems have been solved. Great work.

Matt61

Matt61

There are others, take a look at the Air Arms SLR (self loading rifle)

Basically, a TX200 type gun with a rotary mag.

Matt61

Sorry about that post I MEANT THEOBEN SLR-88 NOT Air Arms!

I’ve got an RM2000. The feeder isn’t so hot, and sometimes it squirts slightly undersized pellets right through the shuttle. And other pellets don’t fit the feeding port well. It’s really only made for Mendoza pellets, a pickiness that the rotary mag doesn’t suffer from.

Well, the Crosman site seems a bit irritable right now. I guess we’re all trying to get on it to read the new products coming out. You can see the new .357 bullet for the Rogue, a new Chinese made break-barrel, the AR -177 / 16 look-alike – a PCP for competition, and a new pistol – Silhouette but I couldn’t open that URL up.

Fred PRoNJ

Vince,

That is a nice rifle to write up — I can’t resist an underlever, even the ones that take off a finger tip or two every now and then. Its my favorite design, although breakbarrels are somewhat handier and sidelevers have technical advantages of their own, and this one is a really nice looking speciment. I guess the rotary mag takes away the issue finger biting issue, but also I’m guessing it is going to affect power somewhat with increased port volume. I’ll find out tomorrow if so and how much, I suppose. You hint that accuracy is good, so I’m optimistic.

Guys,

since we’re talking about repeaters, has anyone on the blog tried out QB Mags conversion of a Disco from single shot to repeater? How did it work out? I’m tempted but have no one to do the machine work on the barrel (O ring placement necessary).

Fred PRoNJ

BB,

What would you recommend for a night light rig for use with a .22 marauder to keep an eye on things out back? I’m thinking mounting on the rifle w/scope unless you suggest otherwise. I did notice Elusive Technologies XLR 250 and thought it kind of interesting. Thanks for your help and I hope you are feeling better this year.

Steve

Steve,

I have no recommendation because I don’t use night vision.

Anybody?

B.B.