by B.B. Pelletier

The Tech Force 79 Competition rifle is a lot of value for a very low price.

Today, we’ll look at the trigger of the .177 caliber Tech Force TF79 Competition Rifle, which I promised would get a report all its own. Back before the QB 78/79 rifles came to market and back when I was still reporting on the original Crosman 160s, I discovered that there were different variations of the model that came with different triggers. The first 160 made back in the 1950s had a dirt-simple, direct-release, sear-type trigger that had no special advantages. This was the rifle that had a crossbolt safety through the stock. Back then and probably still today, those rifles commanded less money than the later models that have the trigger I’m going to discuss today.

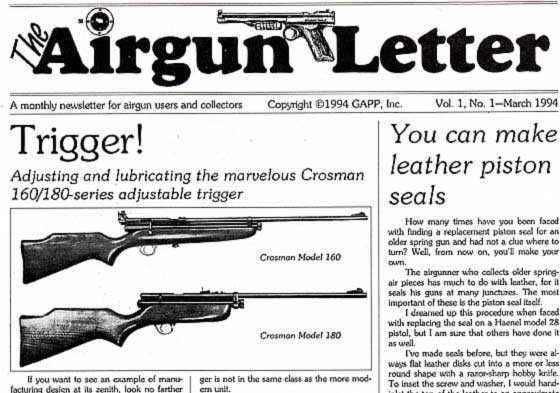

In fact, this trigger I’m discussing today was the cover subject of the premiere issue of my newsletter, The Airgun Letter, published in March 1994. So, for those folks who wonder if I’ve ever looked at the TF79 before now: I have been looking intently at both it and its direct ancestor for the past 17 years, which is my entire airgun writing career.

The first article in the first issue of The Airgun Letter was about the adjustable trigger in a Crosman 160.

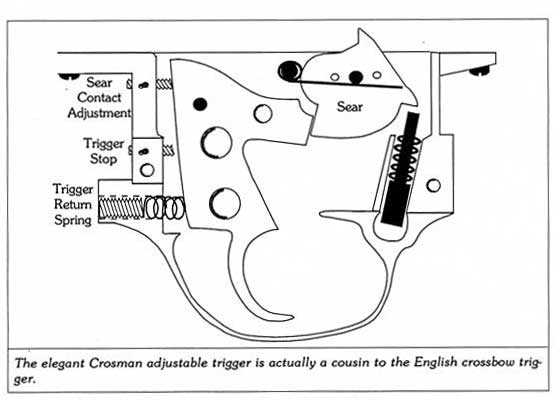

Back in 1994, I was just learning how to take pictures with a 35mm film camera, and it would be more than a year before I started having much success. When it came to capturing the inside of the trigger, I didn’t photograph it, I drew it! It took about four hours to complete the drawing, but I’ve used it many times since.

Before I could take good pictures, I drew things to illustrate them. This is my drawing of the 160 adjustable trigger. The only difference between this trigger and the one we’re reviewing today are two tiny coiled springs that put side tension on the two trigger-adjustment screws. Today, things are simpler and better.

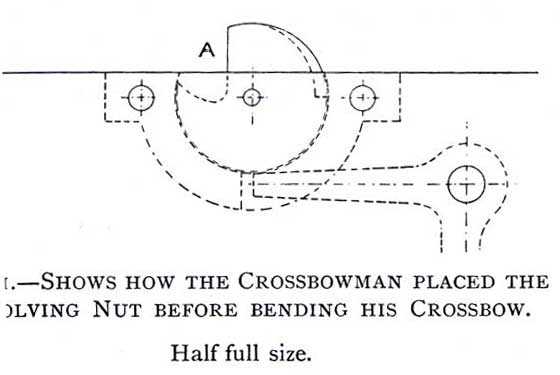

At the time, I was aware that the 160 trigger was based on a crossbow trigger from the Middle Ages. In The Crossbow by Sir Ralph Payne-Gallwey, a reference book I’ve recommended several times, you can see the cross-section of a crossbow trigger and apply it directly to the 160 trigger design.

From Sir Ralph Payne-Gallwey’s historic book, The Crossbow, this sectional drawing of a crossbow trigger shows the similarity to the 160 trigger. Gallwey refers to the sear as the revolving nut.

You can see how the crossbow trigger was able to restrain hundreds of pounds of force, yet break with relative ease. Well, the 160 hammer spring is not nearly as powerful as a crossbow; so, with adjustment, it can be made very fine. And, the adjustments are what differentiate this trigger from the primitive crossbow trigger.

From the factory

The trigger-pull right out of the box measured between 1 lb., 8 oz. and 1 lb., 10 oz. It’s a two-stage unit with stage one being extremely light and stage two rather long and very creepy, if also light. I can fix most of that with lubrication and adjustments.

Removing the TF79 action from the stock requires the removal of one large nut in the bottom of the forearm that requires a large spanner. Then, the safety must be removed. Just rotate the lever down while pushing on the back side of the safety pin, and you’ll feel it give when it’s aligned for disassembly. I used a pin punch to drift it out, not because it fits tightly but because the cam it bears against, which is the actual part that blocks the trigger, is under a lot of spring pressure. You can see that spring in my drawing or in the second photo below.

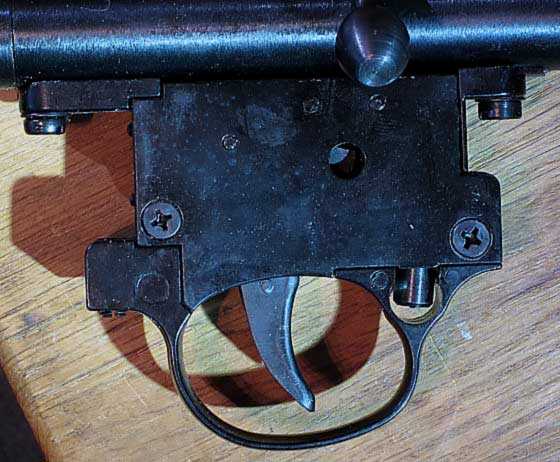

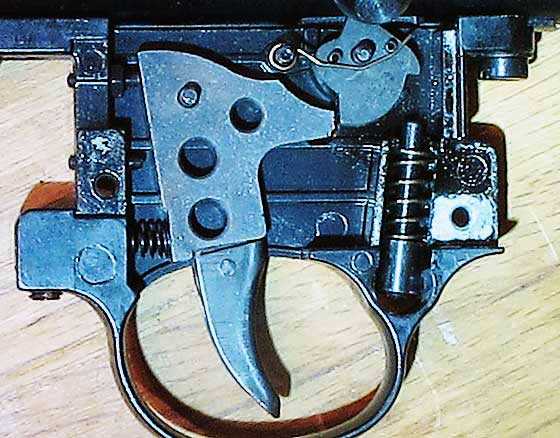

Out of the stock, the TF79 trigger is a unit contained inside a metal box. Remove the two Phillips screws to take off the plate for adjustments. The hole allows for inspection of the sear contact without removal of the sideplate.

With the sideplate removed, you can see how the trigger works. The sear engagement adjustment (top left) has a locking nut, which is an improvement over the 160 trigger.

I found this trigger to be much better built than the old Crosman 160 trigger. With that one, you had to worry about the parts jumping out of the trigger box when you tested the adjustments, but this current one holds together and allows all the testing you want. As a result, I was able to get a fine trigger release in a matter of a few minutes. It’s no lighter than before, but nearly all the creep is gone. I could have removed all of it, but the amount of sear engagement when I did so seemed too small for safety. So, there’s one very repeatable bit of slippage in stage two and then the let-off is crisp. Now, the trigger stops immediately after release. The feeling is one of precision, and I found it much easier to achieve than with a genuine Crosman 160 trigger.

I also lubed both the sear and the trigger catch with moly. Hopefully, this will bond with the metal surfaces and improve the smoothness of the pull over time.

Assemble the rifle

Putting the trigger plate back on is no chore at all, because the three pins that use the plate as their other bearings remain in alignment with the plate off. In the 160, you had a heck of a time with some guns, because these pins would tilt from the spring tension they were under. Putting the trigger plate back on a 160 was a lot like picking a lock. That’s no longer the case.

The next step is to drop the action back into the stock and tighten the spanner nut. After that, the safety goes back, and there’s a trick to it. From the opposite side of the safety hole (the left side of the gun), push the safety cam up with a thin-bladed screwdriver to allow the safety lever to be inserted in the right side of the hole. Once it’s in, it’ll hold the cam out of the way and easily go in the rest of the way. The rifle is now assembled. Taking the safety out or putting it back in is a 15-second drill once you have the knack.

Guys, this is a hundred-dollar trigger when it’s properly adjusted. It’s not quite a Rekord, but it’s in the Walther LG 55 class for sure.

BB,really nice diagram of the 160 trigger.I’m feeling the need for one of these,really impressive for the price point.On Pyramyd’s site,the description paragraph ends by stating this is a single stage trigger

so it needs correcting.

Frank B

HA! I knew it wouldn’t last. You had me scared there for a minute though.

Of course it “wouldn’t last” it’s an air rifle and he MUST have it!

As BB noted, the trigger group is really well made and better than the model 160 or Crosmans’ current crop of 22XX’s and their offspring. When I opened mine up, I was pleasantly surprised to see no stampings with oblique edges or scars, as a matter of fact, the main trigger piece and the “cam/sear” actually look like investment castings, not stamped parts.

I waited for all the pins and springs to pop out a-la-Crosman and they did not.

FrankB, from where I sit this still looks like a single stage trigger – the sear catch isn’t released in two distinct stages as it is on the Rekord, AR1000, TO5, etc. To me it looks like the ‘first stage’ is really nothing more than some spring-loaded slop in the trigger, like the older Gamo’s (don’t know about the newer ones).

BB, is this correct?

It is single stage.

Loren

Frank,

Not to argue with Loren or Vince, but this trigger really is two-stage. However, the way they achieve a two-stage pull is odd and some might say artificial.

The trigger blade is actually hinged. So when you squeeze the trigger, the first stage is just the trigger blade rotating backward until it comes to a stop. But when you shoot the rifle, it feels exactly like a good first stage, so I guess it qualifies.

From a design standpoint, though, they are correct. It really is a single stage unit.

B.B.

The working advantage of the 2-stage trigger, as I always understood it, is that it allows for a LOT of engangement for safety’s sake. But the vast majority of that engagement is taken up by the 1st stage, so that when you’re at the 2nd stage the trigger is right on the ‘knife’s edge’ of firing. Which gives the trigger a very predictable and controllable feel.

A single-stage trigger can also be adjusted to ‘knife’s edge’, but when it is that’s all you’ve got – and the gun is susceptible to going off when bumped or if the parts wear just a wee bit… and when you have so little engangement wear might tend to increase.

The first stage being nothing but movement in the trigger blade – that’s a trick that was used by Gamo, BAM, Norica and a bunch of others to more or less mask a mediocre trigger.

Of course in this gun the trigger is not trying to controll 200lbs of spring pressure, which means that it is easier to make a decent-feeling trigger with a simpler mechanism… and I imagine that it can be adjusted closer to ‘the edge’ than a similar mechanism in a springer without compromising safety.

So maybe I’m splitting hairs here.

I was aware of the idea that a “two stage trigger” traditionally has the first stage removing an adjustable,and therefore variable amount of the sear engagement.I was just completely willing to defer to the judgement of a man who has written about this topic for 17 years.

The description on Pyramyd’s site still needs to pick one,however….it refers to the trigger as being two stage AND single stage.

Off subject here, but which one is better, Benjamin Trail Nitro Piston XL or Walther Falcon Hunter, both in .22? Accuracy? Power?

They are both within the same $ range, so I’m trying to decide which one to eventually purchase.

Thanks,

Conor

Conor, I own the Trail XL and can get groups of .8 inches but at 28 feet. I haven’t been able to get a 1″ group yet at 30 yards but the rifle is still fairly new and hasn’t had many pellets through it (couple of hundred). Best pellet I’ve found is the H & N Barracuda. I don’t own a Walther so can’t help you on a comparison. I would check PA’s site and see what the reviewers say about the Nitro and the Walther while you wait for others on the blog to chime in.

Fred PRoNJ

Fred PRoNJ,

This thing is huge isn’t it? How does that translate to in practical shooting? 9 lbs w/o scope is like a heavy barreled varmint rifle.

ka

KA,

the Nitro really isn’t that heavy (6.5lbs per website). The model I have in .22 is the Hardwood. Don’t get me wrong that it’s not a fun rifle – I really enjoy shooting it but it’s definitely not in the same league as my RWS 52 (8.5 lbs per PA website) or Beeman R-9 (7.3 lbs per PA website). Those rifles can put pellets into the same hole. Case in point, I achieved groups in the .4″ range with both or half the size of the group that the Trail gave me, all at 28′. I can’t hold any of them steady enough for pinpoint accuracy in off-hand shooting to remotely get groups like this so if I was walking in the woods hunting, I would look for something to rest on. At home, I typically rest my elbow on something while I use the artillery hold. Lately, I lay my left arm down on the table or other solid object and rest the stock on the back of my forearm. This way I get rid of the waving around of the sights I suffer when just resting my elbow on the solid object and using the artillery hold.

Fred PRoNJ

Fred,

Thanks for the info, though I’m not sure what you mean when you say, “(6.5lbs per website)….(8.5lbs per PA website)”…..ect.

I’d be shooting it from 20yds-100yds, that’s why I’m wanting something with more power-yet still some accuracy.

Thanks,

Conor

Fred,

Nitro NP XL per PA website: /product/benjamin-trail-np-xl-air-rifle?m=2052 Just over 9 lbs.

Nitro NP hardwood per PA website: /product/benjamin-trail-np-nitro-piston-hardwood-air-rifle?m=2050.

Are you shooting the behemoth 49″, 9lb XL, or the 43″ 6 1/2lb NP version?

I think Conor was asking about the difference between the two larger versions, I’ll have to go back to confirm, but…

Anyway, I was asking because the XL, seems like a LOT of rifle! The picture of the guy holding the Trail NP XL that he won in Benjamin’s raffle last year put it into perspective for me. I gave up looking for the link to that photo or I would have posted it here.

ka

KA,

I have the smaller, lighter rifle and that’s what I was referring to. It’s very easy to cock and as I said, lighter than the other two rifles I referred to. A 9 lb rifle in the woods will probably get heavy after an hour or two of lugging it around.

Kevin, thanks for jumping in and clarifying what I was referring to.

Fred PRoNJ

Fred,

Yea, sounded like it. I just can’t get my brain wrapped around the size of the XL. Seems huge to me.

ka

Conor,

IMO the Falcon Hunter is better by $50 and just over 1lb. Though I’m not a fan of the camo stocks. The real bargain however, is the Trail NP with laminated stock, it’s not a behemoth like the others, more of a practical sized rifle AND it’s got a laminated stock! Oh, and did I mention the laminated stock?

ka

KA,

Although the laminated stock looks cool, I kinda like the plain wood better.(I know, I’m crazy!;-)

What do you mean by, “Falcon Hunter is better by $50 and just over 1lb?” What’s the “just over 1lb?”

Conor

Conor,

Oops, I should’ve said UNDER a pound. check ’em out.

/product/walther-falcon-hunter-new-trigger-22-cal?m=1491

/product/benjamin-trail-np-xl-air-rifle?m=2052

Also, I see that I compared the spring piston Falcon to the gas spring Benjamin.

Apples to apples the cost difference is only $60, advantage NP XL.

/product/benjamin-trail-np-xl-air-rifle?m=2052

vs.

/product/falcon-hunter-np-new-trigger-22-cal?m=1638

Conor,

They’re referring to the weight of the guns listed in the specs on Pyramyd Airs website. The weight of the rifle listed is unscoped. If you intend to add a scope to your gun add that weight to determine the overall weight of the gun you’ll be shooting/carrying in the woods.

kevin

Kevin,

I wish that were the case across the board, but it’s not. The manufacturers supply the weight, barrel length and overall length of a gun. However, the weight isn’t always just the gun. Some mfrs supply the weight of the gun, scope & mount but don’t tell us that’s what they’re doing. In at least one case, the mfr supplies some gun weights with the scopes and mounts but also gives us just the weight of the gun for other models that also include scopes and mounts.

As long as I’m laying things bare, let me say this: The terms low profile, medium profile and high profile as applied to scope mounts are pretty much meaningless. There’s no standard, and a mfr can say something’s a low scope mount, while another mfr has the same height mount and calls it a medium. Plus, a low see-thru mount would actually be called a medium height if it didn’t have the see-thru cutout…usually. Crazy stuff!

I’m sooooo glad I could help 🙂

Edith

Edith,

Exactly… scope rings give me a go around every time I shop for a new set. As far as the weight given per rifle on PA’s goes, I usually compare specs with unscoped models to scoped models and then cross refernce with other brands of likeness if I am in question. Not precise, but accurate enough to make a purchase.

ka

Okay thanks!

BTW, who determines what the gun is suggested for? ‘Cause the Benjamin Trail NP XL is suggested for “small game hunting/plinking”, and the Benjamin 392(going 685 fps) is suggested for “Hunting!” What’s the deal here?????

Conor

Conor,

Actually, I determine how a gun is used. Here’s the issue with that. At the time the Benjy 392 was written up on Pyramyd Air’s website, it’s quite like that “hunting” was the only suggested use that made sense. Some time later, the option of “small game hunting/plinking” was added as a selection.

Should I spend the time to go back and change all the older models so they say “small game hunting/plinking”? It sounds like a good idea, but I’m already behind the 8-ball with a mountain of work, so that’s probably not going to happen anytime soon. However, for your benefit, I’m now going to change the Benjy 392 gun to “small game hunting/plinking” 🙂

Edith

Oh, sorry if I undermined your job, (it kinda looks cool when the gun is suggested for “Hunting” ;-), I just wasn’t sure if someone @ PA messed up when labeling the Benjamin Trail NP XL.

Conor

Conor,

Ultimately the shooter. It is the responsible hunter that does his homework by comparing what the hunted requires. In other words, match the energy to the prey, with the distances considered for what you’ll hunt. If that pesky Raven is out past 40yds, don’t take a shot at it with that Benjy 392. You will likely only wound it and that’s not good. Use the Benjy NP XL, that’ll do it cleanly.

ka

Mrs. Gaylord,

Soooo, you’re bragging about your job security? No end in sight for work or paychecks?

I thought about the gun and scope combo’s when I typed my answer but hoped Conor would get the general idea. As usual, you’re the fine detail brush while I’m just a broad stroke kind of guy. LOL!

kevin

BB

That is an excellent illustration of the 160 trigger. I am assuming that you have some prior drafting experience?

SL,

No drafting experience. Just the desperation of not being able to produce the photographs I needed.

I used Mac Draw Pro, one of the finest drawing programs ever made. I still miss it, as Corel Draw and all the others, which I own and have to use, are made for real skilled drasftsmen.

B.B.

BB,

This looks like a fantastic rifle for the money, and it may well find a place in my small 10m rifle collection. I have a question about the two stage trigger. I have been under the impression that a two stage trigger uses two different lever rates to achieve the different trigger weights. However, from your drawing and photograph, I don’t understand how this trigger functions with two stages. Maybe triggers could be the topic of another blog or series for those of us with limited trigger experience? Thanks!

Jay

BB,

Another question – is the spring loaded pin at the front of the trigger housing part of a safety mechanism, or does it simply limit rotation of the sear?

Jay

Jay,

That thing you call the pin is actually what I call the safety cam. When the safety lever is rotated, the cam moves up and stops the sear from rotating, just like it looks like in the drawing.

B.B.

Jay,

I explained how the trigger functions as a two-stage unit in an answer above.

B.B.

The TF79 trigger really does feel like a two stage due to the hinged trigger design. Mine breaks crisp at approx 1 pound, 2 ounce pull and with a little moly lube, it seems to feel better each time I shoot it. The hinged trigger design and smoothness has a very similar feel to the Rekord first stage on the HW97.

They got this one right!

I think I just fell in love. I shoot 99% in my garage, so 50 feet is my longest shot. How will this rifle work at 25 yards when I can get outside?

I just looked at the description of the TF79, and it says a 20lb CO2 tank can be used, but not included. Under accessories I see a “20oz CO2 tank”. Are these 2 tanks the same?

Thanks

Gene,

The TF 79 will shoot fine at 25 yards. Just like any other 600 f.p.s. rifle.

No, a 20 pounds CO2 tank is not the same as a 20 ounce paintball tank. The 20 pounder is also known as a fire extinguisher.

Stephen Archer at Archer Airguns has the right adaptor to fill this rifle from paintball tanks.

B.B.

Got it. Thank you.

Just to further clarify…..not ALL fire extinguishers are Co2,be aware that there are many different kinds of extinguishers.There is a buisness next to my daily breakfast restarant where I hoped to get

Co2…..they do nothing but fill fire extinguishers but they had no idea where to send me.That would have been very convenient!

Gene: I do a lot of garage shooting too at 10 meters. This rifle is perfect for the type of shooting that you are describing. The power on mine has been bumped up to 720 (ish) fps with the modified bolt probe and transfer port etc but, it still works well as a 10 meter gun. I have a Leapers 2-12 x 40AO scope and UTG Bi-pod mounted to mine and it not only works well, it looks cool! I did some minor polishing and cleaning too and the stock now looks like a mirror after some rubbing compound and car wax.

Bottom line, this is a fun gun to shoot, play with and improve on the few rough edges.

I just made a few local phone calls. I can get the 20 oz refiled for $5.00 at a hardware store. He said they use a 20 pound tank to do this. He says I can rent a 20 pounder from a welding supply shop, for he thinks 8 dollars a month, plus the co2.

Gene,

I own 4 – 20-pound tanks. I paid $50 for the most expensive. It used to cost $14 to get it filled at an industrial gas company. Probably up to $20 today.

B.B.

Thanks again.

BB, or any other “trigger guru”.

Please explain the function of the “hairpin” looking spring that runs across the sear. If it does what I think (pushes the sear up to engage the hammer when cocked), then what prevents the sear from dragging on the hammer when fired,thus reducing hammer strike, and power? TIA. JR. PS- I second that request for a full blog on trigger mechanisms!!

Not sure on that, but this rifle sets the trigger upon the rearward bolt movement, and sets or primes the hammer/valve spring on the forward movement. Opposite and in two motions versus say… a 2240 that does it all in one, rearward stroke.

JR49,

Yes on the hairpin spring, only the sear jumps out of the way of the hammer/striker until the gun is cocked, so there is no dragging that I can see.

B.B.

Go to… http://www.arld1.com/tx200trigger.html for some great animations of triggers and other airgun internals.

A trigger is about half the shooting experience at least in my opinion and this sounds like a good one.

Vince, thanks for the history of the GTA trigger. As to why people could get so upset over triggers, perhaps the answer lies with a comment by my organic chemistry professor in college: “When people attack your ideas, it’s like they’re attacking your children.” … I guess that would do it. For what it’s worth, I’ve found Rich Imhoff to be a heck of a nice guy and an incredible craftsman, and his trigger has made all the difference for my B30. It is a tad heavy but I don’t bother adjusting it lighter since it shoots plenty well as is.

Another bit of debriefing from my Hawaii shooting. I found that the subconscious is really responding now whether its from my dry-firing, airgunning, Gordian Knot method or whatever. It’s sort of like…Jaws rising from the depths of the unconscious to grab onto the the elusive shooting moment. How about that? 🙂 Just at the right moment, I would feel those mental jaws clamp on, Munch Munch, especially with the Ruger Single Six.

Also, I had a good experience that went a long way towards reconciling me to the turret-locking feature on my Leapers scope. As someone here mentioned, just don’t lock the turrets. In my defense, I had supposed that the locking feature was meant to be used and the clicks are not very positive and do not inspire confidence. However, they held zero through multiple trips to the range in and out of the rifle case. And they adjusted very finely to put my Dad right in the X-ring which really made his day. I still think the scope would be improved with a different lock set-up that does not require an Allen wrench. But it is very usable, and with this small modification would be really tops.

I came away from my trip with a guaranteed million dollar idea. All the expanse of ocean around Hawaii is limited to the daytime. None dare swim at night. If someone could just design waterproof night vision, this could change radically. And if color could be used–surely not far away–that would be even better. All who have the wherewithal to develop this should listen!!!

The connection to airgunning is not obvious. However, my information is that one of the most effective weapons for warding off sharks is a device called the SharkDart which is sort of like a giant hypodermic needle that injects gas into the shark and causes it to rise to the surface and basically, pop. That’s an airgun of a certain kind. More conventional is a “bangstick” which appears to be a sort of shotgun which is touched to the target. I guess that would count as a firearm.

Matt61

Matt,

Sharks feed at night (dusk to night) and they don’t feed alone and they are not interested in being just curious. They also don’t co-operate by always attacking from the front and visibility at night and with a mask is severely restricted. And a “bang stick” is a single shot shotgun. Sharks #2-5 will have your arms before you reload.

I think the idea of the SharkDart is cool. I would love to see that thing in action.

BTW, I’m currently scuba diving in Bonair, NA. just off the coast of Venezuela. I have yet to see a shark here but I know they’re here somewhere. Lots of illegal immigrant Lion Fish here, however. Let me know when your night vision invention needs testing.

-Chuck

Afternoon B.B.,

My Crosman 180 has a through the stock safety. I’m thinking that, based on what you said about the 160 with that safety, that my 180 has the dirt-simple direct sear type trigger, but am I correct? Thanks

Bruce

Beuce,

You are correct about your 180, but later 180s also had the adjustable trigger like we are discussing here.

By the way, are you aware that your rifle has adjustable power? The tiny screw accessible through the end of the cocking knob allows you to increase and decrease the tension on the hammer spring.

B.B.

Yes sir, I am aware of the adjustable power feature of the Crosman 180 because I read your excellent blog on it. My brother-in-law found it in a trash pile waiting for a pick up. It needed more than pelgun oil to hold CO2 so off it went to Rick Willnecker for repair. I’ve left the tension on the hammer spring right where Rick set it.

Bruce

Just a word of caution regarding moly and triggers: This applies mostly to those of us who mess around with vintage springers. Some vintage guns with less sophisticated triggers have near vertical, or sometimes over-vertical sear surfaces that rely on a bit of “stiction” to maintain engagement. Moly can make some of these down-right dangerous, easily as dangerous as altering sear geometry, especially if the mating surfaces are worn from age and use. Just use common sense when lubricating sear surfaces, and make careful note of the geometry before applying ANY lubrication. I learned this lesson the hard way. It’s very difficult to remove all traces of moly, once it has been applied, since it bonds to steel.

Amen to that Jim.

And… as you noted there are a lot of devices and materials (not just gun triggers) that rely on some level of friction or affinity to each other to operate as needed.

For trigger parts, geometry, surface finish and hardness (temper) are critical components

I sure wish I’d subscribed to The Airgun Letter and saved them all!

BB, have you considered scanning your Airgun Letters to digital format and selling them on DVD?

flobert,

For many years, we’ve talked about reproducing the newsletters, Airgun Revues, the R1 book and all of Tom’s articles in Airguns Illustrated magazine. It’ll happen. We have almost all the files digitally (we had a Bernoulli Jaz 2GB removal hard drive, and it had a unique feature…it would overwrite files when it got 2/3 full…but no one knew it until the mfr discovered it!). The files that are lost can be recovered through scanning. This affects only the newsletter and perhaps part of one of the Revues.

All I need is time to do it 🙂

Edith

Do the scanning and set the price Mrs. G.!

There are a lot of us out here who will buy that great, late night reading.

(if I’m not out shooting, I’m probably home reading about it)

The way to go for any graphics work is a Macintosh, you don’t need a new one but try for a recent one.

The Zip/Jaz drives are/were such POS’s it’s amazing they stayed on the market as long as they did.

flobert,

We’ve never owned anything but Apple computers. I even owned an Apple II before the Macs came out. We’ve been using Macs since 1985. The Bernoulli Jaz 1GB removable hard drive was actually very good. It was only the 2GB drive that was a problem.

Tom currently uses a very big, fast Mac tower, and I have a zippy little MacBook Pro that I bought 11 months ago when my iMac died. I plan to buy an iPad for Tom to use while he travels, but we’re waiting for the iPad that has a built-in camera so we can Skype while he travels. His current travel laptop is okay, but we think an iPad will be easier to slog around.

You got me started…we LOVE Macintoshes! Can you tell?

Edith

Flobert,

yes, we have considered it. Perhaps someday when we can hire an assistant to do other jobs like that it will be possible.

B.B.

The argument over single-, double-, x- stage triggers gets silly sometimes. I prefer a good single-stage trigger because I can’t stand excess travel, and there’s no reason they can’t work well; the problem with them in terms of reputation is that it is the default implementation on cheap guns and making them lawyer-safe requires more precision and quality or more slop, depending on the price point. I also wonder what class a set trigger goes into — obviously it has more than one “stage” of setting, but the firing thereof is one very sharp action, the best of both worlds as far as I’m concerned, and common on hillbilly rifles since probably the Revolution.

VERY SHARP!

I shot a 12 gauge once that had set triggers, don’t want to even breath on that second trigger!

To me, the best two stage triggers have adjustments for the weight, travel, fore and aft position, etc. In that way your own length of pull, effort in lbs. and degree of travel in the first stage can all be set.

One of the guys brought a match specific rifle to the ML’er match a few weeks ago, and it was set so low that the trigger once set would go off with a gentle rap to the butt of the rifle. That was a “little” less than I like — in fact I couldn’t even feel it when dry-firing. Of course, my hands are completely stiff and numb, anyway, and it was 20dF and snowing as well :). Just to be clear — I wouldn’t use anything set that light in the field, in fact I prefer about 4 lbs. of trigger pull anywhere but under the most controlled conditions.

I have an LG 55 Tyrolean with double set triggers,and I have left them the way I recieved them.I can assure you this vintage match gun would fire if you touched it with a feather duster.I won’t pull that first trigger until I am settled on target!I couldn’t use a firearm set that light,no way.

I used to run the HW97 with very little 1st stage travel and just a “breath” to let loose on stage 2 but, since then I have slowly increased weight/pull on both stages to a comfortable/safe level. I actually prefer the slightly heavier feel of both stages. This TF79 has a very similar feel to the HW trigger even if it is not a true 2 stage.

Note: tonight, set-up a 10 meter paper target that has 1″ sq grids across a 6″ x 9″ area and shot one pellet into 40 of the grids with the TF79 (on 2 cO2 carts). Happy to report that all but 4 of the shots landed within one (1) pellet diameter of center in each grid. No bench, just sitting with left elbow supporting gun on left leg. Using 2-9X40AO scope at 5X power with Gamo Match .177. This barrel and trigger is world class for my needs.

The addition of a plunger head type set screw replacing the over travel screw can make the trigger even better than it is. Gives a real two stage set up as the trigger will return to full engagement when released if you don’t fire. Replacing the trigger spring with one from a BIC pen will lighten the trigger but can make it too light, got one down to 4 oz. that way and it was good for targets if you knew it was there but would be a bugger in the field…

I have a JW75 Whiscomb since new, with a serial number of 75-0005. It has .0177 and .022 barrels. It shoots Crossman Premier 22’s at 975 f.p.s., and, as everyone would know, is a remarkably smooth shooting gun. I won several silhouette matches in the ’80’s with this gun and became obsessed with improving it’s 50m accuracy to even beyond what anyone would believe a .22 capable of. I contacted John Whiscomb by phone and sent him my rifle with a new Anshutz .22 match barrel. The gun was shooting 10 shot 50m groups at 0.75″ with a usual “flier” out to perhaps an inch and a half. I always felt that this was the barrel with its square cut rifling loading up with lead. The Anshutz barrel was design for lead projectiles with half round cut rifling and about twice the twist rate of the original rubber-bedded barrel. Was I ever right, as the group size went down to 0.75″ at 50m, with half or more often falling in less than 0.5″.

I had Mr. Whiscomb do whatever upgrades he wanted to the gun while he had it. These included fitting his amazing custom match trigger, replacing the springs with better alloy parts, installing his adjustable port kit, and replacing the piston seals with the newest burn resistant materials. It is an incredible gun in perfect, mint condition with the fully checkered Tyrolean stock and adjustable butt plate. No where is the bluing even worn. It is a truly one of a kind but does not make sense for me to keep at this time in life.

I am asking out there, if someone knows the best and most appreciative home for such a gun that has been so cherished. I am also curious about what the fair market for such a piece would be.

Doug

Doug,

I forwarded your address to a reader who indicated interest in your gun. He should contact you soon.

B.B.