by B.B. Pelletier

Announcement: Here’s this week’s winner of Pyramyd Air’s Big Shot of the Week on their facebook page. He’ll receive a $50 gift card.

Shariq Bukhari with his Diana 350 Magnum on his farm.

Before we begin, it’s time to make all of you aware of an anti-gun movement taking place in California right now. California Senate Bill 798 will change the current code so that all airsoft guns and BB guns can no longer be black. They will have to be completely clear or all red or all blue or all green.

Even if you don’t live in California, this bill has the potential to affect you. Many of these guns are imported from China, Japan and Taiwan, and their ports of entry are in California. If the law passes in its current form, it will impose fines on those who distribute these guns if they aren’t clear or brightly colored. If this passes, it will embolden legislators in other states to pass similar bills — and perhaps even more stringent ones. To paraphrase an old saying, as California goes, so goes the nation.

To read more about the bill and what you can do about it, click here to read our facebook page, which has additional links to the bill in its current form, other web pages about the bill and videos about it.

Now, on to today’s blog.

Have you ever seen anything like this? It’s a single-shot breakbarrel modified into an underlever repeater.

Blog reader Kevin asked for this report, but several other readers have also indicated their interest. It was Kevin who also gave it the nickname pogostick. It’s really a homemade repeating spring-piston airgun that was created by a mad-scientist airgunner more than 30 years ago.

In fact, almost the only historical information I have on the airgun is that it was bought over 30 years ago by the man I bought it from. It was always his plan to get it working again; but now that he’s in his 80s, he has other priorities and was open to an offer.

I visited him just before the Malvern airgun show, and I was in his gun room looking at both firearms and airguns this past April when the odd shape of this long gun attracted my attention. The owner brought it down and handed it to me, telling me a brief tale of how he came to own it. Like me, he was attracted to the strange mechanism, and I think after you see it today you’ll feel the same.

Description

The airgun began life as some model of a Diana breakbarrel, probably an old model 27. The Diana trademark and name can just be made out on the spring tube, but I haven’t been able to pin down the exact model yet. I’m guessing it’s a model 27 because of the size. Of course, I’m referring to the pre-war 27 that was made without a forearm, as most pre-war Dianas were.

No doubt who made the gun originally. The model will be harder to determine, though.

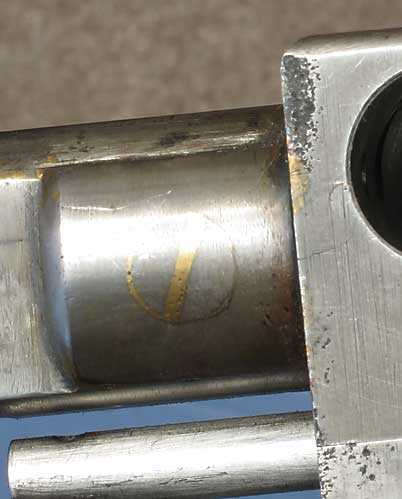

And yes, it was originally a breakbarrel. You can see that the person who modified the gun started by brazing the breakbarrel joint shut and grafting in a new mechanism.

The pivot bolt was brazed in place.

Right side of the pivot bolt.

After brazing the joint, it appears to me that he cut the compression tube and spliced in an action block that houses both the repeating mechanism and the magazine. You machinists will appreciate the level of skill it takes to cut a spring tube, graft in a block of steel, then reattach the front of the spring tube and keep the whole assembly in perfect alignment. It has to be aligned pretty well because the air transfer port in the back part of the tube has to shoot air through the sliding magazine and into the rear of the barrel that’s grafted on. If my descriptions don’t explain it well enough, the photos will.

Then, he had to create a separate underlever mechanism, find a way to attach it to the gun and rig a link that connects the underlever to the piston while bypassing the new block he’s grafted in. Once again, the pictures show this very well.

When the underlever cocks the gun, the cam on the lever presses the steel shaft straight back. It acts on one of the three pins inside the action. That detail is shown later. The straight shaft is missing a spring to return it to the front when the cocking lever goes back to the stowed position.

Now, we come to the difficult part! This mechanical genius, and I mean that as a compliment, devised a way for the spring-loaded magazine to advance every time the gun is cocked. That’s where the pogostick look comes from.

To the right side of the action, he attached a steel magazine housing for the cylindrical magazine that holds 6 pellets. The magazine fits into the mag housing under spring pressure, and an escapement mechanism of two separate pins allows the mag to advance to the left, indexing the next pellet each time the rifle is cocked. I call it an escapement mechanism, because a watch escapement is the closest thing I’ve seen to it. One pin drops down out of the way when the underlever is retracted all the way during cocking. That allows the mag to advance to the next pellet hole. When the underlever returns home, the pin that dropped away pops back up to lock the mag securely. A spring that is missing from the mechanism’s shaft takes care of moving the shaft.

The other pin behind this middle pin must also move for the mechanism to work properly, but I haven’t figured out how it works yet. It’s spring-loaded, so maybe that alone is all it needs. There’s a headless screw in the front of the mechanism to keep the cylindrical magazine on its track.

The magazine has detents cut into a track in the base. These detents are angled, so the pins that work the action can slide over them under spring pressure when the action is working.

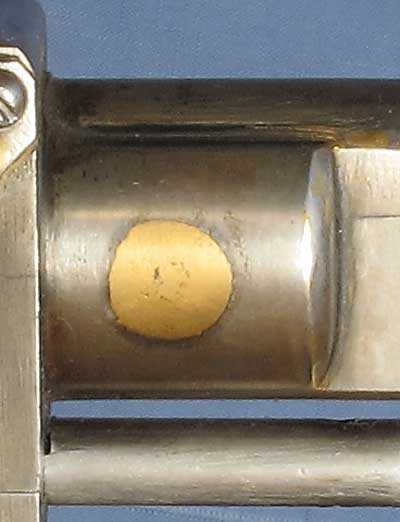

The magazine is shown out of the gun. The coiled spring and steel guide keep tension on the magazine when the gun is cocked.

A look at the operating escapement mechanism. The front pin is solid and is just there to guide the magazine in its track. The middle pin is connected to the straight shaft under the gun and retracts when the gun is cocked, allowing the magazine to advance to the next pellet. The rear pin is under spring tension alone, and I’m not quite sure of its function.

This track in the bottom of the magazine keeps it on track. I took the photo on this angle to show the detail of the detents. You can see how they’re sloped to permit the magazine to advance under spring tension every time the gun is cocked and the middle pin drops out of the way.

The gun came with these parts in a plastic bag. Those two pins are obviously for the escapement mechanism, but I don’t know where the spring goes. It’s too large for the escapement shaft.

The gun is 42.25 inches long. A Diana model 27A that was made from 1936-1940 is 41.3 inches long, so this could be made from that gun. But there’s no way of knowing for certain without a lot of comparison with similar Dianas that are in original condition. This rifle weighs 7 lbs., 4 oz. with the magazine and spring installed. The magazine itself weighs 6.2 oz., being made of solid steel bar stock.

At the current time, the magazine is outside the gun and will not install because the inner spring-loaded pin stands too tall and will not compress out of the way. My buddy Mac thinks the mag is supposed to be captive and has to be installed from the right side of the gun; if so, that’s a cumbersome way to reload a repeater. I don’t think the guy who could dream up this contraption would leave a detail like that unaddressed.

The gun cocks with 22 lbs. of effort. The sear does catch. Since the magazine cannot be inserted, there’s no way to shoot a pellet. The trigger does release nice and crisply, though. There isn’t the hint of an anti-beartrap mechanism, so the gun can be uncocked.

But wait, there’s more!

Our mad scientist wasn’t satisfied just building this impossible mechanism. He also made both the front and rear sights. While the folding rear sight is crude compared to the rest of the work, it’s an aperture that adjusts for both windage and elevation, though the elevation adjustment is nothing more than a sliding part held by friction. It’s an extremely tight fit, so once you get it to the correct positio it won’t shake loose.

A simple yet quite effective adjustable peep sight. It adjusts in both directions and also folds flat.

The front sight is a tall, slender pin in a dovetail. The bead on top is small enough to do careful work, though I think the designer’s mind was more focused on getting the gun to work at all rather than on accuracy.

A tall, graceful front sight with bead. This is also homemade.

I cleaned the barrel, to see if there’s any rifling. As near as I can tell, there isn’t. This is a smoothbore. The Blue Book of Airguns, 9th edition, says the model 27A did come as a smoothbore. The sights are nice, but the gun doesn’t warrant them. The difference between a gun and a rifle is the presence of rifling, so this doesn’t qualify as a rifle.

Harmonica gun

Although I call the gun by the name Kevin gave it, the correct name for a repeater of this kind is harmonica gun, for obvious reasons. They exist as black powder firearms, as well as other airguns like the IZH 61 and certain target air pistols.

What to do next?

I bought this gun because I was compelled to own it. I just had to be able to examine this mechanism closer, to report on it and maybe even get it working again.

Yeah. Right!

Well, I’ve examined it as far as I can without disassembly. Then, I took a long, introspective look at my schedule and realized that this is as far as I am probably ever going to go. Contrary to popular belief, I don’t sit around all day with screwdrivers, just taking apart airguns for my pleasure.

Like most of you, I would enjoy knowing if this gun can be made to work and would love to be able to give it a complete test with velocity and accuracy. Then, we’d really find out if our genius knew what he was doing. Short of voting eight days into a week, I don’t see it happening any time soon.

So, maybe in 20-30 more years, one of you younger collectors can add it to your collection.

B.B.,

I’m still trying to wrap my head around the person that was the devoted airgunner/engineer/inventer/machinest that created this innovation over 30 years ago. What an amazing individual. It’s hard for me to estimate the time that went into that gun since I don’t have an ounce of these required talents.

For the past month I’ve been trying to figure out the reason for the pogostick design. I thought it was an attachment by bubba to fit easier in a rack or on a wall and you would soon be removing it. Yes, I’m a simpleton. A magazine for a repeater? Never would have guessed.

The spring in the spare parts bag is a stumper. Appears too short to be a replacement spring for the piston in this gun.

The design for the rear peep sight sure reminds me of the scope mount for the Walther Lever Action you showed yesterday. Interesting.

If anyone can figure this out it would be VINCE THE WIZARD.

Kevin,

I am seconding your suggestion to send this work of art to Vince.

Pete

Absolutely! “Send this thing to Vince” was the first thought that popped into my head after reading this article.

If anyone can figure it out, he can.

Les

Kevin,

I concur, this gun needs to be brought back to life. Utterly fascinating, and apparently, typical of engineers, tremendously overbuilt. Makes me proud to be an engineer myself even if I can’t work with metal very easily.

If Vince couldn’t do it, then my bet would be with the guys at Another Airgun Blog (http://anotherairgunblog.blogspot.com/). Nick, Derrick, or Felice are all machinists by day, so they have the toys to build any missing parts from scratch, and the experience to intuit that something is indeed missing at all. It’s on my daily must read list right after this blog.

Or Loyd! Not sure how I forgot him. *facepalm*

That thought had occurred to me too. This could be Vince’s crowning achievement. The torch passed from one brilliant designer, craftsman to another.

Matt61

B.B.

Off topic I am wondering about scoping my new Crosman 1701P. I just recieved one from PA. I recall you mentioning that Crosman was coming out with a scope well suited for this pistol in May. Any word about it or did I miss its release? Thanks.

Mark N.,

I remember writing about that, but I don’t think I ever saw that scope. I’ll ask Crosman what the status is.

B.B.

Mark N,

Just heard back from Crosman. The sight isn’t a scope. It’s a dot sight. It’s listed on their website right now:

http://centerpoint.crosman.com/sights/CPMDWC

B.B.

Thanks B.B. This sight is labeled as a “Quick Aim” sight. In my limited experience with dot sights I have found the dot to be too large to take advantage of the precision that this pistol seems capable of. It looks like a nice dot sight however. I will take some time to evaluate what the options are. Thanks again

Mark

Mark,

I was as surprised as you that it turned out to be a dot sight. I was told it was going to be a scope.

B.B.

B.B.,

VERY neat gun devised by somebody with either too much time on their hands or a whacked sense of priorities…but I totally understand the obsession.

Does that additional spring fit into the magazine cross tube to keep tension on the ratcheting mechanism of the magazine bar so that it feeds across with each cocking action? From the pics, I can’t tell if the diameter is correct, and actually the spring looks too stout for that function. But maybe so.

The spring goes in the bottom of the cross-tube first. The magazine is loaded and pushed in with the single detent notch entering first. The magazine is pushed all the way in to compress the spring and click through all the detents. With each cocking action, the detent pin is retracted just enough such that the the spring pops the magazine out one detent position. (The actual speed of the cocking motion might be touchy for the thing to function properly, and not accidentally let the mag pop all the way out. ) After the last shot, a partial cocking action will pop the mag out to the farthermost detent position and expose all the pellet holes for reloading , without actually cocking the piston. The 2 pins look like extra detent pins…wear items.

Can the spring just be threaded back into the cross hole past the 3 pins?

B.B., thanks for the GREAT photos, which by now, I sometimes take for granted. But they explained a lot!

I agree with Kevin. See if you can talk Vince into taking it under his care and getting it operational again.

Lloyd

B.B.,

Wow, that’s what I get for writing in the wee hours of the morning. Looks like i just rehashed evrything you had already said about the functioning of the magazine mechanism.

Egg on my face!

Lloyd

This has cool written all over it.Passion,determination and the right skillset all coincided to bring this to life the first time.There is much proof here that it’s inventor just wouldn’t take no for an answer.How great it would be to know the whole story! I had a harmonica gun that was really cool.The Aeron B96 “chamelion”……I let it go to an equally cool airgunner….who has the same skills as the inventor of this one.I wonder if the rest of the airgun is “stock”?

Neat! Being the type who enjoys retreating to the laboratory…er, basement workshop to improve and invent stuff, I enjoyed this one. Thanks for posting about SB798, I sent my letter off to Senator de Leon a few days ago. An Air Arms Pro-Sport just wouldn’t look right in bright red.

On SB798, Received my E-mail warning last week from PA . This is a real, real bad one! Another one of those seemingly “reasonable” gun laws, like were mentioned a week or two ago when I mentioned that all shooters should join a group like the NRA to fight this stuff? Perhaps we should require a permit to buy pink and orange paint , so the gang bangers won’t paint their real guns to further confuse authorities? I know, we’ll just pass a companion law that limits the number of spray paint cans those folks can buy. That will keep society safe! Like magazine capacity, barrel length , trigger locks, and other restrictions on all types of guns, these jokers are playing for keeps. I’m still waiting for a reply to my question on what constitutes a “reasonable ” gun law ,and why we need them from the gentleman who questions my adversion to any politician or liberal group who would suggest such regulation. All these laws will incrementally destroy your gun rights. The average shooter needs to wake -up. I notice on the forums where SB798 has been mentioned ,that the moderators in charge ,dummy down the tread and won’t allow discussion , or debate. Not PC enough for them apparently.

Robert From Arcade,

It was my reply last week that shut down that post. I fully understand freezing political discussions since they frequently lead to juvenile name calling then chaos and finally bedlam.

I can’t understand the majority of airgunners attitude on that forum which seems to be “ignore it and it will go away” when it comes to proposed gun legislation. If you don’t have the time to write representatives about your outrage at this kind of stupid gun legislation at the very least join and donate money to an organization that has a long track record of defending your rights. I like the NRA but there are other options.

Pyramyd Air’s email to most of us last Friday regarding California Senate Bill 798 was the catalyst for the thread. Here was my contribution that lead to the modertators locking the thread and ending all discussion:

“The precedence is the precedent.

This is not about Pyramyd AIR although we owe them thanks for helping to remind us about this ominous black cloud that looms over the horizon for airgunning in the USA.

Please take the time to read the proposed bill. The link is above and has also been posted in numerous places this past week on many websites.

This is serious.

A tragedy involving a series of bad judgements has been utilized as a springboard, by one low level California State politician, to force into law a far reaching bill while public emotion is cresting a wave. All to familiar headline grabbing at the tragic expense of others to further their own agenda. THIS IS NOT POLITICAL THIS IS A HISTORICAL FACT THAT FREQUENTLY GETS BILLS PASSED. Remember the Brady bill and its’ far reaching implications?

This proposed bill does apply to pellet guns. The vague language can easily be construed to include all airguns since the roots of this bill can easily be traced to a dark night where identifying the guns was difficult by law enforcement. Make no mistake the judge and/or jury will be made aware of the circumstances that this new law was incubated when the first case is heard along with the 2nd, 3rd, 4th etc. Failure to identify in dark includes all metal and wood airguns and most likely others that are clearly plastic in direct sunlight.

For those that chuckle and think this means your next purchase of a white, blue or red airgun will be ok to you, I say wake up. Do you actually think that manufacturers with worldwide distributors will start making their guns white, blue or red because the California consumers are only allowed to buy those colors?

The bigger issue in my experience with laws/bills that originate in California (it’s amazing how many do) is the precedent it will set. Don’t lull yourself into a false sense of security thinking you’re immune from this law because you live outside of California. Legal precedents cross borders.”

kevin

What I find incredible, is WHY they’re doing this… 3 young guys shooting at each other in a park with airsoft guns (this is already looking bad for them) someone calls the cops (duh), police shows up, tells the guys to drop the guns, one of them refuses to drop it (bad idea) and gets shot…

When a cop is pointing a firearm at you while you have a gun in your hands and tells you to drop it… YOU DROP IT!!! That guy got what he deserved IMHO.

We sadly already have only clear airsoft guns in Canada. So this isn’t going to change anything here, act while you can.

J-F

Thought the same myself. Why oh why, when a policeman with a gun tells you to drop what looks like a gun, do you not drop it? It’s like the crazy Harvard professor, Henry Louis Gates, who gave a policeman a hard time about perfectly reasonable requests then yelled when he got himself arrested, or the crazy professor in Alabama who shot a bunch of her colleagues after killing her brother, tried to hold off responding police with a shotgun so that they had to sneak up behind and disarm her. No doubt there are police abuses but my sense is generally that our police like our military abroad tend to exercise enormous restraint. You’ll never legislate out stupid people, so its futile to try beyond a certain point. If an orange tip doesn’t signify, I don’t see that blue, green, yellow colored guns will.

Matt61

Matt61,

A friend of mine (a women), has a violet colored assault rifle. It looks almost like a toy, but is as real as can be. Painting guns is not a solution. It’s an attempt to play with reality, which runs much deeper than the surface. If (or when, should this law pass) criminals decided to paint their weapons to comply with this law, what will be the next reaction?

If a criminal paints his gun and puts a bright orange tip on his firearm, that might buy him an advantage in reaction time, when confronted by an officer, IF the officer is now to assume that such a gun is a not deadly. Again, the real issue is responsible handling of guns. Kids who can’t comprehend that their actions matter, when holding a non-firearm, should not be allowed to own one. In such case, the parents should be the law. But this also means that the parents should teach them, including the obvious. Never point guns are people if they fire a projectile, no matter what type of gun it is.

Victor

Victor,

That’s already happened. Two goofballs painted their firearm a bright color. I think it was pink but can’t swear to it. They used it to try to hold up a bank. Not being very bright to start with, they were quickly apprehended. If I’m not mistaken, this happened in 2010…in California. I subscribe to Google news alerts, and that’s how I found out about that story.

Edith

Edith,

I think that at this day and age, parents should teach their kids to never point their guns at anyone, especially the police. Police in many areas are very quick to defend themselves. – Some would say, too quick. Now, this is a point of contention with lots of people, because sometimes officers are clearly wrong, but on the other hand, civilians usually don’t try to put themselves in the officers position. If I were a cop, I’d want to go home to my family at the end of the day myself, and the future of my family isn’t worth the risk of giving a potential bad guy the benefit of the doubt. BUT, there are many cases where the officer panicked, or already had a propensity to over-react to things. My personal feeling is that psychology and lack of sufficient screening, and/or, training plays a big role in this. I’ve had personal experiences with cops who are either mentally unstable, or just plain old jerks. My roommate from college is now a prosecutor in LA, and he says that lots of cops are “bullies gone legit”. I know guys from high school who became cops to “kick butt”. My point is not to bash cops, but rather to temper “ideals” with reality. While there are some very good cops, like personal friends of mine, and neighbors, there are also cops who are in the wrong profession. Mix bad with stupid, and someone is going to get hurt or die.

Any kid (or even adult) who thinks that the law is executed in a purely black and white fashion, and thus assumes that police officers are going to act like robots, programmed to the letter of the law, may find themselves with a rude awakening, or permanent sleep, when they point their gun at one – even a toy.

Victor

Now we know what Lloyd was doing 30 years before he designed the E-Valve!

David Enoch

Kevin : yes, in regards to the political name calling that usually results from such treads, I can understand the shut down, but it is a known fact that over on the yellow the moderators and the owner are very left leaning in their views. They won’t tolerate the mention of the NRA or any of it’s attacks on the liberal politicians that sponser these bills over and over again. I also find that in general, many of the airgun forums ,will not tolerate talk of firearms ,or laws pertaining to them. They are also overly too PC in regards to hunting, and gun ownership for my tastes ,which is why I do not ever participate in any of them anymore. They are under the delusion that their guns are not guns, and that gun laws won’t apply to their hobby. Unfortunately, it has been reported that the bill SR798 has also passed the senate in Cal and has gone to the assembly floor. We may lose this one. The senator that sponsored the bill is also of the belief that your car and your home are fair game for a search, and seizure if weapons are suspected, or displayed. He is not in the least concerned with accidental shootings by police of children displaying realistic looking BB guns. It will do little good to write to these kinds of politicians, What will do good, is to have a powerful and well funded lobbiest group like the NRA , crush and overwhelm their political ambitions. That’s the hard reality of it ,and shooting folks will have to make the choice. It’s that simple. Also, yes I really identify with this scenario of gun law trends as I live in NY and we are often next in line.

Robert from Arcade,

It’s my understanding that the NRA has stayed out of the fight in California when it comes to SB 798. I don’t know the reason.

For those who don’t read Pyramyd Air’s airsoft blog, you might want to take a hop over there & see what Tom Harris says. He lives in California, and his day job is as an accountant. The fiscal effects of this bill on California’s indebtedness will not be pleasant.

Edith

Edith: This is just speculation on my part , but I beleive it boils down to resources. With attacks coming on all sides due to the recent tradgedy in Arizona, and a lack of support of the general shooting public due to the popular media perception that the NRA is made of far right wing nuts. I think that they have to pick their battles and sucker punches like this get over-looked. If it weren’t for the economy , wars in the mideast, and the natural disasters that have plauged the world lately, I think that the present administration would be all over the gun issue. Regards ,Robert.

You are right, Robert. This proposed law is so wrong on so many levels it is hard to find a starting point to discuss it.

Perhaps the most important flaw in the reasoning is that all airguns are harmless toys on the same level as airsoft guns. If our pellet guns are equated and marked as airsoft guns, a dangerous situation is being set up which could result in serious injury or death. On the other hand, what is to prevent a criminal from painting his firearm to look like an airgun? Like most anti-gun legislation, this assumes the criminals are going to play by the same rules as everyone else.

There is an even darker side of this debate, one that is hardly ever mentioned. Airguns (as discussed in this forum, not airsoft or paintball guns) occupy a rather unique position under the law. Although treated by state and local governments in some jurisdictions as firearms, they are legally not firearms under Federal Law. This exempts them from Federal restrictions applied to firearms. They can be legally mailed and are not tracked by Federal registration. This is generally considered by the airgun hobbyists to be a good thing.

But, firearm ownership is protected by the Second Amendment. Airguns, not being firearms by Federal Law, are not protected by the Second Amendment. So a state may enact a law that requires all airguns of any description to be painted certain colors, but not firearms. Maybe there is protection for firearms that should be extended to airguns.

Adding to the confusion is the fact that some airguns already are available in colors. And, so are some firearms.

It really upsets me when a tragedy is exploited for political gain. Kids having a shootout in the dark with airsoft guns reflects youthful bad judgement. If the police thought that the guns were real, they should be excused for protecting themselves in that circumstance. Would they have been able to identify say, a green airsoft gun in the dark?

Does the State of California really want potentially lethal, lead firing air guns identified as harmless, plastic-projectile firing toys?

Les

The Second Amendment protects the right to keep and bear arms. There’s nothing in it whatever that says that those “arms” have to be firearms! Where do legitimate definitions of protected weapons begin and end? I don’t think there’s a right to your own nuclear missile, nor even your own canon or howitzer. I doubt a boat owner can claim the right to own mines and torpedoes. I think government can rightly restrict operation of a BB gun by a 6 or 12 year old, or maybe even a 17 year old. I don’t see how “pellet guns” can be banned.

If you look at the times that the Bill of Rights was framed, it is pretty obvious that they meant guns. Any kind of guns.

They could not forsee what kinds of guns would come in the future. They could not forsee that there would be so many possible attempts to subvert our rights.

Originally, they thought about our ability to protect ourselves from tyranny no matter where it came from. Even our own government. Power was to be given to the people, and not the government.

A tyrranical government fears an armed scociety. So do thieves (same as the government).

If they can undermine the second amendment enough, then only the criminals will be armed. No matter where the criminals are or who they are. Then there will be an outcry to removing the rights of the accused because of the increase in crime. Other articles of the Bill of Rights will be removed. Then nobody will have any rights at all.

twotalon

Twotalon, Pete,

My concern about lack of Federal protection for air guns comes from the existence of a Federal statute specifically exempting air guns from Federal laws pertaining to firearms. it specifically states that air guns are not firearms.

Maybe I am making too much of a leap in logic here, but it would seem to me that a law that exempts our guns from proscriptions against them would also exempt them from protections granted firearms.

It would be inconsistent to have it both ways.

The Second Amendment has traditionally been considered to apply to firearms. “Arms” could mean a lot of things besides firearms: swords, crossbows, mortars, etc. Weapons of mass destruction fall under their own prohibition.

People on both sides of the issue seem reluctant to acknowledge that the Second Amendment is not about hunting, target shooting, or gun collecting. It is about citizens’ protection against government run amok.

Les

Government run amok ????

Now where would that happen ??

Oh, yeah.

twotalon

While I do not expect an armed revolution in this country, the more I cogitate on the 2nd Amend. the more I’m convinced that the framers did not have protection against burglars and muggers in mind. Take the militia cause as you will, but what is essential to protect is “the security of a free state.” Burglars don’t threaten that.

If you put the security of a free state foremost in the logic, then most of the other anti-gun arguments are amenable to rational negotiation. I still don’t think you should be able to buy your own Abrams M1A1 tank or your 155 Howitzer under the 2nd amend. That’s where the “Well regulated militia” part might come in.

Robert,

This topic is being covered on the gateway to airguns forum with no moderator restrictions that I can see. They even have an entire sub-forum for political discussions, which nicely short-circuits any moderator with an itchy ‘ban’ finger 🙂

http://www.gatewaytoairguns.org

Here’s one sample posting: http://www.gatewaytoairguns.org/GTA/index.php/topic,12633.0.html

Everyone,

Concerning California SB 798, the wrong topic is being discussed! It isn’t the color of the guns that will insure safety; it’s the actions of the owner. That kid should not have been brandishing his airsoft gun in public in a place that was not sanctioned for airsoft play. That’s the real crux of this issue. But legislators find it simpler to attack the symptoms of a problem, rather than the root cause. And the lapdog media hasn’t got a clue, so they follow obediently.

The root of this unfortunate incident was a lack of responsibility. The kid had obviously never been trained in the handling of firearms (I’m not departing from the discussion, here) and therefore lacked the responsibility he needed to control and operate his airsoft gun in a safe and responsible manner.

Almost ever airsoft store and every manufacturer warns owners to never carry their guns in public unless they are in a bag. What they mean is a gun case, but bag is the term they use. That way, no officer will feel threatened.

That would also be good advice for firearms owners and airgun owners to follow. Although I live in Texas, I try never to display my guns, be they airguns or firearms, in public. Although this state is very open to gun ownership and even to concealed carry, there is a social obligation that goes along with ownership. Not everybody feels the same as I do about gun possession. So I carry my guns in bags until I get to an approved place where they may be brought out into the open.

I was lucky to have been 13 (the age of the boy who was shot) at a time when that wasn’t as threatening as it is today. But still, I didn’t carry my airguns openly even back then in 1958-1960! Even though I had practically no responsibility, I knew the consequences of having the police see me with guns in public.

The problem today is children feel they have “rights.” And they seem to think their “rights” grant them immunity from responsibility. They can do what they want because no one would ever harm a kid.

Children have no such rights, but so many institutions seem to be willing to lie to them that they do, with primary education being the worst offender.

How would it be if a required primary education introduced the kids to the real Bill of Rights? Instead of believing they have unlimited right to say anything (Free Speech), they would be forced to learn what the First Amendment to the Constitution really does. It limits Congress–not citizens.

And if kids were forced to learn firearms safety as a prerequisite to graduation, how might that affect the social order we see today? Would kids then understand that they have a responsibility toward firearms regardless of their personal likes and dislikes?

{As an aside, in Maryland in the 1980s, one school in Columbia had a day when all the young girls were introduced to lesbian activities. They were lectured by lesbians, after which they were made to embrace and kiss one another, in order to round out their life experience in this area. These were girls aged 12 and under. Imagine if that same school had had a firearms familiarization day.}

Back to the issue of gun color. In the dark a colorful gun and a black gun both look the same. I say put the onus on the gun-holder, not on the policeman. Make whoever holds the gun responsible for what happens.

AND TRAIN ALL THE KIDS!

B.B.

No legislation can ever take the place of personal responsibility.

Airsoft guns can be used to teach the basics of firearm safety, but it all goes out the window when the kids start using the airsoft guns to shoot each other. The concept of airsoft guns as surrogate weapons (for teaching gun safety) and the concept of airsoft guns as toys for mock battles are mutually exclusive.

This is why I am opposed to airsoft guns for young people. They are really models of fire arms with limited operational features. Toys for adults.

Tom Harris attacks the issue from a different direction. He emphasizes that airsoft guns are dangerous because they can cause eye injury. If they are so dangerous, why do people insist on having shoot-outs with them? Because a pair of safety glasses renders them harmless.

The real danger presented by airsoft guns is what they teach people: that it is OK to aim guns at each other and shoot each other. The exact opposite of the ideas we are trying to instill with airguns and firearms.

He is also worried about the economic impact on his state if all non-firearm guns have to be painted bright identifying colors. As BB pointed out, this sidesteps the issue of personal responsibility. To make all air-powered guns appear equal is bound to result in some getting hurt or killed when shot by someone thinking an airgun is the same as an airsoft gun. Even as it is now, what’s to prevent a criminal with a roll of masking tape and a can of florescent orange spray paint from making his firearm appear as an airsoft “toy”?

Les

That lesbian story is pretty outrageous, especially for underage girls. It seems rooted in the movement from the 1960s and dramatized in the Billy Jack movies about how role-playing and other experiments with the lowering of boundaries will set you free. The result was that a black friend from that era met my Dad shaking with anger after some seminar where some woman told him honestly how she thought he was a big monkey. Another friend told me how in that same period, she was in a class where she was smacked in the face by a black person as payback for the sins of her white forebears, and no one did anything. I, myself, serving as a college reporter in the 1980s was reporting on a talk by lesbian nuns and found myself in a small group, like the rest of the audience, reading from a script, “As a lesbian, the first person who I would tell my secret would be ….” And then there was a college event, lavishly funded, whereby all of the audience’s questions about sex would be answered without restriction. The attendees certainly tested that claim and it was for real. The panelists answering were a man and a woman under the guidance of a Ph.D. in sexology–she was a thin, ascetic bespectacled woman, not really what I had envisioned, and she had a way of making everything very dull and academic-sounding. I told a British friend about this event and her eyes bugged out and she said in Britain, the whole thing would be impossible because everyone would die laughing. Maybe this kind of activity is uniquely American, although somehow I can’t imagine any teaching activity like for firearms–not sanctioned in the educational system anyway.

Matt61

Matt61, just when I think I’ve witnessed everything and that people can’t get any stupider, someone comes up with a story that just makes my jaw drop in amazement. Just how low a level in intelligence can the human race can sink to? Incredible.

Fred PRoNJ

Most of us played with cap guns when we we’re I know I sure did, and mine looked exactly like a small .38 and we would run around the house shooting at each other and we knew very well the difference between a cap gun and the real thing and if a cop ever showed up pointing a gun at us yelling at us to drop it that cap gun would reach the ground faster than you can say fake gun.

Kids need to be kids and play cowboy and indians (or cop and robber or …) and it’s part of groing up, you need that to see and know the difference between the games be it paintball, airsoft, cap guns or video games (I did all of them) and I learned (thru my parents education) where the difference was.

I don’t think there’s much that can be done exept educating the kids, if it’s not airsoft it’s gonna be paintball or cap guns or water guns or guns made out of wood (the father of one of my friend made rifles for us when we were young, I still have mine) or anything else kids can get their hands on. A criminal escaped of prison here in the 70’s using a gun made out of soap and shoe polish, if he had let the guards a chance they would have shot him down because he had gun shaped soap… (he certainly couldn’t just run away… he was so fat he hid the gun between the fat of his belly).

Kids will be kids and they need to do this and they need to be shown what is acceptable and what isn’t BY THEIR PARENTS!!

J-F

Matt61,

This is why parents have to be active educators of their children. I once thought that this was common knowledge, but it isn’t. Too many parents, especially in the now typical, two family income households, are too busy and/or too tired to actively participate in “parenting”. They leave the educating up to everyone else. I don’t think that those parents are even concerned about the influence of peer pressure anymore.

We raised our kids with only one TV in the house (the living room), and when we watched, it was “family time”. We also ate meals with the kids, and shared whatever we could, as far as “life lessons”.

As we moved more towards becoming a “service economy”, fewer jobs payed real livable wages, with benefits. Multi-income jobs became the norm, and the “family unit” has become a rare entity. I know of many households that now need their children’s income to survive. That doesn’t necessarily make such a family closer, because everyone is busy working.

I grew up knowing some very good role models. Men who were honest, sincere, devoted, self-respecting, moral, and with vision. – They had substance. Nowadays, I see men who only project an image, but don’t actually walk the walk. Substance is much more rare.

I can hardly stomach the TV shows that young people are so captured by, like reality shows. Young people are now surrounded by bad examples of what to be, and how to be. Parents have turned their kids over to TV. TV is a lousy baby sitter. I’ve seen several younger managers try to manipulate their teams as if the work place was a “reality show”. Rather than operate in a solid, professional, manner, they opt for manipulation. The respect just isn’t there.

It really is up to the parents!

Victor

Victor,you said a mouthful! I couldn’t agree more with your assessment.If only the act of creating a child was 1/10th as complex as raising that same child! God bless those who are doing a good job,the challenges never end.

The lesbian story reminds me of a line by Jim Garrison in the movie “JFK”. Referring to alleged federal involvement in the President Kennedy assassination: “We are through the looking glass here. What’s right is wrong and what’s wrong is right.”

If such a thing had happened when I was in school, the Superintendent would have been handed his head on a silver platter. Probably followed by the School Board.

As parents, we are just as entitled to our opinion of what is appropriate as is the school. This is the reason I sent all my children to private schools. It was expensive but worth it.

Les

Could somebody please give me a citation to this lesbian story so I can read what happened for myself?

Thanks,

pz

Pete,

This wasn’t some news story Edith and I read. We lived through this one. We lived in Ellicott City, next door to Columbia, Maryland, where it happened. Since the press in that part of the country is very left-leaning, I don’t know if they even covered it. It was on the local news, and of course there were some parents who were outraged, but the education system was in the hip pocket of the very people who wanted to do these things, so nothing was done about it, as far as I know.

B.B.

Pete,

Actually, it was a news story that I read in the “Howard County Times,” which was basically the same paper as the “Columbia Flier,” which was circulated in Columbia, Howard County, Maryland. The principal and teachers of the school segmented the girls from the boys and created this idiotic scheme that girls needed to be told that it’s okay if you don’t like boys but DO like girls. The article was written after the event, when girls came home from school crying and very upset. When the parents found out what happened, they went off! This happened at least 15 years ago. Many of the girls needed counseling. Apparently, forcing young girls to do things that they knew in their gut was not right was so traumatic that their minds couldn’t deal with it.

Think the above stupidity is a one-time occurrence? Not in Columbia, Maryland.

Some time after the above story hit the presses, another event was to take place. (Fasten your seatbelts, because the stupid meter is about to go round 2x & fly off!) Because parents were so incredibly upset that they were not alerted to this extra “teaching” given to their children, the school administration (I can’t say if it’s the same school or a different one, but it was still a school in Columbia, MD) was approached by wiccans who felt that children were inappropriately afraid of witches because they did not know that witches came in two flavors: good & evil. The “good” wiccans wanted an opportunity to tell the children about good witches and how they differ from the other type of wiccan practitioner. It was announced in the Howard County Times as an upcoming event…along with the announcements for bake sales, charity events and car washes to raise money for the band. The paper came out weekly. The following week, the paper announced that the wiccan school event had been canceled due to complaints from parents.

The Columbia Flier & Howard County Times were just 2 of the many newspapers published by Zeke Orlinsky’s Flier conglomerate based in Columbia, MD. He sold his company while we were still living in Maryland, and I’m not sure there’s anything available online regarding this. Here’s the current link to the Columbia Flier:

http://www.explorehoward.com/columbia-flier/

I seriously doubt the community announcements from 15 years ago are available online.

At that time, there was little going on internet-wise, so local & community papers were it. I scoured the Howard County Times every week because at that time I had a desktop publishing business and was constantly on the look out for new businesses who could use my writing and graphic design skills.

Obviously, you have take me at my word. I won’t feel bad if you don’t believe me. People have told me so many idiotic things that I refuse to believe much of what I hear. And, yet…in more cases than I’d like to admit, I find out that humans can make some profoundly stupid decisions and the wild stories are not only true but they’re not even localized, one-time events! Just as soon as I think people can’t get any dumber, someone does something that proves me wrong.

Edith

I take your word; that wasn’t my problem at all. I just wanted to get a sense of the background.

Wicca is a hard nut for me. I am not a believer, at all, any longer (although I accept the wisdom of Isaac Asimov’s comment that runs roughly “atheist or not, I’m still Jewish.”), but many others are believers, and the various religions should be treated with an even hand. The armed forces have been persuaded that Wiccans are enormously sincere in their beliefs, enough to warrant commissioning Wiccan chaplains. I don’t understand that, and probably would have decided otherwise. But given that some kind of official recognition has been given, then Wiccans should have a chance to compete in the marketplace and to defend their beliefs. I don’t have to like it, but the First Amendment says I shouldn’t try to forbid it. So long as they are only describing their beliefs, and not trying to persuade others to accept those beliefs.

pete

Pete,

Separation of church & state isn’t being treated equally. It’s being applied to Christian believers almost exclusively. I’ve read a number of news reports about schools in the U.S. & England telling children they had to remove their crosses because it offended those who don’t believe, yet they allowed other religions the right to wear garb, accessories and adornments that signify those non-Christian beliefs to others.

The pendulum has swung the other way from when I went to school, and I fully expect it to swing back the other way — and go back and forth until the end of time.

Edith

{hopefully no HTML typos this time}

You might want to reference: ftp://ftp.paganlibrary.com/chaplain.zip

Though the Word document seems to lack any dates/page headings… I suspect someone reentered or scanned the text but didn’t bother creating Word header styles to make a live ToC. (Must be a retype — “Aleister Cruelly”? Should be “Crowly”)

Don’t know how recently it has been updated (It still lists Kirby J. Hensley under Universal Life Church, but I think after his death there was a schism — his widow trying to hold to ULC in California, but a lot of the rest of the leadership wanting to make it a more respectable group [I have a ULC “Minister” card in my wallet, from back in the day when a $5 donation got one a certificate of Ordination… Also have certificates for Doctor of Metaphysics, Doctor or Immortality, and a Doctor of BS; maybe one more beyond that).

Down in the “Other” Groups section, one will find both “generic” Wicca, and Gardnerian Wicca… And what /I/ (currently a non-practicing solitary eclectic Wiccan) consider disturbing… Church of Satan, Church of Scientology, and the Temple of Set

Wulfraed,

When I was a personnel director for a hospital in Houston many, many years ago, I was interviewing people for the position of stationery engineer, which also required certification.

So, in walks a very soft-spoken man with hair that would make Don King jealous. I went over the job requirements and asked if he had his certification with him. He said he had something even better…a doctor’s degree. I looked at him quizzically and reached out with trepidation for the paper he was handing me. And it read: Doctor of Hot Stickology. End of interview.

Edith

I’ll presume you did not “stick” the paper somewhere impolite.

I doubt I’d even claim the D.BS even if I were to be looking for a position as an assistant in a class on comparative religions — even though Biblical Studies was the one ULC “course” that did require sending back a “final exam” (open book — though I wasn’t about to buy /their/ recommended bible; I had a newer bible on me). D.Im. and D.M. just required reading the pamphlets and laying out name/date information in a desktop publishing program, then running the blank certificate through it (which is why they have the nice formal “Wedding Text” font, while D. BS appears to be standard Selectric typeball)

This bill is stupid. Color won’t work in low light, unless you mandate that all air guns have a lightbulb inside to light up the plastic. Cops are trigger happy when they think somebody has a gun that might be pointed their way. If you’re going to make a color difference, firearms (and even high-powered air guns) should get the distinctive coloring, since that’s what can hurt the cops — base the requirements on deliverable energy to the target, not how that energy was gotten. We know there are plenty of lethal air guns out there.

Train the kids. Train the parents.

And for G-d’s sake, let’s recognize that the whole “sport” of Airsoft negates everything taught in every gun safety course on earth. First line from the instructor: Never point a gun at anything you are not prepared to kill. So the game is to point a lethal-looking weapon at your friends. It is too easy to slip if that line isn’t drilled into you from day zero. Line two: All guns are loaded until you prove they aren’t yourself. Cops have to believe that too.

Do what the cop says. Put down the gun. Then, if LE has acted improperly, or you think it has, get the guy’s badge number and name.

Train the kids. Say it again: Teach your kids gun respect and also how to conduct themselves in the face of LE. Everybody on this group agrees, but don’t preach to ourselves. Go talk to your school board. One week, hell two days, of gun safety and gun respect instruction in PE could save a lot of lives. Wouldn’t even have to pull a trigger on a gun; that’s not the point of the instruction.

Do you think this school ever allowed a similar class?

https://www.youtube.com/watch?v=AxWWJaTEdD0&feature=youtube_gdata_player

How can he be that dumb??? He’s as stupid as some of the comments.

There’s nothing like learning, but I don’t think it should be done in school, it should be done at home or in special class, not in school where they cram over 30 kids in a room, there is no way they’re all listening (well until that guy shoots himself in the foot 😉 ). You have to learn how to drive a car because it can quickly become a 2 ton bullet, same thing with guns, educating people is the only way.

J-F

J-F

We have drivers’ ed classes. Would you object to 5 hours of shooters’ ed? Clearly in a gym or on a range, a place, perhaps where a 10 meter range could be set up.

Of course I wouldn’t object!

I don’t know how drivers ed is in the US but in my province we study the theory alone and pass a written test before going ALONE with the teacher in an actual car.

If I remember school correctly when in class LOTS of things happened and many of them didn’t include learning… that’s my only objection. The larger the group the dumber the people get.

J-F

Personally, I’d be happy to just get the “Eddie Eagle” program into all elementary schools (with refreshers every few grades)…

And /that/ program is one that emphasizes: “See a gun laying around, don’t touch, find an adult to dispose of it”

Then we can work on getting “safe firearm handling” into high school.

Of course colored air guns would work. IF they made you put glow in the dark ingredients in the paint as well.

Then if an officer sees a “glowing gun” he will KNOW it is a toy and there fore he can holster his own gun.

Now before you all go off on me, the above was all “tongue in cheek”!! A poke at how insane this law really is! And of course it really isn’t funny, but some times you gotta laugh to keep from crying!

Why not put blinkers on them? Flashing guns…

J-F

Unless you resurrect the long discontinued radium/phosphor paint once used on watch dials, the “glow-in-the-dark” is going to fade fast… Presuming the material is even permitted to charge up (purported-kid: “What do think? I’m going to let it charge up so the ‘enemy’ can spot me from down the block? I’m going to keep it covered until I’m in good spot.”)

b.b. I’d like to submit a pic to Big Shot of the Week…call me a luddite, but no way in heck can I find a place on Pyramyds facebook page that allows me to do so.

I’ve can find the past winners not problem, but not how to submit.

Now realize…I am a true luddite…sometimes my ballpoint pen confuses me 😉

CBSD,

You upload a pic to the “wall”:

http://www.facebook.com/PyramydAirCom?sk=wall

Look near the top of the center part of the above page. You’ll see Share: Post Photo Link Video

Click Photo & follow the prompts.

Edith

I like this week’s pic. Very Western and cowboy-like. I’ve actually just finished reading a Western novel about how a villain disguises himself as a sheriff and makes the town give up their guns for the sake of peace. You can guess what happens next. The hero, a mysterious wandering character, has little sympathy for the townsfolk and tells them that anyone stupid enough to give up their guns doesn’t deserve to own them in the first place.

For the pogostick, I like the magazine repeater and the genius that can work in metal the way this guy did. Not sure about the looks. They remind me of the modern raceguns used for benchrest shooting. Vince, the trumpet calls for you.

Shaky, very interesting about your work detecting cracks in helicopters. I discovered a Zyglo crack detection kit that works in a similar way by painting various substances onto metal that will sink into hidden cracks and then expose them in various colors. I was all set to buy one and paint up my milsurp guns, but then I discovered that the price of a kit is about $600. Too much, even for me. It’s cheaper to buy a kevlar helmet. Calculated risk is my watchword. At what distance did you see the M1 carbine producing keyholes? Can’t get to excited about that gun. Pistol cartridges in a rifle design seems like too much of a throwback to earlier, more limited technology.

Duskwight, thanks for the info about Sepp Allerberger which I was absorbing without a lot of critical reflection I admit. On the other hand, I don’t know that some factual discrepancies prove the entire falsehood of the story. There was a similar controversy about the Guy Sajer’s The Forgotten Soldier. One of the most damning criticisms was that Sajer claimed that some insignia was worn on the left arm instead of the right as he stated. Good heavens!! In response, he said that during the war, he was so disoriented by what was happening that if someone had told him he was in China that he would have believed it. So, in the midst of this, the exact location of an insignia had escaped his notice. This seems plausible to me, and apparently new evidence has come to light, having to do with the location of certain bunkers in northern Germany, previously unknown, that seems to substantiate his story. Do you have an opinion about The Forgotten Soldier? So, I will look into Sepp Allerberger. However, I like the superiority of the Russian sniper rifles that I am seeing in the book. 🙂

As to airplane design, I agree with the general notion that physical laws determin engineering. The fact is that even for the human body with its amazing complexity and adaptability which has carried it through evolutionary history, there is definitely a convergence of martial arts where just about every system, when you get to a high enough level, is doing more or less the same thing with very similar techniques. However, I come out a little more strongly in favor of variety and possibility in design as suggested by counterexamples to what you and PeteZ suggested. The dolphin and fish are similar in their body design and method of propulsion but the up and down action of the tail for mammals is distinctly different from the side-side motion, and the tubular construction of mammals is distinct from the flattened bodies of certain fish.

As for WWII airplanes, not all of the exotic designs were the result of artistic fancy. The bent wings of the Corsair were made to shorten the landing gear but the resulting anhedral design with its right angle junction to the fuselage turned out to be more aerodynamically efficient than the flat wing. The P-38 in some ways was a look ahead to jets with its nosewheel landing gear and steering wheel control system. The P-47 with its enormous size to accommodate a turbocharger was actually a huge departure from the small acrobatic fighter designs of WWI so much so that the RAF laughed at it and thought it would be a disaster. The big, fast fighter jets of the Vietnam era like the F4 Phantom, the F111 and even the F-15 were completely different from the highly maneuverable F-16 which was resisted bitterly by the Air Force brass. The fact is that our very own rocket scientist was unable to list all of the forces and their influence on as simple a case as the ballistics of a pellet, so one would think that there is plenty of room for experimentation left in aerodynamics. The question of whether there is a single line of development or a series of paradigm shifts has not been answered for scientific progress as a whole, so I don’t know that it can be for specific fields of technology either.

Matt61

Matt61,

Yes, it IS very Western & cowboy-like…yet the winner lives in Bhopal, India, according to his facebook profile. His favorite hobby is hunting. Airgun friends in every corner of the world 🙂

Edith

Matt61,

sorry I didn’t mean to mislead you they were fan rotors mostly navy for ship ventilation , they all were dye checked. The process was Zyglo it was a requirement of the navy. The steel welded centrifugal mine and tunnel fan had all the welds Magnafluxed. I do not remember the range exactly for the carbines but I believe 200 yds. was the maximum. In all fairness they were pretty worn out by 1960, if not from firing from cleaning. They were never intended for long range . A year later we all got new M14s , M60s and M113 APCs.

Matt,

You wrote

****The P-38 in some ways was a look ahead to jets with its nosewheel landing gear and steering wheel control system. The P-47 with its enormous size to accommodate a turbocharger was actually a huge departure from the small acrobatic fighter designs of WWI so much so that the RAF laughed at it and thought it would be a disaster. The big, fast fighter jets of the Vietnam era like the F4 Phantom, the F111 and even the F-15 were completely different from the highly maneuverable F-16 which was resisted bitterly by the Air Force brass. ****

Form follows function. The F-16 and F-15 had very different roles. The original F-16 that John Boyd’s philosophy influenced was a light weight air-to-air day and good weather fighter designed for dogfighting. The F-15 and the Soviet equivalents were heavy all-weather attack aircraft with much less emphasis on dogfighting and much more on ground attack payloads. If you want an example of a wholly different plane, one where form and function match excellently, and one which looks like nothing at all else the USAF ever flew, look at the A-10 Warthog. Ugly as sin, particularly if you happened to be in an enemy tank and the Hog was the last thing you ever saw.

Aircraft of the USSR and USA designed for the same roles look incredibly alike because we understand aerodynamics awfully well.

Pellet forces: Usual four of lift drag thrust and weight to which you need to add in the magnus effect because it’s spinning. There will, of course, be turbulent flow over many designs in many speed regimes. A pellet is a pretty complicated shape, and I doubt that Crosman and RWS and H&N actually rent time on true super computers to make their designs. They could, and if they did the most skilled implementers of the modeling would dominate the market for precision pellets for everything from 10 meter to field target, and maybe even to hunting. But is the whole market for those willing to pay for the absolute best big enough to warrant the effort? I have my doubts. I’m with Scott Pilkington when he says that up to the world championship/Olympic levels it is not worth the effort to size and weigh pellets from the top manufacturers for AP competitions. The 10 ring, and even the X-ring, is just too big.

Sea creatures: Dolphins and fish don’t fill the same niches, so differences are to be expected, and their fundamental power plant technologies are different (lungs vs gills, for example). Besides, evolution does not guarantee optimal design. As witness the incredible fragility of our spines and the difficulty pandas have in conceiving and birthing. It just says that the winner was better at exploiting the niche than whichever organism was in second place.

I ought to get some sleep. The back is killing me, and I may have to put down a wonderful cat tomorrow. He is 19 and not doing well at all.

–pz

The kitty gets to live another day, but it’s his heart and it won’t be too awfully many weeks.

That’s a sad story, losing an old friend is always hard but he probably lived a long happy life with you.

J-F

He’s had a good life from when he would fit in one hand until today. We’re treating him very gently, letting him do what he wants, be comfortable. He likes having his head stroked, and his purr is still strong. He gets around, but very slowly and with a need to rest after exertion. Changes from day to day; this morning is a good one. We’re going on a long vacation in mid-June, and that will probably be when we put him to sleep. It’s our job; a pet sitter shouldn’t have to deal with it. So unless he looks as if he will certainly live 3 more weeks without serious pain, that’s our target.

Thanks guys.

Pete,

I know what it’s like to lose a pet you dearly love. I’ve had to euthanize many elderly and sickly cats over the past 40 years. It never gets easy…and I never stop tearing up when I reflect back on them. It hurts to the very core of my being.

Edith

Had a cat that needed to be euthanized. The vet wanted to take her into a treatment room and do it without me. I didn’t think that it was fair to make the cat die alone and scared. So I nixed the vet’s plan and held her. When I cradled her upside down, and scratched her tummy she would purr like crazy.So that is what I did when the vet gave her the shot. It was hard at the time, but I never felt bad about it afterwards.

Pete,

I’ve been thinking of your poor cat all day. Back in 1995 I put down my 18-year old cat. I can’t really express how bad it felt to do that. I’ve experienced a lot of bad days in my 62 years, but that one day stands out as the worst.

On the one hand I wanted to put her suffering to an end. Nothing wrong with that. On the other hand, I knew that doing this meant killing an old friend who trusted me with her life. Plenty wrong with that.

Her suffering came to a quick end. My pain is still with me. My heart goes out to the both of you.

Les

PZ,

Whether you believe it or not I do know how you feel. My wife and I are big time animals lovers, supporting many causes. At the moment we have 6 cats and 6 dogs. I have had the regrettable experience over time of burying and euthanasia of many pets. Everytime it has broken my heart, sorry but I can’t say it gets any easier. My wife and I pray for you and your mate (kitty).

rikib

B.B.,

This is why we need more shooting ranges, and/or clubs to use those ranges, to promote safe, responsible, and positive use of guns. There is very little out there to promote the sport of shooting in it’s various forms. I have yet to meet someone who didn’t get a thrill out of shooting a gun, especially they hadn’t before. Hitting our mark is a natural desire, whether it’s throwing a rock, bowling, or shooting a gun. Humans have been doing it since the stone-age.

Victor

Last night,while flipping channels,I came across the Chicago evening news.The story being covered was a bank hold up.I half listened to the brief story…..two armed men and a teen robbed bank.The three were later apprehended.What caught my attention was the last photo….a shot of a police car,and just in front of the tire on the pavement:a clearly thrown down Gamo PT80.Dumb enough to rob a bank….yet smart enough to drop the airgun.Go figure….

Neat contraption! I can’t speculate on the inventor but just know that he would be an interesting person to know.

This is off topic, but I thought some of you might be interested in this video from about 3 years ago. I was just working on max velocity/power with no real concern for air conservation.

Lloyd

[url=https://www.youtube.com/watch?v=mIpBdP9RQ5I#]https://www.youtube.com/watch?v=mIpBdP9RQ5I#[/url]

Twice in one day. Try this link. Lloyd

https://www.youtube.com/watch?v=mIpBdP9RQ5I

Lloyd,

Thanks for showing us these videos. They go with the test of the Rogue, of course. This was how you demonstrated the gun to me, after telling me about it.

I hope every reader has the opportunity to see these videos, because they show how carefully you tested your design before taking it to Crosman.

B.B.

Lloyd,

This is like another chapter in the Rogue story. I’m beginning to understand the enormous amount of work that went into this gun.

kevin

B.B. and Kevin,

Yes, this video shows just one small facet of the performance, and as I said in the video, more for demonstration than practical application. The valve timing was increased to almost a dump valve type dwell time to make that kind of power. Interestingly, you can use about half as much air and loose less than a quarter of the velocity. There is definitely a laundry list of requirements, most of which are in direct conflict with each other. I want big power with a big shot count. I want big power on low air pressure. I want low power with max tank pressure. I want a flat velocity curve across all pressures and powers. I want to be able to shoot any weight and style of pellet or bullet. I want long shot strings. I want it to be frugal with air.

Some of these conflicts are resolvable, some are partially so, and some are not. And that is just the performance criteria. Add manufacturability, durability, servicability, adaptability, cost, style, customer service, plus all the resources to support such a project, and it seems pretty daunting. But wow, what an experience!

Lloyd

Matt61,

Thanks for the tip on the Mike Melick tune up. I sent him my IZH-61 and got it back one week later to the day. He’s in Iowa and I’m in Illinois. Here is the result of my last 5 shot group, scoped at 10m using RWS R-10 Match 8.2gr. These two subgroups were touching. I hope this isn’t one of those lucky groups Herb mentions.

https://picasaweb.google.com/cjrley/IZH61Melick?authkey=Gv1sRgCIz-yInFyaWrDQ#5608975590851817522

I did lose between 33fps and 71fps after the tuneup, depending on which of my other three IZH-61s I compare to, but didn’t lose any accuracy as you can see. The rifle cocks smooth, no creep in the trigger and there is no spring noise, just a nice solid pop with recoil. It’ll be interesting to see what happens after another 500 shots.

-Chuck

BB,

The slide the cam on the lever works that moves the pin looks to have a stop on the rear and a hole in the front possibly for a cross pin, would the spring fit on there to return it forward after the lever pushed it rearward, It is hard to tell the size without a reference. Just wondered.

Shaky,

That is a possibility. The spring is quite a bit too large for the job, though, so I discounted it.

It’s a powerful spring, so it would work that way.

B.B.

It’s me again and off topic. I love my modified 2240, one thing I wish is that Crosman would come up with either a magazine or clip to make this an even a better pistol than it is. Anyone ever heard of this type of modification? Single shot is nice for targets or plinking, not so much for much for moving pest unless your very accurate and the pest don’t move.

On another issue, is anyone familiar with the Mossberg 500 Home Defense Series of shotguns? I’m interested in buying one, just wondering if anyone has any experience with them in any gauge.

rikib

Rick

Go here:

http://www.qbmags.com/

It isn’t made by Crosman, but I have heard it works pretty well.

Thanks I’ll have to look into that. Did a brief look, but I think I’ll download their manual before I make a decision. Thanks again!

rikib 🙂

rikib,

My brother had one of the Mossberg 500 series “home defense” shotguns. It is a very nice gun. Very reliable, short and easily maneuvered. I like it so much I am thinking about getting one myself.

You certainly can’t go wrong with it in my opinion!

pcp4me,

Thanks for the reply. As soon as I get the extra cash on hand I plan to pick one up, I’m retired military and there is a Marine Corps Base here that sells them also a Walmart. Do you have a preference for gauge?

rikib 🙂

B.B.,

In the last report on the HW50s, you mentioned a part four. Is that still in the works?

Hm

Hankmcrae,

I just read Part 2 of the HW 50S report from May 1 of 2007 and I don’t see where it mentions a part 4 or even a part 3, for that matter.

B.B.

/blog/2010/07/testing-the-hw-50s-part-3-2/

Kevin,

Thanks. I looked for that but didn’t find it.

I’ll have to review the file that Mac sent to see what Part 4 could have been.

B.B.

As I remember, you had other things on your mind back then.

Kevin,

Yes, I seem to have forgotten to finish quite a few of the reports in that timeframe. Fortunately this is one Mac did, and I kept all his notes, so I may be able to recover whatever it was I wanted to say next.

B.B.

B.B.,

In the accuracy report, Mac noted he needed to tighten the front sight, so maybe part 4 covers using that big ol piece of glass. He’s so good with peep sights I can’t imagine the groups getting any smaller. Thanks for taking the time to look into it. Have a good rest of your weekend.

Hm

Hankmcrae,

I have searched for the notes on the HW 50S and can’t find them. So I guess there won’t be a part 4.

Sorry,

B.B.

hello, I’m new to this website and everything but have been into air guns for a while now, is there any information you can provide about the harmonica repeater?

wprejs,

Get a Bakial IZH-61. It is a Harmonica air rifle in that its clip resembles a harmonica. You gotta see it to know what I’m talking about. Regardless, the IZH-61 is accurate and inexpensive and mine loves those RWS R-10 Match 8.2gr pellets.

-Chuck

wprejs,

Thus gun is a one-of-a-kind airgun. I have told you everything I know about it. It looks like the gun will go to our reader named Vince, who is very good at fixing things. He may be able to get it to work, and then we’ll know more.

B.B.

The 5 shot precision 10 meter match guns, such as the Steyr LP-50, are all (or mostly) harmonica repeaters. A small bar with and index and 5 holes for 5 pellets serves as the magazine. For single shot work you replace the 5-shot bar with a magazine having only room for one pellet. I’ve never handled one, but I wonder if a look at the mechanism wouldn’t be helpful in figuring out this rifle.

pz

Kevin…

R7 #2 showed up friday. The stock had a few minor dings in about the same location that you get them with a Diana side lever from cocking against your belt buckle. The outer box was beat to crap but the inner box looked OK. Possibly rough handling with the bag containing the scope rings just floating around in the box?

Anyway, just a bit of droop, with the breech closing much tighter (still a tiny sliver of light). VERY nice barrel! Tight like it should be, and smooth as glass. AA Falcons give the best firing cycle so far. I can load about anything because of how slick the bore is. Drooper mount installed and a 4-12 Bushy scope. No problem with getting zeroed.

Most of the time I can feel something rubbing during the last part of the cocking cycle. Not caused by tube distortion from the 6 bolt drooper mount. may be the cocking link rubbing.

Have to see if Air Venturi can get me a new barrel for R7 #1.

twotalon

twotalon

On my R7 the forward stock atachment screw was two long or a washer may have been missing causing the a friction between this screw and the link arm. also Maccari sells a teflon strip to install inside the cocking link to prevent scraping and galling on the receiver tube.

Loren

I might be able to make something out of nylon . Not much room to work with. Will shoot it a while then take it apart and see what is happening as long as no grinding sounds are heard.

Will look at that screw. I know it has a washer. Will look at the end and take measurements to check length.

twotalon

twotalon,

Congratulations on the R7. Hopefully this one won’t have as many issues as the other one did.

Does the “rubbing” you’re referring to in the last part of the cocking cycle feel/sound like you’re riding over a washboard?

kevin

Towards the last of the cocking cycle. Almost bump-bump-bump-bump. Maybe the spring coils bumping up over the guide. Something like that.

No grinding.

twotalon

twotalon,

Sounds like the cocking shoe is riding too close to the spring. It will wear itself down but if you don’t want to wait for that to happen taking a little metal off the shoe with a file usually remedies this.

kevin

I have trouble believing that is it. The bumps are long and smooth. As if the piston is being forced past some tight spots. I would have to tear it apart to find out for sure. Perhaps indents where the stop pin holes are are?

Will just let it wear for a while.

twotalon

I am more inclind to say (now after a bunch of plinking this morning) that it maybe feels like the piston is getting tight near the end of the cocking cycle. Also, no forend screw contact with linkage.

twotalon

Might it be the piston riding over the sear mechanism?

nope. not it.

twotalon

Super, oh and chuck i own a izh-61 and its splendid, but I’m no longer interested in buying guns unless they’re old or need repairs since its a challenge that lets me get a rest from my school work.

BB.

Amazing job done by this unsung hero but did the design ever actualy work?

What I mean is.

The guy you bought it off was going to try getting it working again.

Does that mean it didn’t work when he bought it 30 years ago or it did work when he bought it but it broke?

Either way a unique air gun well worth owning and if you can get it operating properly..WOW!

On the topic of air soft guns.

When politicians pass legislation like this,do they not think,

‘Isn’t it sad we live in a society where the cops have to assume kids carry guns with the intention of harming others.’

Their solution is to paint air guns pink,so the cops don’t shoot the wrong kid.

How about re creating a civilised society based on high moral standards and discipline,where you could stick a REAL gun in the hands of a kid and the last thing on his mind would be to shoot someone.

That is not some crazy dream but used to be reality once.You older fella’s will certainly remember.

Where did it all go wrong?

We all know where it went wrong but the politicians continue to plumb the depths of legislative madness to prove their ‘Progressive’ ideas right.

DaveUK

Dave,

I don’t know if this gun ever worked. But Vince has kindly accepted the challenge, so I’ll be sending it to him to find out.

B.B.

Dave