by B.B.Pelletier

This report is going to start a controversy, because it dares to question the things that are currently held dear among airgunners and firearms shooters, alike. Sorry, but here it goes.

What is a crown?

The crown is the end of the barrel, or the place at the muzzle that has the final influence upon the bullet as it transitions to ballistic flight. One popular belief is that if the crown is not perfectly symmetrical, then one side of the pellet or bullet can exit before the other and allow escaping gas to impart a destabilizing effect on the bullet at the beginning of its path to the target. So, crowns have to be perfect, according to the vast majority of shooters.

The other side

But there have been experiments done that show that escaping gasses have zero effect on a bullet in flight. The most well-documented of these were done by Dr. F.W. Mann, who wrote about them in his book The Bullet’s Flight, From Powder to Target. Dr. Mann did numerous experiments until finally he demonstrated that a plank six inches long placed within 1/16 inch of the muzzle blast has absolutely no effect on the accuracy of a bullet.

You see, in Dr. Mann’s day riflemen believed that the muzzle blast had a deleterious effect on the flight of the bullet, and they warned shooters to keep the muzzle clear of any and all obstructions.

The issue

But is what Dr. Mann tested the same as an inaccurate crown? Maybe not. The question seems to be what, exactly, does the crown do?

The end of the rifling and the face of the muzzle bore must be as square as possible to the bore for the crown to be perfect. The reason for this is as I stated earlier — that the base of the bullet/pellet leaves the muzzle at exactly the same point around its circumference, rather than one part coming out before the rest. But there are all kinds of crowns, including some that don’t look like a crown at all.

Let’s look at some crowns now.

The crown of this Ballard target rifle is flat and polished like a mirror. The old-time shooters felt it was easier to see the distribution of the bullet lube — as it made a pattern on the face of the muzzle. There’s almost no break between the bore and the muzzle on this rifle — which is one of the more accurate ones I own. In the 135 years since this rifle was made, there has been no damage to this crown.

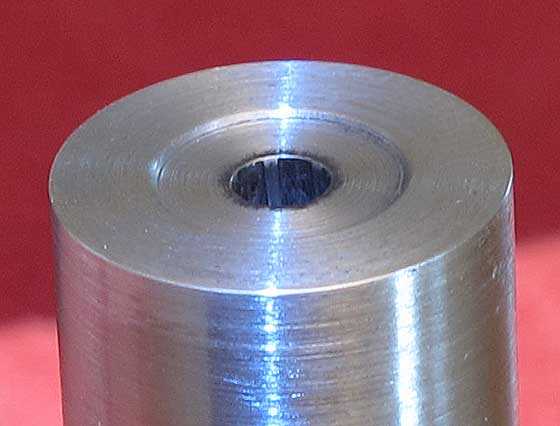

This Butler Creek bull barrel for a Ruger 10/22 has a recessed crown that’s similar to the Ballard crown except for the recess. However, on this one, it’s possible to see a tiny break (chamfer) at the muzzle. With the right ammunition, this rifle can hold 10 shots close to one-half inch at 50 yards. The recess supposedly protects the actual crown from inadvertent damage.

No doubt that this crown on an FWB 300 target rifle will look more familiar to most shooters. It’s the traditional rounded or radiused crown with a protected chamfer at the true muzzle. It’s on my most accurate ten-meter target rifle. Doesn’t look so pretty up close, does it?

The crown on this HW55 SF air rifle is similar to the one on the FWB 300, but up close it looks pretty disgusting. The rifle is one of the more accurate 10-meter target rifles I own. So, looks can be deceiving, and a “perfect” crown may not be all that it’s cracked up to be.

Not looking like your typical crown, this Swedish Mauser M1938 crown is a lot like the “redneck” crown job that hobbyists do on their guns. This is on a very accurate rifle. The lighting makes the bore seem to have a shoulder around the inside of the muzzle, but it doesn’t.

The redneck crown

Since the 1960s, there has been a hobbyist approach to crowning a barrel. It consists of a round-headed brass screw and a grinding compound — like automotive valve grinding compound. Chuck the screw in a hand drill and coat the domed screw head with grinding compound. Then, run the drill motor slowly while allowing the axis of the drill to oscillate to avoid making an oval cut. The result will look something like the crown on the Swedish Mauser M1938 shown above.

The crown on a custom barrel for a .17 HM2 rifle. Though brand-new and not even broken in yet, this rifle has already shot a five-shot 50-yard group that measured 3/8 inches across the centers of the widest shots. Note the powder burn pattern around the muzzle. This is the same thing that old-timers analyzed on the mirror surface of the Ballard muzzle when it was bullet lubricant that spread out instead of carbon fouling. This is another deadly accurate rifle that has no noticeable “crown” to the muzzle. The transition is very close to 90 degrees.

The crown on an AirForce Condor is very similar to the recessed target crowns shown before, except that this one has a definite chamfer or break at the muzzle. This rifle shoots half-inch five-shot groups and three-quarter inch 10-shot groups at 50 yards. And, yes, I did notice that it is time to clean this barrel!

So, what’s the verdict?

I’m not sure. That’s where I am on the whole crown issue. The reasoning makes some sense, and I can see why a PCP or a CO2 gun would then need a good crown, but a springer barely has any compressed air exiting the muzzle, so where’s the advantage there?

Don’t say anything about crowns removing burrs at the muzzle, because Dr. Mann did an extensive test in which he screwed blunt-tipped screws into the side of his Pope barrel at the muzzle to see if burrs at the muzzle that deformed bullets affected accuracy. They did not. He set his blunt-tipped screws to plough to the bottom of the grease groove of the exiting bullet, and no change was noticed in its accuracy at 100 yards.

Are crowns placebos?

I’m still undecided on the importance of crowning a barrel. I’ve read what everyone says, which is that the crown is of paramount importance to the accuracy of the barrel, yet I’m not convinced that it is. I’m also not convinced that it isn’t. I just don’t know.

I think there’s something more that has not yet been discussed about crowns and their importance to accuracy, but I’ll be darned if I know what it is. Do shooters shoot better after receiving (or doing) a crown job on a particular barrel? If you read what they write, they seem to. And most shooters believe that the barrel’s crown is of great importance to the performance of the barrel.

I wish I knew for sure, but I don’t.

I think this is a great bucket o’ worms to kick over.I can see where neatness and symmetry might give confidence,but the physics may not agree with the hype.My gut instinct is that if the projectile has enough inertia going foreward and spinning on it’s axis that the gas venting a little out of time on one side or another should make no real difference in the flight.

That being said,I have used a ball bearing epoxied into a dremel bit with a concave end to polish crowns.I score the face of the ball bearing radially with a medium diamond lap and then use JB bore polishto “charge” the surface.I use a cordless drill for lower rpm’s than the dremel.It also allows me to reverse direction to make sure no burr is left.I have never seen proof of any increase in accuracy but it looked great.Call me a high tech redneck…

Interesting blog BB. I’ll share one of my experiences with a bad crown. A few years ago I purchased a Crosman 1377. I basically bought it home and put it in the gun cabinet. I didn’t get around to shooting it for about a year. When I did, it just wouldn’t group well, the best it did was about 5 pellets into 2 inches from 20 feet using a braced shooting position. I know the gun should shoot a lot better than this so I started looking everything over to try to find the problem. The only thing I found wrong was that while the muzzle was cut square the chamfer of the crown was seriously uneven and by uneven I mean it looks like the chamfer tool was held at about a 60 degree angle to the muzzle instead of 90 degrees. Since this was going to be a project gun anyhow I added a 2300 barrel to the order when I called Crosman to order a steel breech kit for it. At this point I had nothing to lose so I decided to try to fix the crown. I have a barrel crowning tool I have used on past firearms projects that cuts an 11 degree target crown on a barrel but it isn’t small enough to work with a .177 caliber bore because the hole for the pilot is too large. So I grabbed my 60 degree countersink, chucked it into a drill and ran it into the crown until the chamfer was even. I then took my crown lapping tool with some 600 grit abrasive compound and polished the chamfer. Obviously a countersink isn’t intended to do any kind of precision work and as a result the new crown didn’t look pretty but it was at least even. After putting the gun back together I tried shooting some quick groups. The gun now put 5 pellets in under half an inch, a major improvement and about what this gun should shoot from the factory. This experience proved two things to me. First, a bad crown can indeed effect accuracy and second, as long as a crown is relatively even and square it doesn’t have be perfect to shoot well.

cmz128,

Well, that’s one vote “For.” I will be interested to see what kind of response this report gets.

Thanks,

B.B.

Count me as another vote “for”, BB. I re-crowned the barrel on my TF99 .22 as part of the rebuild and saw a noticeable improvement. Maybe it was just the “magic feather”, but I don’t think so. The crown was noticeably lopsided before the work. Even on a springer, air passes by the pellet skirt as it exits the barrel. The skirt, being lighter than the base of a bullet, is more easily affected by whether the crown is even or lopsided. The pellet won’t actually tumble, but I think it aggravates any imbalance it already has.

/Dave

I know this is old but feel like adding a comment anyway.

When I shortened my first barrel and crowned it with great success I was feeling like I really accomplished something great, now the wind was taken out of my sails. LOL

I will still make things as pretty as I can though function is always more important.

You know those cowboy movies where the hero is shot up and is using his rifle as a crutch, on rocky ground? Mess up the crown like that and you could compromise accuracy….

Nice fix on the 1377, a pistol that does not impress me at all. A 2300S would be nice to have someday though.

Probably what matters is how symmetric is the crown in the end of the rifling zone so that the bullet/pellet exits the barrel without tumbling, not how the crown looks like.

The how it looks is only important to prevent any damage in the rifled zone.

Long story short, I had my gamo main spring broken, so I replace it to a new one and I also lube the main spring with a grease based on MoS2 (molybdenum disulphide, AKA moly grease). I noticed that the inside of the compression chamber was dry or gamo used some dry lubricant.

I mounted everything without removing the piston of the chamber and also removed the bear trap (it only prevent the trigger to not be pulled, it doesn’t grab the piston in place) and removed the spring on the trigger peace so that the trigger pull is now night and day, so much light.

The gun was more powerful than It ever was and it cock much easier, I was very happy with it, specially with the light trigger pull.

But after a while it started dieseling (which never did or I didn’t notice it) it also started to group bad.

Shooting on paper I could see the mark of the skirts of the pellet and almost all marks showed the skirt mark on one side of the hole instead of even around the hole. The pellets were tumbling.

The pellets that showed the skirt mark on the same degree also grouped in the same place.

For me the only reason for this had to be the dieseling that created excess gases, but still, a gun with excess gases shouldn’t make the pellets tumble unless the pellets were near the sound barrier. But that was not the case since the heavy pellets (10 grains) tumbled the same way as the light ones (7 grains) and the light ones didn’t pass the sound barrier. The gun was more powerful, but not that much.

I removed the silencer (muzzle) cover on my Whisper and removed the blue plastic responsible for the “sound attenuation” and looked at the crown, I barely saw any crown but instead I saw a ring after the crown that was meant to hold the silencer. But this ring had a too small diameter, it had almost the same diameter has the diameter of the inside of the barrel (without the rifling), just slightly larger (if the barrel was suppose to be 4.5mm, the ring was near 4.8-5mm, I’m not sure).

If the pellet touched this ring it for sure would tumble, and now with the excess gases it probably was.

(for curiosity, the gun does make a BIG sound without the blue plastic inside the muzzle and without the muzzle cover, probably because of the conical shape of the muzzle).

I didn’t have much tools, only a portable screwdriver that works with batteries and a simple long iron pipe (5-6mm) and what I did wasn’t pretty, I used that iron pipe to drill the ring and make it larger, I also ended up drilling a bit of the crown. There was no other way, the ring was attached to the crown…

Now I don’t notice any tumbling and is grouping better but I don’t know how much better it is since I didn’t had the time for proper testing.

Although I used moly grease, I didn’t thing I bought one with high tolerance for high temperatures, the one I brought was only up to 140ºC, probably too little for a spring air rifle, next time I will be more careful and buy one with up to 400ºC or more, I will not care if is moly grease or not, only a grease with high tolerance for temperature.

Regards!

ZeChico,

Yes, I have also had accuracy problems with things that touched the pellet after it left the muzzle. Pretty doesn’t matter here. You just have to clear the obstacle out of the way.

B.B.

Easy to test out.

Take a Crosman barrel put it on a 2240 (or something similar), test accuracy, take the brass screw in the drill with the abrasive compound and put it on sideways so the crown is messed up badly, re-try accuracy then re-do the crown and re-re-test accuracy. Easy.

Anyone willing to try it out?

I have the 2240 and the time to test it out, I’m only missing a barrel, anyone has a spare one?

J-F

Nawwwww…..

Cut it of at any old angle with a hacksaw and leave all the burrs in the muzzle. Think it will shoot as good?

twotalon

JF : Col. Townsend Whelen in his book ” Mister Rifleman” ( published by Desert News Press , 1965 Library of Congress # 65-16552)

did just that to a Winchester High Wall that he was going to re barrel anyway, nearly a hundered years ago. He took a rat tail file and filed the end of the barrel lopsided. Then he tested the accuracy with ten shot groups and found that only that the gun now shot to a different point of aim, and the sights needed to be moved to correct for that.

J-F,

I knew it would not be long before someone came up with an experiment for this.

Good luck and I hope you take good pictures as you go.

B.B.

And here I thought you were planning the Next Great Experiment (after the CB vs PCP test)…

Though I was thinking of starting with a spare Talon barrel in your super silent custon (remove all the sound reduction stuff to ensure no effects from trapped air)… Find best pellet for barrel… Shoot for Record. Then file/mill the crown to match your Ballard style crown, repeat shoot… Mill/file at a 45 degree angle (or even steeper, say 60?), shoot for group… Hacksaw at same angle (shortening barrel by 0.5 to 1.0 inch) — NO CLEANUP/polish/file; shoot this rough edged angled barrel for groups; finally, hacksaw perpendicular to bore but leave rough and shoot that for groups. Oh, and maybe a last extreme — cut a 1/4″ off on just half the muzzle and shoot that.

Wulfraed,

That’s a lot of work, but you know — it might just be worth it. Because I could then wear out the end of the rifling and see what effect that has.

Lotta work, but a big payoff. I’ll see what I can do about securing a barrel to test.

Let’s do it!

B.B.

<:Eeek> Open mouth, jump in with both feet…

If I had the tools and the skills (my “sight in” of the Condor was still in multiple inches at 50 yards), I’d probably have some time in a month — between packing things up to move — to have done such a test myself (granted, I’d have to order a barrel).

The slant cuts should be the really revealing ones as, until the pellet is beyond the point where the slant intercepts the mid-line of the bore, the pellet is still supported by rifling yet has this big air gap on one side. Prediction: distinctive corkscrew spiraling…

Man, I love this place, and to think all of this info is FREE. Where else are you going to find great info and respectfull argumentation like that. I can’t wait.

Edith : I’m not getting the wordpress emails saying that someone has answered a post made by me. I don’t really mind as I’m getting every thing that’s getting posted (and read each and everyone one of them). I checked and I’m logged in since my avatar is showing.

J-F

J-F,

Don’t know why you’re not getting the comments. Your email address was still listed. Since stuff happens that has no explanation, I deleted your email address and then added it, again. It’s possible the responses are being quarantined (I see you use gmail). Have you checked that possibility?

Let me know if it works, again.

Edith

Edith you we’re right (as usual), for some obscure reason these emails sent to by wordpress like all the others got sent to the spam folder?!? Why can’t computers be smarter?

Thanks again, I should have checked it myself.

J-F

Also I never tought it was the gases exiting more on one side than the other, to me it was just the pellet not leaving the barrel everywhere at the same time kind of like a daredevil jumping a car if the ramp wasn’t squared, if the left wheels left the ramp before the right ones wouldn’t the car go sideways in the air?

J-F

BB: I think that the term “crown” is mis-leading. To reference a well known mid 20th century gunsmith , Roy Dunlap (who gunsmithed Garands into match guns before some of the oft referenced folks mentioned here by certain members of this blog were even born), said that” there has been more stupid nonsense about crowns written than anything else”. A crown is just a raised area that protects the rifling at the end of the barrel from getting bashed.If the rifling is true at the end of the barrel ,the accuracy will be as good as the quality of the gun and the ability of the shooter to extract that accuracy out of that gun. If the rifling at the end of the barrel is damaged the gun will shoot to different point of aim. That would be bad, and by recessing the “crown” that area of the rifling is protected. The crown is not the issue ,the rifling being true at the end of the barrel is for maximum accuracy.

Robert,

I didn’t know about what Roy Dunlap had said, so thanks for that. Townsend Whelen’s “experiment” I had read years ago. But what Mann did so far surpassed anything else that I sort of keep his writing in my sights on this issue.

B.B.

Robert from Arcade,

Your point is well made. It seems that the term “crown” has become generic for any potential accuracy problem at the business end of a barrel.

I think the reason that crowns get discussed so much is because this is the most visible piece of the barrel accuracy puzzle to shooters. There are so many other factors of equal or of greater importance, i.e., a straight hole of uniform diameter and correct size for the intended caliber; a smooth and uniform surface finish that lays parallel to the rifling; a uniform rifling pitch; stress-free steel; adequate stiffness for the type of shooting it will be used for; and a first-rate installation job with special attention paid to the throat. An accurate barrel is the result of a happy marriage of all of these.

I’m not familiar with Dr. Mann’s test using screws in the barrel to replicate burrs. This seems to fly in the face of barrels that have been improved by re-crowning. In my experience re-crowning/re-cutting the barrel end to be true is the equivalent of a hail mary pass. A last ditch effort that sometimes works but most times does not.

All I know is that it takes many factors to have an accurate barrel and when you find one of these rare birds you should keep it.

kevin

Kevin,

While I have sold a number of accurate rifles over time, I have always sold the ones that don’t shoot instantly. Sure I will check stock screws, scope mounts and the like, but after that it goes to a new home so a “tinkerer” can play with it. Or perhaps someone happy with mediocrity.

As you suggest, crown, choke, etc – too many variables and too many rifles that will shoot to waste my time.

Robert from A,

perhaps doing the “redneck” re-crown as I did on my Nitro XL (and blogged it here some time ago) actually removes a thousandth of an inch and/or burring at the very end of the rifling, thus providing that improvement in accuracy? I don’t know but many people, including myself, have gotten major improvement in accuracy by doing just that. Certainly the perfect place for sloppy work and damage to occur is when one starts the rifling process or the tool is finishing the rifling process. I know I have to be very careful when cutting a thread by hand when starting or finishing the process to avoid screwing up (no pun intended) the thread.

Fred PRoNJ

Fred ; You might be interested to read just how Mr Dunlap crowned and polished the end of the barrels he installed.( My copy of his book is titled “Gunsmithing” by Roy Dunlap, ISBN #8117-0770-9, Library of Congress # 63-21755, second edition copy right 1963. Stackpole Books). He states that he used a lathe for most jobs (which he said takes like 60 seconds to do) and for those he couldn’t , he used a hacksaw, file, and a breast drill with a round grinding stone. He also mentions that the lathe is the best method as it naturally trues the end of the barrel making it square with the axis of the bore. He mentions that this is dependent on the ” bore being concentric with the outside , which it should be!”( This is an issue ,especially with these china made air guns we mess with). He then polished the end with abrasive cloth and his finger. He mentions that” you do not want to make a gradual curve into the lands- they should have a definite angle”. The muzzle crowning ball to finish the job (if you made one) should be twice the diameter of the bore,and preferably be made of brass, or bronze, and used with progressively finer grits of polishing compound. Sound a lot like the” redneck methods” most of us employ.

Thank you for the recommendation, Robt from A. As I’ve finished reading Axtels’ book on Zhukov, The Man that Beat Hitler, recommended by Duskwright, I’ll put this on the list for next book. By the way, that Zhukov book pretty much was about Zhukov’s party and army life and did not go into his strategies for combating the German Army. However, Axtel did talk about “the madness” where a number of experienced Russian Generals were “removed” from active service from 1937 to ’39 and that Zhukov was saddened to see a number of them disappear. Axtel does mention that the Germans believed the Russian military was seriously weakened by this purge by Stalin and Beria.

Back to crowning. BB didn’t show the Crown on an FWB 124 but it looks very much like the FWB 300 – very small chamfer and then that convex angle. Does the chamfer qualify to what Dunlap refers to as “a definite angle”?

Fred PRoNJ

Fred: Yes, according to Dunlap, the correct crown should form a distinct corner at the junction with the bore. In his book , there are drawings that show different crowns and also an example of a incorrect job. Pages 222-223.

Like yourself and a few other commentators I am still quite ambiguous about the effect of crowns on accuracy. Lord knows I’ve re-crowned enough barrels for both myself and others that a definitive pattern should have emerged by now. But it hasn’t. At times I have seen a vast improvement. In the majority of cases however the results were inconclusive.

The most glaringly obvious case of a bad crown was on a quite inaccurate .22 cal. Milbro/Daisy that I’ve had for decades. The factory ‘crown’ was a countersink that was offset from the bore by a full eighth of an inch. I finally used a Brownells 11degree crowning tool to correct it. With absolutely no effect. It still won’t hit the barn—-from the inside of the barn.

Anyone who has ever spent much time inspecting pellets under magnification will know that skirts are far more likely to be uneven than crowns. I now suspect that a pellet change could well cause more improvement than re-crowning.

Like yourself I simply don’t know at this juncture. Frustrating! Tom @ Buzzard Bluff

The you -tube video of the magnum springer being fired, posted the other day was telling. Showed that there are a lot more issues with barrels and what contributes to accuracy, than how good the condition of the end of the barrel is is in.

B.B.,

Unless you are setting us up to reveal some new insight, maybe you should add a question mark to the title of the this blog.

On a philosophical note, isn’t it interesting how some things we were sure affect accuracy don’t seem to and some of things we thought unimportant seem to matter a lot? I have a Ruger .270 that has a loose spot in the bore. If you push a really tight patch from the breech, about six or eight inches from the muzzle you get a sudden “jump” for a couple of inches. I have had the rifle since new, and I sure don’t think it was anything I did. There is certainly no bulge on the outside of the barrel at that spot. I think this rifle was made when Ruger was supposedly getting barrels from Douglas. Yet I have come to expect and often get sub-inch five shot groups at 100 yards with a good hand load or the right factory load. If it ain’t broke, don’t fix it.

Gun Doc

Don,

I have had a number of firearm barrels and airgun barrels with loose spots. In contrast there is my Ballard barrel that is just as even as a glass rod. I believe in results, like you, but it’s also nice to know that everything is the way it is supposed to be, isn’t it?

B.B.

So a definite maybe :)! I think it does matter, but that the effect is at least an order of magnitude less significant than most “gun writers” want us to believe. Where I think it might or actually does matter is not at the level of MOA, which is a pretty easy mark to hit these days, but at the level c/f BR shooters strive for, which can be more like 0.1 MOA. That assumes that all other things are correct for the projectile, i.e. spin rate and velocity for length/weight/caliber. If the load is off, I can imagine that any imperfection in the crown might be multiplied in its effects somewhat. That is one thing I think that is happening often with pellet rifles when a crown job does so much good, since I think that the spin rate for pellets is almost always incorrect and also in opposition to their drag-induced stabilization, and a bad crown just adds insult to injury.

BAG Farmer,

I thought that this was going to be a piece on British Royalty, was all set to have tea instead of black coffee while I read it. Figured we were getting an update on the royal honeymoon. Oh well.

As far as the spring compressor we spoke of before, you can go ahead and shelf that project for good. Since I am only using mid powered springer’s these days I have found it is no issue doing it by hand. I am not exactly 5 x 5 -the guy on the new show “Car fellas”, but I am thick enough that I can manage it with no issues.

I have not got around to really ringing out Discovery number two yet, but i can say that at $150 – it’s a refurb from Crosman, it is at a price point that makes sense. I was also glad to see that it is not marked as a “refurb” on the rifle at all.

BG farmer,

Sorry about the “BAG” . I tend to answer yes to the spell check without looking.

Hey BB …

What a refreshing review. It sure does my old heart good to read something from an honest man who isn’t afraid to say that he really doesn’t know for sure. You need to be respected for that and I will be sure to do that. We live in a world of computers, electronics, instant communication, mass distribution and “experts” who don’t have a clue, or in most cases, an identity, but will still claim authority for anything.

On the subject of “perfect crowning”, my position is simply … maybe you’re right.

John

I kinda think I’m with B.B. on this one.

I only have experience with 3 rifles:

Avanti 853c, whose crown looks much like the Ballard in the first image.

Slavia 631…looks like the HW55.

B3-3…looks like the HW55 but no where near as pretty or well finished.

All are easily more accurate than I am. Even the lowly B3, with open sights will group 10 shot 2″ groups at 30yds offhand.

I think there are far more important issues at play in accuracy than the crown (unless it has been seriously damaged).

BB:

For crimes against a barrel crown I plead guilty.

Back in 1985 I had a plastic stocked assault rifle style airgun,made by ‘Air force’ I think it was.

The new SA80 bullpup had just been adopted by our military and I really liked the stubby look.

I set to work on my rifle with a hacksaw and file,chopping off all but two inches of the barrel and filed down the rest to slip my suppressor over the top to hide my handywork.

The cut was off by several degree’s and I deburred the crown with a round file.

How did it shoot?

Over the distance I was used to at the time(30ft) at my target of choice then(bean cans) it shot about the same really.

It makes my toes curl now to think what I done back then though.

Dave.

I just had Rich in Mich whack the end of an HW50 barrel off by about 4 inches and I also have a stock version. It will be interesting to see how the two compare at 40 yards.

DaveUK,

And that is a solid vote “Against.” I don’t suppose we are going to resolve this question.

B.B.

B.B.,

Is that a picture of the barrel on your new, custom built Mossberg 42 in .17HM2?

Would you mind sharing your technique for breaking in a new barrel? Seems this barrel is being broken in right since it “has already shot a five-shot 50-yard group that measured 3/8 inches across the centers of the widest shots”.

kevin

Kevin,

Yes, that is the new Mossberg. I goofed, though. It’s a 44, not a 42.

The barrel is nondescript. It was bought off Ebay, as a group of three. All have been tackdrivers.

There has been no special break-in for this barrel. The group I shot was in the first 15 rounds. But my process is to shoot and clean the barrel at the range. Shoot 20-30 rounds, then clean the bore. Shoot and clean.

I think the .17 HM2 must take all the credit for the good groups. It is the tack-drivingest cartridge it has even been my pleasure to shoot.

B.B.

B.B.,

Frankly I’ve been on the fence about the .17HM2. I think you just might have pushed me over. Who does the mossberg 44 build?

kevin

Kevin,

Let’s go off site for this.

B.B.

Wouldn’t the effect of “bad”/”good” crown be more or less influential from gun to gun? I’m no expert by any means, but the amount of escaping gas at the muzzle that would potentially effect a pellet varies considerably from say a co2 powered 2240 pistol with a 7″ bbl compared to, say a non magnum spring piston rifle with a 24″ bbl. It seems to me that the 2240 with a sloppy crown and all that gas flying out muzzle would wreak havoc on a pellet, Yet on the longer bbl the expanded gasses have done all it would do in the bbl before reaching the muzzle, even if we were comparing two identical co2 powered guns with the only difference being the length of bbl one would definitely be more effected than the other, no?

I also have a 243 Savage that is pretty much factory (barreled action untouched) that seemingly shoots 1 1/4 moa regardless of the conditions, dirty, clean, cold rain, whatever, and the crown on it looks like it was chewed in rather than machined!

I gotta go down as a definite “it depends” Great article, BTW. Thought this would’ve been a subject for a week end, yet you surprise yet again with a near midweek morsel!!

ka

I’m still wondering when the first tuition payment comes due for this class. Thanks, BB. Totally unexpected education this past couple weeks.

BB,

I am one of the ones who don’t think the crown has a bit to do with the accuracy unless it is really messed up!

Cut at a 60 degree angle instead of square would qualify for “really messed up”!

I have never had a gun with accuracy problems which could be attributed to the crown. Most with poor accuracy are the result of very poor manufacturing tolerances. In other words poor quality.

So I am a skeptic about crowns as a culprit other than the ones that would fit into the poor quality catagory.

I’m looking to buy some tools to make a good crown?

I see there’s some crowning tools at Brownells…but I dont know which ones will work good.

I’d like to be able to have the tools for crowning .177 .22 and .25 barrels.

I’d rather not use the brass screw method…I would much rather get the tools.

In some cases I can use my hobby lathe, but I sure would like to have the proper tooling to make crowns when I need to.

For you guys that like to pump

http://www.gunbroker.com/Auction/ViewItem.aspx?Item=251248524

kevin

Does not the condition of the pellet skirt play an important role? If not square to the center of the pellet will not there be a gap in one area leaving a square crown?

Walt,

Good point but lets not forget obturation. When the blast of air hits the skirt it typically is re-sized to fill the bore. Velocity and material of the projectile play a role of course. A crosman premier with antimony added vs. a pure lead pellet with a thin skirt like the air arms falcon pellets are two ends of the spectrum in my view (Brinnell hardness scale).

kevin

B.B., well this certainly does tackle one of the sacred cows. The theory behind the importance of a crown makes sense to me, and while I didn’t understand everything about Frank Mann’s experiments, I don’t see that anything disproves the importance of the crown. If his plank in front of the muzzle was perfectly squared up, I don’t see how that gives any information about the crown regardless of how close it was. And the ugliness of different muzzle designs doesn’t matter if they are symmetrical which they seemed to be. So, my sense is that even if we don’t fully understand what is going on that a good crown can only help and not hurt accuracy.

Gun Doc, I would say that my ideal set-up for a professional hunter would be a double rifle and then a high-powered lever gun which, I think, are known to be generally faster than a bolt gun. But most of all, I would have plenty of wingmen preferably armed with M1 Garands. Not very sporting, but it would be safe. As to why the bolt guns have superseded the lever guns, I suspect that it may be partly fashion but more because bolt guns allow hunters to take game more reliably at a greater distance because of their accuracy which is the most desirable scenario. That way, you don’t need to worry about a fast follow-up shot at a close distance. Yes, your clip of the SMLE shooter was one of my models, and he isn’t the fastest I’ve seen. I believe I can equal him now dry-firing at a spot that is a couple feet away. Hitting a target with real ammo is something I haven’t tried yet. 🙂 In any case, the mathematics are not on his side. At one shot per second, supposing the lion appears at 50 yards out of the bush and he misses his first shot, he will have time for one shot in a kill zone with the lion howling down on him. Mighty risky. And just to make the scenario real, I will relate an incident from one of my favorite books of all time, called Gilligan’s Last Elephant by Gerald Hanley.

https://www.amazon.com/GILLIGANS-LAST-ELEPHANT-GERALD-HANLEY/dp/B000H09I6K/ref=sr_1_1?ie=UTF8&qid=1316112363&sr=8-1

It has to do with a white hunter in Africa modeled on the experiences of the author who was a genuine British bushman who fought in Somalia in WWII before going to Burma. The man knows his rifles. His characters hunt elephants with a number 500 double rifle and shoot antelope to feed themselves with a .318 which I found from this blog is an obscure sporting version of the Mauser design that was made between the wars. Anyway, Gilligan, the professional hunter has a friend who likes to go on photo safaris and take pictures of animals with Gilligan backing him up. They go in quest of the ultimate bull elephant and find him as he bursts out of the brush in a charge. The friend is absorbed in his great picture of the elephant, secure in his confidence in Gilligan. But Gilligan misses with the first barrel of his 500! The African bearer knows that it is already too late and turns to run. And, alas, in a life-changing moment of panic so does Gilligan who does not fire his second shot, but throws down the rifle and runs away too, even passing the bearer (the source of painful memories in future years) while his friend is lifted up and “smashed like fruit against a tree.” The rest of the book is about a vendetta with the elephant. Anyway, it’s a great read and I do recommend it, and it certainly does dissuade me from being a professional hunter.

On the subject of ogives, I see we have some diversity of opinion. As far as I can tell, the strict definition has to do with the shape of the bullet tip as represented by various trigonometric functions of tangent and/or secant imposed onto a longitudinal cross section of the bullet. Thanks for the pictures Herb. This sense of ogive impinges on the ballistic coefficient. But the direct application of this idea is by defining the point at which the bullet meets the rifling as suggested by Flobert. That is what I was thinking of in terms of reloading. But there are a couple of problems here. It seems that even when the round is chambered, the ogive does not necessarily touch the rifling. Apparently some benchrest shooters design their rounds to have a slight jump before they meet the rifling although I can’t imagine why. Secondly, even if your round does meet the rifling when chambered, you can only find the ogive after the bullet has been loaded into the case–so that it can be chambered. So, this implies a very roundabout process of loading your bullets into cases, then chambering, then measuring the length to the ogive mark, then adjusting your bullet seating die…. I think I’ll stick with measuring to the tip.

For airgunning, I suppose the ogive motivates the practice of seating pellets deep into chamber, but that’s about it. Incidentally, I wonder if the IZH 61 has an advantage here since the cocking motion engages a loading rod that pokes the round forward from the clip into the chamber.

Matt61

Matt,

What Mann’s plank test proves is that the muzzle blast doesn’t affect the flight of the bullet like some people think. The plank reflected the blast back into the bullet that disregarded it entirely. So if that is true, then perhaps gas escaping from one side of a bullet before the other also has no effect.

B.B.

You seem to using “ogive” as the transition point between the cylindrical body of the bullet and the tapering nose portion of the bullet. Everything I’ve looked at uses “ogive” to describe the tapering curve itself, independent of the cylindrical body. Tangent and Secant appear only to describe what the “join” between cylinder and taper looks like — secant having a distinct angular transition, tangent being a smooth curve all the way.

Get a thick flat glass plate, a rubber roller, and some viscous slow drying ink (fingerprint ink, maybe). Distribute a THIN coating of the ink onto the plate. Then, without rocking the bullet onto its nose, roll a bullet across the glass plate. The edge where the body picks up ink but the nose didn’t is the transition point between the cylinder and the ogive taper. From there (presuming the bullet is sized to the grooves or a fraction larger) it should be a matter of geometry (maybe a touch of calculus to handle the ogive curvature) and knowledge of the depth of the lands (and depth of throat and any taper of the lands at the chamber) to determine contact length.

You may find that feeding live ammo in the Enfield is a little different that dry firing. You have to push a good bit more to feed the rounds. But, it sure is fun!

Mike

Do they sell dummy rounds/snap caps in the Enfield’s cartridge?

Only 7.62NATO/.308Win and 5.56/.223Rem for rifles here: http://www.stactionpro.com/308-cal-action-trainer-dummy-rounds-p-7.html

Doesn’t look too good here, either: https://www.brownells.com/.aspx/pid=247/Product/DELUXE_SNAP_CAP

But this one has a good list of rifle cartridges: https://www.brownells.com/.aspx/pid=40859/Product/CENTERFIRE_RIFLE_DUMMIES

B.B.,

I’m no gunsmith, but all top shooters that I’ve personally known do make a big deal about the importance of a good crown. I simply never shot a gun that did not have a near perfect crown. My Anschutz 1413 was bought used, but also re-crowned by Karl Kenyon. If I dropped an X at 50 yards, I’m convinced that it was my fault. My pistol coach, Stan Hulstrom, also believed that the crown was critical. He believed that the most common way to ruin a crown was by too vigorous a cleaning brush, and not over-use. At 17 years of age, I wasn’t going to argue with a man with over a dozen national and world records. In any case, I’ve always felt that my rifle was special, accuracy-wise.

Victor

I guess “how critical” depends on the application. If being able to shave a piece of a tiny scoring ring more times than not is important, then it’s very critical. The 10 ring of a 50 meter smallbore target is 0.41 inches. Most top competitors will have several 10 shot groups within that diameter size within the course of a single day of shooting.

Victor,

Perhaps ypou have provided some insight into this question when you said the crown could be ruined by too-vigorous cleaning. It most certainly can, and every arsenal in the world knows it. Like someone said earlier (Robert?) the crown is the transition point between the rifling and the open air, and if it isn’t sharp and defined, accuracy can suffer. What suffers is the condition of the lands at the muzzle. If they get worn down by over-active cleaning, the bullet will wander.

I know many Mosin Nagant rifles have been back-bored to eliminate such wear at the muzzle. That effectively move the crown back into the barrel, recessing it deep inside.

Maybe that is what this is all about.

B.B.

Yeah, this is why I bought one of those cleaning snakes. In fact, a selling point that they make is that they are safer for both ends of the bore.

Victor: Personally, I have always distrusted the bore snakes ( or the weed wacker line deal championed by the tuner guru’s on some online forums ) for cleaning. My problem with them is the same problem I have with aluminum or soft brass sectioned cleaning rods. IMO, they pick up crap and are more abrasive than a proper hard steel one piece cleaning rod used with a guide. They probably are OK for occasional field use like drying out a wet bore. If you need a cleaning rod in the field what good is a piece of fat string if you have to clear a bore obstruction? I carry a very short (6″ pieces) steel ,multi sectioned rod I made for myself to deal with emergencies in the field.If you are target shooting you usually have room for a real one piece cleaning rod in your range box.

Robert,

Thanks for the insight! I’m still neutral on this. I do know that I don’t like segmented cleaning rods, as I can see and feel them hitting the crown. I can’t help but think that this is damaging. I’ve actually sanded the segments down so that they don’t expose sharp edges.

Victor

BB,

You have contributed to my general unresolved discontent! I would have bet money that the crown, being the last solid object a bullet touches, would be vitally important. Just like we all “know” that the end of a pellet or bullet must be nice and square. Thanks for shaking up our reality, LOL.

A 900fps pellet leaves a 1 in 16 barrel spinning at 40,500 rpm. Maybe that trumps the crown?

Middle school math coming up: A bullet traveling 900 fps hits a 50 yd target in .17 seconds. A 20 mph cross wind travels 5 feet across the face of the target in that same time, but the bullet only drifts a few inches. The momentum and gyroscopic stabilizing effect are so much stronger than a gust of wind. So what makes a barrel or bullet inaccurate besides inconsistent velocity? Just a rhetorical question, but how many more things can you scratch off the list of accuracy sacred cows?

I have a number of barrel liners in various calibers that are too long and need to be shortened. Darn.

Lloyd

Edith,

I made a post on the plank test around 6:15 EDT, but it hasn’t shown up. Did it hit your spam box, or did it maybe never go out?

Pete

Pete,

I don’t see it in the spam folder. Don’t know where it is. You’ll have to resubmit it.

Edith

Is Mann’s test really a good one? The question is whether the bullet is fast enough to outrun the shock wave from the muzzle blast and/or the Mach shock wave from a supersonic object. Well, trivially if the bullet is supersonic, then the sonic boom lags behind the bullet, so a reflection from the plank will always be behind the projectile, and so won’t influence it “very much”. Probably not at all. The bullet didn’t “disregard” the blast; it didn’t know about it.

The question might be different for an air gun pellet that’s subsonic; the reflection off the plank might well catch up to the bullet (it travels at the speed of sound, and the pellet is slower than that), but it probably depends a lot on the distance between plank and pellet, the speed of the pellet, how fast is the reflection (not fast from wood; with less delay from steel), the length of the pellet, and probably the air temperature.

Ok, I know I’m late to this discussion, but I couldn’t resist. I wanted to keep my remarks on the same thread, so I know most will miss this.

(1) Imagine that you cut the bore at an angle. As was mentioned this could be expected to shift the POI. So it would seem that there is no doubt that the muzzle blast can effect the projectile.

(2) Given (1) can we surmise that shifting the POI would IMPROVE the group size?

This doesn’t seem reasonable at all. the best is that shifting the POI would have “little effect” meaning that the increase in group size is too small to notice.

(3) We’ve all read about group size not increasing with geometric distance so that a 1/2″ group at 20 yards is only a 3/4″ group at 40 yards. This would seem to be a measure that could be used to predict if a new crown job might help.

(4) The discussion missed the point that air is a compressible fluid. So the air in front of the pellet is compressed as the pellet goes down the barrel. This air is pushed out of the barrel before the pellet, and an asymmetry in the muzzle would cause an asymmetry in the turbulence. This is couple with the compressed air behind the pellet. At the instant the pellet clears the muzzle the compressed gas comes out of the muzzle. Gas molecules can travel faster than the pellet, given that the pellet is not super-sonic, and hence the pulse of gas exiting the muzzle initially overtakes the pellet. The pellet has to fly though this air turbulence.

The turbulence has to be coupled with some movement of the barrel to result in less predictable flight of the projectile.

The shadow-graphs that the Cardews have in their book clearly show pellets flying through such muzzle blast turbulence.

(5) Mann’s work with planks aside, but US army has used a flat deflector just below boreline to give projectiles yaw to test yaw characteristics of the projectile. The closer deflector is to the barrel line, the more yaw is induced onto the projectile. The gismos clamp over the barrel, and just have a flat plane protruding just away from boreline.

See: pages 320-322, McCoy “Modern Exterior Ballistics.”

For yaw inducer used by army see:

http://www.dtic.mil/cgi-bin/GetTRDoc?AD=ADA216846&Location=U2&doc=GetTRDoc.pdf

Page 12, figure 1.

Also in McCoy’s book, I misspoke. the yaw inducers had a curved surface not a flat one. Sort of like half of a muzzle brake was cut away.

Herb,

You are drawing on some serious “firepower” by a man who literally “wrote the book” (and every other well deserved pun one could think of) by bringing McCoy into it. Seriously, that man is a true authority on the subject.

Matt61,

I am going to go with Terry Wieland’s advice: Dangerous-Game Rifles. He knows the subject, discusses the history, and has been there, done that. He covers doubles, bolts, levers, and even single shots. For what it is worth, the man who wrote the forward, PH Robin Hurt, says he prefers doubles and believes there were times it saved his bacon where a bolt likely would not have been fast enough. On the other hand, Wieland mentions two personal experiences where the third shot from his bolt gun was needed when things were happening too fast for a reload of a double.

Have a look at the NRA museum website. There is such a thing as a repeating (bolt action) double!

-Gun Doc

Very good read. Thank you for an article unbiased by a pre-determined opinion.

You wrote a great article that leaves me with more questions. With a stock barrel on my Crosman 1377 it was pretty accurate once I found the pellets that it liked. In a search for a little more power and accuracy I put a 24 inch barrel on the gun and once again had to find the pellets that worked best in it. It was a longer barrel than I wanted, but figured I would use it for a while. This week I made the decision to shorting it. Being a bit paranoid about the barrels crown, I researched every possible way that it could be done. The method I used was clamping a hand drill in a vice sideways making a makeshift lathe. Cut it and shaped the crown with the barrel spinning. The results were amazing!. The gun is now more accurate than ever shooting 5 shot groups in a 3/8 inch area. ( which is an improvement for me and a $60 airgun.) The other quirk is that it also works well with most pellets that are close to the same weight. Did the new crown make the difference, or cutting six inches off of a 24 inch barrel?

Dan

Dan,

Or is the new barrel more accurate than the old one, but the last 6 inches were not rifled as well?

It is impossible to tell the exact reason why the accuracy improved. It was probably a combination of all those things.

B.B.