by B.B. Pelletier

S&W 327 TRR8 is an exciting new BB revolver.

Today is accuracy day for the 327 TRR8 BB revolver, and there’s an additional surprise in this report. I was glad to get another chance to shoot this interesting BB revolver that feels so good in my hands. It actually has made me curious about the .357 Magnum firearm. Ain’t that always the way?

I inserted a fresh CO2 cartridge for this session, and we know from the velocity test that there are at least 65 good shots from a cartridge. I’m talking about the best part of the power band, where no excuses for accuracy can be made. So, I could conceivably fire 10 cylinders (60 shots) and be safe. As it turned out, I didn’t even need to shoot that many.

Before the cartridge went in for piercing, it got a couple drops of Crosman Pellgunoil on the small, flat end. That ensures some of the oil will be blown through the firing valve, where trace oil will coat every surface, including all seals and valve seats. I want this gun to hold gas forever, and this is cheap insurance!

I used Daisy zinc-plated BBs, which have proven to be the most accurate steel BBs I’ve found. I was recently surprised to learn that Daisy imports these BBs from China in 55-gallon steel drums, but I do know that they then put every BB through a sorting process here in the U.S. before packaging. Whatever they’re doing is working, because these are the most accurate standard steel BBs I’ve seen. Only the Avanti Precision Ground Shot is more accurate — and you’ll probably only see the difference in a precision target gun like the Avanti Champion 499.

I shot the gun at 5 meters, which is the international distance for BB gun competition. I used a rested two-hand hold with my forearms resting on a sandbag. I don’t believe I can hold the gun any better than I held it for this test.

I had said earlier that I thought I’d be using the bright green fiberoptic sight for this test. This revolver has some of the brightest sights I’ve ever seen. But when I lit the target with the 500-watt lamp, I found that I had to use the conventional sight picture of the front post level with the rear notch and lined up at 6 o’clock on the black bull. The bright light on the target made the fiberoptic tubes of the front post and rear notch go black. It was as if this was a conventional set of sights. The sights were crisper than I originally thought when the target was lit this brightly, so everything worked out quite well.

First group

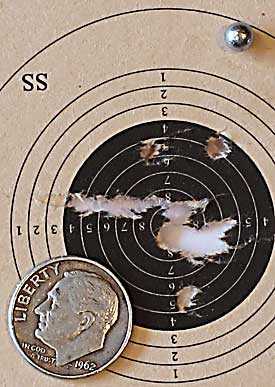

The first group was shot single-action, which proved to be the most accurate way of shooting this revolver, as expected. I was so close to the target that I saw the first shot rip through the black bull. After that, I fell into a rythym and didn’t check the target again. I shot 12-shot groups, since the cylinder holds six loaded cartridges. When all 12 shots were fired, I checked the target through binoculars and couldn’t believe my eyes! It really appeared as if only 6 shots had been fired, because nine BBs all went into a single tiny hole. I doubt very much that I could repeat such a grouop if I tried 100 more times.

The first group was phenomenal! It appears that 9 of the 12 shots went into the tiny group at the lower right, though the hole just above it may have more than one shot. Entire group measures 0.685 inches between centers.

Second group

With the success of the first group under my belt, I thought it prudent to shoot a second group single-action, just in case the first one was a fluke. As it turned out, it was. But I could see this group as it formed, and it looked better than the first one from the firing line. I wasn’t until I examined it in the binoculars that the whole story became obvious.

The larger hole in the center of the bull was visible from the firing line as I shot, but the holes that aren’t in the main group were hidden until I looked through binoculars. This is a more representative 12-shot group and measures 0.858 inches between centers.

I’m satisfied that the 327 TRR8 is an accurate BB gun. I was very relieved that the fiberoptics didn’t have to be used, because look at the precision I got. Combat sights (fiberoptics) aren’t ever going to give you that kind of group.

Double-action

Next, it was time to try my hand at double-action shooting. This is more difficult, because the longer, heavy trigger-pull causes the gun to move in the hand as the trigger is pulled.

The first 6 shots went so well that I thought I’d be recanting my position on double-action shooting, but the first shot from the second cylinder fired before I was ready and as a result it went wide. It was a called flier that I could see because I was concentrating on the front sight so intently.

The rest of the shots went into a fairly nice group, except that there was one high shot that I cannot account for. But when you’re pulling a double-action trigger and the gun shifts by just a few degrees of angle, it’s enough to throw you off target.

Not bad for a double-action group. Only the shot at the low right, next to the BB was a called flier. Group measures 1.44 inches between centers.

The surprise

I used the quick-loading procedure that was reported in Part 2 of this report. That’s where you press the mouths of the 6 shells into a layer of BBs, and they all pop into the cartridges. While doing this, I noticed one time that two of the BBs had not popped into their cartridge all the way. That would cause them to have less friction than the other four BBs and that could cause a variation. In handloading firearm ammunition, it would be called neck tension — and it’s a vital component of accuracy.

This is what happened when the cartridges were not pressed down evenly on the layer of BBs. Two BBs are sticking out the top of the cartridges and will have less friction than the other four that are deeper. When they were pushed into the cartridge, a noticeable pop was felt.

The bottom line

This completes the test of the S&W 327 TRR8 BB revolver. We’ve seen how it works and all of its good features. It is a very well-made BB gun that looks like it will give good service for a long time. Accuracy is above average, and the power is well above the modest advertised velocity.

Hmmm this seems like a sweet little revolver if only it wasn’t so darn ugly… I just can’t seem to get used to the angular, non-traditional cuts on the exterior “barrel” and I’m usually not that picky. The AirForce line of airguns and the IZH-60/61 look good to me…

On tue subject of dry firing. I was still a airgun and shooting noob but I kept reading B.B.’s reviews talking about nice triggers this and that and the proverbial glass rod but wasn’t getting it at all. Sure I prefered a single action revolver or pistol to it’s double action version but to me it was all yanking that thing back smoothly and that was it… UNTIL I tried dry firing. I could FEEL the trigger, I knew what first and second stage meant and I realised about everything I had been reading about for quite a while now and I LOVED IT.

J-F

Concur…

Those scallops on the barrel just don’t work… Especially when compared to the real thing, where the barrel shroud has a straight line from muzzle to cylinder crane — not the S-bend of the airgun.

http://www.smith-wesson.com/webapp/wcs/stores/servlet/Product4_750001_750051_765661_-1_775655_757896_757896_ProductDisplayErrorView_Y

Wulfraed,

Are you referring to the Weaver rail that is mounted on top of the rear of the barrel and front of the receiver? Is that what you mean by “scallops?”

That rail is attached to the gun with twi 0.050 Allen screws, but to get it off the revolver, the rear sight must be removed. That entails drifting two tiny pins out and removing the sight. I don’t have a pin punch small enough for the job, plus it will probably damage the finish of the gun, so I’m not going to attempt it.

B.B.

No — I mean the cuts on the top-side under the front sight, and the opposing cuts on the bottom-side over the extraction rod, behind the under-muzzle rail.

If you compare the airgun to the real model you’ll see how the side of the airgun barrel makes an _/—

while the real gun has a straight line.

{sorry for the delay — power company was doing something that killed power to the entire housing district from 8AM to ~4PM, so I went out and returned around 6PM, and spent the evening restarting computers, fans, clocks}

Wulfraed,

Okay — gotcha! No way to change that.

B.B.

While I don’t expect an airgun look-alike to perfectly match the parent firearm, this is one where the differences are non-functional and just (IMO) horrid looking.

In contrast, the difference between my P99 and CP99 actually make the CP99 better (my first generation P99 has the proprietary rail, while the CP99 has a Weaver compatible rail [for the audience: the P99 has a slope on the frame and the rail is closed at both ends; the CP99 is flat, open ended, and has a cross-cut for the Weaver “stop”])

J-F,

It’s wonderful when you make a breakthrough like that — isn’t it? That’s what makes reading about our hobby so rewarding. Now that you understand how a trigger should feel I expect you will be much more critical of them in the future.

B.B.

It was like finally seeing the light!

I am more critical and stopped shooting all of those with crappy triggers except for the TrailNP.

The dry firing lets you focus only on the trigger and when you’re used to it, it becomes natural and you can focus on the sights only.

The first airgun I started dry firing with is the lowly Beeman P17, you can cock it just enough for the trigger to catch without letting any air in so it doesn’t shoot, the Alecto is made the same way, very useful and easy to then adjust the trigger.

J-F

The seal in my old FWB 124 finally gave up so it’s time for a fix. I’ll be sending it to Pyramyd for the work. While it’s there, what’s every ones take of what to have done to it. I’m not looking for more than factory power. I like it’s easy cocking and accuracy. The gun has never been worked on in the past.

Mike

If you are happy with it the way it is other than a shot seal, then I think that all they should have to do is look it over, clean it up and lube it , and change the seals. Hopefully they will not find anything that looks like an impending failure.

twotalon

Mike,

When the rifle gets back, how about a short update on how the whole fix went?

B.B.

Sure, good idea.

Mike

Mike,

Since you asked here’s my two cents.

If your FWB 124 has never been opened up, I’d consider replacing the spring as well. You may also consider having the trigger cleaned, relubed and adjusted. Although there are a few folks knowledgable enough to properly adjust that trigger I prefer the aftermarket trigger that JM sells for the FWB 124.

kevin

Kevin,

Pyramyd AIR will look at Mikes gun for anything it needs. They are using Maccari mainsprings and their own custom piston seals for the jobs. I tested their seal in that lengthy 124 report I did and it seems to work fine.

They have done dozens of 124s already because they are the Beeman repair center and Gene told me they are very familiar with this rifle.

B.B.

For the record, I want to provide clarification and elaboration on my “two cents” of advice to Mike and his FWB 124.

I did not suggest, nor hint, that Mike send his gun to anyone other than Pyramyd AIR for service. I have first hand experience with the very competent airgun technicians at PA and am confident they will do a very good job.

Nice to know PA has Maccari springs in stock for Mike to choose from in the event the PA tech suggests replacing the spring.

I remember B.B.’s introduction of the proprietary piston seal that PA had made for the FWB 124 when he did his multi-part series on his FWB 124 way back when. Since B.B. was impressed by the performance I’m confident that Mike will be pleased as well. I did not suggest using a different seal.

As stated, if it were my FWB 124 I would send in a JM aftermarket trigger (now available but not always available on JM’s site) with the gun when shipped to PA and ask them to install it. Although a well lubed and well adjusted trigger on the FWB 124 is good the aftermarket trigger is better. I’ve shot both.

kevin

Thanks Kevin. Pyramyd did suggest a new mainspring. I’ll be going with one.

Mike

Mike,

Makes sense. Looking forward to your update after you have at least a tin of pellets through the gun to break it in. I’m a real fan of the FWB 124 and am close to having a highly custom 124 back in my hands.

kevin

Mike,

I just installed a JM ‘soft’ pro mac kit in a 124 and it is really very nice. It shoots just a click over 11 fpe. Have PA install their seal and keep Jim’s as a spare. Maybe even cover it in grease, zip it up in a plastic baggie and build a nice wooden box for it!

-hm

That’s what all the cool kids do with their 124’s :)!

Indeed. I do have a Maccari spring and seal for it “Just in Case”. I’ll probably skip the box 🙂 Since Pyramyd has everything I need, I’ll just let them work their magic!

Mike

American Airgunner tomorrow 4:30 pm on Pursuit channel (240 on Dish). Title…”Showdown”.

twotalon

B.B., would you say this this BB pistol shot better than the Dan Wesson BB pistol you tested?

Bradly,

No. I liked the Dan Wesson better.

B.B.