by Tom Gaylord, a.k.a. B.B. Pelletier

Today, we’ll finish the conversion of a Gamo 220 from steel spring to gas spring, and blog reader Vince gives us a report on the outcome.

If you’d like to write a guest post for this blog, please email us.

Take it away, Vince!

by Vince

When we last saw the Gamo 220, I’d disassembled the powerplant and compared the old parts to the parts I ordered from Crosman. Today, I’ll install those new parts and test the gun for you.

The gun is laying on the bench, ready for assembly. The new piston slides in, followed by the gas spring. Be careful when sliding the piston seal past the end of the cocking slot and tuck the soft seal material away from the sharp edges of the cocking slot so the seal isn’t damaged. A flat-bladed screwdriver works well for this.

The new piston that works with the gas spring is slid into the spring tube. Notice that I’ve lubricated both ends of the new piston with moly grease.

The new gas spring (Nitro Piston) slides in after the piston. The small end of the spring fits into the socket inside the new piston I mentioned in Part 1. No lubrication is required.

The trigger and cocking link go back in (reverse order of removal), and the plain plate gets dropped into the rear spring retainer.

I’m dropping the plain plate into the rear spring retainer.

Now, I’m starting to sweat a bit. You see, I KNOW that the gas spring has a TON of pressure on it even when fully extended (very much unlike a coil spring) — so, how on earth am I gonna compress it enough to reassemble the gun? Oh, well, I’ll cross that bridge when I come to it –which is, well, right about now. After I install the rear retainer, I notice something.

There’s almost no preload on the gas spring

Almost no preload at all! THAT’S right. Because the gas spring is ALWAYS at or near full pressure, there’s plenty of preload pressure as soon as the piston comes off its stop, so very little preload travel is required.

What is preload?

When a conventional coiled steel mainspring is installed in a spring gun, it’s usually longer than the space into which it must fit. It is, therefore, necessary to compress the spring by some amount to get it to fit inside the spring tube. This compression causes the spring to be under pressure even when at rest — this is called preload. If you’ve ever seen a long, empty flatbed trailer on the interstate that looked bowed up in the center because there’s no weight on it, you’ve seen what no preload looks like. It takes several tons of weight just to get that trailer flat again — and much more to make it bow the other way.

Airgun tuners can add spacers that preload the mainspring even more when it’s resting, which causes it to develop greater power when compressed because it’s closer to its maximum potential that exists at the point when all the coils are touching. But gas springs don’t work that way. They’re under full compression (internal gas pressure) when they’re at rest. All cocking the gun does is move the internal piston against the already-compressed gas that’s ready to blast it back when the sear releases it. There’s a very small amount of additional compression of the gas, but it isn’t what makes the gas spring work as well as it does. The gas spring unit is always at full potential — even at rest.

So, this gas spring unit has very little farther to go at this point…under a quarter-inch, in fact. THIS sure makes things easy for me. Pry the retainer forward on one side while starting the pin through the other. [Note: If I used a mainspring compressor, I wouldn’t need to pry anything. I would just tighten the compressor until the assembly pin holes lined up, then insert the large crosspin.]

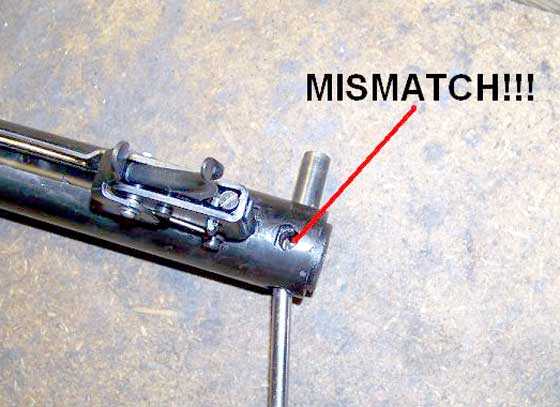

The crosspin will go in, but the hole for the rear spring retainer bolt (that large-headed bolt I removed when I disassembled the powerplant in Part 1) doesn’t line up with the hole in the spring tube. This is a problem.

Immediately, a problem becomes apparent. Look at the hole where the rear spring retainer bolt goes. It’s not lined up with the hole in the tube. There’s approximately a .080″ misalignment here. This ain’t gonna work. My first inclination is to simply elongate the hole. But when I reinstall it, there’s another problem.

There’s a gap between the plate on the spring retaining bolt and the trigger assembly. It won’t support the trigger this way!

The trigger isn’t properly supported by the plate that’s attached to the bolt. Worse, this changes the spacing between the front and rear stock screws and doesn’t allow the action to be reinstalled.

Hmmm. I’m wondering if this is exactly what Crosman (or BAM) had in mind — preclude an easy conversion with existing parts (since the same problem would exist on a normal Quest). That leaves me thinking: Can I just butt the gas spring against the original Gamo spring retainer?

If you look at the picture of the new rear spring retainer above, you’ll see that there’s a small plate that drops into the cup that retains the gas spring cylinder. The cylinder wants to butt up against a flat surface, and the Gamo retainer has a large (approx. 1/2″) hole in it. I need a metal plate to go over it. Wait a minute! I’ve got one right here in my pocket!

A perfect spacer for the new gas spring and it costs — well, about a quarter!

And, so, it gets reassembled. Believe it or not, the whole thing works.

Time to test!

I’ll run through this pretty quickly — the velocity is now up to about 964 f.p.s., which represents a muzzle energy of about 14.5 ft-lbs. Not killer, but obviously a lot better than the detuned gun. Accuracy shouldn’t be changed — or should it? Oftentimes, guys will detune their guns to make them more accurate — or to simply make them easier to shoot. That might have some merit, as I now couldn’t break 0.37 inches at the same range. Not a big difference, and I’m certainly not gonna suggest that the gas spring decreased accuracy. But I don’t think it helped.

So what’s it like to shoot?

First of all, everything anyone ever said about “thunk” vs. “sproing” is absolutely correct. The gun “wumps” with a gas spring, and you can actually feel a kick back into your shoulder. Nothing like a typical centerfire gun, although maybe something like an 1894 shooting low-velocity .38 specials might be comparable. But that’s just a guess.

Cocking the gun is another matter. Effort peaks at about 33 lbs., which isn’t all that high — except for the fact the effort before that peak is certainly a lot higher than with a normal coil spring. This is what we’d expect, of course, with the relatively constant pressure of the gas spring. It isn’t unbearable, but it does take some getting used to.

Back to a coiled steel mainspring

After about 40-50 rounds, I decided it’s time to restore the gun back to original spec. I rummage around my spring box and find a REAL low-mileage Gamo spring, and put it all back together the way God intended it. NOW, I can really get a back-to-back series of impressions.

First, the velocity did drop a smidgen. It’s now down to an average of about 943 f.p.s., or a little under 14 ft-lbs. Second, and despite the tar on the spring and rear guide, we DEFINITELY are sproinging ourselves rather energetically. Lastly, the cocking effort is predictably much milder. Peak effort is down by 5 lbs., and the effort before that peak is even easier. Accuracy is unchanged from the gas spring.

How did my quarter, er, my impromptu gas spring backing plate pan out? Not too well.

The pressure of the gas spring punched a deep divot into the quarter.

The flip side doesn’t look any better.

I flattened it back out with a hammer, and I’m really hoping it’s still legal tender. Anyway, as I sort of expected, the relatively soft quarter didn’t do well. The backing plate really ought to be steel, 0.060 inches (1.5mm or 1/16″), just like the original.

But the bigger problem wasn’t the quarter.

There’s a serious indication of metal-to-metal galling.

There was some serious metal-to-metal contact going on here between the cylinder of the gas spring and the inside of the piston. If you look at the above pictures of the quarter, you’ll see that the indent isn’t centered. The pocket in the original rear spring retainer keeps the spring cylinder right in the middle, and apparently that’s real important because it won’t center itself.

And that’s about it for now. If this is going to work, we need a simple and cost-effective way of keeping the gas spring centered properly without permanently altering the original parts…and do it in a way that the average tinkerer can accomplish on his own. The first thing that comes to mind is to drill and tap a new hole in the new rear spring retainer, opposite of and slightly forward of the existing hole. I tried that, and found (predictably) that getting the hole in just the right spot is a bit difficult without a custom drilling jig.

For now, I’m just going to give it some thought.

WAIT! I JUST GOT AN IDEA….

My experience of converting my Gamo CFX to a gas spring did not work out well. It was literally tearing it apart. PA had to machine down a scope mount for me to get a better grip. I had to put Loctite on the adjustment screws of the GRT III trigger. Then shortly after I had worked those issues out I had a massive detonation that blew out all the seals and sent the breach handle sailing who knows where.

Nevertheless, I intend to try again with a FWB 300 and a low power gas spring in the hopefully not too distant future.

My Russian gas spring for the IZH came with a piece of steel with a small indent in it to center the rod of the gas spring.

Here is the link to what we ordered, there’s some pics on page 2 of what we received.

Couldn’t you use a washer welded to the steel plate that would fit around the rod to keep it from moving from side to side?

J-F

What link?

Vince,

I was wondering how long is the extended gas spring and what’s it’s diameter? Also, any idea of the resistance rating of the gas spring? I ask this because I found a website that sells these springs but they’re rated from 20 lbs to 90 lbs and was wondering if I could use them instead on other rifles.

Fred DPRoNJ

Vince/BB,

This is interesting. But frankly I’m more interested in the low-power tune you did. Especially the part where you said its very easy to cock compared for a gun getting 10 ft-lbs muzzle energy. I don’t suppose there was a blog article about the low-powered tune?

J.

Not much to tell, really… just get the spring I referenced and install it in a Gamo or Quest variant… and there ya go. I seem to remember something like 20lb cocking.

Vince,

First things first… Thanks for the reply. I have to say the more I see of your low power tune the more interesting it sounds. Its probably beyond my technical abilities, at least without an instruction manual. But very interesting.

What really struck me though was that what you’re describing with that low-power tune sounds a lot like the big brother to the Bronco that Tom’s been saying he wants to see developed/marketed for several years. I wonder whether there would be a market (or enough of a market) for a low-power tuned version of the Crosman Quest/Phantom/etc… from people who want a bit more punch than the Bronco but not the 14-16 ft-lbs of the typical “magnum” springers to justify a factory version. Especially since it looks like it uses parts Crosman already produces, just in a bit different combination, which should reduce the development costs.

J,

Interesting concept. A power backlash among the community. I wonder if it has been tried commercially?

B.B.

BB,

Honestly I don’t know if it has been tried commercially. I do remember you saying the Mustang was a bit of a disappointment/not exactly what you were thinking when you reviewed it though. If I’m remembering what you originally were thinking correctly (and I may not be) when you envisioned the Bronco’s big brother it was supposed to be an accurate, easy to cock springer that was sized for an adult, not hold sensitive, and put out 7-10 ft-lbs muzzle energy. What Vince assembled sounds like its pretty much dead on those specs.

As for whether or not it would be commercially viable or not… I don’t know about anyone else, but I’d be more interested in buying something like that than I would a “magnum” springer with 30/40/50/etc… lbs of cocking force. That’s because I really don’t hunt anymore so I mainly need something to knock over soda cans at 50-60 feet with that won’t wear me out. (It kinda takes the fun out of plinking on a summer day when you’re covered in sweat after one or two shots from pumping the gun up…) I’ve been considering buying either a Bronco or IZH 60 the next time I buy an air-rifle since either should do what I want. (Though that’s going to either have to wait until my penny jar gets a bit fuller, one of my multi-pumps wears out, or I hit the lottery since I’m not swimming in money right now.) However something like Vince’s detuned Gamo 220 (either a QuestPhantom/etc…) would probably be better since it would be easy to cock and still have enough power to knock over a rabbit or squirrel at 20 yards (about as far as I would feel comfortable taking a shot) if one decided to raid the lettuce patch. And if the price was around the same as the Bronco…

As for others… I seem to recall a fair number of people asking about airguns to plink in the backyard with (not getting into the legal issues there this time…) and maybe knock over the odd rabbit or squirrel on Yahoo Answers. A lot of times, if they’re kids, they ask about whether the 20+ ft-lb, nitro springers would be good for that. Something like this may not be perfect, but it would be a better plinker than the 20+ ft-lb nitro springers or even the “1000” fps springers since the cocking effort is lower. And its about the same power as the UK legal springers (which usually are what 11 ft-lbs muzzle energy to avoid accidentally going over the 12 ft-lb limit) that people in Britain use for rabbit, squirrel, etc… Kids probably wouldn’t be hugely interested (though they do occasionally listen when they’re told that they really want a less powerful springer because the super-magnum springers take ridiculously high cocking efforts), but older shooters might be. Ditto on people who want to do a combo pack with a gun for Jr. and a gun for Dad to plink with.

The real question though is whether Crosman would sell enough to justify pulling the parts (a Canadian legal x500 spring and a US Quest/Phantom) and paying people to assemble a low-power tuned Quest/Phantom. And I don’t really have a firm answer for that. I just know what I’ve already mentioned. It may be that this would be something that would work best out of Crosman’s custom shop if they don’t think it wouldn’t sell enough for regular production.

J.

J.,

Mustang? That rifle was never made. The Tech Force M12 is not the Mustang. What I probably said was I was sad that the Mustang was never built, as it was envisioned.

As for the Tech Force M12, I am still testing it.

B.B.

BB,

Ah, that was it. I just remembered seeing something about how the Tech Force M12 wasn’t the Mustang or something to that effect in the review of the M12.

Was I correct about the description for the proposed Mustang? Or did I get that messed up and not remember it correctly?

J.

J.,

You were correct. The Mustang is supposed to be a larger companion to the Bronco. A “dad” gun to the Bronco “son”. I was hoping for velocity in the 800 f.p.s. range or less, in a rifle of adult proportions.

B.B.

BB,

Do you think a detuned Quest/Phantom meet the criteria/specs for the Mustang? And do you think it could be produced for about the same price as the Bronco?

J.

J.,

No. I want an accurate barrel in the Mustang. Something that goes beyond okay and is great!

B.B.

Hm, well you don’t want to try using the 1 trillion dollar platinum coin in place of the quarter. This is all very relevant to another line of research. I’ve been wondering about Sauron, the dark lord of The Lord of the Rings trilogy. Who is he? What’s he look like? What drives him? Reading into the mythology, I see that he is a Luciferian type of higher being. And now we come to it. Where the Lucifer of Christianity was a creature whose generalized virtues were corrupted by pride, Sauron’s downfall was his love of order and system. AND, he expressed this desire through his skill with craftsmanship–hence the rings. Apparently everything became a material object to him to be controlled in the quest for perfection that became tyranny. In other words, he was a tinkerer gone wild. He’s like the guy who goes into Air Force guns and wrecks them while trying to make an improvement. You tinkerers know who you are and should take warning! 🙂 I can at least say for myself that I am free from temptation in this respect.

I also found myself wondering about the One Ring of Power. It never seemed like a big deal to just make yourself invisible. But it turns out that the Ring confers power proportionate to the ability of the wearer. For more powerful beings than hobbits it can do all sorts of other things that are unspecified. But perhaps its greatest power lies in controlling the other rings of power in secret and dominating the wills of the wearers. In other words, Sauron is a kind of super-hacker. Maybe the way the mythology strikes so deep and stays so current explains how it gets such a popular following, even if I happen to be more interested in the kung fu antics of the dwarves.

I was not able to comment on B.B.’s SHOT Show report yesterday. It’s nice to see our man in there! There certainly is a lot of effort invested in assault rifle look alikes. If the frantic buying of assault rifle could be skimmed with the airgun versions, someone will make quite a killing. Here is a market question. Supposing I’m interested in a non-assault type weapon, like a revolver, do you suppose that this will be a better time to buy? On the one hand, if people are putting so much into assault rifles, they can’t be buying other guns at the same rate. On the other hand, perhaps people are just buying every kind of gun and ammo that they can.

I’ve heard mixed reviews of the SCAR rifle which B.B. was holding a reproduction of in a photo. One of its attributes is supposed to be its ergonomic design. It certainly looks that way. But one guy said that it is too bulky, like “holding a german shepherd in your arms” and he concluded with disgust at the “fish-shaped rifle.” I could kind of see that too. So, B.B. did it feel like you’re holding a german shepherd?

It makes me wonder what exactly is meant by ergonomic. (Definitions, Victor!) I think this is supposed to mean adapted to the human body, but if it means there is one answer to this, I doubt that is true. What is meant by ergonomic today, as exemplified by the SCAR, seems to mean optimized for the shooting position, like target rifles. But my Anschutz, which is rock-steady in any standard shooting position, is about the unhandiest, clumsiest rifle when moving around. And that’s true to of any assault rifle with an extended magazine which is very asymmetrical in shape and of a “dirty” design with things hanging off of it. Also the new model rifles have a straight stock which is optimized for controlling rifles in rapid fire but otherwise doesn’t make much of a difference. So could it be that through semiotics and a confluence of circumstances, modern assault rifle design may be optimized for soldiers with automatic weapons but actually unfavorable for anyone else who has more of a need for a handy rifle than one with target accuracy?. The M4 addresses this problem by cutting down the barrel to 14 inches but this seems to me a kind of meat-cleaver solution that creates a lot of new problems with range and penetration.

For ergonomics in a more general all-purpose sense, I think it would be hard to beat the Winchester 1894 invented before the term ergonomics was ever created. Also, I find that the old and sometimes maligned military rifles of the WWII era all feel great and handle extremely well. Even the curved grips of the Single Action Army revolver may have been optimal for what it was designed to do. Elmer Keith claims that the SAA was superior in the fast draw to the 1911. This could be precisely because of the curved grips. Someone claimed that the reason the original M14 was uncontrollable in full-auto was because of what he called its “wrist” which referred to the thin curved section of the stock connecting the butt to the receiver area. This non-straight line stock cause rapid muzzle climb in full-auto. But the same principle might have allowed the SAA to roll more quickly out of the holster on the quick draw. Anyway, unless you plan to use an assault rifle as an assault rifle, I do wonder if the ergonomic claims are all they are made out to be, and I would be suspicious about the use of this term.

Matt61

It seems the M-14 isn’t controllable on full auto do to it’s lack of weight for the cartridge if fires, the 7.62 NATO (.308 Win). A G-3 or FNFAL with a straight line stock still isn’t very controllable either. You just don’t need full auto in this platform. Hand held full auto is only useful at very close range when you need to take a threat out fast. You use your ammo fast. It’s almost always better to use semi-auto.

Mike

Matt,

If you are a fan of Tolkiens work I highly recommend the Silmarillion. Perhaps you have read it. Although the rings of power are only lightly dealt with, Sauron is explored in greater detail than in the LOR trilogy. I believe that Tolkiens genius is revealed to a much greater extent in the Silmarillion. A masterpiece IMHO.

Mark N

Vince , what about sleeving the piston or making bushings for the gas sping, in addition to making a ring that centers the end of the gas spring in the end cap? Maybe like a lock washer flattened out instead of the quarter.

Robert,

Lowes and Ace locally have a good assortment of spacers, also, like a thick washer — they might go that big. Just to sympathize with Vince, I have several times needed to drill hole in a thin slice of rod (e.g. a button for a patchbox release), and it is tricky to get well-centered without a jig (or maybe a lathe)!

Related to sleeving, how about “buttoning” the gas spring? I think the “new wave” way to do it is a thin ring or two of some high density plastic glued to the piston; it might do the trick on the spring cylinder in this case.

On your recent hardship — you are not alone. From the news, apparently everyone in NYS is confused by the new regulations, including law enforcement. It may turn out like some other places where local rules in rural areas are relaxed a little. Probably you are like me, though, and don’t like having a rule hanging over you even if it is not enforced.

Just tried again…

Still no email, Vince. If you don’t mind, maybe you can have Edith, BB or someone else you know send me one with your email address in it and I can try yours. That’s if you don’t want to post it here in the “off” format that I have given you mine. I hate posting the real one with the “at’s” and “dots” correct because that seems to generate a lot of spam in my account.

Thanks,

/Dave

1+1=2 (my kind of math! 🙂 )

vfblovesnancy(at)yahoo.com

BG,I’m spoiled as I have a lathe.Actually two of them ,a 3.5 Austrian Unimat and an old 10″ 1930’s Atlas, and we have a Fastenal store right here in the village. But in the very distant past I’ve used lock washers that I’ve heated and cooled to draw the temper as spacers on stuff, and have even sliced slivers off of bored rods that were once part of some old machine. I was thinking a delrin ring could be used to prevent the galling of the outside of cylinder of the gas spring.

As far as the NYSAFE law , I have been gathering all the information I can to protect my rights. You are right NO ONE knows how they are going to enforce this new law and keep track of all the useless data it will generate.There apparently is also little to fund it, NY state is billions in debt, so we might just be able to overturn some of it.