by Tom Gaylord, a.k.a. B.B. Pelletier

Today’s blog is a result of several blog reader comments about the BSA Scorpion 1200 SE PCP air rifle I started reviewing for you several days ago. Reader Lee asked if there was any advantage to the higher fill pressure, and J-F followed up with a couple comments of his own. I find this to be an excellent question since it touches the core of precharged pneumatic operations. I thought I’d start a discussion of the impact that fill pressure has on precharged operations.

The modern precharged pneumatic air rifle was built by Daystate in 1980. It was a .22-caliber rifle called the Huntsman that was roughly based on a dart gun Daystate was making for game management. When I got into precharged guns in 1995, I bought a used Huntsman Mk II and was surprised that the maximum fill pressure was only about 2,500 psi. I discovered that by shooting the rifle over the chronograph, which in the olden days was the only way to do it. Nobody published any data on the number of shots a gun got, and this blog was still a decade in the future. At that pressure, I got 30 good shots at 12 foot-pounds. But that raises a good question. What do I mean by a good shot?

What is a good shot?

This is a huge precharged topic and a grand area of misunderstanding. What is meant by a good shot? When I say it, I mean a shot that falls within a tight band of consistent velocity that will enable me to shoot great groups at 50 yards. Regular readers of this blog know what I mean by great groups, but for the newer readers I would define a great group at 10 shots inside a group that measures 0.75 inches between the centers of the 2 shots farthest apart. To me, that would be great at 50 yards.

But when many shooters talk about good shots, they mean that the pellet still comes out the end of the barrel. They’re standing in their backyards. They don’t own a chronograph. To them a good shot is when they pull the trigger and something comes out the end that has the little hole in it. If it also happens to hit the tin can they’re shooting at, it’s a great shot. Yes, people do think this way — even the owners of $1,500 super-dooper PCPs. In fact, there’s good evidence that more people think like this than those who agree with my definition.

So, the more universally accepted definition of a good shot is one that launches a pellet from the airgun. That being the case, there’s a big misunderstanding when it comes to the number of good shots a particular airgun may have. Manufacturers have trended toward publishing the number of shots that will result in the way most shooters define them, while I have always published the number of shots that fall within a tight velocity band. Both numbers are correct, but they don’t tell the same story. I’m going to be sensitive to this difference in the future, and I’ll probably expand my velocity testing of PCPs to accommodate the two definitions when I feel it’s necessary.

Back to the title question

So, what does higher fill pressure give you? Do you get more shots on a fill? Well, which definition are you using? If you use my narrow-velocity-band definition, then the answer is probably no. All a higher fill pressure does is move the starting and ending air pressure levels higher. You may have to fill to 3,365 psi and shoot until the velocity variation exceeds 30 f.p.s., which leaves you with 2,600 psi remaining in the reservoir.

But if you use the broader definition that as long as the pellet comes out of the muzzle the shot is good, then a higher fill pressure will give more shots. You can probably keep right on shooting until there’s only 800 psi remaining in the reservoir, and the shot count will more than double. Of course, the velocity may vary by over 700 f.p.s. from start to finish; but to the guy rolling cans in his backyard, that makes no difference. He begins to sense his gun needs a fill when he starts seeing the pellets in flight and notices how they arc slowly toward the target. I sense a need to refill when my 50-yard, 10-shot, three-quarter-inch groups expand to more than an inch!

Okay — let’s say you understand that there’s a large difference between my definition of what constitutes a good shot and the more generally accepted definition. What should you do about it?

To answer that, you have to ask yourself what it is you want to do with an airgun. Do you want to pursue the ultimate in precision? If so, you probably want to use some variation of my definition of what makes a good shot. The reason for variation is you may not shoot at 50 yards. You may shoot only at 35 yards. If that’s the case, you can accept a wider velocity variation than I. That will give you a few more shots per fill than I get.

Or are you trying to shoot good groups at 100 yards? In that case, you’re probably going to be more critical than I am about velocity variation. You’ll get even fewer shots per fill than I do.

But if you’re just out for a good time with your airgun and your targets are big enough to provide some leeway on where they’re hit, you could care less about the velocity spread. You just want to fill your gun and start shooting. You don’t stop until you can no longer hit what you’re aiming at.

Two categories of precharged valves

Given the discussion above, I see precharged valves falling into 2 categories. The first category is a valve that holds back the air until it’s knocked open. When that happens, it lets the air out as long as it remains open. We call this a knock-open valve. A valve like this gives its most powerful shot as the first shot, then the velocity starts to drop in nearly a straight line. Start to finish, the velocity is always dropping as the shot count increases.

Many of the Korean precharged guns have this type of valve. I remember the old Career 707 lever-action rifles would drop velocity in a straight line from the first shot to the last.

The other category of valve is one that’s balanced to operate within a certain pressure range. By balanced, I mean the following. The weight of the valve return spring is adjusted to compliment the weight of the striker, the power of the striker spring and the length of the striker stroke. The size of the valve seat, which determines the size of the air passage out of the valve, is adjusted to compliment the return spring strength, striker spring strength, striker weight and the length of the striker stroke. You could call a valve like this a “balanced valve” since all these considerations have been balanced against each other. It operates the same way that a straight knock-open valve does, but in this case a lot of attention has been given to the individual firing components. There’s no formal definition for a balanced valve, but these are the considerations that are taken into account when that label is used.

When Crosman developed the Benjamin Discovery PCP air rifle in 2006, they had to carefully balance the valve to work at a fill pressure of 2,000 psi. They were working in unfamiliar territory; because at that time, 3,000 psi was a nearly universal PCP fill pressure. I’d given them a presentation of a PCP rifle that would operate on a lower fill pressure, and I used the USFT rifle made by Mac-1 Airguns as an example of what could be done. That rifle used 1,650 psi to get 55 good shots by my narrow-velocity definition. It did so because it has a huge air reservoir.

The Mac-1 USFT rifle uses low-pressure compressed air but gets a lot of shots that are very close to each other in velocity. It has a delicately balanced valve that uses the air from a very large reservoir.

As a second example, I also told Crosman about a .25-caliber air rifle made for me by Gary Barnes. That rifle operated on a fill pressure of just 600 psi, yet it got 10 shots that developed as much as 27 foot-pounds of energy. That rifle did what it did because it had a valve that remained open for a very long time, and it also had a barrel that was 32-3/4 inches long, which gave the compressed air a long time to push the pellet.

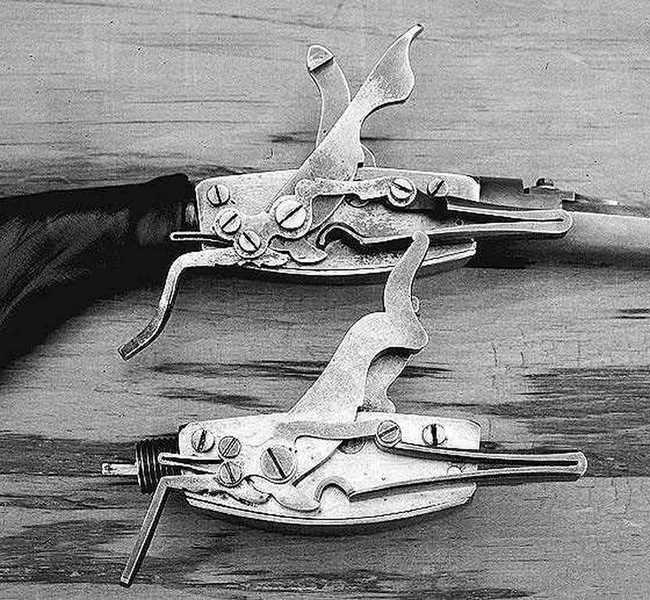

Gary Barnes made this outside lock air rifle in .25 caliber. It was a copy of an 18th century airgun lock whose parts were attached to the outside of the lock.

Gary Barnes made the rifle with the outside lock (shown at the top). The bottom lock is a genuine lock from the early 1700s that Barnes used as a model. The way the lock works, it holds the air valve open much longer than a traditional impact valve.

Crosman was amazed to discover that the lower air pressure idea really worked. In just 3 days, they built prototype .177- and .22-caliber rifles from their 2260 CO2 rifle. Once they had the concept down, they fully developed the idea into the rifle that we know today as the Discovery. To keep the retail price as low as possible, that rifle was hardwired with all the lessons they’d learned about air valves.

But one year later, they came out with the Benjamin Marauder, which allowed the owner to adjust the air flow, the striker spring tension and the striker stroke length. This put the capability to tune the gun into the user’s hands. And this report has given you the information you need to understand how it all works.

I will continue to test PCPs like the BSA Scorpion 1200 SE in the way that I always have, and I’ll keep telling you what kind of velocity spread I’m accepting for the shots I call good. But I’ll also shoot these rifles a lot longer, recording the velocities as I go. I’ll give you the data that most backyard shooters never have, nor seem to want. From that, we’ll get a much larger number of usable shots from a fill. And, to paraphrase the Fox News tagline, “I’ll report. You decide.”

With me, the useful shot count can change from day to day, depending on what I am doing at the time. Most of the time I am trying to produce the tightest groups possible at the longest range possible. Now when my son-in-law comes over, we are usually content to be able to send the soda cans spinning at various ranges and are not concerned where we hit them as long as they tumble.

RR,

As long as you know what you are doing and understand the difference (and I know that you do), then there is no problem. I wrote this report for those who haven’t really give this much thought.

B.B.

Thank you very much for that report. It answers all my questions.

But given this great blog article I still think it may look good on paper but in real life I think a higher fill pressure isn’t such a good idea. The gun airtank has to be heavier to hold the higher pressure and getting a higher fill might not be easy. Especially when we know that they can be made to operate on a lower fill pressure!

J-F

J-F,

Yes, and it goes on past even that. Higher pressure means you need higher pressure sources, which become increasingly more difficult to find.

B.B.

When I was contemplating getting into pcp’s I had a hard time grasping the concept that more air (higher fill pressure), at some point, didn’t translate into more shots or even more powerful shots.

B.B., said something like, “If you overfill your gas tank on your car, spilling gas on the ground that can’t be used by the vehicle, will your car go faster or farther? No it won’t because the vehicle can’t use the fuel.” Same thing applies to a pcp when you try to give it more air than it can use efficiently. The difference being that if you overfill a pcp it may not work at all. This helped me make sense of filling pcp’s.

So far my Discovery is all tuned and I made it to the shooter can adjust the velocity of the shot by a simple turn of a knob. Personally I like this a bit more than I like the marauder’s way to tune the valves. The marauder needs to partially disassemble the gun to tune the valve. My discovery all you need do is turn a knob which can be done on the go. Maybe you want to target shoot so turn it all the way down to save air then see a muskrat you have been waiting for, turn the knob all the way in and waste the muskrat. Then turn it back down and continue target practice. And all of it done fairly quietly since I installed a stage 5 TKO muzzle brake on the gun.

I’ve also been inside the thing working on all the springs, valves and whatever else to bring the performance up to that of the Marauder. The gun has been my on and off again passion for the last 3 years tweaking this, tuning that. Now it sings a sweet song on the range. Now that I am done with it and I had my fun shooting it, I’m selling it in order to go on to build my next abomination…..A bb spitting monster capable of 2000 rounds per minute at 900 fps using around 4500 psi of onboard air. Ever see a pop can disappear in a second or less?

John you need a youtube channel. I want to see those things perform!

J-F

I’ll consider it. But first I have to get the base gun, A Drozd Blackbird, then begin gutting it and putting my own guts in it. By the time I’m done it won’t look like the Blackbird you get at Pyramyd AIR. This thing will look more like some space age tactical swat rifle. I decided to go for high power high rate of fire over accuracy for that gun. At 2000 rpm accuracy is kind of a moot point when you throw 400 bb’s at a can in a matter of a few seconds. That one is being built for the pure adrenaline rush.

The Discovery looks like just any other Discovery out there but with a few minor cosmetic tweaks that give you a clue that it just might be a bit more. Just about all the performance I put in the gun is all internal in about 6 inches of space. I can’t show the huge air valve I tucked in where the stock valve used to be. There’s not much to see in the breech other than the extended probe. And as of now I am still waiting on the TKO stage 5 muzzle device. So that gun will be a bit boring to see fire.

I think the Crosman Rogue deserves mention here too. Using electronics to adjust the valve offers greater flexibility that can be achieved with a purely mechanical valve. Yes there are problems with electronics. But look at automobiles. Autos have more and more electronics. Under the hood in a car is a very harsh environment. So it isn’t if electronics will work, but putting the money and effort into creating good designs.

Edith,

I’ve been a busy boy and bad boy.

Missed your celebration by a week. A belated Happy Birthday!

kevin

Kevin,

Thank you. It was the best birthday ever!

Edith

Shame on us! Sorry Edith!

J-F

J-F,

No apologies necessary. We took the day off (although B.B. did a bit of blog work that day). It was a relaxing and fun day.

Edith

You touched on something I’ve been wondering about for awhile now, namely the Discovery’s considerably lower fill pressure. Is there a specific reason other brands require a charge to 3k+ psi? I live nowhere near a dive shop and the tiny fire department in my town won’t fill scuba tanks-and I can’t imagine I’m the only one in the same boat. It seems to me the airgun manufacturers would be able to sell more pcps if they weren’t so difficult to fill.

dangedongle,

Let’s turn that around and say the Discovery was created the way that it is because of the problems you just mentioned. In other words, it bucked the 3,000 psi trend and went to a lower and more manageable fill pressure, which today’s report informs you used to be the norm, rather than the exception.

When things stand out like this it means there are business opportunities. But they aren’t always capitalized upon.

B.B.

Getting off the subject I have to ask this. I have a brand new Gamo Big Cat that I rarely use. I optically centered the scope then mounted it. I then used a laser bore sight to verify the reticle was where it is supposed to be. I found it was set high and to the left. but it was hitting low and left. So I ajusted it to where my laser said zero was. It still hit low and left which required quite a bit of adjustment to get the gun hitting the target where I wanted it to hit. What might the problem be with this gun? Is it a lemon that I can’t use for anything smaller than a barn?

Not my first choice of guns when I go target shooting but I do like all my guns to have some manner of accuracy. Even the cheap junk from Gamo.

John,

First, abandon that laser collimator. It may work with firearms, but not too well with man airguns since the true barrel isn’t where the spud wants to be.

Next, try my 10-minute sight-in procedure. When I worked at AirForce Airguns I had to sight in hundreds of guns with scopes for the first time and this procedure saved me hours of time.

/article/All_about_scopes_Part_3_April_2005/22

While I have several issues with Gamo the accuracy of their rifles isn’t one of them. I find them to be accurate if the right hold is used.

B.B.

The laser is projecting a straight line extension of the barrel bore (providing it isn’t centering on an offset “muzzle brake” or shroud).

But the pellet will be dropping from the moment it leaves the barrel. Firearms have enough velocity and mass to hold fairly flat trajectories (and since you sighted the scope onto the dot at some distance, you have the >angle [visualize laser/bore horizontal and scope angling downward to intersect]).

The firearm intersection is probably being set up around 25-50 yards, or the upward “first zero”. Second (downward) zero may be around 150 yards. The bullet will be above line of sight in the intervening space.

For pellet guns, 25-50 yards is second zero (when the pellet falls below the line of sight). But if you use the laser point at that range, you never angle the bore high enough to get above the line of sight. You may need to put the sighting distance around 15-20 yards to get the first zero laser/scope intersection.

Great description of “good” shot. As you said this is very important.

Also a good point about the difference in fill pressure not meaning more shots. The higher fill pressure will allow you to take more “not good shots”, but I rarely care to take those or at least understand what I am working with if I do take them (at 20 yards (my “indoor range/basement” length) I (almost) always will finish a clip even if I am off the curve.

Also for those with Marauders (or thinking about one), there are limits to how high or low of pressure you can tune a gun to meet the “good shot” requirement. This will often vary with each individual gun. Just as you cannot force the pellet that will work best in a Marauder, you also cannot force the pressures that will work best in you gun. From experience I know that some Marauders (at least in .177) can be tuned for a starting pressure of 2000 psi and get “lots” of good shots. I also know that some Marauders just don’t seem to want to work that well at 2000 psi and may rather have a higher starting fill pressure (such as 2300psi). Don’t try and work against the gun, you won’t “win”. Let it tell you what it wants to do. This also means don’t try to force a gun to shot at a higher FPE than it is “comfortable” with. My personnel prefference is to tune the .177 Marauders to as low as a pressure as makes them still efficent. This means that even with a lowly 3000 psi SCUBA tank, I can get over 3000 shots before needed to refill the tank. (I also own a 4500 psi carbon fiber tank as I shoot guns that like close to 3000 psi fill pressure which the 3000psi SCUBA tank can’t do much of – but I rarely use the 4500 psi tank to fill the low pressure guns)

Also a good point on the Korean rifles. I am not sure why they ship them the way the do, as it is relatively simple to make them behave in a fashion that meets your “good” shot criteria.

I have a Rainstorm .22 that out of the box fired its first shot at almost 50 fpe (1029 fps). It was down over 100 fps by the 10th shot. I think after 40 shots, I had AVERAGED about 35 fpe. This was not of much use to me. I decided to change the hammer spring. I put one in that was 2lbs lighter (same length and same diameters, but fewer “twists”. I can’t remember if it was 8 lbs or 10lbs. Then the gun really started to shine. At a 200 bar fill, the first shot was 41 FPE, It peaked at 42 FPE and after 40 shots it was down to 40 FPE. EVERY shot fell into the “good” shot category. I was also able to fire 10 more shots between 40 and 38FPE which by the 10 shot in a row definition you defined, would still be “good” shots. I don’t consider them “fully” good shots as the scope is zeroed for 41 FPE, but understanding what I have in the last 10 shots, I certainly would take the as opposed to not taking the shot. I REALLY like the flater power curve that I get with the lighter spring AND the increased “good shot” count. 50 FPE does have some sort of appeal, but the FPE drops SO FAST from there it is just not worth it.

Bob,

Okay, you had exactly the right experience. The one I was hoping for. You realized that you could back off the power a little and get a big return in the number of similar shots. That is how I would approach this situation.

Thanks for sharing that.

B.B.

In all honesty, Discovery is my inspiration when tweaking my pcp. I don’t own scuba, so efficient pcp is a must. In my opinion, Crosman with their Discovery is really opened up the door for newbies like me who shy away from pcp due to high fill pressure that cannot easily achieved with pump. Ok not that hard pumping to 3k psi. But 2k is REALLY no big deal with reasonable air tube capacity. Even if you flinging 200 pellet a day.

My rifle originally (the valve, hammer spring, hammer travel) optimized for 2300psi fill down to 1500. It hit 1000fps or more with 10.5gr pellet out of the box. Of course it was also air hog with loud report. Accuracy was so-so.

BB’s blog helped me tremendously on tweaking this rifle and setting specific target . I know that more fps toward supersonic is not always better for accuracy. BB also pointed out that sacrificing few fps could easily doubled shot counts.

So after long hours of quality chrono time, lots of different springs, valve tweaks and all, I can say that the balance is there. And this blog helped me achieved that.

I’d agree with J-F that the only immediate advantage of high fill pressure is if regulator involved here. For non regged rifle, finding the sweet spot and balanced parameter we want at the lowest possible pressure is, in my opinion, the ideal.

Lee,

Thank you so much for your feedback. See, I didn’t even know you owned a Discovery, but you were already thinking like I was, so my explanation made sense to you.

I’m glad you have been able to adjust your Discovery as you have., Now — what advice would you give to other shooters about the importance of owning a chronograph?

B.B.

Start to save your money. Beg. Steal. Anyway to get the chrono.

Or do like what I did, “poison” a couple of shooting buddy and share the cost of decent chrono.

Seriously, without chrono you cannot unleash the full potential of your rifle. Oh you can get by the ear-o-chrono method or POI change. It comes with experience, but will never substitute a chrono.

By the way BB, I don’t own a Disco. What I have is locally made PCP with design parameter similar to Disco. But the decision to buy and tweak that rifle did come from reading about Disco.

Lee,

That’s even better!

B.B.

Very interesting article, as always, B.B.!

LOVE that Barnes rifle! Don’t suppose you still have it and can blog it???

Maybe regulated guns are also worth discussing. A regulator gives us yet another way to think about useful shots on a fill, and it changes the meaning of the max. fill pressure, right?

The pyramyd product page for the BSA Scorpion 1200 SE describes the rifle’s valve as self-regulating, but Paul Capello’s new video review claims that it is regulated (IIRC!). Any idea which is correct? To my mind, the unusually high fill pressure on that rifle makes a little more sense if it’s regulated. In that case, the max. fill pressure is really something more like “as high as you can go beyond the reg’s pressure, up to the reservoir’s rated max”, right?

I’m on the same page as RidgeRunner on reckoning my shots per fill. I know where my Marauder’s 48 shots at 11.5 fpe within 2% are for the FT matches, but I can happily push it to 90-odd “plinking grade” shots, depending on the range.

Then again, with an mrod with a big scope and well known dope, “plinking” often winds up being paintballs at 45 yd and other small stuff, and you find yourself reverting to the “match grade” shot string. Plinking with precise rifles like the mrod demands smaller tin cans!

-Jan

Jan,

I sold the Barnes gun more than a decade ago, but I can still blog it. I have the pictures, plus a huge report I did in an Airgun Revue.

Not a bad idea, because it happens to dovetail with a second article/test I did with Dennis Quackenbush about the hand pumps of antiquity.

Good idea!

B.B.

You already did a 3-part blog on the old site about the vintage pumps. As before, here are the links. Read it soon as the links may change when they move these to the new site permanently:

http://airgun-academy.blogspot.com/2008/11/hand-pumps-of-antiquity-part-1.html

http://airgun-academy.blogspot.com/2008/11/hand-pumps-of-antiquity-part-2.html

http://airgun-academy.blogspot.com/2008/11/hand-pumps-of-antiquity-part-3.html

Edith

GenghisJan,

B.B. already did a blog about it on the old blog.

They’re in the process of moving the old blog & blog comments from blogger to this site. So, here’s a temporary address for that article. Read it soon, as I don’t know when it’ll disappear because they’ve assigned another/permanent address to it:

http://airgun-academy.blogspot.com/2008/12/outside-lock-rifle-by-gary-barnes.html

Edith

Edith,

I will still do the other article on the hand pumps of antiquity, and tie it into the Barnes gun.

B.B.

Thanks, Edith! You’ve done more than help me find the old Barnes article; you’ve dispensed with this notion I must have been harboring that I’ve read ALL the old blogs! Remedying the fact that I haven’t is going to be FUN!…

And thanks, B.B., for thinking of fresh blogs on these topics!

-Jan

BB

You have mentioned many times about what a usable shot means. And it is about how the shooter is using his gun. And personally I like the way you give that information when you test guns.

One thing is definitely important is a chrony.

I have a few guns with the Marauder design of adjustment. Each one of the guns like different pellets. And each one I can shoot with a lower fill pressure or higher fill pressure.

The twist rate blogs with the different weight pellets explained alot also. The fill pressure and the way the valve hits can only do so much for the fps of the pellet and when you get to that limit.

Your just wasting air at that point.

The Talon SS has been a interesting gun for me also. I like the fact of being able to adjust the gun up or down easily with the thumb wheel adjustment. When I first got it I was happy that it was shooting at a lower fill level. I have tryed higher fill levels and it actually hurts the performance of the gun.

What I learned from the Talon SS is you have a gun that can be turned up or down easily for fps with the given fill pressure.

And the way I see the Marauders with that type of striker and spring adjustment.

To be a set it and forget it kind of tuning for the fill pressure you want and fps it shoots.

The transfer port flow adjusting screw on the side of the air tube is more of a fine adjustment.

But what happens when you don’t have a adjustment for the spring or striker like the Discovery.

Could a Discovery shoot at a higher fill pressure if it had a adjustable spring and even a modified striker that would give a longer stroke. Or would it waste air also at some point.

I already know that answer. I done it. It only picked the gun up a little in fps (maybe 50fps) and I actually got less shots per fill because it was wasting air. On the other hand when I backed the adjustment all the way off the spring tension the gun would hardly shoot (partial valve lock) but I lowered the fill pressure and the fps came back up and I got alot more usable shots per fill.

I think its all about finding the right balance for the gun you have and the pellet you use.

GF1,

And now you know a lot more than most people about how a Discovery works.

B.B.

BB

Well you know the blogs are very informative. 🙂

And I sure have messed some things up learning the hard way.

And it seems like you always get the blogs done in just the right order.

That can’t be by accident is it? 🙂

GF1,

I am listening to you guys and keying off what I see you talking about.

B.B.