by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Knock-open valve

- Dwell time

- Window of operation

- Timed valve

- Outside lock

- How it works

- Pure genius

- Skill beyond belief

- More to come

My new book, BB Guns Remembered, is a collection of short stories that deal with airguns. The stories aren’t really about the guns — they are about the people who owned them. It’s a nostalgic look back at a simpler time. The last chapter is a fictional account of the invention of an air rifle that takes place in the early 1700s. In The Wind gun of Prostl, I take the reader through the thought processes that might have transpired when the outside lock airgun was first invented.

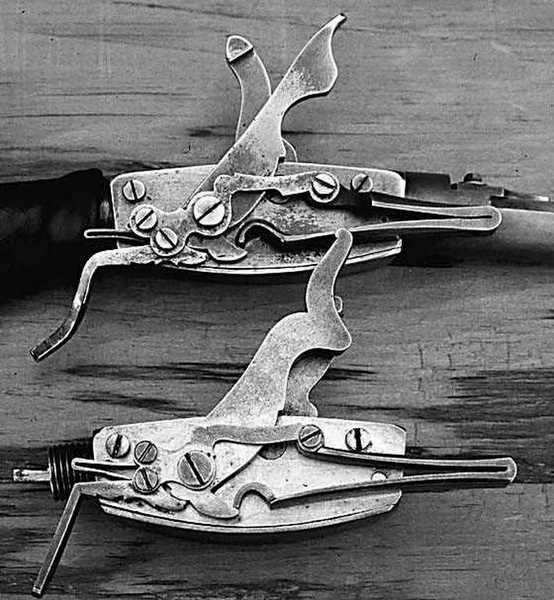

Nobody knows when or where that took place, nor do we know who the inventor was. But I had the unique opportunity to watch airgunsmith Gary Barnes examine a lock from about the year 1730 and then struggle — first to understand how it worked and then to determine how it might have been made in the early 1700s.

Knock-open valve

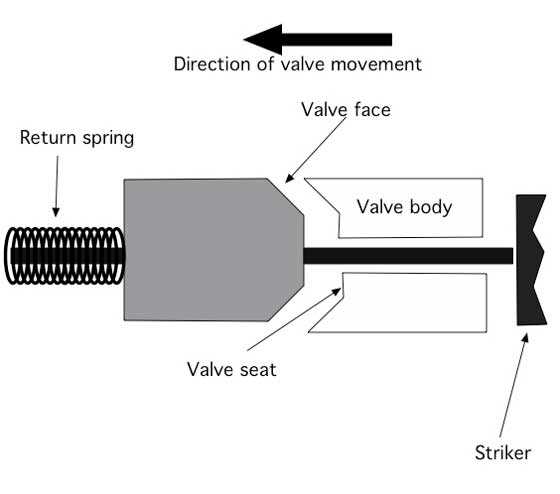

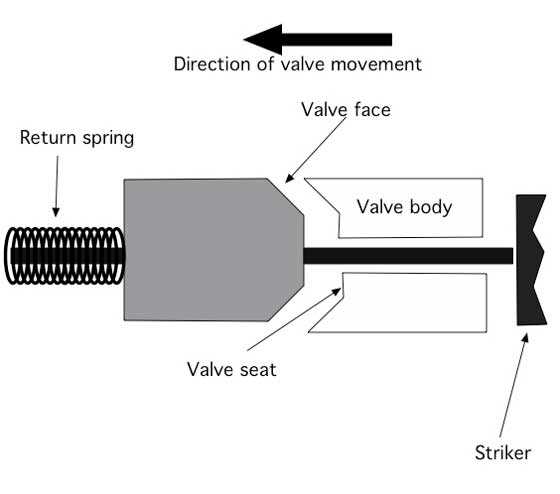

Today I want to show you around the outside lock as Gary and I saw it years ago. Most of you are familiar with a knock-open air valve. A weight caller a striker hits a valve stem and forces it to move, opening the valve. That allows compressed air to flow out of the reservoir the valve is sealing. Here is a graphic of a simple knock-open valve.

A knock-open valve works wonders in modern pneumatics.

Dwell time

Knock-open valves work well in pneumatic guns. They rely on a number of things to do their jobs, and those things are: the air pressure inside the reservoir, the size of the valve seat, the size of the air passage through the valve, the strength of the valve return spring and the force with which the striker knocks the valve open. All these things taken together determine the amount of time the valve remains open for air to escape. That time is called dwell time.

As the air pressure inside the reservoir drops, the pressure that remains puts less force against the valve as it closes. Therefore the valve stays open longer. But the air pressure is lower, so less air flows out. But lengthening the amount of time the valve remains open offsets the slower air movement, with the result that the projectile gets about the same amount of push every time. You either have high pressure air available for a short time or lower pressure air for a longer time. When a valve works this way we say it is a self-regulating valve.

Window of operation

The self-regulating valve operates within a window of air pressure inside the reservoir. If the pressure goes too high, the valve doesn’t open all the way and the velocity is lower — if the gun even works at all. Then, when the air pressure drops to a certain level, the valve starts to operate as it should. And when the air pressure drops below a certain point, there isn’t enough air remaining to sustain velocity, because the pellet leaves the barrel before any additional push can be delivered. So there is an upper and lower limit to the reservoir pressure within which the knock-open valve will work well.

This window can be adjusted by changing the size of the valve seat, the air pressure inside the reservoir, the size of the air passage through the valve, the tension of the valve return spring and the force of the striker. But, as the maximum fill pressure in the reservoir goes lower, a limit is eventually reached where only a couple shots are possible, and those even have widely different velocities. At low air pressure the knock-open valve is not the optimum design. Enter the timed valve.

Timed valve

A timed valve operates differently than a knock-open valve. It holds the valve open for a specific length of time each time it operates. A differing amount of air flows through a timed valve, depending on the air pressure inside the reservoir. There is some self-regulation, because the air does resist the valve from opening and also helps close it again, but compared to the knock-open valve the timed valve isn’t as consistent.

However, the timed valve does work well at lower air pressures. It was an ideal valve for the airguns of the 17th and 18th centuries thqt had to operate at 500 to 800 psi. The valve we will look at in this report is an early form of timed valve.

Outside lock

This valve has several names and none of them are official. Some people call it a Liege lock because many of them were made in that city. I call it an outside lock, which describes what it is. This lock has most of its operating parts on the outside of the lockplate, because several of them are too large to fit inside.

The one part that absolutely has to be on the outside is the mainspring. To generate enough power to operate the lock there is no room inside the action for this spring. Because it is outside, it makes good sense to put all the parts it powers outside, as well. That way no complex linkages have to be made to pass through the lockplate.

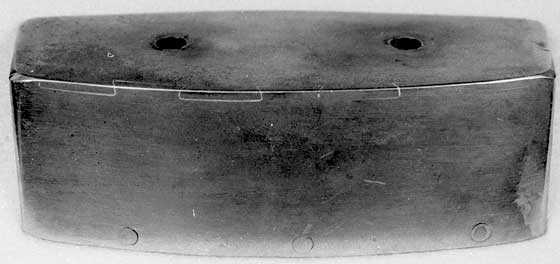

Here is a thousand-word picture. At the bottom is an original outside lock from about 1730. On top is the lock made by Gary Barnes, after he studied the original to learn its secrets. Both locks have a mainspring that’s too large to fit inside the action.

Barnes’ outside lock rifle is a .25-caliber single shot.

How it works

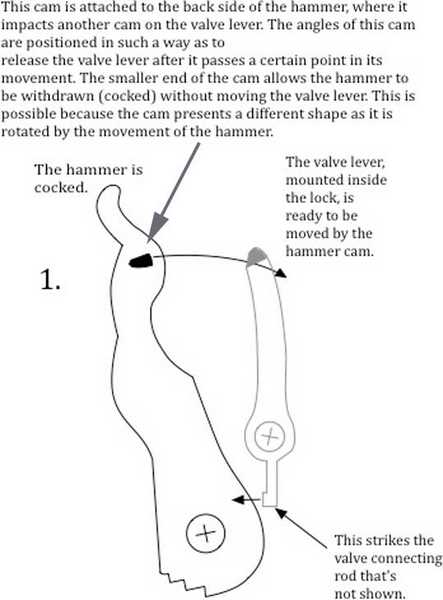

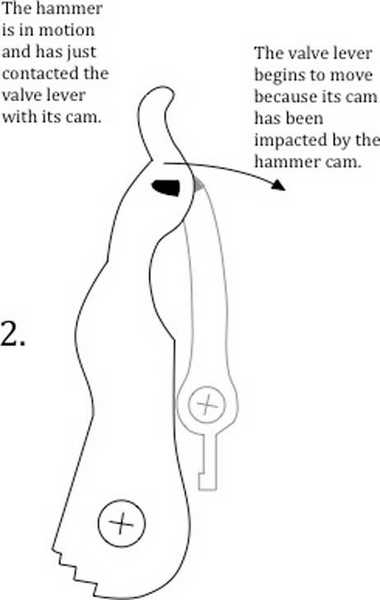

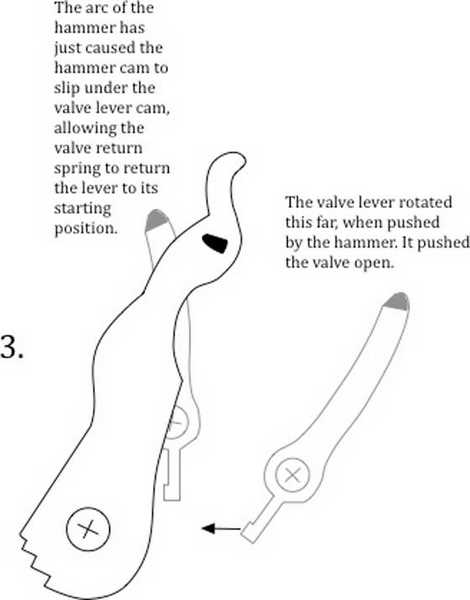

The outside lock works by pushing the valve open, rather than hitting it. The hammer moves through its arc and for part of that arc a cam located on its back side engages a part I call the valve lever. The valve lever also has a cam, so the two parts move together for a time until their respective arcs cause their cams to disengage. The bottom of the valve lever pushes a connecting rod that opens the valve.

Is that confusing? How about a drawing that illustrates it?

These drawings are very busy and may have to be enlarged to see all of the detail, but this is how the outside lock works. Don’t concentrate on the top of the hammer. The real action takes place at the bottom of the valve lever, because it pushes the valve open.

When the hammer is cocked the two cams do engage on their back sides, but the hammer then pulls the valve lever away from the connecting rod, so there is no loss of air.

Pure genius

When you look at how this lock works you realize it took a genius to figure out all the complex relationships. Remember, this was all done at a time when air was just an invisible substance. People didn’t really know what it was, yet these guys learned how to harness it most effectively. In the next report I will tell you just how successful they were.

Skill beyond belief

But the wonder of the outside lock doesn’t stop with the design. The craftsmanship that was employed to make it is at a level we seldom see today. The bottom cover of the lock, for example, is made from two iron or steel plates and is curved to accommodate the bend in the lock. The plates are joined by a complex dovetail that extends 90 degrees into each plate. In other words, there are dovetails cut into metal that’s bent 90 degrees, then the entire assembly is brazed together with joints almost too tight to appear in photographs. They can be seen with a jeweler’s loupe or in an enlargement. Gary Barnes replicated the work, but with joints large enough to be visible.

Here is a 5X enlargement of one dovetail joint on the original 1730 lock cover. I had to Photoshop this image a lot to show the joint line! This work was done by hand with a file, and it extends along the entire joint.

Gary Barnes’ lock cover joints are more visible because the braze is fresher. They go all the way along the plate at the bend. You just can’t see the joints on the right because they are too small. Notice the 90-degree bend in the dovetails.

More to come

There is more craftsmanship to see in the next report. Then I will tell you about the performance of this unusual piece that I was fortunate enough to own for a while. If you are interested in my book, BB Guns Remembered, Pyramyd AIR should have it available soon.

Thanks for this timely article. I was just wondering what were the factors involved in a knock open valve for the past week and here you come with an article describing just what I need to understand it. There are a lot of factors involved I see and a lot of people have been playing around with all of the factors you mentioned. Unfortunately or fortunately, over here de-liar Chronographs are just coming into use, so separating what works from what sounds like it works is going to take some doing. Previously pneumatics were tuned only by ear due to the cost of getting a Chronograph. Now we have a tool that can tell us how good or bad a tuning really is.

Maybe you should include the link to your original article of “An outside-lock rifle by Gary Barnes”?

/blog/2008/12/an-outside-lock-rifle-by-gary-barnes/

Siraniko,

I left that link out intentionally. because I plan to cover the same ground in this report. I will also touch on some other reports — like the test Dennis Quackenbush and I did with single-stage hand pumps.

B.B.

After reading that article I did notice you covered the ground that was in the article more thoroughly this time. The explanation on how the cam actually works was not in the previous article, must have been from your article in Airgun Revue. I await the rest of the story for more inspiration on how pneumatics have evolved.

Siraniko,

No, I actually described how the action works this time more thoroughly than ever before. I knew from past questions that people have a difficult time understanding how this lock works.

I guess practice makes perfect.

B.B.

Intriguing for sure! I’ll try to get on the computer tomorrow so I can blow those diagrams up. The black & white with absence of a hint of color speaks volumes of the lack of visual stimulus you endure daily. Sorry for that but it makes me sad and I had to spit it out.

I recall checking out the Giradoni design a few times but I guess that would be a cross between a hammer and striker design anyway I thought I understood it fairly well considering how much detailed information there’s available for review, this one’s gonna take some time and work to get my head around though.

Reb,

Actually, the Girandoni is also a timed lock. It is just a simpler design with few moving parts. You need to keep in mind that the Girandoni was made in Italy and the Liege was made in Germany.

RR,

Liege is in Belgium. You’re right about the Girardoni, but it came along more than 50 years after the outside lock.

B.B.

BB,

I have seen photos of several of this design that were labeled as being German and as you pointed out this design has been labeled as a Liege lock, hence my confusion.

Reb,

Those pictures were taken back when I used a film camera. I was getting the greatest detail with a certain type of B&W film, and all out publications were B&W, so color wasn’t an issue.

It wasn’t until I started writing for “Shotgun News” that I had to learn about color, and by then I had switched to a digital camera.

B.B.

BB,

I truly wish I could find someone to build me such a lock. A .357 muzzle loader such as this would likely finish off my “collection”.

RR,

Dennis Quackenbush built at least 10 Liege Locks about 15 years ago. People just didn’t respond to them. You might be able to find one floating around. At least one was a .40 caliber.

B.B.

BB,

Oh, I know. I have tried to talk to him about them and it is a very sore spot. I think he built about 20 back in the late 90s and it took him about 5 years to sell them. I wish I had known about them back then.

B.B.,

Is this concept of dwell time used in the Discovery and/or Mac1 USFT, allowing for lower reservoir pressure levels Than most pcps?

Also, why don’t multi-pump rifle makers employ this design? COULD it be applied to them? Steve Woodward’s modified Benjamin has a “hammer de-bounce device.” Pump it up eight times to begin with, shoot, and from then on, pump just 3 times for each shot. Does the de-bounce device likely work by increasing dwell time?

Sorry for all of the questions, but I have found this design fascinating.

Michael

Michael,

Both the Discovery and the USFT have knock-open valves. I’m not aware of any timed-valve guns being made today.The air pressure they work at is about half that of the USFT and one-third of the Disco.

The hammer de-bouncer simply reduces the effects of the hammer strike. Something similar was done with the original AirForce guns by putting an o-ring under the top hat.

B.B.

B.B.,

Reducing the force of the hammer strike is by design a way to lower velocity and increase shot count with the Marauder, isn’t it?

Please forgive me if my questions are kinda basic, but I’m not one who understands science and math quickly.

Michael

Michael,

The Marauder actually has two different ways to do this. One is by adjusting the striker and the other is by adjusting the flow through the transfer port. They work well together, but when one changes it affects the other.

B.B.

I think the Rogue used a timed valve, but of electro-mechanical in nature. Some of the electronic Daystate rifles may use a similar system.

David Enoch

David,

Good point! I was thinking about mechanical valves and missed the electronic ones.

B/B/

David,

If I understand Lloyd’s explanation of how the Rogue works, there is a solenoid valve that opens when the trigger is pulled and stays open as long as the program says. The air released by the solenoid valve is used to open the main valve. The problem with the Rogue is Crosman only used a single solenoid valve to open the main valve and relied on the main valve spring and/or air pressure in the reservoir to close the valve instead of a dual solenoid valve to open and close the main valve as dictated by the program. This is one of the reasons the Rogue does not work too well.

RR

Yep that’s a shame they didn’t stay with the 2 solinoids. That’s the whole purpose of the system to control the air flow efficiently.

That’s why I always say if a small bore air gun was made using 2 solinoids and a programmable computer you could have so many combinations of air flow at the touch of a finger. High pressure or low pressure could be used. You could even have saved programs that could be pulled up for different pellet types for that particular gun for a precise air flow.

If Lloyd’s system would of been used as he designed it the Rogue could of been a success.

Does it have a gauge? Sounds like dwell time is severely reduced from the stock configuration to leave air in the reservoir, which without a gauge installed would make it hard to determine residual pressure and additional pumps required.

RDNA,

No gauge. Gauges were two hundred fifty years in the future when this gun was first made. People had to count the number of shots they had taken, to know when to refill the gun.

B.B.

Sorry, not the outside lock, was asking Michael about the Benjamin pump debouncer mod he brought up.

Steve Woodward’s modified Benjamin forgoes a gauge by having a nodule pop out slightly, just like those “It’s done!” nodules that pop on a Thanksgiving turkey. It signals when to stop pumping, lest one risks a case of valve lock.

For pest hunting, pump it 8 times, shoot, pump it 3 times, shoot, pump it 3 times, shoot, etc. OR for plinking you can pump it up 8 times and get three shots off, each of which is at about 40 % power. Ah, but then to continue you need to pump it up from scratch again. It seems that a plinker could just pump it, or any Benjy, just 3 or four times for each shot.

Michael

The craftsmanship involved in making the outside lock is dumbfounding, I can imagine if they had a cnc machine back then we would actually have flying cars and space colonies by now! Unfortunately the ability to quickly produce a part, and do just about everything quickly now days, seems to have dissuaded the majority from doing things by hand with the meticulousness of old invention. Luckily there are exceptions, like Barnes and Qaukenbush, Duskwight here on the blog, and Tom Gaylord, whos writing is certainly meticulous and persistent toward a masterwork collection like none other in the field. Thats why I love building fences, I did it for 5 years and its almost all types still done like it was a long time ago, and getting wood buried in the ground to stand up straight and follow a beautiful aesthetic is a fulfilling task.

Thanks B.B.! My favorite kind of blog!

Happy Monday all!

Fantastic, Tom! I can’t wait for the follow-up article!

BB,

I have had the idea of a muzzle loading airgun which holds only a one shot air charge. Ron Sauls suggested that a dump valve similar to that used on a Crosman 140 rifle could be attached to an external hammer. You might be able to hide a small air tank in a powder horn and use the powder horn to charge the rifle, similarly to charging with black powder.

David Enoch

David,

Makers don’t like to make muzzleloaders because if there is a valve leak the gun can fire at any time. Dennis has made a couple and I think Gary Barnes made a few, but as a rule they don’t want you out in front of the muzzle with a gun that might fire on its own.

B.B.

B.B.,

That is why I wait to cock my 499 until after I load it and have it pointed in a safe direction, After all of the “You’ll shoot yer eye out, Michael” yucks I’ve had to put up with from friends and family when they hear I’m an air gun enthusiast, the last thing I’d need is to actually do it.

Michael

Very interesting. We believe we are more advanced technologically and idealogically. Mankind has been capable of really advanced things for 5000 years. I am often intrigued by the early watch and clock makers not to mention pre industrial crafts. Sharp tools and big brains can accomplish wonders.

Kind of a coincidence. Me and Buldawg was talking about the outside lock and the electronic valve of the Rogue over the weekend.

I would love for somebody to make a modern day outside lock again. Maybe as mentioned above. By Dennis. Or even a small bore electronic valve system. Not a big bore like the Rogue.

Could you imagine the shot count you could get from a .177 Marauder with a electronic valve system.

GF,

If you replace the striker and spring in the Mrod with a solenoid, and then have a microprocessor that controls the solenoid pulse length (and/or voltage?) to strike the valve with a variable pulse length and/or force, with possibly a pressure transducer in the reservoir so it knows how much oomph to give ‘er…then it would likely perform darn near perfectly from 3000 to 1000 psi or even lower. Would take some time to develop the programming to get the most perfect pulses for every pellet (say that three times fast). Fun project for somebody’s 13 year old who has learned to program arduino controllers.

But you still need to get a barrel/shroud system that responds the same way to every shot. My .177 can give consistent shot velocity for about 50 or 60 shots from a 3000 psi fill, with the current tune. But after about 30 shots, the POI starts to drift around more than I like, so I usually stop and pump it up again at 30. Of course, the bent barrel that came with the gun is probably part of the problem.

BenT

I thought you had a .22 caliber barrel?

GF,

My Mrodr was a .177 first, then I tried changing it over to a .22, twice, to no good end. Maybe I should have bent the .22 barrel to match the .177? I never knew the .177 barrel was bent until I took it apart to change barrels. It’s back to being a .177 again, and I’m happy with it (can still take doves and pigeons at 50 yards, as long as the wind isn’t gusting too hard).

BenT

How did you test to tell if the barrel was bent? And where was it bent at?

GF,

I rolled the barrels across our granite countertop. The .177 and the first .22 barrels both had about a 1/16″ of bow, near the muzzle end. The 2nd .22 barrel I got (swapped with Crosman) was pretty straight, but it didn’t shoot much better than the 1st one.

BenT

That would not be good with the shroud and baffles in place that’s for sure.

I have heard people say they have bent there barrels back straight. But I never tryed it so don’t know how that turns out personally.

And I don’t know if you ever watched the FX factory tour video. But one of the processes in making the smooth twist barrel is straightening it. The video shows the owner of FX straightening a barrel and checking it on a fixture with a dail indicator.

If you get a chance watch the video. It’s got some other cool stuff to see also. Search “FX factory tour video” and it should come up.

GF,

I’ve looked at the FX videos, and there is also a YouTube video of a guy who tries to straighten his Mrodr barrel. I don’t have the cojones to do that, especially with the .177 shooting as well as it does, within its somewhat limited pressure range. If I ever decide to, I might put a Marmot Militia .22 barrel on the Mrodr…but then what would I do with the .177 barrel?

BenT

I’m sure somebody would by that .177 barrel if you listed it.

BB,

Great article.looking forward to the follow up.

Thanks

Pete

A new Book??!!!

Amazing what you can accomplish when you can’t sleep.

kevin

I was going to ask where to get your book and you held that back until the final line. 🙂

As for the wonderful craftsmanship of the air-lock, the great is the enemy of the good i.e. mass production.

Matt61

Tom, that is a great article. Love the closeup shots of the dovetail joints. I wonder how many hours with a jeweler’s file it took to make those? Then again, what a great way to while away the winter evenings? Thanks again, and looking forward to the next one.

BB,

Will there be a kindle version of your book?

Ton,

It’s already up for sale on the Smashwords website.

B.B.

BB, You are such a resource! To have all this knowledge and, just as important, publish! Too many people have the knowledge (not just about airguns) and never share it.

Thank you, BB!

Gunfun,

I finally got around to installing the safety detent on my 2240, I had quite a bit of difficulty guiding the trigger and search pins into their bosses in the plastic cover but finally got it right.

I tried finding the thread we started to post this as a reply but there it is.

I’ll work on the transfer port again tomorrow.

Reb

What are you doing to the transfer port?

Trying to eliminate the need for more than one piece due to the steel piece moving during barrel swaps.

It looks like it’s alright if I do have to use it but it’s a pain and I plan to be swapping more than once.