by Tom Gaylord

Writing as B.B. Pelletier

Today’s report is written by reader 45Bravo. This is Part 1 of his report on resealing the Beeman P17 air pistol. This report will go differently than some in the past. We will first learn how to reseal the pistol and then I will test one for you in the usual way.

If you’d like to write a guest post for this blog, please email me.

And now, over to you, 45Bravo.

Resealing the Beeman P17 air pistol

This report covers:

- Help!

- What it is

- The reliability problems tend to come in 2 forms

- Where this pistol came from

- The repair — things you need:

- Parts

- The easiest and most common repair

- Editor’s notes

Help!

My Beeman P17 pistol just died! Should I toss it and buy a new one, or should I fix it? Perhaps that sounds wasteful, but for an air pistol that costs less than $30, maybe not so much. If you haven’t been living under a rock, you probably have heard of the Beeman P17.

What it is

The Beeman P17 is a Chinese-made copy of the German-made Beeman P3, or Weihrauch HW40 PCA single stroke pneumatic pistol.

The P17 evolved from the Marksman 2004 that B.B. did a short blog on back in February 2006.

It is a single-stroke pneumatic, single shot pistol, styled after a modern semi automatic pistol. The grip is very reminiscent of a Walther P99 9mm firearm, though I have linked you to the CO2 pistol that looks the same.

The pistol has fiberoptic sights, an 11mm dovetail rail running between the front and rear sight, a very good trigger, and a dry-fire option, it also delivers excellent accuracy for the money.

The Beeman P17 has a hit-and-miss history of reliability issues that can be expected from a $30 copy of a $230 pistol.

The reliability problems tend to come in 2 forms

1. Not building pressure.

2. Dumping its air as it is cocked.

Both problems are easily repaired. Even with the reliability problems, in my opinion this is the best thirty dollars you can spend on an air pistol. Let’s get started!

Where this pistol came from

A fellow GTA forum member posted about his P17 dying after about 2500 pellets. He said he was going to buy a replacement, as he had gotten his $30 worth out of it. He wanted to upgrade to the Air Venturi V10.

I asked if I could buy it from him to write this blog about repairing them, and he kindly donated it to the cause.

My theory is, if something doesn’t cost you anything, and a replacement is inexpensive, you might as well take it apart and learn from it.

Even if you can’t put it back together when you are finished, you still have a neat bag full of spare parts, that is actually a 3D jigsaw puzzle, waiting to be assembled.

The repair — things you need:

2.5mm Allen wrench

2mm Allen wrench

Needle-nosed pliers

A 13mm wrench or an adjustable wrench

1/8-inch pin punch

A thin flat blade screwdriver to help separate the grip panels

Your favorite o-ring lube

Parts

1 #117 o-ring, for the main piston.

2 #009 o-rings, one for the breech seal, one for the valve body seal.

1 #006 o-ring, for the valve seat seal.

Many people say to use a #116 o-ring for the main piston seal, but on this particular pistol the #117 fits better.

The o-rings can be sourced online, or from local stores as they are not subjected to CO2, I bought enough for 2 reseals from a local Ace Hardware for less than $4.

Yes I could have gotten higher quality o-rings for more money, but since this is a price point pistol, I wanted to see how long hardware store o-rings will last.

The easiest and most common repair

The pistol doesn’t build pressure when pumped.

1 – Make sure the gun is unloaded.

2 – Pull the “hammer” back to open the action, (it is actually just a latch to keep the barrel latched closed.)

3 – Using the 2mm Allen wrench, loosen the set screw in the muzzle end of the piston arm.

Loosen the setscrew that locks the pin.

Using the punch, just push out the cross pin holding the piston in place.

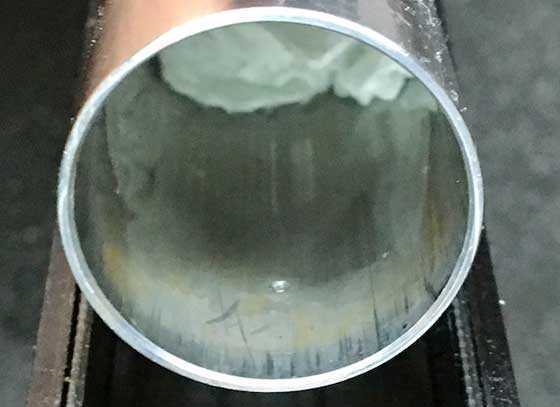

Pull the piston out, and wipe it down and examine the o-ring. You will probably notice a small divot cut in the o-ring. This is normally caused by a small burr at the air inlet in the receiver tube.

Replace this o-ring with the largest o-ring and set it aside.

There is the offending burr inside the compression chamber. It cuts the piston’s o-ring, destroying the airtight seal.

That tiny burr (arrow) was made when the air hole was punched into the compression chamber. It cuts the o-ring on the piston when it slides past during compression.

Looking into the opening of the receiver tube, you will see a small hole at the front that allows air to enter when the barrel is fully extended in its cocking stroke.

As you run your finger over the port on the inside of the compression chamber, you will feel a burr if there is one. We need to remove that burr or it will cut the next piston o-ring, and the next and the next…

Tip: I put paper towels inside the main tube to clean and seal the tube.

Using 0000 steel wool, you remove the burr. When you are finished, any particles of steel wool will be removed when you take out the paper towel.

If your pistol was not building pressure, but you could feel some resistance when cocking, you can now lube the piston and o-ring (the manual says to use white lithium grease,) and reinsert the piston in the tube. Replace the front pin and tighten the setscrew to hold pin in place and you are done.

Cock the pistol, point it in a safe direction, and function test the pistol by dry-firing. Hopefully it is fixed. Unfortunately that was not the case with the pistol I got, so that is something I will cover in Part 2.

Editor’s notes

I never had a problem with my Beeman P17. After 15+ years it still functions fine. But like many of you I have wondered what the differences are between the genuine German-made Beeman P3 and the Chinese-made P17. The prices are so far apart that there must be some differences.

When I was at IWA (the German SHOT Show in Nuremberg) in 2006, Hans Weihrauch, Jr. told me his company fixes P17s (they were called Marksman 2004s at that time) because people think his company made them. They do it to maintain goodwill, though there was not a licensing agreement between them and the Chinese back then. I don’t know if there is one today. What can the differences possibly be?

Because this pistol is a classic and because I am curious, I bought a used Beeman P3 off Ebay to examine. It comes with a $200 premium dot sight and the price for everything including shipping was less than that, so like 45Bravo mentioned, I won’t be out anything. And with this report plus the one that’s coming I will be able to fix it if anything goes wrong. Just for fun I followed this post and disassembled my P17’s piston. I then cleaned it and lubed it with lithium grease. The inlet hole in my pistol had no burr.

When I test the P17 for you after this resealing report is finished, I plan to move on and also cover the P3. Maybe we will finally learn the difference between a $30 pistol and one that looks similar yet sells for $230!

When I started the rebuild I looked online, the P3 compression tube and valve are about $53,

Hello?, that’s almost 2 p17’s!

It will be interesting to see a side by side comparison between the two pistols.

Ian

Thanks for this. I do have one of these, but have hardly shot it yet.

Ian,

Won’t it, though? I guess it was meant to be.

B.B.

Ian,

Did you know that .22 barrels are supposed to be available for these guns? I saw it on the internet so I know it’s true.

Half

While comparing Beeman P3 parts cost, I did see that .22 barrels are available for the P3, so they should be a drop in for the P17.

But I wonder what the velocity drop would be.

45Bravo,

Titus Groan posted a comment below that has the answer to that question, in case you may have missed it.

Half

Halfstep

Yes, barrels are available from Weihrauch in .177, .20, and .22 cal for about $45 Can five years ago. I changed the barrel of my HW40 from .177cal to .20cal. It only shoots 297-305fps with 11.42 H+N FTT pellets, so I will probably switch back to .177cal where it achieves a steady 387fps with 7.33 JSB Exact RS pellets. Much better for accuracy in my opinion.

Ciao Titus

Titus,

Wow! $45 CD for just the barrel. I won’t be going that route anytime soon. I would be interested in the .22 barrel anyway and that would probably be verrry slow. Thanks for the info.

Ciao, right back at ‘cha!, Half

This is a fantastic pistole for the price with some TLC it will be similar to the P3. Polish the barrel at both ends and the burr on the intake air hole on the cylinder and this is a fantastic pistole. It is easy to work on and simple what more do you want.

45Bravo great report on a gun that loves a little TLC. BY FAR A BEST BUY.

Don

Don,

I have 2 of these guns and would like you to explain further ” polish the barrel at both ends “, if you don’t mind. My guns are accurate but pellet picky and I hope you are describing a fix for that.

I have cheap 2X pistol scopes on mine with 2 piece rings. It gives better leverage for much easier cocking but makes the guns heavier than ideal for my taste.

Thanks in advance for any tip, Half

Half,

Good questions. Before I proceed let me say that these efforts can make things (accuracy) worse. I have only had that happen once so far, at least to the point it was significant.

I start by pushing a pellet through the barrel with a brass cleaning rod. I usually start at the breech and push to the muzzle. Often you can feel a spot where the pellet hangs up. If it is a burr the pellet normally has a scratch or gouge at one spot on the side of the pellet. A prime place for a burr is where the hole in the side of barrel is drilled for the air to enter this pistol, as you know, does not have a port, the air enters the end of the barrel. if the pellet hangs up but shows no scratch or gouge then it is probably a ridge left from machining the barrel and can be at either end of the barrel. Sometimes just shooting pellets through the gun will eventually take care of a burr. Shooting pellets through a barrel with a significant burr or ridge to smooth it out may take forever. Often times there is a ridge on the crown and the pellet will stop as it is being pushed through the barrel just as the head of the pellet reaches the muzzle end of the barrel, the crown. If the pellet is hard to start in the leade there may be a ridge right at the breech end of the barrel. Push the pellet through from the muzzle and see where it stops.

I check the barrel with a flashlight and magnifying glass at both ends looking for a burr or ridge. If there is a burr I try to remove it by hand without using any power tools. I then polish it with a felt tip on my Dremel tool or a hand drill and some automotive polish. On the leade over polishing is not of too much of a concern but on the crown I try to be very careful. On the leade I have some felt tips that fit inside of the barrel and give it a good polishing once I have the burrs removed. On the crown I use a felt tip that is on a very flat taper and does not get into the barrel. I watch with the magnifying glass and stop when the lands and grooves look symmetrical all the way around inside the barrel. I try not to polish past the taper in the lands. Many folks use a brass round head machine screw and polishing compound for the burrs or ridges on the crown or lead end of the barrel.

I have numerous sets of diamond Dremel tips that are all shapes and sizes they also come in various grits from 200 to 800 More or less. I use these most of the time to remove a ridge. For this I want to maintain the alignment and make sure I keep the crown or leade centered in the bore. I put the barrel in my drill press to spin it while I remove small amounts of metal while holding the diamond Dremel tips in my hand. I don’t have a lathe. As I am doing this I frequently remove the barrel and push a pellet through to check my progress. Less is better than more in this case. Go slow and inspect your work often to be sure it is resulting in a symmetrical shape to the lands and groves. A ridge on the leade does not need to be done quite as careful as you are just smoothing and opening it up for the pellet to get started, still go slow and check the progress often.

This is a bit of an art to take your time. If you have one good pellet and are happy with the accuracy, I would stick with it. If you proceed select the pellet you want to shoot and use it for testing the barrel. Be sure to compare pushing the pellet that is accurate to the one you would like to shoot. There are many things that affect accuracy besides the barrel. If both your guns are shooting the various pellets the similarly that mite be something inherent in the guns and not necessarily the barrels. I will say mine does not seem to be pellet picky.

One thing I just thought of is I seat my pellets in these guns. The P17 pistols seem to like the pellet to be seated. Below is a tool I made to seat the pellets in these type of pistols.

Hopefully others will chime in on their thoughts.

don

Don,

Thanks so much for your quick and very informative response. I have the tools to do those operations and have very recently bought a .177 bore scope that I think would be perfect for this project. I think I will try seating the pellets first though to see how well that works out. Your tool looks as though it has a different “pusher” at each end. Is that to accommodate different skirt designs? Are you aiming to get contact with the skirt rim or are you trying to push more on the center of the pellet? Or do you think it even matters?

Half

Half,

A bore scope would be great, It would help. I don’t have one.

The pusher on each end was supposed to be for .177 and .22 caliber. Good eye. I seem to use the smaller one for both calibers. I was trying to only get contact on the center of the pellet not the skirt. It was also made for shorter pistol pellets and may not work on a very long pellet. Whatever way it works repeatability is the trick.

All of the pellet guns I can think of that push on the skirt fit snug against the inside of the leade matching the outside diameter of the skirt. Making a pusher for that would be tricky.

On a side note my IZH 46M does better without seating the pellet. The pellets also are easy to push just past the end of the barrel with my finger.

Don

Don,

I happened to be messing with my Colt Polymer Python when we started this discussion so I thought I would try pushing some pellets deep into the cylinder clips of that gun to see if it made any of them more accurate. I gathered up an assortment of ball point pens and felt tipped markers, along with their caps, in an effort to avoid deforming the skirts. I found that a retractable ball point was required most of the time, using the fully extended pen cartridge to get down inside the skirt. It made a few pellets more accurate, at 7 yards anyway. I don’t remember the pellet right this minute but I got a 10 shot group that was under a half inch and that was half the size of the group when I just flush seated it. I’m looking forward to trying it with the P17.

Oh, it did make some groups worse for me as well, so gotta try each one to see what ya get, I guess.

Half

I just purchased a P17 from PA a couple of months ago. It’s sweeeeet for the price tag. I put a tasco silhouette scope on it (1.5 x) with beeman hollow-points, 25 yard starlings don’t stand a chance.

My ten yard groups are one hole. Fun toy to take camping and plink ants and flys (only cause the chipmunks here in oregon are protected 🙂 )

45Bravo

Well $2 to rebuild one gun is better than $30 to buy a new one I think anyway.

And I bet those o-rings will last a long time now that the burr is gone.

Nice report.

45Bravo,

Nice report and pics. Looking forwards to Part 2.

Good Day to you and to all,……….. Chris

Ian,

Great job! Your report on the simplicity of repairing and maintaining this pistol is encouraging to us to go out and get one for ourselves. You are well on your way to becoming an enabler!

RR,

Isn’t he, though? I didn’t think of that, but that’s exactly what he is. 😉

B.B.

BB,

He certainly is. I have no interest in one of these things, but now I want to get one and fiddle with it.

RR,

Yeah, and strangest of all, you probably want to get one that needs resealing!

B.B.

BB,

Why of course. Close to half of my airguns were not functioning or needed seal replacement when I got them. That is one of the ways to get a really nice airgun at a very low price. You should have seen what I paid for two FWB 300’s.

Thanks guys, I try…

Tom, do you remember the nice boxed 79G that Chris picked up at the Texas Airgun show?

You used it as the opening photo about the show.

Well, that got him hooked on the vintage co2 guns, he had never explored that area of airgunning before.

I told him if he liked the S&W, he would LOVE the Crosman MK1&2 guns.

I told him I had a Crosman MK1 for him, but before I could get it to him he had bought a MK2 from ebay a day or so later.

1 month later, he now owns 6 of them, has ordered a LD from Mac1, and a LD kit to build his own.

Truth be told, when he finds something that interest him, he never dips his toe in to see what the water is like, he always does a cannonball off the high dive…

Ian

Ian,

Oh, my! He is in deep! Well, at least we know the water he’s in is safe! 🙂

B.B.

45Bravo,

This is an excellent report. Thank you. I own a P17 — everyone ought to — and so far I have been fortunate in that the seals have held up. However, I have always believed it was only a matter of time before one fails. You have provided an excellent guide here. I have bookmarked it for future reference.

Michael

Great report Ian!

I bought a pair of the P17’s and as preventative maintenance did a tear-down/deburr/lub before I shot them; your blog report will be a great benefit to anybody who owns one!

Just for the record, neither of mine had a burr inside the compression chamber so maybe the manufacturer is being more attentive to this (known) issue.

I found loading pellets to be a bit difficult and traced the problem to a sharp edge on the breech (where the barrel had been machined smooth/square where it rests against the seal) that was catching the head of the pellet. Removing (chamfered it slightly) that sharp made loading pellets much easier.

Overall I like the P17, they are very consistent in their velocity and were great shooters – an excellent value for the price!

Hank

Hank

That would be the lead in to the barrel. Basically like the crown on the other side of the barrel.

Sounds like they needed a inside chamfer on the loading side of the barrel.

That could be a accuracy problem like what a crown can cause on the muzzle end of the barrel.

GF1,

Yup, A light touch (by hand) with with a tapered Dremel grind-stone (followed with a good cleaning) was enough to take off the edge and make pellet loading easy.

I wanted to try de-tuning the P17 to reduce the cocking force so my daughter could cock the pistol easier. Figured that 400 fps wasn’t necessary for plinking cans at 10 yards so I was going to drill into the solid aluminum piston to reduce the compression a bit. Thought I would drill & tap a 1/4-20 thread into the piston and install a grub-screw so I could adjust the volume of the compression chamber to suit. Never got around to trying that.

Hank

Now that’s a cool idea.

Might even make smoother shot cycle.

Hank

I think you meant to stop the piston sooner after I thought more about what you said.

What I was thinking is make a air bleed adjustment. So in otherwards you could control the blow by of air in the compression chamber. Kind of like the old compression releases on the bigger cc dirt bikes so you could start them easier.

GF1,

I was thinking in simple terms – if I increased the volume of the compression chamber by drilling away some of the solid piston then the pressure, cocking force and velocity would be less.

Since I was going to do the mod by “trial and error” rather than calculation it seemed that threading the hole and adding a grub-screw would allow me to adjust the volume of the compression chamber by screwing the grub-screw in or out. In other words, if I drilled away too much material from the piston, I had a way of putting some back.

Hank

Yep I know what you meant.

But remember your making a piston stop by adding that screw to the front of the piston.

That piston will slam to a metal to metal stop with out the cushion of the front piston seal.

I think a bleed would be a far better idea then a stop.

GF1,

The hole is drilled deep into the center of the pistol. When the screw is adjusted it’s always below the surface of the piston. All he is doing is adjusting the volume of that hole by running the screw up and down. That adds volume to the compression chamber when the piston is all the way forward.

B.B.

BB

I thought that too.

But that will probably do nothing that you would ever notice.

That bolt would have to be a big diameter and drilled pretty deep in the piston to see any change when adjusting.

A air bleed would be the trick.

GF1,

The top of the grub-screw would be 1/16, or 1/8 or 1/4 inch BELOW the surface of the piston – the more it is screwed in the more volume there is in the chamber and less cocking force.

Hank

I know what it does.

I built alot, alot of race engines and understand compression pretty good.

Remember the old dome pistons. Then there was the flat top pistons and even the dish pistons.

What I’m saying is your idea will change the volume. But your going to need a big change to see a effect on velocity.

I played with all that on one of the FWB 300’s I had. The one that had the after market heavier single spring. I used a o-ring instead of the cast iron factory ring and I also put different front piston stops on it. I had a cupped or as I mentioned above. A dished piston stop and a flat top one. Really didn’t see much of any change in velocity with the different front piston stops.

But I seen a big difference in velocity with the fit of different o-rings.

Trust me. Blow by will control velocity more than the pistons volume will. Especially like what your talking about doing.

I did alot of taking apart and putting back together with my modified FWB 300 to get it where I wanted it.

All I can say is try your idea and let me know what happens. Then we will know for sure.

45 Bravo ,

One thing here to note is the o-rings. The o-rings You source at a Hardware store will be better quality than the ones used in China . My local ACE has a SAE and METRIC selection of o-rings and they are all made in the USA. This is the biggest QC problem on guns from China . Keep in mind not to buy your o-rings at Harbor Freight !!

Gene,

I gotta smile, because you see this from the other side — fixing the broken ones!

B.B.

Gene

Amen

Ian,

Nice report as usual, thanks for the repair lesson that many will use if/when the time comes. I wanted to comment on the P17’s soft, flexible polymer dovetail rail: I put a laser sight on mine and had trouble with the zero drifting, because the rail deformed when the tiny mounting ring was tightened. Very frustrating! My solution was to attach the laser with two rings (I bought two lasers) and the laser attachment became reliable and the zero stays constant.

Best regards,

Will

Great information Will, it stands to reason, 2 points of contact will always be more stable than 1 small point.

Ian

Will,

That’s a good tip. Thanks,

B.B.

My very first pistol was the Marksman 2004. I picked it up at the local WalMart, and it was so long ago, I have forgotten the price, but it was similar. I started shooting it in my back yard and, since I had never shot a pistol before, I thought all pistols shot that well. You aim at the target and that’s where the pellet was to go. That’s what happened with this one! Then I found that not all pistols shot that well. I have put all kinds of shooting helps on it: laser, cheap red dot, even one of those fancy multi-scopes. The latter let me see where I shot, but the 2x would have been just fine, or maybe a little bit better red dot. What an amazing value.

MichaelinGeorgia

Great report and looking forward to part two!

I’ve owned a couple of the P17’s and now am ready to do a re-seal when the time comes due.

Glad to see this report. I have had three of these, all have leaked as described. Seems to me that even when there is no burr in the cylinder, the O-ring will be affected by moving past the port. I know some people have had better luck. And when cocking the gun, putting pressure on the rear site with my hand repeatedly broke one of mine.

So, I wonder, is there some perfect O-ring (metric? something other than nitrile?) that would stand up better. I certainly agree the gun is a bargain, but if it were free, it has little value broken.

Thanks for the effort to describe this repair in detail, I will certainly give this a try.

Jerry

That’s a good point. It will eventually wear in that spot. Bummer.

JerryC,

I have polished the hole on the inside of the cylinder to remove the sharp edge I have not had any problems after that. I don’t know how long they will last but a good O-ring does not cost much.

Never expected to see a P17 report. The trigger alone is worth more than $30. I have had no problems with my P17 in several years shooting it. It is both accurate and powerful.

Tip: Use a golf club to cock it. Yes, load it with glove on also.

Deck

Deck,

I think you meant to say use a golf GLOVE to cock it. 😉

B.B.

BB

Yep. My bad.

I too am curious to know the differences between the P17 and P3 other than steel vs resin or plastic. Hope to find out soon.

Deck

I recently replaced the piston seal on a HW40 (i.e. the German-made original) with a quad seal – not because I had to, but to check it would work in an SSP before doing the same in a Chiappa 6004 – again, not because I had to, but I wonder if any of the benefits of quad seals over o-rings would become apparent, such as retaining lubrication better?

Unfortunately I’ve not used either gun much to get any long-term view of this,other than a quick chrono check which showed no great gain (or loss) in velocity. I wonder if anyone else has any views on this?

Iain

lain,

That’s one I have not heard of before. I wonder how well it works, long term?

B.B.

B.B.,

I bought one of these after I read your recommendation back in 2014:

/blog/2014/10/airgunner-christmas-gifts-for-2014-part-1/

which you repeated in 2016 (because the gun is that good =>):

/blog/2016/11/christmas-gifts-for-the-airgunner-part-1/

It was very accurate and shot great…till a friend talked me out of it…he loves it…guess I need to buy another. =>

Take care & keep up the great work,

dave

45Bravo,

Great report!

I purchased one of these for my Father-in-law a couple of years back for Christmas to shoot the mice in the barn, I don’t think he uses it much anymore and I have considered getting one for myself. Now I know how to replace the o-rings if ever needed!

Hi BB, thanks for this blog! i have the P17 and use it a lot! However, recently, it’s showing some of the symptoms of what you are describing. it just won’t keep the air in after cocking. i can’t wait to read the remaining parts!!

Regards,

Peter

Well another glitch in the system.

PA has the free shipping over $99 sale going on till August 1st.

Well just tryed to make a order and put in a discount code from the most recent catalog and it said the discount code was a better deal than the free shipping. So it gave me that and wanted to charge me $13 for shipping instead of the 10% discount code and the free shipping???

The free shipping discount over $99 says nothing about not being able to use with a discount code. Again???

Yep cancelled that order.

And yes contacted PA and the phone operator couldn’t do anything about it. At least he said he would make someone aware.

I know old Gunfun1 is showing signs of old age. Maybe I’m not reading it right or they are a bit off on their wording.

GF1.

Were you going to buy Daisy WC pellets in that order, too? I’m waitin’ for you to find us a reliable source for the “good” wadcutters. 😉

I think no combining is the policy all the time at PA and AGD unless they phrase it “such and such sale or % coupon AND free shipping “. I think it is a little misleading myself, also. And I, too, have cancelled orders when it happens, if I was on the fence about the order to begin with.( Fighting against my addiction, ya know.)

That comment about the hole in the pump wall eventually cutting the o ring, even if it were smooth, would hold true even on the more expensive versions of the P17, since they all use that pinhole as the inlet for the air. Might as well let it happen on the cheaper gun, I say, if it’s gonna happen anyway. Would bother me a lot less on a $30 gun than a $230 gun, know what I mean?

Half

Halfstep

I just received 6 tins of the Daisy wadcutters yesterday that came from their shipping house towards the west coast. I opened them immediately when I got them and they where the new type Daisy wadcutters. (What a relief there)

And for some reason my order of 8 tins got split because they said they was out of stock. So the last 2 tins got shipped from the Ohio house. I’m happy to say they arrived today and also was the new stock wadcutters. (Again what a relief)

So I think it’s safe to say that the new Daisy wadcutters are what’s in stock. Although I have received orders from a Pennsylvania house in the past. So not sure what they have there or if that is really where they ship from. (In other words no Daisy wadcutters from that house yet)

And yes I know what you mean about the addiction. I have scaled down my stock of pellets for awhile now. I order as needed instead of keeping well stocked ahead. Trying to budget better if you know what I mean.

So when the sales come. Even if they are a little more savings than normal I have been starting to stock back up. But not on their last 4th of July sales and such. I didn’t need them so I didn’t order.

Plus now I add up the costs and such and make high dollar premium pellet orders and the low cost pellet orders because of the by 3 and get the 4th free. Which is always the cheaper pellet ordered. So yes if I’m spending money now I want to save the most I can. And why not.

Oh and today was going to be a order of premium pellets. That’s when the better saving comes in. The 4th tin of the free pellet on a premium pellet could be up to $22 or more. The cheapy pellets is only $4.55.

So when PA says they are having such and such sale then I’m adding up costs. Then I order and they say nope that’s not what we meant. It’s like what the …. !

Yep I just realized I am getting old. Wouldn’t of even cared about it when I was younger. Darn anyway.

GF1,

Thanks for the quick response. I’ll add the Daisy WCs to my next PA order. I hope they are as accurate for me because my RWS Basics are now over priced.

Half

Halfstep

When you get them and try them let me know how they do.

GF1,

Yes, I sure will.

Half

Halfstep

Thanks. Will be waiting.

GF1,

I just opened my last beltpack of Daisy WC pellets and lo and behold they were the “good” variety !! I guess I had bought the last of the old stock with that order. I’ll let you know how they work out in my Poly Python and C02 and PCP 1077s when I get a chance to shoot them. I think those were the guns that got this debate started in the first place.

I can’t get over how much better they look than the crappy ones that I’ve been shooting all these years. I’ve seen lots of other people’s impressions that mirrored mine and since they also talked about how poorly shaped they were and with bent skirts and flashing, I think they were probably shooting the older ones too.

I also ran across a Daisy Match Grade WC. May have to get a tin of those to try even though they are the same price as the others but only have 250 pellets.

Half

Halfstep

Yep big difference. Never would of thought it till I got ahold of them old stock Daisy wadcutters.

Glad you got some. Do a side by side shooting difference between the old and new at some target paper at what ever distance you think is feasible.

All I can say is I seen a difference in group size between the old and new pellets.

But I’ll wait and let you tell the story when you get there.

Again will be waiting to hear.

GF1,

I found a local source for the new Daisy WC pellets in the tin. I remember that you thought that the ones in a tin were more accurate than the ones in the belt pack. It turns out that I have a half a pack of the old ones in the belt pack left over, so I did a side by side between the old style and new style in both the tins and the belt packs. I shot them from 10 yards out of my Colt Poly Python. I didn’t find any real difference between any of the 30 shot groups that I shot. I hadn’t shot this gun for accuracy in the past because I just planned to shoot Crosman WC or RWS Basics out of it to stay on the cheap, but as long as I was experimenting with this pellet I decided to test others, as well. That particular gun is hard pressed to do better than 2 inches at 10 yards with any pellet. RWS Basics were 1.40″ as the best pellet. I don’t have pics of those shots but I did get some pics of the next test, which is one of my 1077s at 12 yards.

In this test I shot 60 shot groups because I find that where in the power curve, on a CO2 gun, that you are shooting, affects the accuracy of the pellets, even at close range, and especially with wadcutter style pellets, for some reason. Collecting a record of all the shots over that curve is more meaningful to me than 10 shots with one pellet followed by 10 from a different pellet with a shooting platform that may have changed from the previous shots, then another 10 pellets and so on.

I filled 5 clips with 12 pellets each but, before I fired any pellets, I first fired 6 shots unloaded down the barrel to cool everything down a little. I saw from earlier testing that a fresh cartridge and warm gun shooting at over 600 fps for the first few shots skews the results and I think maybe the barrel shrinks a bit after it starts cooling, so I did it this way to mitigate those effects. I see these things happen because I am usually shooting through my chronograph to monitor the velocity while I shoot for accuracy. The gun was vised and I fired with just a second or two between shots. The first shots went off around 525 fps and shot sixty was usually around 250fps, depending on pellet weight.

In the pic the top roll is the New Daisy WC, the Old Daisy WC, and Crosman’s WC that comes in a 1225 count milk carton. You’ll probably recognize those black clips from the Umarex Colt Python. They are a little over 1 1/2 ” in diameter and I put them there for scale. These three seem to group about the same in this 1077. The lower row is the Daisy HP that I told you I usually found to be more accurate that their WCs, Crosman’s Pointed pellets from the milk carton, and then my faithful standby RWS Basic. I think the Basics seem most accurate here.

I’ll post some pics of the Daisy containers, the new pellets have a different look and Part #, and I have other 1077s that I will test the same way in the near future.

Half

belt packs

tins

Halfstep

Not really.

The new style Daisy wadcutters are much better in many ways. Cleanliness, accuracy and totally a different shape.

Show me some pictures of the Daisy wadcutters you have right now.

And I’m not going to say yet how my new laminate stock HW30s is doing. I was holding off till you gave more info on the Daisy wadcutters when you got them.

And I think you need to try all those pellets you show in a different gun. That’s not a very accurate 1077 after looking at the pictures.

And a Co2 gun is probably not the gun to test with. Too many variables. How about some known accurate pcp’s or springers. Show some old and new Daisy wadcutter’s and other pellets in those types of guns. Co2 guns are cool but not when we are talking accuracy.

Oh and by the way what distance?

GF1,

I’m sure I have the new pellets based on the pics you posted. What do you mean by the ” Not really” comment? I don’t follow.

I used the Python and 1077 because those were the guns we were discussing way back over 2 years ago when the topic of accurate and cheap pellets came up. The results I mention with the Python are at 10 yards and the 1077 was fired at 12 yards because that’s the max distance in my basement and it’s too hot outside for this old man.

I agree that there is a huge physical difference between the 2 pellets and I feel that the new ones are going to prove out, since they look better by all all standards. I just haven’t found them to be more accurate so far in these 2 guns.

I have many other guns that I WILL try them in, but first I want to try them in the many CO2 repeaters I own, which includes revolvers, blowback semi-autos (which are my brother’s favorites) and rifles like the CO2 and PCP 1077, since they are the ones that I want to get acceptable accuracy from at a reasonably cheap cost. I am willing to buy expensive pellets for the guns that I won’t be shooting a few tins through in an afternoon with my grandson and brother, but when I’m supplying the ammo for 2 or 3 people it needs to be cheap.

Go ahead and post your HW30 results. I suspect that you got good results and they will probably motivate me to stick with this new testing if I see what I can potentially get out of these pellets.

Half

Halfstep

I seen after I looked closer you said 12 yards.

And what I meant by not really is about the tin verses the box. If I remember right I said they could be different from the box to the tin. But that I’m now talking about the old Daisy wadcutters verses the new.

Let’s see some 10 shot groups with some different guns and just using the old style Daisy wadcutters and new style. Not worried about the other pellets.

Would like to know what your different guns do with just the Daisy wadcutters.

And haven’t got any pictures right now of targets from the new HW30s. But when I get some I’ll post the picture.

Gunfun1

I looked at the PA ad. I’m not only getting old, I’m already there. However there is nothing in the ad I received about not combining free shipping with their discount coupons.

I like PA and they need to fix this in my opinion.

Deck

Deck

Thanks for the response. Yep the way I read it is I should automatically get free shipping if I order over $99. Then I should be able to put a code in and a gift card from my bullseye bucks. And it should all apply. Kind of misleading if you ask me.

Great report! Simple and useful. I loved it. I enjoy a lot this pistol, it is awesomely accurate. My Walther CP88 is collecting dust.

I once saw in an Umarex catalog some little darts made for 0.177 air guns. Have anyone any info about it?

Greetings to all,

Anthony

Anthony

What you going to do with those little darts?

Yes they are available in .177 caliber.

Mainly bug plinking. But not much really. I just wonder about their behavior; I know that FX makes air guns that shoot arrows, but I have never seen one. And for those 0.177 darts, I don’t know what Umarex makes them for.

We use them for playing darts, You know, with a dart board.

Anthony

There kind of expensive to be plinking with if you loose them. And I guess you could reuse them. But I don’t think I would put them in a good gun. Don’t know but maybe might do something to the rifling in a barrel. But then again might do good in a smooth bore barrel.

If you get some let us know how they do.

45Bravo,

You lived up to a ’45Bravo’ in creating this Guest Blog about the P17!

I really enjoyed the complete Tools/materials and Parts required lists.

Great photography that showed exactly what was needed and no more.

Your Tips to make the work go smoothly (pun intended) were spot on!

Ian I’m looking forward to Part 2 of your Guest Blog.

shootski

I am not a big fan of the glow worms that were put on the sights in the recent versions of this pistol. Here is a picture of my front sight that I fixed with JB-weld. I also plugged the glow worm holes in the rear sight. I like it much better this way.

Don

I have done that on a couple P17s myself using both JB Weld and the liquid steel putty.

I was thinking about doing a report on how to do that.

45Bravo

Hoping you do a report on replacing the glow sights. They are not suitable for target shooting. I have painted them black but the sight picture is still not anywhere near as good as it could be. This goes for any gun, not just the P17.

Deck

That would be a good blog and apply to many new of the new guns. Please do it.

Purchased a Marksman 2004 when Tom first wrote about them in 2006. Have streaks at shooting it. Still just as hard to cock as new. Has the non-glow sights which are nice to use. Just have to avoid the rear sight when cocking, That can hurt. No problems in all those years. Just a nice pistol that all can afford, well worth it.

Thanks to 45Bravo for the repair how-to……

45Bravo,

Thanks for a great and very instructive report, I will be looking forward for the next entry.

I also have a P17 that shoots very well – when the trigger works, which unfortunately is not every time. I tried a couple of times to fix it with no luck. I am not done yet, I will keep trying until I fix it or wind up with a bag of parts.

If I am lucky fixing the trigger and with your information I will replace the o-rings and check for burrs.

Henry

PS. Sorry for the late comments but I am catching up. Cheers!

45Bravo,

I wondered if anyone was going to mention this. I had the same problem with the first P17 I bought. I looked around at other blogs and it seemed to be the one common subject for this pistol everyone was talking about. I tinkered with mine over and over and finally lost a pin and couldn’t fix it. I just bought another one – they must have fixed the trigger problem because I haven’t had any trouble with my new one.

Larry from Algona

henry_tx, when the trigger sometimes works, it is normally the sear spring is in the wrong place.

This will be covered in part 2.

But the trick is, the tail of the sear spring needs to goUP into the right grip side, not down into the left side.

The spring is put on the sear and the post in the left side, but when putting the right grip on, the sear is put under spring tension and the tail has to go up into the right grip frame.

If it is put in where the springs tail is in the left side it puts the sear at an angle where it doesn’t engage reliably.

Hope this helps.

Thanks 45Bravo, and I think that you hit the nail on the head.

The last time I took it apart was last year and I remember paying attention to the spring tail position. The bad part is that it worked well for a time, but then it started failing again. I suspect that at some point the spring re-positioned itself.

Next time I will try to find a way of making a more permanent placement for that spring. I am planning in making a ledge or stop with UV cured epoxy (Bondic). I will let you know how that works.

Meanwhile, looking forward to your next installment.

Best,

Henry

I had some extra $ 2 or 3 years ago and bought one & let me state not in love with any pistols rifles all the way for me, but the price and good reviews. First off its hard to cock now i am by no means weak or shy of expending effort i just don’t think i could mount a site without it being a real issue. I also have issue with 177 pellet size loading it. I even have a real love hate issue with the sights.

I can ignore every one of these things for one reason i can hit a dime @ 7m or in my terminology from the door of my chicken coup to the back i can shoot a mouse head shot using cheap CHP.

Nothing beats accuracy and i do like the weight of it so all the other things aside if this cheap pistol did not exist and i was guaranteed the accuracy of the more expensive pistol. I also figure i got lucky as ever P17 couldn’t do as well as this or they would find selling more expensive ones like the HW40 all but impossible, but i would hope the HW40 would have a far superior trigger.

It is the only pistol i own not the only one i have ever used amend that i do have some horrible plastic Daisy around somewhere that i don’t want to find. I see people mocking people who expect more than many people here think they have a right to expect for a reasonable price and i have been given the same in the past. The P17 is living proof it can be done. I have to resist my want for a tirade against the industry i like & dislike and just settle for my glowing admiration of the P17 & the gun it is a copy of HW40 dollar for dollar some of the best money i have ever spent.

I really appreciate this post as if my P17 ever develops a problem i will use this information as i agree this is a perfect learning platform as you now have me thinking the hard cocking effort might be something i can just try and fix. I just have to resist the urge to make or buy a spring compressor and risk getting sucked hopelessly into this [I lack restraint in these things] anyhow very much like the post and looking forward to follow up if one is coming.

I know its not perhaps on many peoples wish lists, but i am kind of hoping for a review of the new Stoeger S4000-e .22 when they come in.

Mike,

I agree with you on the sight. But I plan to mount the UTG Micro Reflex sight that is ultra small and will work perfectly.

B.B.

Yes i have seer you talk about that one. The only red dot i ever used or rather tried is a BSA 50mm red dot my dad bought about 15 years ago it sprang a leak, long story. I understand the reflex sight is very different and i keep kicking around the idea it would i think make the mousing easier plus something to try on squirrel rabbit yard setup.

Mike,

Hmmmmm! You’re giving me an idea!

B.B.