by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- WD40

- WD40 as penetrating oil?

- Not for clocks!

- Air Rifle Headquarters

- Light oils

- Use for airguns

- Special purpose weapons-grade oil

- Household oil

- Special purpose oils

- Ballistol

- Silicone lubricating oils

- Silicone chamber oil

- Crosman Pellgunoil

- Summary

Okay — today is a report several of you readers asked for — some common sense talk about which oils to use on airguns, and where. It has to be common sense because I am not a petroleum engineer. I’m just a guy like you who has used a lot of oils over my 73+ years. And I will start with the one that started the discussion.

WD40

WD40 was created in 1953 by a small aerospace engineering firm called Rocket Chemical Company. They were looking for a formula to displace water for the aerospace industry. On their 40th attempt they succeeded and called the product WD40.

Aerospace contractor Convair first used WD40 to protect the outer skin of the Atlas missile from rust and corrosion. It worked so well that some employees sneaked some cans out of the plant to use at home. A few years later, Rocket Chemical founder Norm Larsen put WD40 into aerosol cans, to see if the public would find uses for it. It hit the shelves in San Diego, Rocket Chemical’s home, in 1958.

My own introduction to the stuff came around 1965, when my stepfather showed me how to dry the points of a car that had stopped running after splashing through a high puddle. But a few years later I was spraying all the firearms on my tables at gun shows because the stuff smells so nice. The purpose was to prevent rust, which the product does, and when you wipe it off, all the fingerprints and spots come off the blued finish.

My use for that purpose came to a screeching halt in December of 1977 when I returned from Germany and retrieved the guns that I had left with my parents. I had sprayed all of them with WD-40 when I left them there in 1974 and they were now covered with a yellow varnish that was so hard I had to pound on the bolt of my bolt-action rifle with a plastic hammer to get the action open! It took me months of cleaning to get that varnish off all the guns and WD40 was what I used. The solvent vehicle is naphtha (its hidden as a petroleum distillate in the US product contents but specifically called out in Australia) and it works wonders to dissolve the dried product.

WD40 as penetrating oil?

I see on some of the British car shows on TV that WD40 is used as a penetrating oil, and I can’t deny that it does work that way. I never used it that way myself, but that was probably more because I was a gun guy rather than a gearhead.

I no longer use it on guns like I did in the 1970s, but like many households there is a can or two around. Yes, it will quiet a squeaky door hinge, but less than a year later the squeak will be back. A shot of silicone lubricating oil lasts for a decade easily.

Not for clocks!

I attended an horological (clock and watch repairman, as well as those just interested in the measurement of time) club’s meetings for about 6 months in the early 1990s — thinking that I might take up horology as a hobby. That was until I discovered that the tools a horologist needs costs thousands to acquire and the knowledge takes years to learn! I was about 44 years old and was the youngest guy at the meetings by several decades.

One meeting we had was all about oils for clocks and watches. When WD40 was mentioned everybody went into low earth orbit and they all had horror stories that were pretty much the same as my gun story from years before.

I have no recommended applications of WD40 for airguns. If you do use it, remember what I said about it drying and leaving a varnish residue.

Air Rifle Headquarters

Yes, Air Rifle Headquarters did recommend WD40 for displacing water and preventing rust, which it was formulated to do. But they also called it a multi-purpose lubricant, which is was not and still is not today. ARH also recommended a lubricant called Dri Slide that was moly particles suspended in a volatile petroleum distillate (naphtha) base. I used Dri Slide a couple times until realizing they every piece of uncoated steel I used it on developed rust within a week! Dri Slide is still being made and sold today and no doubt it has applications but I’m warning you not to put it on steel parts that are in the white (uncoated). You must remember, Air Rifle Headquarters wrote their catalogs in the 1970s, when less was known about many things.

Light oils

Okay — got that out of the way. Now let’s talk about some oils you can use on airguns and why you would choose to do so. I’ll begin with light oils. Like I said, I’m no petroleum engineer, so I’m just going to talk about this like I would if you were standing right here beside me. There are lots of light oils, and by “light” what I mean is oils with low viscosity. I suppose penetrating oil qualifies, but I would like to address it separately. What I’m talking about now are light lubricating oils.

I’ll start with your wife’s sewing machine. If it’s a good one and if she knows how to care for it, she has a bottle of very lightweight oil. It’s white mineral oil. Every so often, based on the amount of use or the time that has lapsed, she oils several places on the machine and then runs the motor wide open to spread the oil. It doesn’t collect on the parts and gears like WD40 does.

Another light oil is clock oil. Most of it these days is synthetic and is very low in viscosity to penetrate between the jeweled bearings or just the brass plates and the steel pinions that turn in them. This oil comes in grades that are formulated specifically for wall clocks and grandfather/grandmother clocks.

Skateboard oil is yet another light oil for the bearings of skateboards and roller blades. It is thicker than clock oil and sewing machine oil. It has superior wearing capability despite the lower viscosity.

Use for airguns

Use light oil sparingly for an airgun. Most of it won’t stand up to the heavy wear it needs to, but on things like triggers, beartraps, some detents and things like that, it is okay. If the detent will see heavy use, like a breech locking detent, I wouldn’t use light oil.

Special purpose weapons-grade oil

These oils didn’t really exist when I was a kid. I think LSA (lubricant, small arms) was my first encounter. And by the way, this stuff is also called lubricant, semifluid, automatic (weapons) and lubricating oil, semifluid. When I was in the Army we all carried a small plastic bottle of it for our M16s, and, if used correctly and in the right amounts (which is more than most soldiers think), it works well.

Other weapons-grade lubricants are mostly a mystery to me, but I did use EWG (Extreme Weapons Grease) in place of Tune in an Tube to quiet the mainspring and cocking link of a Diana model 50 spring-piston air rifle. It worked great and the spring was quiet. This report isn’t about greases, so that’s all I will say, except to note that if an oil says it is specially formulated for weapons, it probably is and should be worth a try. I would use special purpose weapons-grade oils according to the directions on their label.

Household oil

When I write “household oil” for this blog I’m thinking of 3-IN-ONE oil. But it doesn’t have to be just that. I’m sure there are hundreds of household (general purpose) oils around the world that are all pretty close or identical. By sheer coincidence, WD40 purchased 3-IN-ONE oil in 1995, so there you go!

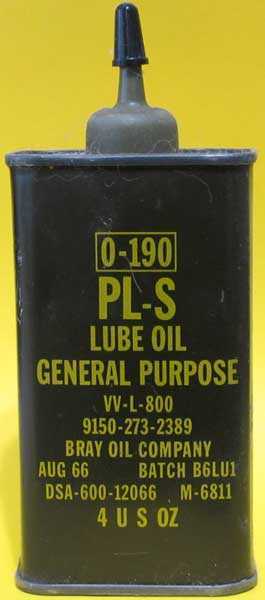

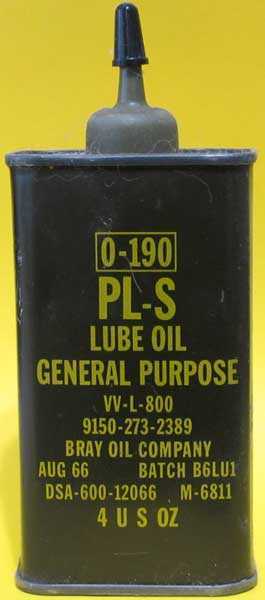

For the past 50 years I have used a can of PL-S Lube Oil, General Purpose as my household oil. As far as I’m concerned it’s the same as 3-IN-ONE, though I’m sure there are experts who know different. But I use it for the same purposes and yes, I also own a can of 3-IN-ONE.

I probably got this one when I was in the Army, or I bought it at a gun show. I use it for all general lubrication, and on airguns that includes lubing the cocking linkage and the pivot bearings (in the action forks of a springer), and any general purpose application there might be. I use it when I need to lubricate without disassembly. It’s a little too viscous for use on triggers that are more complex than the direct-sear types that you find on American multi-pumps. For them I recommend light oil or special purpose greases such as moly paste.

I have used this can of general purpose oil for the past half-century.

Use household oil on airguns in the same way you would use it on other things around your house. Just remember, a PCP trigger mechanism is far more complex and not as robust as a door hinge, so keep the household oil use to high-stress parts.

Special purpose oils

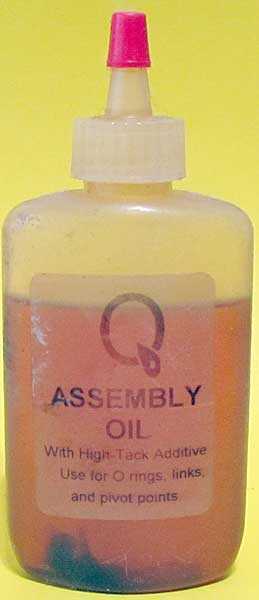

Most of you will not have heard of assembly oil, but those who work on complex mechanisms might have. Like assembly grease only lighter, assembly oil is tacky — to hold those bothersome little parts in place as they are put together. Two good uses on airguns are those teeny tiny ball bearings and super-light coiled springs. After assembly you don’t want heavier grease to impair their function, so assembly oil could do the trick.

This bottle of assembly oil from Dennis Quackenbush has lasted me more than a decade.

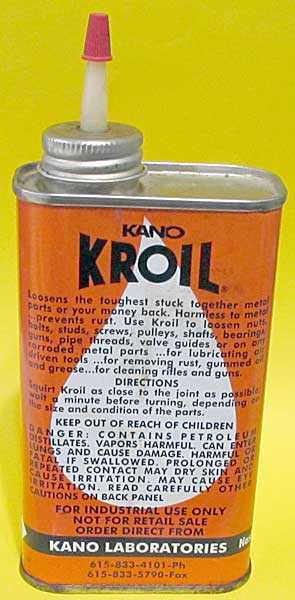

Now, what about penetrating oil? Well, WD40 may work well, but I have found that oils that are blended specifically for penetrating work the best. I use Kroil because when I did an internet search it was the product that kept coming up. It’s not the only brand — I used Liquid Wrench for many years. And lots of people swear by PB Blaster.

Kroil is one of several penetrating oils.

Use penetrating oil as intended. In other words, use it to free stuck fasteners. It’s not a lubricant, strictly speaking, except in a very narrow and limited way. If you need a thin oil, use either one of the light oils I mentioned, or perhaps a weapons-grade lubricant that is also light.

I mentioned oiling the mainspring of the Winchester 422 in Part 2 of that report and I told you I used Snake Oil. Snake Oil is the sort of special purpose oil I’m now referring to. I used it because the 422/Diana 22 is a very low-powered pellet rifle and I didn’t want to hamper its performance in any way. But the mainspring, spring guide and piston were all dry and I wanted to get something on them just to keep them from galling. When steel rides against steel without lubrication it wears the parts away. That’s galling. Any oil in that case is better than nothing.

Ballistol

Ballistol is probably close to a special-purpose weapons-grade oil but it is used almost universally. Besides being good for lubrication it is a superior rust preventive. Many armies around the world use it for their fully automatic weapons. However, where WD40 smells nice, Ballistol smells like a fish market!

Silicone lubricating oils

Now comes a question that people have asked me for many years. Can they use silicone lubricating oils on their airguns? They obviously have a can of the stuff that they use on door hinges and will it be okay on their airguns? Well some will and some won’t. Silicone lubricant is a class of lubricants that spans too wide a spectrum for me to make specific statements. I have a couple cans of it, too and I use it mostly on the many hinge joints of my segmented garage door. For that purpose it works great and it lasts a long time. On airguns, though, I would like to see something more specific and something with a higher viscosity.

Silicone chamber oil

And this is where we get into a lot of trouble with silicone lubricants. Silicone chamber oil has almost no viscosity and will not protect metal parts from galling. But it does have two redeeming features. It seals synthetic piston seals well and it has a high temperature flashpoint. In other words, it doesn’t burst into flame or explode easily. It’s ideal for lubricating spring-piston airguns that have synthetic piston seals. And that’s about all it’s good for on airguns. Use petroleum-based oils on all leather seals exceopt those that are pushing the boundaries of performance, such as the Diana 45.

Oh, some companies recommend silicone chamber oil on the tips of new CO2 cartridges, but only because they don’t have another product to recommend, and they sure aren’t going to recommend a product made by their competitor. Which brings me to today’s final oil.

Crosman Pellgunoil

Crosman Pellgunoil is a blend of non-detergent motor oil and an o-ring preservative. Its number one use is for sealing each new CO2 cartridge before it is pierced, so the oil gets blown into and around the inside of a CO2 gun powerplant to get on all the internal seals. I can’t recommend it highly enough, because it preserves CO2 guns for a very long time.

I use the oil Dennis Quackenbush formulates that’s equivalent to Crosman Pellgunoil.

I keep a bottle of Pellgunoil out all the time. I use it for CO2 cartridges and also for the linkage pivots on multi-pump linkages, as well as on their pump cup heads. Besides the bottle I have a pint of the same stuff in reserve what I hope is a lifetime supply.

Summary

Well, that’s my report on lubricating oils and their uses on airguns. As you can see I didn’t tell you specifically which oil to use on the inner cocking link of a Diana 48 sidelever. That’s for you to decide. But, after reading my report, I hope you won’t use silicone chamber oil, Dri Slide or WD40. Household oil would be okay and there might be a special-purpose weapons-grade oil that would be even better.

B.B.,

Where does ATF fall under? I have found it to be a slightly tacky oil with good penetrating property.

Siraniko

Siraniko

ATF is a hydraulic fluid not an oil. Its a bunch of chemicals and additives combined to keep a hydraulic systems functioning. When parts are operating in a fluid they don’t require much lubricating oil although I’m sure there is some friction reducing additive in there along with seal preservative, viscosity stabilizer, anti freeze and probably something to keep it from catching on fire.

Bob M

Bob M,

I don’t quite agree that the ATF I’m using is a hydraulic medium. It does not act or feel like hydraulic fluid (which is hygroscopic) which I use for my clutch and brakes. It feels more like an oil somewhere between mineral oil and SAE 40w. I do agree it is not a pure oil having a whole lot of other additives.

Siraniko

Siraniko

All I can say is Automatic Transmission Fluid is not classified as an oil. Look it up on line in Wikipedia. Sure it’s slippery like oil and does lubricate the gears as well as perform other functions in there with the torque converter, clutches and valves, but it is not called Automatic Transmission Oil for a reason.

It is interchangeable with power steering systems, to a certain degree when it’s chemically compatible by brand.

Bob M

Bob, I’m with Siraniko. Wikipedia isn’t the end all on stuff. I’m in the lubricants business. I know lubricant manufactures consider ATF’s as oil. I also know it does lubricates more than just Auto trans. In fact there are/was autos and trucks that had ATF as the fluid in a manual transmission. Also Hydraulic oils do lubricate. If they don’t the pumps will fail early. Some have high zinc in them to combat this.

Doc

Siraniko,

I left ATF out and also ATF sealant.

BB

I worked for a jet engine manufacturer. WD-40 was forbidden for use on any jet engine parts. It actually attracts moisture. If some of you remember the old days of coil/distributor ignition on cars, we used to use it to spray in our distributor caps to get rid of moisture when the car wouldn’t start.

Hmm. Makes me wonder how many guns ARH sold over time. Wonder how many got WD40 used on them. And where are they at now days and what do they look and work like. That would tell a story wouldn’t it.

GF1,

Probably none got WD40. As far as I can see it was just a product they sold.

BB

Thank you for this blog. I have slowed my use of WD40 over the years, but now it will probably come to a screeching halt. Oh, and thanks for the early morning chuckle from your 4:48 response.

Rk,

Oooops! 🙂

BB

BB

That probably would be hard to prove unless you have one of those guns and know its life history if WD40 was used or not.

Especially if that was the thinking back then to use WD40. I bet it was bought and used by people back then on thier springers more than you think. I mean why wouldn’t you if that is what was written about to use back then. Just like how your writing about lubricants today.

Oh and by the way I have one of my 760’s I bought probably in the early 80’s and I used WD40 on it regularly and don’t see anything on it like your talking about. And I used that gun out in the rain over the years and it still shoots fine. Matter of fact I use to spray the wiper and pump plunger and seal with WD40 also. Even the cocking arms and bolt. No problems with it from what I can see.

And that is a true story about my 760. Not speculation.

GF1,

If you wipe it off then there will be no residue.

BB

BB

So what does that mean if I wipe it off.

What will happen. No finger prints like you said above or should I be looking for something else if I wipe my 760 off. Which I have.

If your talking rust. Nope haven’t seen that either.

And maybe the WD40 is why my 760 still makes good pumping compression.

GF1,

If you wipe it off, which you have, the brown varnish will never form.

BB

BB

I have wiped the gun down but not the cocking linkages or the pump plunger and wiper or the bolt. Don’t see no varnish.

I would like to see if anybody has some pictures of what they have used WD40 on and what it looks like over time.

GF1,

You can do it. Get a clean unfinished piece of steel and spray it. Then let it dry for some time.

BB

BB

I have. Remember I said I have a 35 year old 760 that I used WD40 on and in.

I would like to see if anyone else has anything that they used it on over a long period of time.

Proof is in the pudding as they say.

BB,

Good article. For water logged distributor caps and wires, I used silicone wire dryer. I had a ’74 Ford E-100 van and used that stuff religiously for years. More than a few times it saved the day,.. roadside. Pull the engine cover, pull the cap, manually dry anything and blast away. As the years passed, it got used every time that I was under the hood of any car.

For a light oil, I will use 0-20 or 10-30 synthetic motor oil. Mobil 1 to be specific. My Rav4 runs 0-20 as well as Honda’s. As I recall?,.. as in 0-20,… 0 is the cold viscosity and 30 is the hot viscosity. Viscosity may be the wrong term.

I had an uncle that sold Amsoil products and he showed me a brochure that had information from 8? tests that oil manufacturers perform on any oil (industry standards) and Amsoil ranked #1. Mobil 1 synthetics were right behind and since Mobil 1 is commonly/easily found, that is what I use.

Looking forwards to more comments today.

Chris

B.B.

One you forgot to mention, “Snake Oil”. Seems to be real popular right now……..

Perhaps next blog should be on grease? If so, please talk about Krytox.

Stay safe,

-Yogi

What about Ballistol?

Lioniii,

Did you read the blog?

BB

Sorry, I missed that short paragraph. This pandemic isolation has mucked up my brain-eye communication. Guess I need some Ballistol for my noggin!

BB ,

I try to explain the WD40 thing to people all the time about the varnish . I believe for most firearms and airgun lubrication Ballistol is best . In most applications a film of Hoppes #9 will be sufficient . The only Two things that I do not use Ballistol on are Mainspring guides ( Grease) and Bolt Carriers in AR pattern rifles , I use LSA in my AR . I bought a quart of LSA from SARCO for $7.99 , That would probably take care of 100 guns . This topic always reminds me of my Grandfathers arguing about oil , My Grandpa Salvino was a fan of Valvoline and my Grandpa Poorman was a fan of Kendall . You know what, both of there cars were well maintained , the moral of the story is do the maintenance. I have streamlined with Ballistol , Tune in a Tube , Hoppes #9 solvent and LSA for my Firearms and Airguns .

Gene Salvino

Gene,

This is really scary, but your list is exactly what is sitting on my gunroom workbench. The only addition I have is a bottle or two of Backyard Air airgun lubricant for multi pumps. It’s cheaper than Crosman pelgun oil and comes in larger quantities.

As a side note, I prefer LSA over Ballistol when it comes to oiling rifle bores. Just a personal quirk I guess.

Have a good one!

BobF

BB ,

This company has a excellent tutorial on basic lubrication . Very informative , I enjoyed the sections on LSA and history of gun oils .

https://www.cherrybalmz.com/

Gene Salvino

BB,

I know this can get kind of touchy, and downright dangerous if the wrong oil is used, but you did not mention silicone oil, petroleum based oil and HPA (High Pressure Air).

This is something I recommend ONLY to the well experienced. It can be a very good idea to occasionally introduce a few drops of silicone oil that you KNOW has absolutely NO petroleum based products in its formulation, into the HPA reservoir of your PCP. It will end up on the seals, helping to keep them fresh and also helping to seal any minor leaks.

DO NOT USE PETROLEUM BASED OILS! When petroleum and HPA come in contact with each other there is instantaneous combustion, usually resulting in an explosion. Do not be a “Junior Mad Scientist” and experiment with such. Your experimentation days will likely soon be over.

Chris USA ,

You are correct about Mobil 1 , it is a good lubricant that can take the heat . I know quite a few people who use it exclusively on the AR pattern rifles . The problem with it in that application is it starts to flow everywhere and it will fling out of the rifle . It has been my experience that Ballistol is the best protectant due to it’s ability to not resinify when exposed to the elements like motor oils will do . Motor Oils are made to work in a closed , filtered machine . If all I had was Hoppes#9 and Ballistol I would have no worries . I have used Ballistol in AR rifles and it works well , but LSA stays put and can take the higher temperatures in the bolt area .

Gene Salvino

Thank you for this informative primer (no pun intended) on lubricating oils. For some reason, the subject brought back memories of a love-to-hate cartoon character from the Mighty Mouse series – Oil Can Harry. Pretty slippery fellow! As for WD-40, it saved the day more than once when my MG Midget would stall out when driving over puddles which could not be avoided. Recall once seeing sparks dancing and arcing on the top of the distributor. A few shots of WD and the Midget would roar – maybe squeak? – into life again.

Made sure to get Crosman Pellgun Oil for the Umarex MP-40 when I ordered it per your advice, B. B.

Good report for reference. The education of a novice friction engineer for air gunning can begin here with assurance. Reader comments contribute for sure.

Deck

Great blog B.B.!

Have a cupboard full of lubricants for different applications 🙂

One of my favorites for linkages and such is Chain & Derailleur Lubricant by Moly Slip. Used the oil to maintain the cable and drum system that moved the film trays on an Escher Grad photoplotter. When I left the company the Escher Grad rep contacted me to ask what I had done to maintain the plotter, evidently the cables typically lasted a year before failing and the ones on my plotter were still fine after 8 years of heavy use. The secret was a couple of drops of Chain & Derailleur Lubricant (4 time a year) to lubricate the strands in the cable.

The other thing I use is Dow Corning 200 Fluid (50 and 100 CTS) which is a food grade silicon oil. Years ago when I bought my FWB 124 I could not get silicon chamber oil (it was always out of stock) so I contacted Dow Corning and their technical rep suggested the 200 Fluid. Been using it wherever moving plastic parts (like piston seals) needed lubricating.

Yeah, Ballistol has a distinctive odor but I associate that with air guns and air guns are a good thing so I don’t mind the smell at all 🙂

In speaking about lubricants, would you do a blog on lubricating pellets/bullets? These days I am experimenting with higher velocities, lead fouling is a potential problem and I think that some type of lubricant might help things.

Hank

Hank,

Here is something I have written about lubricating pellets:

/blog/2016/11/some-talk-about-airgun-lubrication-part-2/

BB

Thanks B.B.!

Will check that link out later.

Seems that lubricating pellets is a hot topic – it comes up regularly on the forms and gets quite a bit of attention.

Hank

Hank

DC200 brings back bad memories.

We used it for transmitter coolant/dielectric .

That stuff crawls over everything. It appears to want to spread to one molecule thick. Very hard to clean up any spill. Causes silicone rubber to swell up and turn into mush.

Nasty stuff to live with.

tt

Thanks for the comment tt!

I was warned about keeping the DC200 away from silicone.

That it wants to crawl over everything very thinly is something that I want to explore – thinking that a couple of drops of the DC200 on the foam liner in the pellet tin might be just the ticket for lubricating pellets.

Any thoughts on that?

Hank

Hank

I would not want to use that stuff around any seals that might be silicone.

That stuff will climb up walls and tires from the floor.

You get it in your mouth or your eyes, you can tell it is there. Has to wear off (transfer to something else) before it is gone.

We used to use Heavy Freon (not the 50 below stuff) to get rid of it . It seems to float to the surface and can be wiped up with clean rags. We used to get 20 pound tanks of the Freon(it was called something else) for cleaning it up. Looked like the propane tanks you would get for the BBQ. Not cold as the Freon 50 below stuff. We did use the cold Freon for cooling circuit boards for being temperature sensitive. We even had a big freezer in the shop that we could put entire black boxes in overnight for trying to find temperature sensitive problems.

tt

OK, thanks for the heads-up!

I have always used the DC200 fluid very sparingly – just a couple of drops in the compression chamber of my 124 every once in a while.

I was advised that a small amount goes a long way so for lubricating plastic parts I would use a Q-tip to apply a film of the oil or a needle for a fraction of a drop and let the oil wick-in between the parts.

Goes to show that you need to know the chemicals what you are working with!

Thanks again,

Hank

Hank

I heard of a guy who wiped down his car with DC200 one time. Made the car nice and shiny.

UNTILL….The DC 200 worked it’s way through the paint and got to the metal. All the paint fell off.

tt

.hmmmmm All the paint fell off eh?

Have two liters of the DC200 Fluid and a neighbor that is a real twit… interesting thought but naa, not going there 😉

Hank

Hank

Could have been one of those “War Stories” , but I would not want to find out the hard way.

tt

tt,

At least one of the Dow Corning Silicon Oils works exceptionally well as a parting agent for a bunch of different materials. I think the confusion comes from so many variations of Silicon Oils being produced and mixed with other organic and inorganic products.

Black Box is a term along with receivers and transmitters you don’t hear used to often ;^) Raven or Old Crow?

shootski

shootski

B52 ECM shop.

tt

Worth mentioning, I think, that if the instructions on the bottle tell you to shake well before use – google tells me LSA does, for example – that’s probably there for a reason.

Not everything comes in clear bottles.

iain

BB, I wish the WD40 smell was a cologne. Right next to the Bay Rum. Hey, in the 70’s 80’and early 90’s in any bike shop that stuff was used as a cleaner as much as any thing. It would not last one ride in the rain. For race day, you might have a set of nice handmade wheels but take the grease out and use a light oil. Not WD40 tho. Even grease will ultimately harden into varnish chunks. I use Ballistol on metal finish surfaces, higher pressure applications, it depends, but the wax based lubes are an alternative to greases, they work well the water. Bike shop is a good source for a wide variety of oils and greases, as well as a car parts or gun shop. Be very careful about any oil or grease around HPA , or regulator/ welding apparatus. But if you do put a drop of diesel in your transfer port of your springer, you see what happens. Use a Wally World special. Some times clean and dry is best, some folks are sensitive to smell.

Rob

Something I discovered by necessity a few years ago. I had a stuck bearing. I was not at home so Kroil was not handy. I looked around my daughter’s garage and found carb cleaner. It actually worked a little quicker than Kroil. So next time you need a penetrator, try it.

mobilehomer,

I use carburetor cleaner to clean my licensed silencer. Great stuff!

BB

Hello, all,

Another great BBP post, well worth study.

I’ve thought about this a lot, and to begin, I have predominantly used Ballistol. It seems to have mostly good characteristics, and works nicely – to keep bluing from rust, and on wood stocks. I buy the liquid (non-aerosol) can and apply with either a rag or dropper bottle. It is an excellent long term corrosion preventive. To me, it smells like licorice (and I hate that). Use outside, and wipe down well.

In my working career, during production of telecom electronics, a Bellcore requirement was imposed to lubricate separable connectors. We used a viscous synthetic oil (polyphenyl ether) diluted to 1-2% with a volatile solvent. The lubricant did aid to avoid friction wear, but the main reason to use it was to keep oxygen from acting on the metal and metal plating. The residue of this thick material (developed as a turbine lubricant) is so stable, it will almost never evaporate or react. I mention this, because the concept applies. Like some of these formulations, the product is mostly carrier – you spray it out, the lubricant gets into all the crevices, the propellant evaporates, and we hope we have enough lubricant film to be effective and last. Lecture over.

Now, I have some notes on the subject of pellet (and airgun) lubrication, I will share. There is no great conclusion to it, just some references to those products promoted, in advertising, and in discussion groups. Some of this is likely just hype. See this link:

https://docs.google.com/document/d/1glZJsDKiQtq1VlBQ1pgmcJlBbVP79g2Qdy6y0GD7hqg/edit?usp=sharing

I now use WD40 as a cleaning solvent to remove old grease from motorcycle and bicycle chains before applying the correct lubricating spray can oil. Works great and much safer than using gasoline.

Yesterday, I tackled an outside door whose locking finger turn bolt was too difficult for the wife to turn. It’s located in the inside while the keyed lock is outdoors. Taking the lock out of the door and examining it, I decided to hit the exterior part of the handle’s turning mechanism with Ballistol. Problem solved!

I love the smell of WD40 and Ballistol in the morning! (with apologies to Robert Duvall)

Fred formerly of the DPRoNJ now Happily in GA!

BB,

(et al),

Thanks for another great report full of useful information. I was hoping for some clarification on a few oil related issues.

I can’t find it now, but believe that I have read in the blog archives that you recommend the use of Ballistol inside the receiver tube, outside of and around the sliding compression chamber on underlever spring rifles. On a TX200 should one be applying a light coating of Ballistol to as much of the interior walls of the receiver tube (avoiding the air transfer port) as is possible through the loading port?

I also believe you advise treating wooden stocks with Ballistol. I have read elsewhere, that it may be inadvisable to apply oil to checkered areas, as it may adversely effect the checkering. (Perhaps this only applies to certain methods of checkering- i.e. pressed vs. cut checkering?) The Tx200 walnut stock seems minimally finished. If one wanted to apply an oil finish to such a stock in the hopes of bringing out the figure and protecting/ stabilizing the wood, what product would you use, and would you apply it to the fish-scale checkering? Is Ballistol the best choice, or would you suggest another oil product? I don’t want a finish that builds up a coating or film on the wood, so I was thinking an oil that absorbs into the wood would be best for conditioning/ protection. Walnut oil perhaps? Minimal applications of Tru oil (so it soaks in but doesn’t build up on the surface) ? Any advice on products or techniques would be welcome. Thank you!

AOB,

My friend, Mac used Ballistol on all his guns. His eastern Maryland property flooded and the butts of all his firearms and airguns were standing in water for about a week. When he was able to get to that house he dried off all the guns with zero damage to the wooden butts. I would use Ballistol everywhere on a gun — both steel and wood.

BB

I will give it a try. Thank you for the reply.

Can anyone comment on how Boeshield fits into this picture? It’s an aerosol like WD-40.

In my experience it can leave a sticky varnish like residue if left to dry on a surface. I stoped using it on cast iron machine tables for the above reason.

flintrocker,

I’ve heared nothing but good things about Boeshield.

BB

T-9 is great if used as intended – primarily a corrosion preventative coating which also has some lubricating properties. It’s basically paraffin wax in a carrier solvent packaged as an aerosol. The wax is left on the surface when the solvent evaporates.

Nowhere

Sounds like how WD40 works.

Hi BB, hope you are keeping well during this pandemic! I use WD40 like the “penetrating oil” that I thought it was. Although it might be ok for some applications, obviously not for our hobby! A few years ago, I purchased a nice old type-K diopter, but the iris was frozen solid. Went on some forums and someone recommended using WD40 to free it up. It did so very well and have not had any issue of it freezing up…yet. as you had firsthand experience of WD40 turning into varnish after storage, is there something I can do to get the stuff off without using the solvent? It hasn’t turned into gunk yet.

Regards,

Peter

B.B.

When I was in my Teens and 20’s, I used nothing but WD40 on my Marlin 60s. I never hardly cleaned them (once a year). I’d shoot a brick a week through them. When they would jam, I’d just spray some WD40 in the action, work it a few times, then keep going. I would wipe them down with WD40 after shooting. I never notice a build up of the WD when I would take it a part (about once a year). That said, I heard all kinds of stories and stopped using it. Now for firearms, It’s Rem Oil mostly. Airguns it’s Pell gun oil for the inside and outsides (I don’t own a PCP yet). I’m always looking out for the all purpose lubricant though. Oh on some 22 pistols, I have used grease on the slides with good results. I have a friend that was in the Air Force (Vet) and they used grease on their rifles back then. I thought it was crazy till I tried it. Held up better than oils.

Doc

Everyone,

More than 10 years ago I mentioned in a blog that ATF sealant (stop leak) would rejuvenate seals and o-rings in airguns. Several readers told me it did so by turning the seals and rings to mush, so I put some o-rings into it and left it sit. Those rings are STILL in the stuff and they are still like new today.

Since nobody else seems willing, I will find some clean untreated (non-blued) steel and spray it liberally with WD40 and then let it sit. In time (I don’t know how long) I will show the results.

BB

B.B,.

I remember those O-rings good to know they are still going strong. The WD40 experiment is a good one.

I just figured out your Oil talk – and no action. I can be pretty dense. LOL

Don

BB

How about just pick one of your air guns you have and do the experiment. That’s what we are talking about today. Not a piece of clean untreated steel.

Come on BB get real. Stay on track of what the report is about. WD40 used on air guns.

I just finished my prototype of a low pressure airgun valve. It works pretty good although not any better than the hose nozzle I tested before. I used a .22 caliber Maximus barrel and AA Falcon domed pellets same as in my previous tests. I ran some velocity numbers. Here they are.

shot psi fps

1 130.0 402

2 130.7 404

3 131.4 409

4 132.1 405

5 132.9 409

6 133.6 411

7 134.3 412

8 135.0 417

9 140.0 428

10 142.5 434

11 145.0 436

12 147.5 436

13 150.0 445

There seems to be linear relationship between pressure and velocity. I did not do a good job keeping track of the pressure but should do another run and keep better track.

I was trying to maximize the velocity and made the valve volume very large based on the results compared to the hose nozzle the valve could be much smaller and still get the same results. I used 1 1/4 inch pvc for the valve body. Not sure if I will try to build a gun for this valve but it does give adequate power for a back yard gun and is quiet as far as I can tell.

To fire the valve you pull the hammer back towards the valve body and let it go pulling the valve open. The seal on the valve stem is made from a bonnet seal off of a small water gate valve.

Here is a picture of the completed valve.

Don

Here is an exploded view.

Here is a picture of the stem guide plate inside the valve that the return spring pushes against.

Don

Way cool. I knew that low pressure air could work.

Imagine now if the manufacturers would start making something we could use shop compressors or tire pumps to fill our PCP’s.

You should go somewhere with the idea.

Don,

To me, those seem like pretty darn good numbers for low pressure and .22! I think you are definitely doing something right! 🙂

Chris

Think patent?

FawltyManuel,

That sounds like work. I am happily retired. I have no idea if it is a new design. I used mostly off the shelf parts. I would be happy if anyone wants to use the idea.

Don

Don

One day you might think you should of answered a bit different here.

I think a low compression shop compressor air gun has been long over due.

BD,

so if you had a HPA tank and a regulator set to 100psi…. what do you think would get more shots? high pressure/small volume versus low pressure/large volume at the same fps, off the same HPA bottle….. just wondering. I like the slide hammer on the valve stem. That is genius. Is that an original idea or borrowed? Great work! Robert.

Robert,

The valve is a combination of airgun and potato cannon valves. I have a bad memory so not sure if I have seen one the same before. My goal was to get a direct linear air path to to the barrel. I tried to build an ellipse transition from the valve body to the exit port, like a venturi.

I started out using an air nozzle and then a hose nozzle. The hose nozzle worked well and I used its design. I have posted their pictures but don’t know how to get find them since the blog software was updated.

I am not getting email notifications of responses to my comments. I will likely see them only if they are on the latest blog date. Maybe I need to update my profile.

With low pressure air it is critical to deep (all the way into the rifling) seat the pellet. Otherwise much of the energy will be wasted pushing the pellet from the leade into the rifling. Some pellets won’t even move.

Don

BD,

If I could click on your user name and see all your posts…. that would be good.

Deep seating: I understand. I do that with my FEG as it has a narrow bore and low oomph. Also the pellets are quite tough.

Have you tried skimpier pellets? Thin head and thin skirt where it touches the bore. and lubrication helps too.

Barrel length: Have you considered a very short barrel? About 9″ is I think what the experts say. Robert.

RobertA,

If it were a spring piston power plant your suggestion regarding barrel length would have merit. A low pressure pneumatic power plant would need as much barrel length timed to the valve’s opening to utilize the power being sent to propel the pellet. Too long a barrel and it would create drag, but too short a barrel and the power would be wasted. It’s all a matter of balance.

Siraniko

When I was a kid, it was Hoppes #9 gun solvent to clean and Hoppes gun oil as a preservative after cleaning. I loved the smell of it then and to this day. I never remember cleaning or lubricating an air gun barrel, mainly because there wasn’t any powder involved. Now I use Ballistol for pretty much everything and like the smell of that. I use Birchwood Casey Synthetic gun oil as an all purpose-cleaner and preservative for my powder-burners because you can just spray it down the bore and then use a bore snake. I know now why my dad liked the fact that I took over the gun cleaning chores as a kid 🙂

Brent

No mention yet of silicon embedded cloths. They are handy for wiping down the exterior of any gun when finger prints are the only concern. It lasts a long time too. No mess when traveling either. I enjoy cleaning guns and the smells of household oil and Ballistol almost as much as just fired empty shotgun shells. But I don’t want to overwhelm the boss with these delicious odors lest she complain that I’m over doing it.

Deck

I’ve only used WD-40 on my guns for 50 years, so maybe I don’t have enough experience yet to judge…. but so far I haven’t found anything that prevents rust better. Brownell seems to agree….https://www.brownells.com/aspx/learn/learndetail.aspx?lid=12616

Brownell’s did a rust prevention test that used a total of 11 products, all tested in the exact same way to see which provided the best protection against rust and corrosion. I thought they did an excellent job because they even included their own rust preventing product in the test. The amazing part is that of all 11 products tested WD-40 came out on top! There were a few other products that did well, but the WD-40 treated metal visibly fared the best.

Radfordc

Now that’s what I’m talking about. Proof.

Hoppe’s #9 – my shooting buddy and FM refer to it as “The Shooter’s Perfume.”

Regarding WD-40, I have found very little use for it other than removing tar from the side of the car. Yes, it does displace moisture and on older cars that still use spark plug wires, or a distributor type ignition, it works to remove the moisture so the car will run. It is a very poor lubricant, and a good example is if used to stop a squeaky door hinge, the squeak will stop but then return within a week or so. It’s also a poor rust inhibitor. I discovered that when I used it on my cast iron table saw. After just a few weeks, the table began to rust. I use an actual rust inhibitor such as CRC-400 and the table will remain rust free for months and wipe off easily. Ballistol is the very best product I have found to use on guns to prevent corrosion. I spay it on a cloth and wipe down my guns after handling them. Oh, and WD-40 will turn gummy and nasty if left on a metal surface over a period of time. Never spay any linkages, such as carburetor linkage, it will get sticky and cause problems. I would surely never use it on any of my guns for any purpose. That’s been my experience with WD-40. It does smell nice, but that’s about it.

Geo

Geo

I think what is happening is people keep thinking lubricant.

The trick is is the barrier it leaves.

Geo you know what a babbit bearing is and how a thin film will protect the contact surfaces.

Well that’s what WD40 does.

When you spray it on a cocking linkage it eventually will form a I’ll call it a wax barrier.

That does protect the metal to metal surfaces from friction and wear.

Gunfun1,

Yes, I know what a babbit bearing is. My first car was a ’53 Chevy. Those had poured babbit main bearings. When I rebuilt the engine I used plasti-gage to measure the clearances on the bearings. There were shims that you could remove to attain the proper clearance. Those old Chevys could run forever if taken care of. I could shift that old Chevy without even using the clutch.

I still never had good results using WD-40 for anything.

Geo

Geo,

I worked on big diesels (20-30′ long). Some had 2 and 3 piece cranks. Only 400-ish RPM. They had babbit bearings and we used plasti-gage to set main clearance. That was many years ago and I was just a pup.

Chris

Chris,

Yup, that plasti-gage product did work to accomplish the needed clearances. I too was a young pup last time I used it. I don’t know if plasti-gage is even available any longer.

Happy Thanksgiving to you and the family.

Geo

Geo

Let sdo this before we go any farther.

Since you don’t use WD40 on your screen door hinges what do you use?

And let me ask this next. How soon do you have to lubricate the hinges again with the lube your using?

And yes plastic gage. So we both do know there is film of oil the bearings ride on.

That film is what I’m talking about that forms on the cocking linkages of a air gun with WD40. How is that bad?

GF1,

I spray the hinge with silicone spray, or maybe some Ballistol. Silicone spray will keep the cabinet hinges squeak free for a long time. Sometimes I will remove the hinge pin from a door and lube it with a bit of “Red and Tacky” grease. Then is never squeaks or requires lubrication again.

That oil film the bearing rides on requires oil pressure to maintain that separation so there is no metal to metal contact. Your engine won’t run long if the oil pump fails. I have used STP on pivot pins and such. It is my honest opinion that WD-40 has very little lubricity value, and that there are much better ways to reduce wear from friction.

Geo

Geo

Right about the engine failure if the oil pump stops.

There has to always be a barrier between the bearings and the working surface.

We use to assemble our race engines with vaseline on the bearing surfaces just to make sure they was lubricated before the initial start up. And yes we primed the oil pump and pre lubed the engine before initial start up.

That’s what WD40 basically does over time. It creates a barrier.

Why would that be bad?