Oil talk — and no action!

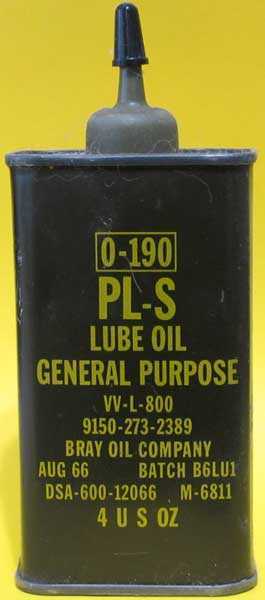

by Tom GaylordWriting as B.B. Pelletier This report covers: WD40 WD40 as penetrating oil? Not for clocks! Air Rifle Headquarters Light oils Use for airguns Special purpose weapons-grade oil Household oil Special purpose oils Ballistol Silicone lubricating oils Silicone chamber oil Crosman Pellgunoil Summary Okay — today is a report several of you readers asked … Read more