Air Venturi Seneca Eagle Claw lever action repeater: Part 1

Part 2

Part 3

Part 4

Part 5

Air Venturi Seneca Eagle Claw lever action repeater: Part 6

This report covers:

- Something I didn’t show you

- What’s wrong?

- A way to tell if something is off

- What to do

- Front ring

- Serendipity

- Two piece rings

- Could it be something else?

- Summary

Today you will get an education on scope mounting difficulties and how to sometimes overcome them. As you can see, I linked to all the past reports on the Seneca Eagle Claw because that is what today’s report pertains to.

Something I didn’t show you

Yesterday we finished on a high note that showed the accuracy potential of the Eagle Claw. What I didn’t show was what it took to get those two groups.

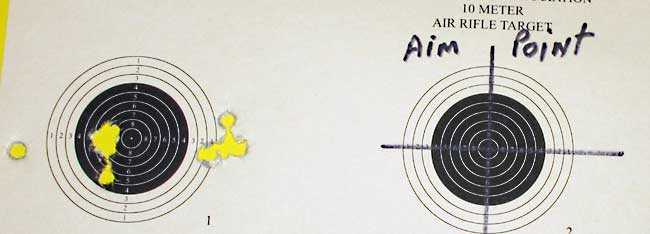

You will recall that I was having a lot of trouble finding a scope and mounts that would work on the Eagle Claw. It wasn’t until the third scope I tried that I found one that worked — sort of. The thing I didn’t tell you is that scope was shooting way off to the left of the aim point. I had to dial in practically all of the right adjustment just to get the pellets to hit the paper. Well adjusting to the right relaxes the erector tube spring, just like adjusting the scope higher does. It’s something I didn’t want to do. And even with the scope adjusted to the right almost as far as it will go the pellet wasn’t hitting the aim point. Let me show you.

There are the two groups from yesterday and now you see the whole picture.

What’s wrong?

When something like this happens my first suspicion is that one or both of the scope mounts (I used two-piece mounts for this scope) isn’t mounted properly to the base on the rifle. But both of these mounts were properly mounted. Something else was wrong.

One of the mounts could be machined incorrectly. I used to see that a lot with cheap rings. But I’ve never seen it with a UTG ring, which these were.

The base on the Eagle Claw could also be machined incorrectly. That would harder to spot because there is nothing to use a reference point.

A way to tell if something is off

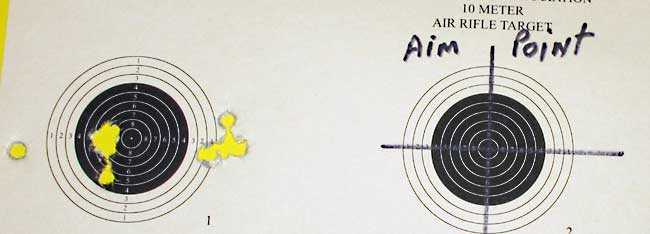

When the scope is as far off as the one I’m describing, you can usually see it by looking down on top of the scope and seeing how it aligns with the centerline of the rifle. So I did that and could see a slight misalignment of the centerline of the scope and the centerline of the rifle.

This is not a good picture of what I saw, but this is how to tell if a scope is way out of alignment.

I know that picture doesn’t show very much, but there is a picture coming that will show the problem much better.

What to do

I knew the scope wasn’t properly mounted, so I set about to mount it correctly. I get so caught up testing airguns that somethings I let things slide and this time they slid too far. Let me show you some detail.

See the stuff coming out of this ring? I need to declutter the ring cap and also to push back the shims so they support the entire scope tube.

When I took the rear ring cap off I found that what was coming out on the sides was a rubber fabric that was in the cap to make the scope move less. It wasn’t the same material that is on the bottom half ring to cushion the scope, but it’s similar. The material that was in the bottom ring was secure and in good condition.

The shims that can be seen coming out of the bottom of the rear ring were taken out and restacked. The bottom shim was swapped with the top one, which made both of them stay in place more securly.

Front ring

All the cap screws in the front ring were loose. So it’s a good thing I decided to do this job correctly. I removed both rings and checked them before installing them again. This was also the right time to clean the outside of the scope tube. I used a soft rag and alcohol for that.

Serendipity

Then I did something that I never do, but because I did this time I discovered something. I usually install the scope in both rings, put on both ring caps and tighten the cap screws in order to spread the stress evenly over the scope tube. This time, for reasons I don’t understand, I installed the rear cap first and was tightening the cap screws when I noticed something strange. The scope was moving sideways in the front ring where there is nothing pushing it. All that push was coming from the rear ring whose cap I was tightening.

When I tightened the cap on the rear ring the scope moved to the right in the front ring.

Maybe this is a common thing. It’s the first time I have seen it. Because I tighten all the screws for both caps sequentially, maybe I have missed seeing this many times. But now that I have seen it I’m hoping to do something about it.

Two piece rings

This is one of the big advantages of using two piece scope rings. They give you more options in situations like this. First, you can swap rings — front to back and back to front. Or, you can turn one ring around. Or turn the other ring around. Or turn them both around. Or swap them and turn both around. That’s five different options two-piece rings give you. With one-piece rings all you can do is turn them around.

I decided to swap the rings. When I did and then tightened the rear ring the scope stayed where it’s supposed to. Did that fix the problem? Who knows? There is no guarantee in this business of mounting a scope.

Could it be something else?

Yes. The Eagle Claw has a barrel band that supports the barrel shroud. If that is off-center it can push on the barrel that’s inside. I looked from the muzzle back and couldn’t see that it was off anywhere. But it’s still worth mentioning. If it is off I have no way of correcting it because an outside spanner wrench that I don’t have is required to loosen that band.

Summary

This excursion wasn’t supposed to happen but it did. It gave us the chance to look at scope mounting again and that is always beneficial. I guess we find out how this worked next time.

B.B.

Where were you yesterday with this article????

I went to the range today with a new scope. First scope that I have with “locking rings”. Pull up to set, turn, put down. It was the put down that Messed me up. I pulled up, adjusted a few clicks and shot. Second shot was not even on paper, as far as I could tell. and this is a 2′ X 3′ wood and cardboard placard! NOT EVEN ON PAPER! How do you adjust a scope that is not even on paper?

Finally figured out about the putting down part. lol. Took several revolutions to be back on track.

-Y

Yogi,

Been there, done that, got the T-shirt and wore it out! 😉

BB

B.B.,

This is why I prefer the simplicity of peep sights. They are just getting harder to find in my locality though. Getting them to fit properly on the dovetails can be a hit or miss proposition also though.

Hmm. With the number of guns you review I think you ought to be putting tags like a 5×8 index card with notes for each gun such as load magazine from front or favors to be shot rested.

Siraniko

PS Section Serendipity 2nd paragraph last sentence, “But now that IO (I) have seen it I’m goping (hoping) to do somethingh (something) about it.

Siraniko,

Fixed it. Thanks.

I need to do something to keep things straight. Or not. I get more reports this way! 😉

BB

BB

Do you really need more reports right now.

BB,

I myself do not mind more reports, most especially like this one. Sometimes things like this leave me scratching my head raw. Often I walk away for a time. When I come back, I usually mentally go through everything from the start. Quite often that shows what I did wrong.

Did you happen to notice that the picture under “Serendipity” is the same picture under “What to do”?

RR,

That was the most important picture of the report. Thanks,

BB

To BB and others on this blog,

An issue I have come across before when shooting is at 25 yards the pellets are hitting on the right side of POA. At 50 yards where it is zeroed, they are hitting POA. At 75 yards they are hitting to the left of POA.

Spiraling?

RR

Could be unless there is a steady right to left cross wind.

I always tighten ring cap screws sequentially as instructions call for. But now BB has opened up a new can of scope worms. Oh my! This discovery could shake up scope mount quality control the way Jerry Couple’s Pelletgage affected pellet head diameter consistency.

Deck

Deck,

That ain’t happenin’ ’round here. Actually there is a prevailing wind direction from left to right as there is a valley with a northeasterly path and my property lies on a ridge sticking out into the valley from the “right” side. The wind comes down the valley, up the side of the ridge and across the top.

RR

Hope you discover what causes the rifle to shoot around corners or mountains. Seriously, my curiosity is up. Do let us know how this turns out.

Deck

RR

Oo, oo, I remember this one RR, pick me! B.B. brought this up fairly recently, but in searching “bore to scope misalignment” I found this blog entry that also tells the story: “Scope dope — I hope! Part 3.” That concept was new and welcome information to me.

Will

Will S.,

You may be on to something there. This was the theory I myself concluded at the time. I may have to find my round tuit and see if this will help. I also have adjustable mounts on this particular air rifle, I may be able to correct this issue.

You have presented a most plausible theory, therefore you are the winner. Send your mailing address to burke 93 at tds dot net. You should be able to fix this email fairly easily.

RR

Maybe rifling has something to do with that.

What direction was the rifling in the guns you was seeing that happen?

GF1,

That I do not know. I am going to give this a try and see what happens. If what Will S. found does not cure it, I will have to take a look at the twist and see if I can get a slo mo of the pellet going downrange.

I can visualize a left twist doing such. A right twist would produce an opposite affect though. If I am not mistaken it only has a 1:26 twist which should have less of an affect. We shall see.

RR

Let us know what you find out.

B.B.,

I find today’s blog as well as yesterday’s rather comforting. As far as I know, there are no other air gunners in my area. I have no source of experience to tap when I have questions or when things don’t go smoothly. Too often in the “go smoothly” case, I’m assuming that I’ve done something wrong but don’t have a clue. Too often that leads to random floundering which may only make things worse. This is not a case of Schadenfreude, but just realizing that even for those who are so very experienced, solutions are found by the same random, methodical approaches that I use. In a kind of perverse way seeing B.B. sort out the things that didn’t go smoothly gives me confidence.

Thanks for your transparency, B.B.

Dan

I wonder if in the manufacture of the rings, the top and bottom are manufactured together – that is, they are bored or lapped or machined so as to make a perfect fit. If you inadvertently switch the parts of the rings, you get a mount that is not perfectly concentric and the result being the scope tube gets moved?

One more correction, BB. In the paragraph above the sub-title “two piece rings”, 6th word from the end – “goping”. Obviously you meant to hit “h” for “hoping”.

Fred formerly of the Demokratik Peeples Republik of NJ now happily in GA and performing proof reading tasks

Fred,

The h was after the word “something” a couple words later.

BB

BB, your eyes have the experience to recognize what you need to look for, and you have a practical remedy for almost everything you show us. I am having trouble with the buttons on the springergis:

there is no way to get the piston head past those plastic bumps that must be there in the compression tube to take out the side to side play that causes most of the buzzing. So I will attempt to cast piston bushings on the piston with urethane( gorilla glue) some orings and a mold release. The glue expands to fill voids. Same for the outside of the compression tube. Maybe milk jug polyethylene will make a decent shim too. I will avoid using an adjustable reamer to enlarge the piston opening, but that is an option.

Hopefully the silencer for the R10 gets here today.

Thanks for the ring info!

Rob

B.B., very interesting. We have all been there, tinkering with something to see what is the matter, and then discovering something along the way. I think it’s the first time I read about cleaning a scope tube with alcohol. Is it standard procedure to clean scope, rings, and bases with alcohol when installing? Once installed, do you wipe off fingerprints with Ballistol, along with the rest of the exterior surfaces of the gun?

Can’t wait to finally see the fruits of your labors.

More errata:

What to do

I knew the scope wasn’t properly mounted, so I set about to mount it correctly. I get so caught up testing airguns that somethings [sometimes] I let things slide and this time they slid too far.

…

Serendipity

… now that I have seen it[,] I’m goping [going] to do something about it.

Roamin,

Okay, that does it. One day I’m just going to write a bunch of words and let you guys put them together to make a report. Did I say one day? I meant Monday.

BB

B.B.,

It’s rare that I offer you advice or even suggestions but here’s one. Only date/court qualified editors that you have vetted. 😉

kevin

I’m truly sorry. The last thing I wanted to do was to offend. I was just trying to contribute to the blog for the good of the order. You have given so much to us newbies in your patient and kind advice. I’m rather new to the blog, so I guess I’m overly eager to contribute.

Roamin,

No one was offended, you are ok, I look forward to the Monday post it should be a good one.

Mike

B.B.,

I suspect you already know this but things get overlooked by us humans all the time to bad effect all too often.

Before i tighten a scope ring (base if two part) to a Picatinny rail i make certain to push it forward against the front of the slot. Even if the rail is exactly to Mil Spec the base usually isn’t tight Fore & Aft in the rail. If you mix Weaver rings with Mil Spec rail it is even sloppier.

shootski

B.B.

I’m late to the party here, but you reminded me of my most recent scope mounting adventure; I bought a one-piece mount from PA, and the reviews on it were good, but I couldn’t see whether it would fit my fixed 6X UTG “BugBuster” scope. On another review sight (not PA!), one guy claimed that that mount “will fit all UTG scopes.” Well, to give him the benefit of the doubt, perhaps he meant “all currently-manufactured UTG scopes.” I bought the mount, and it did NOT fit; hence, I had to hog out some bevels, front an rear (as well on on both rings) in order to get it to work; I also had to shim the scope (at the back) up and to the right, as I was using all of the vertical and left adjustment, and my zero was floating. But thanks to this blog, I knew what to do! I also tapped a couple of 1/4″x28 set screws to keep the scope from moving…heh, that’s a story for another day. =>

Thank you for all the info you give out as it really helps!

Take care & God bless,

dave