The TX200-MkIII is a legendary underlever spring-piston air rifle.

This report covers:

- Background

- The kit

- The transfer port

- Disassemble the TX

- Cocking

- Firing behavior

- How smooth

- Cocking effort

- Velocity

- Red ‘N Tacky grease any good?

- Behind the scenes

- Where are we?

- Summary

Today I install the 22mm piston kit made by Tony Leach (https://airguntech.com/) and report on the results. If you own a TX 200 Mark III or plan to, this report is an important one.

Background

A couple months ago reader Buldawg made a remark that a tuning kit made by Tony Leach that he installed in his TX 200 Mark III made it almost as smooth as a precharged pneumatic air rifle. That started me thinking, because I once shot a rifle that looked very much like a TX200 and it was almost as smooth as a PCP. That rifle was called a Venom Mach II — a two-thousand-dollar custom underlever that was handmade by Ivan Hancock. Well I couldn’t afford it then (the late ’90s) and they are no longer being made, so it doesn’t matter anymore. Could the Tony Leach kit be as smooth as that?

I corresponded with Tony and decided to buy his kit. Here is what he told me.

“Regards the kit, I will drop it in my rifle here, and adjust stroke to push 8.44-grain JSBs out at around 770fps. Every gun is different however, so you may have to fine tune. Cutting the spring is not the way to do it for power drop. Adjusting the stroke by moving the piston nose up and down the rod is better. This means you have to break the Loctite with heat and re glue back on using high strength thread lock or bearing retainer. If this proves to be an issue I do have a fitter in the USA to whom you can ship the action and the piston. He is fully versed in the methods of setup. It may be real close as shipped, so test and see first. Adding a little preload is ok, but there are limits. These small piston conversions rewrite all the rules on airguns.

The kit will be a 22mm skirtless piston, a new compression tube with bearings with honed 22mm bore. The piston has a poly seal of my own design, bronze piston bearings and dual rotating tophat.

The mainspring is my own design — custom wound and it sits on a Delrin rear guide. The setup can in no way be pushed to make 12+ foot pounds, it will break the rear guide in short order (I know you said 11 foot pounds is fine but people will ask).

The pressure these kits create is huge, over 3000psi, all lubes will detonate, they do settle down though. Do not use Krytox or Ultimox, they are dangerous when they burn and they detonate in these kits, plus they don’t last.

I supply piston seal lube, it settles out so shake the bottle thoroughly to mix and only use a drop, every 5k. Piston rod has to run dry or it will cause suction. For spring lube, use superlube grease or a good lithium or synthetic grease. Moly works but does attack Delrin (I just learnt that). I use Lucas Red ‘N Tacky grease and apply it using a paint brush. You only apply enough to wet the guide and the coils.

Lots to take in. The set up is different than for the 25mm piston. There is no excess air; every drop has to be used to push the pellet. Over-springing can in small amounts help harder pellets such as FTT or RWS Superdomes make equal power to JSBs, however JSB performance will go down, especially Express. They let go and fly too early to get a full push.”

The kit

The kit consists of a sliding compression chamber that’s sized to the new 22mm piston, the piston assembly, a mainspring with front and rear spring guides, a small bottle of piston lube and some o-ring seals and three steel washers to adjust preload.

This is what came in the Tony Leach Kit.

The three steel washers vary in thickness and give a range of 0.5mm to 5mm preload, depending on how many washers and which ones are used. I decided to not use any preload when I set up the rifle because I am going for smoothness — not power. If I wanted more or less power the piston head can be adjusted in or out to give more or less stroke. This is exactly what we have been talking about on this blog for years! Forget stronger mainsprings or adjusting the preload.

I examined the fit of the Leach 22mm piston to the inside of the new compression chamber and it is tight! The machining on all the parts is top quality — as good as the Air Arms parts they replace.

The piston has no skirt. The brass rings fit the compression chamber precisely.

The stock TX piston is below the Tony Leach 22mm piston.

The transfer port

The transfer port is a brass tube. It’s recessed inside the end of the compression tube so the barrel breech stub will fit inside and seal tight.

The air transfer port is a brass tube deep inside the end of the compression tube.

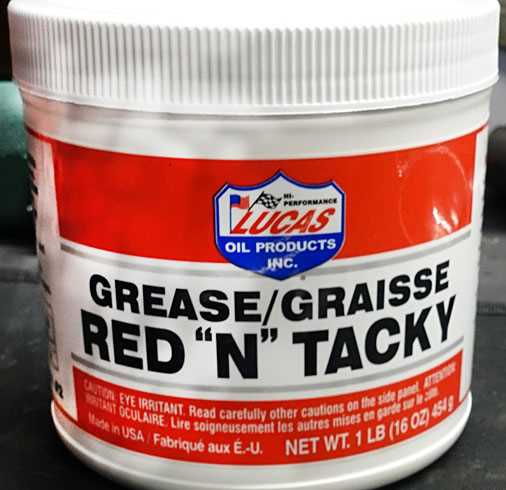

Tony also said he used Lucas Red ‘N Tacky grease for the mainspring. That sounded similar to the Almagard 3752 that I have been using (we know it as Tune in a Tube) for my past tunes, so I ordered some.

This grease looks identical to 3752 and the good news is sells at about half the cost. I guess this test will tell us how good it is.

Lucas Red ‘N Tacky grease seems to be good stuff.

Disassemble the TX

I now disassembled the TX, removed the sliding compression chamber and swapped in the new parts from the kit. That and taking pictures took about 30 minutes. Then I assembled the rifle.

Cocking

The rifle cocks like it did before. But when the sliding compression chamber is closed the fit is quite a bit tighter. It almost feels like it doesn’t want to close, and then it slides closed easily.

Firing behavior

The rifle is smoother than before, but it’s not as smooth as a PCP. As best I can recall from 24 years ago, neither was the Venom Mach II. There is a definite pulse when the rifle fires.

How smooth

Vibration is now completely gone, not that there was much of it to begin with. But now, since I’m shooting into the rubber mulch box/trap, I sometimes wonder if the pellet has even come out of the barrel — that’s how smooth it is. I suppose that is what people are trying to say when they say it’s almost as smooth as a PCP. There is still a pulse upon firing.

Cocking effort

The rifle now cocks with 36 pounds of effort. That is identical to the effort required to cock the factory mainspring.

Velocity

Since Tony set the kit up with JSB 8.44-grain domes, that’s what I used to test the velocity after installation. He said he expected the kit to deliver around 770 f.p.s. with this pellet. My rifle now averages 767 f.p.s. Here are all the shots in a 10-shot string.

Shot…..Vel.

1………767

2………767

3………764

4………765

5………768

6………769

7………771

8………766

9………764

10..……765

The spread is 7 f.p.s. At the average velocity of this pellet the rifle now develops 11.03 foot-pounds at the muzzle.

With the previous tune and a new piston seal the rifle averaged 929 f.p.s. with 7.9-grain Crosman Premiers. That was good for 15.14 foot pounds.

Why didn’t I test it with Crosman Premier lights? Because Tony said the gun is set up for JSB 8.44-grain pellets. I know Premiers are harder to start because they are made from hard lead, so I felt it was right to stick to the pellet Tony recommended.

Red ‘N Tacky grease any good?

I could have used Tune in a Tube (Almagard 3752), but since Tony mentioned the Red ‘N Tacky grease I wanted to give it a try. As far as I can tell, it seems quite similar to TIAT. Since it is less expensive it might be something that you want to try.

Now that the kit is installed and the trigger is adjusted to perfection, I am ready to continue accuracy testing. Of course this rifle is different than it was the last time we tested it for accuracy. But you may remember that this JSB dome gave the smallest 5-shot group at 10 meters. It was just 0.098-inches between centers. That will be hard to beat.

Behind the scenes

I actually installed this kit three separate times. The TX 200 disassembles so quick and easy that you can do this. The first time was with no grease on the mainspring. There was some vibration with that. Then I put an ultra-thin coat of Red ‘N Tacky on the spring and tried it. The JSB pellet averaged 782 f.p.s. with an 11 f.p.s. spread, but there was a bit too much movement at the shot. The vibration was gone but I felt the two-way recoil of the piston.

Then I put on what most people would consider a light coat of grease. That one was the charm and gave me the best velocity (767 f.p.s.) and spread (7 f.p.s.). That was the point where I thought the pellet might not be coming out of the barrel.

Where are we?

My TX200 Mark III now has what must be considered the ultimate tune. The trigger is adjusted to perfection and there is a Meopta MeoPro Optika5 4-20×50 RD BDC3 scope mounted. Only one thing more is needed to complete this ensemble — a new stock. When I bought the rifle it came with a beech stock, but now that I’ve invested the money to make the rifle as good as possible I think a beautiful walnut stock is in order. It’s way in the future, but that’s the way I am thinking.

Summary

Spring-piston airguns get no better than the TX200 Mark III, and now I have tested a kit that takes them to their limit. My rememberer strains to recall how smooth the Venom Mach II was 24 years ago, but I think my rifle is just as smooth.

You do give up power with Tony’s kit. However, it has been successful in removing all vibration and much of the rifle’s movement upon firing.

The good news is the rifle has not been modified in any way that cannot be returned if I want. Just reinstall the factory part and there you are. It takes all of 15 minutes to do.

B.B.

Nice to see new ideas brought to old springers.

-Y

I have two off-topic questions today:

1.) I have a pile of empty pellet tins. Other than turning them into targets, has anyone found any reasonably creative things to do with them?

2.) There’s this guy on YouTube that publishes under the name “Farm Project”. His market niche is to do comparison tests of everything you can imagine and he’s really quite inventive about it. He tested “CLP” (Clean, Lubricate, and Protect) oils including our beloved Ballistol, but Ballistol didn’t do very well: https://www.youtube.com/watch?v=fibRewlndLg. The best one in his test was Clenzoil. Does anyone here have any experience with this stuff? Comments on his test?

Motorman

St. Louis, MO

I fill mine with melted pellet lead and use for paper weights OR drop them simultaneously with feathers through a vacuum to verify that the Force Of Gravity is not racist.

B.B.,

Interesting read and it looks like a substantial reduction of MASS. Did you happen to weigh the Tony Leech kit and compare it to the OEM parts?

Errata: in “How smooth” second sentence,

“But now, since I’m shooting into the rubber mulch box/trap, I sometimes wonder if the pellet has even come out of the barre(l)

— that’s how smooth it is.”

shootski

shootski,

Fixed it. Thanks,

BB

Piston weight is 150g approx. Between 145 and 150. Stroke was set to approx 82mm, I can also build power plants using the the UK spec tx355 OEM spring, these use 90mm stroke and have reduced cocking effort, however some batches of springs have been of poor quality hence I now supply my own spring unless specifically asked for a 355 based power plant.

I also can supply this conversion with a full piston, weight is similar, stroke is not as flexible however.

Regards Prems etc, the pressure these kits produce is huge, this means to set the gun up for JSBs a smaller port is needed, 99% of people shoot JSBs so I default to this, however a new port and some added stroke and Prems will work just fine at the expense of jsb velocity. It all comes down release pressure of the pellets, Prems have near double the holding power but then need greater flow. The comp tube is ported to 3.5mm with a radius inlet, the brass port is 3mm for Jsb, sometimes smaller, for Prems or HnNs I increase port size to 3.5mm.

The power limit is dictated by the pressure created, plus piston weight, right now it’s all balanced around 11fpe, some adjustment can be made but much more can lead to piston bounce. Many people do play around with these kits and set them up away from how I have, some ask I don’t build the pistons as they want to dry fit using weak loctite to set up where they feel it’s best for their gun, every gun is different remember and will work differently. Bench rest shooters are increasingly telling me jsb 8.44s are giving the best accuracy 20 to 25yards at 735fps, one customer hit 250 and 17x with his tx at this speed so there must be something to it.

I also do a sleeve kit to 21mm, this produces even higher pressure, the piston is even lighter so the guns move even less, it uses the same spring as the 22mm and generally produces higher fps with 8.44s over jsb 7.9s as the 7.9s let go to fast. This kit needs installing Into the OEM comp tube.

Accuracy…remember I don’t touch the barrel, the guns are normally easier to shoot however so many see Improvements. If the barrel was accurate before it will still be accurate now.

Spring lube. Red and tacky mixed 2/3grease to 1/3 STP oil additive for petrol engines ( blue bottle) add some moly powder or tungsten disulphide powder, for a pellet tin full of lube around 1/2 teaspoon of powder. Apply with a paint brush to wet the spring , but not the piston rod, that has to run dry apart from the latch face for the sear.

Most FT shooters shoot the conversions around 740 to 760fps with jsb 8.44s, they tell me in a heavy FT stock the guns are almost dead to shoot.

The parts are all CNC made, I’m not a trained machinist, I design and prototype here and make small adjustments etc, hence the kit is of OEM or above OEM quality.

One last thing, the port is brass for a reason, the steel OEM port bashes Into the breech face of the barrel and damages it, I did try Delrin ports but they can erode over time, so I needed something harder and burn resistant to Delrin but softer than steel, ALU was tested but I ended up opting for brass, ALU depending on grade is even softer. The hope is the port will now no longer damage the barrels.

Tony

Tony,

Thanks for anticipating the questions some will surely raise.

Siraniko

Tony,

I had planned to send you an alert that this was up, but you beat me to it. I am really enjoying this kit.

Thanks,

BB

Glad you like it, it’s taken a while to change people’s minds about power Vs smoothness or 25mm Vs 22mm etc and will still be being debated for a good while yet, some just prefer it as it was designed, some like it different. I actually developed a nice 25mm tune that uses a special seal I developed with a lightened stock piston, add the OEM 355 spring 1 coil shorter and it makes for a very smooth shooter, same set up in .22 has shorter stroke.

The change to small pistons for me was originally sparked by watching an old timer trying to cock a 97k, I ended up swapping his action for mine as mine had a 23mm piston with a softer spring and longer stroke, he went from 2 hand cocking to one hand. In the end though as you noted cocking effort is not always lighter, it can be if needed, it’s all in the set up and the parts used, and being flexible makes it all possible.

Tony,

Thank you for the detailed information about your powerplant modification(s) on a coil springer. I went PCP a long time (three decades) back and came from single and multipumpers. Only recently did I turn to a gas spring powerplant. Which leads to this question: since metal coil springs can have great winding, material quality, and condition over time issues have you given thought to modification of gas spring powerplants?

Specifically Is there some modiications that could improve on the SIG SSG ASP20 powerplant?

shootski

BB

You said the same thing on another one of your recent TX 200 reports. It wasn’t me. It was Buldawg. I have never used one of those kits. And if I remember right the kit was kind of ridiculously priced.

GF1,

Sorry again. For some reason I have that fixed in my mind.

BB

BB,

I use Lucas Red ‘n’ Tacky all the time. If is not Almagard, it is close enough. I bought a lifetime supply for about $5 at Lowe’s. Works great.

You should say “hang it all” and dress that lady up, most especially if she is how you want her. Enjoy her to the fullest while you can before she belongs to someone else.

Little further info.

Kit pricing is based on small batch runs, I am not able to buy in huge production runs to drop costs, I wish I could however, I infact make very little from these kits, and they are manufactured in the UK not China etc. Most of my profit goes back Into other parts such as HW97/77 22mm comp tube development and the magnetic under lever catches for the tx I recently released. So while expensive I do feel the price reflects the time and expense I put into development etc. I also carry full spare parts, seals, springs, guides etc.

Clarification on moly degrading Delrin, it seems to bond with the molecular structure of delrin and causes it to soften. It takes a long time it seems, the COF is reduced between steel and delrin with moly however so it can have it’s uses. I also can supply a steel rear guide, this is defacto on the sleeved piston version of this kit. The recipe for the spring lube I just added in a comment, you can swap the moly or tungsten powder for super fine ptfe powder, it works just as good or just run the grease and STP mix and be done.

Versatility; I recently built a 21mm power plant with around 60mm stroke, this was purely for benchrest shooting, 8.5fpe power. The guns owner had experimented with stroke from 90mm right down to 60mm searching for the best accuracy with the chosen pellet, usually in 20fps jumps, so imagine testing 780 then 760 then 740 then 720 all the way down to 650 or so. I even developed a special long piston rod specifically for this. The pistons he used had the MK3 rod to start, then what I call a MK4 rod as it’s of a special length between a MK2 and a MK3, then a MK2 rod finishing with the super long special rod. Piston weight increases as the rods get longer, however this is optimal, going lighter actually leads to worse bounce. The spring in all cases remains the same with the same static preload, just final compression height changes along with swept volume. This is why it’s important to adjust stroke over adding washers etc, a drop in swept volume or a gain of swept volume along with spring final compression height is way better than adding lots of washers and weight.

Last thing, the piston bearings are alu bronze, not brass, little harder wearing, still bearing grade material. The comp tubes are honed to a specific tolerance, the bearings are machined to suit this tolerance to reduce piston side slop as it flies, this means the pistons actually could fly as true as the OEM piston does in its comp tube. My full piston conversion is much like the set up used on a FWB 300s etc, just close tolerance matching.

Thanks tony for your responses!

How about a kit for break barrel airguns?

-Y

They need sleeved actions and skirted pistons, as to cock the gun you push back on the piston. I actually have converted many hw80s to 25mm and one 24mm, I have an old hw95 here with a 23mm piston and my favourite is a Diana 34 with 24mm piston.

It’s in the works, just time and money to get together. Plus the guns are essentially tuned for a given power level, in my case around 11fpe. Many in the USA don’t feel this is enough, and remember the conversion limits how high the guns can be pushed as the pressure goes higher.

B.B.

For the nice walnut stock, think about Custom Stocks in the UK!

https://www.customstock.co.uk/shop/

Otherwise mucho $$$. lol

Let us know what you decide.

-Y

If you want nice wood there are a few

stock carvers here in the UK that are pushing out seriously nice wood, on another level to a CS stock. CS stocks are nice though, I have around 8, my next stock will be from one of the other guys I think though.

Love to hear more about them. Here, over the pond, very few want to touch airguns and the ones that do cost 2-3X what Custom Stocks does.

Now get rid of bumbling Boris…

-Y

Yogi,

Thanks for that link.

BB

Next: The TX200 book! Coming soon! 30 years of experimentation on THE Classic, the Air Arms TX200.

David,

You know, after I self-published the R1 book that was going to be my next one. But I don’t think I can afford to lose any more money! 😉

BB

BB

How does discernible movement now compare to your FWB300S?

Deck

Deck,

Well the 300S’s recoil mechanism isolates me from the recoil, so the TX200 pulse is stronger.

BB

BB, fascinating report, thank you and Tony for the peek under the hood of a seriously nice spring gun action. The adjustable piston head reminded me of an aftermarket compression piston for the lowly Crosman 1377 pumper . Maybe the Dragonfly pump handle can be retrofitted to springer.

Barrel harmonics get tuned as well? Nice stock link, The R10 has to wait.

Rob

“My rememberer strains to recall how smooth the Venom Mach II was 24 years ago, but I think my rifle is just as smooth.”

That’s pretty cool, B.B.! 🙂

Tom

Will this fit in a pro sport? Are they the same power plant? I don’t have either rifle yet but was planning on a Pro Sport as my next purchase. Mostly because I like the looks. Other than the higher cocking effort is one better than the other.

Thanks Speakski

Speakski,

It’s ProSport. not pro sport.

If this kit doesn’t work he probably has one that does.

Ask him. I gave you the link.

BB

Hello BB and people. It’s been a while.

Darn and heck it’s hot here! ( NZ ) and I have two cars to yank engines out of etc. Do I feel like doing it ? No ! A cold drink in the shade is a much better proposal.

I have an idea for a low pressure Air Rifle.

Just thought I would share, especially those who wish to run off a low pressure air compressor.

This is just an idea and has not been rigorously prototyped in the garage at all.

The operating principle is, erm, something like air velocity inertia or “air hammer” or something.

Low pressure air is venting out the barrel. After a sufficient flow has been established the pellet is offered up the breech. The pellet is simply flushed down the bore and ejected.

Rinse and repeat.

The air could be low pressure PCP or maybe a large volume/low velocity piston and spring.

The timing is critical:

Flow has to be established then the pellet offered to the breech, not too early and not too late.

The idea came to me after spitting plum stones, they go better if you purse your lips, blow then offer the stone up with your tongue. Stone spitting? or Pit spitting ? You decide. But there is definitly something interesting going on. Hydro dynamics !!!

Food for thought!

Hope you are all well and ticking along nicely.

RobertA. : -)

PS. I made a diagram. The air flow starts up ( no idea how ), once air is flowing the transfer block slams closed and the pellet is now “in the bore” and air pressure is building behind it, then is it “flushed” down the bore after friction lets go.

RobertA,

Hello RobertA! I hope your rifle’s stock has been finalized. If I recall correctly the pressure rapidly builds up behind the seed as it passes through the constricted lips giving the seeds the velocity. Something like a squeeze bore.

Siraniko

RobertA,

So good to hear from you. Your design would use quite a volume of air but with a shop compressor that may not be a big issue. The velocity of the pellet as it enters the barrel is a plus. The momentum of the mass of air in front of the pellet would create a partial vacuum also a plus. Not sure how you load the pellet but is should work.

I have continued to work on my low pressure pellet gun since you last posted. I have been working on the trigger and accuracy. I will try to give an update in the next few weeks. Keeping up on required chores has kept me busy lately.

Don

Robert,

Maybe your drawing will give someone an idea.

BB

Thanks for ANOTHER great article!

Hello BB!

I made selfmade low diameter gun in last year.

I used 21mm piston in my work and noticed the problem of very high pressure too. There was a very large dependence on the release pressure.

However, I was able to fix this problem by making an ultra light piston weighing about 40g. This was a great solution, even JSB RS work well in this configuration!

https://www.airgunforum.ca/forums/topic43541-75.html

http://gnom256.narod.ru/obzori/molina5.html

gnom256,

Reading through you page by Google Translate. Very innovative and interesting. How heavy is it in the stock? Is it heavier than a FWB300s?

Siraniko

Thanks! The weight is quite similar to FWB300.

5,35kg(11,8Lb) with Nikon EFR 3-9*40 scope