This report covers:

- Be reasonable

- Why write this?

- But…

- No clocks — airguns

- Mainspring compressor

- What about pneumatics?

- CO2

- The money?

- Summary

Today we will explore the possibilities of you working on airguns.

Be reasonable

You want to rebuild your 1924 Crosman multi-pump that is the predecessor of the model 101. You wonder where to get parts and schematics. Sound familiar?

Let me change the facts to make it easier to understand. You just inherited your grandfather’s 1931 Rolls Canardly touring car. Where is a good place to get parts? Where can you get drawings that show all the parts and how they go together?

A good place to get those parts is in your machine shop. Oh, you don’t have a machine shop? Well, get one and learn how all the machines work. Then, in ten years or so, you can make the parts you need, because the Rolls Canardly car company went out of business in 1934. They never really had drawings, either. They had a few scraps of paper that the machinists used when they were making the parts, plus they used the engine block from an 8 cylinder 1929 Packard Phaeton. Try finding out of those! By the way, the reason they went out of business is their car just rolls downhill and can hardly make it up the next one.

Working on a 1924 Crosman multi-pump will be a graduate course in airgun repair. They were put together differently in those days and they require special tools for disassembly. A lot of the parts look similar to the later 101 parts, but they aren’t. That rifle is not the place to start learning about airguns!

Why write this?

The other day I addressed a question written by reader Alex2no in the report titled, What do you need? She wanted to know what sort of spares she should keep on hand for her spring guns. And she told me she was not particularly mechanically inclined. I told her I understood because I’m similarly mechanically inept, and some readers didn’t believe me. After writing the report I noticed that I recommended a lot of things, but not many of them were parts.

And then I took the Haenel 312 apart. You read about that yesterday.

All of that got me thinking — what about all the airgunners who aren’t mechanically inclined. Can they work on airguns, too? Should they even try? And that leads me to the subtitle of today’s report — Is there an airgun, or airguns that is/are simple enough for most people to work on? Now, here’s the deal. When you were young you didn’t know how to tie your shoes. So someone taught you how and then you knew. Or you may wear shoes that don’t have laces for that very reason.

Before you rode a bicycle for the first time someone probably showed you how. Stuff doesn’t always come naturally. Some of it — even a lot of it — has to be learned.

Okay, okay, BB. What does this have to do with me? I inherited my dad’s Benjamin model 130 pistol and that’s the only airgun I have. What do I do?

Well, if you inherited your dad’s 1968 Omega Moon Watch chronograph should you take it apart and clean it? Of course not. In fact, for a complex mechanism like a wristwatch or a clock maybe you should just keepa your hands off it — forever!

But…

But you’re interested in how clocks work! You want to take them apart and put them back together.

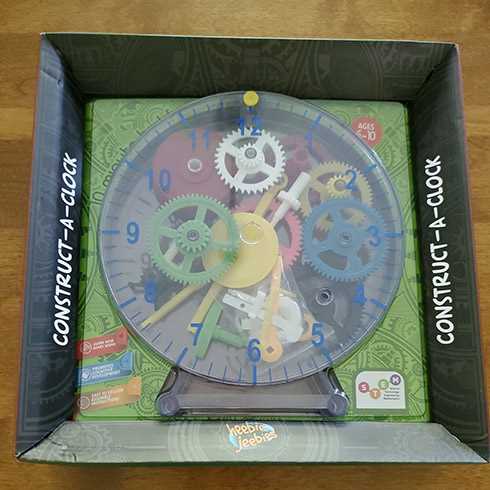

Okay, let’s find a clock that you can work on safely. How about one like this that sells for $10.50?

This construct-a-clock kit is an educational toy for ages 6-10. I don’t know about you, but that appeals to me. I reckon I can do anything a 10-year-old can do, except run around all day!

No clocks — airguns

Okay, you don’t want to build clocks. You want to work on airguns. Are there any out there that would be good for you? Yes, says BB Pelletier! There aren’t many but the Weihrauch HW 80 is a place to begin.

Wait a minute, BB! Isn’t the HW 80 expensive? Yes, it is. What about the HW 30S that you worked on recently?

I didn’t recommend the HW 30S or the HW 50S for one good reason. Their end caps don’t come out that simply. Where the HW 80 end cap unscrews, the end caps of the 30 and 50 require 4 tabs to be punched out and then the inner cap has to be rotated slightly for a tab to clear the spring tube.

The HW 80 and Beeman R1 end caps unscrew, making disassembly much simpler.

BB, what about the Beeman R1? Isn’t it an HW 80 by another name? Yes, it is. Get one and then read my 13-part Spring gun tune report.

What about the Beeman R10, which is also the HW 85. Don’t they have end caps that unscrew, too? Yes, they do. If you can find one, go for it.

What about the Beeman R9/HW 95? Do they come apart easily? No, they don’t. That rifle has those same pesky end cap tabs that BB thinks are too complex for working on a first easy spring gun.

Mainspring compressor

You will need a mainspring compressor to safely disassemble one of these air rifles. Oh oh! BB, you said this was going to be easy. I don’t want to waste money on a mainspring compressor! I just want to work on airguns!

Okay, I have two things to say to you about that. First, you tell me you want to work on your Rolls Canardly but you also don’t want to buy any wrenches. You have a Chinese adjustable wrench that came with your kids’ bicycles and you reckon that’s as far as you want to go in the tool department. That’s like saying you want to learn calligraphy as long as you don’t have to learn cursive!

And second, why not make building your own mainspring compressor your first task in learning how to work on airguns? It’s not that difficult and if you are up to it, then working on a spring piston airgun shouldn’t be beyond you.

What about pneumatics?

I don’t know of very many pneumatics that are easy to rebuild, but there are a couple. The Beeman P3 and the Beeman P17 come to mind. Reader Ian Mckee gave us a wonderful series on resealing the P17, and since the P3 is virtually identical, you are in business. These are both single stroke pneumatics and I rate them as more complex than the spring guns I just mentioned, but still doable for most folks.

The Beeman P17 single-stroke pneumatic is easier to rebuild.

Perhaps there are others but these two I know for sure.

CO2

I know of no CO2 guns that I would recommend to a first-timer. CO2 and pneumatics are guns that need good seals and their valves must be clean for them to work. Yes, I said you can repair a P17, which is a single stroke pneumatic, but it is the simplest of all the pneumatics that I know of, and the guest blog about resealing it is so straightforward.

With just a little practice you could repair some of the older CO2 guns like the Crosman Mark I and II and the S&W G78 and G79. But they don’t make good starter airguns, as far as I’m concerned.

The money?

The P17 is really the only affordable airgun on the short list I have given you. I would shop for the others as used guns. But my point today is, if you want to learn to repair airguns, this is a good way to start. It will be challenging for some of you while others will wonder why I was so cautious.

Summary

If you want to start fixing airguns I have outlined a simple way to get started. Yes there are costs and yes there will be things to learn, but learning is the point, isn’t it?

“…the end caps of the 30 and 50 require 4 tabs to be punched out and then the inner cap has to be rotated slightly for a tab to clear the spring tube.”

B.B.,

Thank you for that reminder; I’ll just keep shooting my HW30S for as long as she continues to shoot; and then, if that sad day ever comes (that she “has issues”), I’ll turn to your blog here, cry a lot about what I should do, then follow your advice. 😉

Take care & God bless,

dave

B.B.

What about the HW 35? Is the end cap threaded also and can someone work on it as “easily” as the HW 80?

Bill,

I don’t know about the 35. That barrel lock leaves me in doubt for newbies, but maybe I’m being overly cautious.

BB

Hi everybody,

I serviced my old HW35E recently (new spring and spring guides, replaced the leaf spring that guides the cocking lever).

I don’t remember having much of an issue with the barrel and its lock. I think I unscrewed the main barrel screw that attaches the barrel to the system and I believe that was enough to be able to remove the whole cocking linkage, too. I don’t remember removing any of the barrel or cocking linkage pins. The barrel lock either stayed in place or I had to put its spring somewhere safe before I needed it again. It can’t have been much of a problem.

I didn’t have that much trouble with the end cap either. I kept things together with a screw clamp while slowly unscrewing it and I may have done it all by hand when putting it back together. But you have to remember I have the 7.5 joule version. It might be trickier with the full power spring and a mainspring compressor might be a good idea.

I would say its possible if you have some mechanical skill. Just be careful with the mainspring and use screwdrivers that fit well. Also, remember to cock, the trigger and insert the safety and its spring before putting the gun back together.

Stephan

P.S.: We are all beginners until we gain experience. And one of the best ways to gain experience is making mistakes 🙂

Stephan thank you for your detailed answer. Screwed on end cap it is then.

BB,

I know it is expensive but at least you don’t really need a spring compressor (usually) when working on an AirArms TX MkIII. Now that may be an idea, if Crosman could sell with the help of their marketeers a sub 12 fpe line of rifles that would also be easy for a first timer to repair.

Siraniko

Siraniko,

Tried that once. It did not sell well. Everybody over here thinks they want a 2500+ FPS sproinger.

The truth is I have a bunch of sub 12 FPE airguns. I still need a spring compressor.

RidgeRunner,

I would like to believe that the market just needs to be created by the same marketeers that have deluded the buying public for years into buying into velocity is everything. They should realize and create a new market as that the current market is already saturated.

Siraniko

B.B.

Every auto mechanic I know started as a kid working on lawn mower engines.

My suggestion to anybody interested in working on airguns is to get a “beater” to work on first.

JMHS,

-Yogi

I grew up using and working on pneumatics, of all kinds, co2, single pump and multi pump.

I didn’t get into PCP’s until my adult life, (my LATER adult life at that.)

So pneumatics just come naturally.

With the exception of the GISS spring guns, (I like unusual vintage airguns) I tend to consider the insides of most springers some deep dark corner of the airgun world I rarely venture, there are things inside that will bite you, and jump out and hit you in the forehead if you aren’t careful.

Ian

ROTFWL! Yes, many of them can indeed bite! It hurts also!

I started with sproingers. I bought a spring compressor similar to BB’s. I have news for you folks, it is still not a cure all. Some of these old gals I work on and fix up, you had better have a very high mechanical aptitude. Some of these you are going to have to make special parts for your spring compressor to hold them.

Some of the newer sproingers are easy to work on as they were designed to be put together by trained monkeys with flashlights. What?! Do you think these airgun manufacturers want to pay engineers to assemble their product?

That is also why they have assembly lines. They only have to train this monkey to do one little task instead of the whole job. If you are going to work on airguns, you are going to have to know the whole job.

I dream of doing this for a “living” when I retire. First, I need to get a machine shop and learn how to use it.

R.R.

You are right about the trained… although I believe we owe that concept mostly to Ford and his trained “employees”, who made this revolution with the Model T.

I think I’m going to get the clock first and see if I can put it back together without too many left over parts. That should be a good litmus test….

As for aptitude, I think sometimes patience and an ability to follow instructions is a workable substitute. Ian’s series on the Mark I / II was a great help, after BB suggested the Mark I as an introduction to pistol target shooting . I have repaired 6 so far and am set to make gifts of a few to newbie shooters.

B.B.,

This report is both inspiring and depressing for me, as I am unable to work on air guns of any kind successfully, ever. I have killed every single air gun I have ever attempted to work on, using proven repair methods and tools described in excellent detail in this blog. (I encourage others to learn to work on air guns; I am, well, unique.)

Example? A few years ago I killed a Benjamin S397 and S&W 77A by applying Bar’s Leaks Transmission Stop Leak Concentrate to their pump heads. They stopped pumping up, so after carefully reading your report on the Daisy 22SG, I put a couple dabs on the pump heads through the slot, and they went from not compressing air and having no resistance on the pumping arm to being virtually impossible to pump. (A few drops of the stuff also removed a couple small spots of finish from the chrome plated S397.) My guess is that each air rifle closes with about 60 pounds of force on each stroke. Is that normal?

I imagine they need to be sent to an expert repairman to be completely dissassembled and many of the parts cleaned with solvent. For three years they have been in the corner of my basement where I keep dead aIr guns. There are dozens in there, many of which were killed by my trying to repair them. I am able to put a drop iof Pellgunoil on the tip of a CO2 cartridge before putting it in an air gun, That is the extent of my abilities working on air guns.

However, I have found that I am different from virtually everyone else who frequents this blog, so no one should be convinced not to attempt a repair bevause of my unique record of 100 percent failure. I am merely cursed ;^)

Michael

Michael,

You do realize that you have waved a red flag to all the guys on this blog?

Come on guys — we gotta help Michael.

What if we took this step-wise? For example, what if Ian McKee walked you through resealing one of your CO2 guns like a Mark I or II, one step at a time and you did what he told you until the job was finished?

BB

B.B.,

I have tried to follow clear, precise instructions for aIr gun repairs on this blog and on other websites. Each time I rendered the air gun inoperable. Therefore, “what if Ian McKee walked you through resealing one of your CO2 guns like a Mark I or II, one step at a time and you did what he told you until the job was finished?” Everything would probably (but not necessarily, see below) be fine as long as the air gun did not have to be taken apart or any parts removed and then put back in place. That’s where I get into trouble 100% of the time. So, what if I followed the instructions one step at a time? I promise you I would end up with a dead Mark I or II.

What if I followed the instructions to the letter? I have never tried to work on an air gun without researching the process and following it carefully. Each time my results were an air gun I could not put back together or, as was the case with my multipumpers, I followed the instructions, even with a job that did not require that I open up the air gun, and I got the opposite results of everyone else. I applied the correct product to the correct spot in the correct way, and it made the rifle inoperable and a candidate for shipping plus repairs that would cost more than the rifles are worth. Therefore, they are for all prasctical purposes dead..

I admit I have twice revived a leaky air gun by flooding the seal with Pellgunoil, loading a new CO2 cartridge, listen to all the gas escape, and repeat five more times. The sixth time, it held! $10 worth of CO2 and Pellgunoil and job done.

Michael

B.B.,

“Come on guys — we gotta help Michael.”

You and the others here are all wonderful, generous and gracious. But I have felt for some time I have been imposing on many of you, taking too much advantage of that generosity. I have decided that from now on if an air gun of mine breaks or simply stops working I have three choices: paying someone out-of-state to fix it, opening it up and surely destroy it and yet again affirming my incompetence, or throwing it in the dead air gun corner.

Michael

Michael,

Most mechanical things stop working smoothly because they get dirty, contaminants in the oil/grease, start wearing the parts then the parts bind and eventually cause a breakdown.

Routine maintenance – cleaning out the dirt, proper lubrication and correctly tightened hardware will keep things working and can usually be done without going inside.

If maintenance has been neglected and the item (gun, fishing reel, tool, whatever) is not working smoothly a clean/lub/tighten may be all that is needed to set things right.

Inspect moving parts/joints for galling, excessive wear or damage. Polishing, shimming might help, if not new parts may need to be installed.

***applying Bar’s Leaks Transmission Stop Leak Concentrate to their pump heads*** might have caused plastic/rubber parts to swell and bind. Flushing it out with varsol or naphtha, letting it sit for a couple of days then applying some oil might help… but it sounds like the seals needed replacing. An airgun smith would be able to do repairs an return the gun to active service.

Mechanical repairs and service can be learned. Do you have a friend or know a gunsmith or mechanic that might give you some one on one help?

Hope this helps.

Hank

Hank,

“Mechanical repairs and service can be learned.” By the vast majority of people, but not me.

“Do you have a friend or know a gunsmith or mechanic that might give you some one on one help?” Nope. A person as unhandy as I am does not easily make friends who are handy. We usually have little in common. On two occasions B.B. generously repaired air guns of mine, and on at least one other occasion he made an offer that I gratefully and politely turned down.

I have taken far too much advantage of the kindness of others. I have for some time now preferred having permanently unworking air guns until/unless I hire someone to do the job. Two-way shipping is about $100 these days, so that means it goes into the dead air gun corner (literally, a corner in my basement).

Michael

Hank,

I just thought of two occasions I approached automotive mechanics instructors at my college to see if they would do a small job for me (paid). The first one took my colleague about five minutes and after he finished, he handed the mechanical item to me and generously said, “It was easy. No charge.” I thanked him and asked if there were any favor I could do for him in return. He chuckled, smirked and said, “Naw. Don’t worry about it. I don’t need any writing to be proofread or anything..”

The other time it was a more involved but simple job my mother was willing to pay for on her 2017 Kia. That colleague (a different one) strung me along for three weeks, telling me he was having trouble finding the part in any of his online sources. Finally, he said he just couldn’t find the part a then-two year old Kia Soul bumper attaches to inside the front end. “Kia doesn’t have them,” For three weeks my 80 year old mother couldn’t drive anywhere because he “couldn’t find” the part on the internet.

And then there was my dad’s mechanic who would always start by saying, “Your first mistake was buying a Toyota.” Or Honda. So perhaps I haven’t been too eager to make friends with an automotive mechanic. Yeah, my fault.

Michael

Hank,

Just now I dug the Benjamin and S&W out of the dead corner and tried to pump them. During the three years they sat there something happened. Both rifles now have pumping arms that can be worked without too much effort. Neither compressed air, but this suggests to me you were correct about the seals swelling.

I positioned them appropriately and put seven or eight drops of 5W-30 non-detergent motor oil on the pump heads. I also put a couple drops on the linkages.

Tomorrow I’ll try them again and report back if anything happens.

Michael

Good luck with that Michael!

I’m pulling for you!

I may have asked you this before, but what all is in your dead air rifle corner, aside from the two you are trying to resurrect?

Roamin’,

A few vintage springers, but mostly vintage CO2 air rifles and pistols from the 1960s and 1970s, the Golden Age of CO2.

Michael

Michael, the blog software won’t let me reply to your last reply to me, so I had to back up and reply here. I searched the conversation we had last Pi day, and I have an idea you might consider. Email me at Bill not William ok (all one word) at G mail dot com.

There is an spring piston airgun class scheduled to run at Murray State College gunsmithing school. Dates are Jun 13-27. Tishamingo,OK. We need 3 or 4 more students to signup immediately or the class may be cancelled. Bring your spring piston guns as we will work on actual guns in class. Spring compressor will be available. Signup now!

Oops

Date is June 13-17!

I can take questions via email. First half of email is jbcje87. Second half of email is sbcglobal.net.

MSC

Sandi Hopson

Gunsmithing Office Assistant

580-387-7480

To signup.

Another good one! Ease of repair is one area where air gun manufacturers could improve their designs and FM believes – he may be wrong – air gunners would be willing to pay a little more for said feature. Yeah, as Yogi said, start with a “beater” air gun you don’t mind beating further unto death and learn from your mistakes. FM ain’t no genius mechanic, but started getting more comfortable trying repairs and maintenance with the wheeled stuff with a couple running derelicts and went from there. Sometimes he actually got things running again! We have access to expert advice both for air guns and vehicles we did not have “back in the day.” Some people are naturally talented when it comes to maintenance and repair of just about anything, my late father-in-law being one of them, and FM is grateful for the things learned from him.

Michael, you don’t have anything to lose with the dead guns in your closet, so – why don’t you give them another try? You might be surprised to find out you’re not as inept as you believe; stop believing that. And, B.B., don’t buy your assertion you’re not skilled at fix-it – trade your skills for mine, anytime. A lot of it involves using common sense which FM grants, is not common.

FawltyManuel,

Regarding manufacturers, I agree with you. However, they have an incentive to keep their products difficult or expensive to fix. If an owner of an air gun finds repairing it problematic, he or she is much more likely to purchase a new one.

You have a good point regarding those air guns of mine that are in disrepair and which I have given up on. I could again attempt to repair them. I would almost certainly be unsucessful, but it would hurt nothing to try except a loss of time (and perhaps more discouragement).. I could try to disassemble my multipumpers and use naptha on the parts gummed up with automatic transmission sealant. But then would I need to purchase more parts? Probably new seals, but they would be inexpensive. Would I be able to reassemble the rifles? My previous experience suggests no.

Michael

The manufacturer who sticks to the concept behind the original VW Beetle – reliability, simplicity and relative ease of repair, without a need to bring out “new and hyper-improved” models every year will have a winner on their hands. Disclaimer: FM is a VW fan – ah, no pun intended. Applies to air-cooled models only. 😉

Michael: this is not an FM original suggestion – it has been stated before by far better people – “do not be afraid.”

Hey Michael,

I’d encourage you to try fixing those guns – nothing to lose and at worst case you still get experience!

Do you have a buddy that you shoot with or is there a shooting club or field target club near by? Could get some help there.

A couple of thoughts…

Review any documentation that you can get a hold of. The manufacturer often has diagrams and parts lists and if you search the web you can usually find detailed information. I found this blog by searching for piston replacement information for my FWB 124, …been here ever since 🙂

For disassembly and reassembly a camera is your best friend – it will see where every part went so you can return it to the correct place – take lots of pictures and make notes!

At every step look at the parts and how they interact. Watch when you remove a part – take the piece out then immediately replace it to learn how it fits together. Pay particularly attention to springs, how they fit and what they lever against Check the parts for damage, wear or burrs.

Keep loose parts in an egg carton or muffin tin so you know the order they were removed in..

A magnet wand, tweezers and needle nose piers can be useful. Small parts can be “glued” in place with a dab of grease to make them easier to install.

Above all, take your time, think positive and have fun!

Hank

B.B.,

I reserve the right to back out, but perhaps I could do a guest blog documenting a failure to repair an air gun. You often encounter a setback or two but always prevail in the end. Maybe it would be a change of pace, heh, heh, to have a couple blog entries in which I attempt something, have a setback, another setback, another setback, another setback and ultimately fail to repair it. Or, I could succeed. :^) Yeah, right. :^(

Michael

Yes please Michael. I would love to read a guest blog written by yourself. What a brilliant idea! 🙂

I have found that the best airgun to learn to work on is the one you can afford to throw away when you ruin it. Or lose multiple vital parts. Or custom downgrade it.

To some extent I sincerely believe this is the natural learning curve. I know I have always learned the hardest (i.e. most expensive/physically painful) lessons fastest.

I just recently bought a cheap Beeman .177 springer specifically to futz with. I wanted to learn how to button a piston, shorten a spring, sleeve a compression chamber- basically try to tune all of the buzz out of a springer and smooth the shot cycle.

I have “upgraded” a couple of guns in the past to both semi-functional and “just-plain-dead” and I knew it would be absurd to try to learn this on a $500 gun.

To my utter surprise everything went great and I have a smooth, easy-cocking, vibration-free gun. The irony is I spent $89 bucks on a cheap Chinese springer and now with all the work I put in it shoots with the accuracy of an $89 Chinese springer. But, you know, smoother.

Thank you B.B. for the fifteen minutes of fame. Reading the blog in response to my question about what parts one ought to have on hand for older springers made me forget the horrible day I had at work.

I have changed the spring and seals on an Diana 22 and 23. Parts were available. I had the tools (gunsmith screwdriver set, hammer, punch set and the oils and grease) and no need for a spring compressor. Have also resealed my Daisys (499, 99s, 299). I have a plunger tool and parts. Traded my neighbor a small garden table with two chairs (the set needed to be sanded, painted and some of the legs soldered back together) for an HW 50s from the late 1960’s. More than twice felt like throwing the garden set in the trash. However, my neighbor’s wife liked it and he has a small machine shop and soldering equipment. The trigger did not work and sat unused for many years. He did not know where to aquiere the parts or the difference between the new HW 50s and the older one.. The bluing is gone in many places and the stock needs to be refinished. After reading the blog, I knew the HW 50s is an Beeman R8 by another name and so we traded. The rifle is shooting now but needs a new spring. I basically paid nothing for the rifle ( since I wanted to trash the patio set). The rifle is far from a collector, but I know where to purchase the needed parts and do not need any other tools than the ones I already have to get inside. The rifle also has the 13mm rear target sight. At times I feel I robbed him

I would like to get a spring compressor and thinker around and gain confidence and skills but do not have the space for a small shop. My husband fixes old fountain pens as a hobby and uses the garage as his repair shop. Do not want to intrude on his space by dropping a compressor on his work bench.

For sure, I know I do not have the skills, knowledge, confidence or tools needed to reseal my two Dianas 6s. Saving my aluminum cans and glass bottles to send them off.

Alex2no ,

Wow on the HW50S. And yes on the RWS 6 pistols. I think you can do the 50S. Just rear about how those tabs come out. And ask your husband to help you make a mainspring compressor.

BTW, I love old pens! Must be something about being an airgunner. 🙂

BB

I nominate the Crosman 2240 as the perfect gun for a newbie like me to “work on”. I’ve found and fixed gas leaks, increased power levels, added bulk CO2 and high-pressure-air capabilities, experimented with different striker weights, changed barrels and grips, etc. It’s possible to completely disassemble and reassemble it. I’ve learned the hard way to carefully document steps and secure items like the tiny ball bearing that holds the safety. Parts and guidance are available from many sources.

Even though I’ve gone the PCP route for target shooting, the 2240 – in carbine configuration – remains perfect for pesting and plinking.