Weihrauch Barakuda 54 EL.

Weihrauch Barakuda Model EL 54 guest blog

Repairing a Rekord trigger

Part 1

This report covers:

- No power lost

- Prepare for the test

- JSB Exact Jumbo RS

- Cocking effort

- Trigger pull

- Firing behavior

- Discharge sound

- H&N Baracuda 15

- Air Arms 16-grain dome

- Discussion

- Summary

Today we look at the velocity of the Weihrauch Barakuda EL 54 ether-injected breakbarrel rifle. Let’s not waste any time getting started.

No power lost

As far as I can tell the ether injector does not degrade the power of the HW 35 it’s mounted to in any way. I didn’t think it would because the hole through which the ether gas is injected is covered in the first fraction of an inch of the piston’s travel. After that it’s a conventional compression chamber.

Prepare for the test

To prepare for the test I dropped five drops of Crosman Pellgunoil down the muzzle and stood the rifle on its butt for several hours. From that I know the piston seal has been oiled! And you can see the effects of that in the first string that I will now show you.

JSB Exact Jumbo RS

The first pellet tested was the 13.43-grain JSB Exact Jumbo RS dome. Instead of giving the usual numbers I will show you the entire string. I do that because the oiling did things to the velocity of the rifle.

Shot………..Vel.

1……………..451

2……………..522

3……………..550

4……………..523

5……………..611

6……………..576

7……………..568

8……………..578

9……………..574

10……………572

11……………577

12……………577

13……………578

14……………575

15……………580

Looking at this string I can see that the rifle was settling down from its oiling. And where it finally settled is a judgement call. The fourth shot was a detonation that went off with a surprising bang.

I say that shot number six was the first shot in a string that I can count on, so that becomes my arbitrary starting point. If we accept that as the first shot, then the average of the ten shots after is 576 f.p.s. The low is 568 and the high is 580 f.p.s. That’s a difference of 12 f.p.s. which is pretty good for an old girl like this. At the average velocity this 13.43-grain pellet generates 9.9 foot-pounds of energy.

Cocking effort

I have to say this rifle is a delight to cock! Once the barrel is unlocked it falls down by gravity and then cocks with only 25 pounds of effort. It cocks so butter-smooth that I guessed it was less than 20 pounds.

Trigger pull

The two-stage trigger I installed in Part 1 pulls through stage one with 4.2 ounces and stage two breaks at 8.1 ounces. It’s a little too light for me so I will adjust it heavier for the next report.

Firing behavior

The rifle fires with a gentle buzz that isn’t that disturbing. There is almost no recoil — just a gentle pulse.

Discharge sound

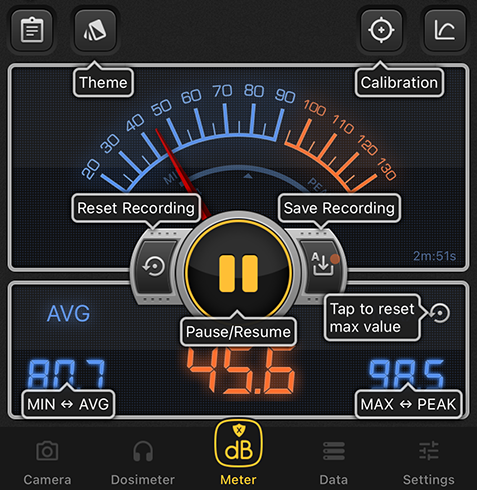

The rifle fires with a discharge of 98.5 dB. That sounds high but to my ears it seems quiet.

H&N Baracuda 15

The second pellet I tested was the H&N Baracuda 15 that weighs 15.89 grains. Ten averaged 524 f.p.s. The low was 521 and the high was 527 f.p.s. That’s a spread of just 6 f.p.s., so my call about where the rifle settled down in the last test was spot on. The rifle has settled down. At the average velocity this pellet generates 9.69 foot-pounds of energy at the muzzle.

Air Arms 16-grain dome

The last pellet I tested was the 16-grain Air Arms dome. Ten of them averaged 524 f.p.s. with a spread from 520 to 528 f.p.s. At just 8 f.p.s. that’s another pellet with a tight spread. At the average velocity this pellet generated 9.76 foot-pounds of energy.

Discussion

It was great to shoot the Barakuda again today. I had forgotten just how smooth it is. I’m looking forward to the accuracy tests. I just need to stiffen that trigger pull a little.

Summary

The HW 54 EL Baracuda is a smooth spring-piston air rifle that’s a delight to shoot. I shall have to find reasons to shoot it more in the future.

Tom,

A little surprised you started out with a lightweight pellet after oiling since a heavy pellet could have minimized the chances of the rifle dieseling during the first few rounds after oiling. This is shaping up to be an oldie but goodie. The only fly in the ointment being the weight of this rifle for offhand use.

Siraniko

PS: Section JSB Exact Jumbo RS 2nd paragraph last sentence: “The fourth (fifth) shot was a detonation that went off with a surprising bang.”

Siraniko,

No, it was definitely the fourth shot that detonated. I was surprised it went slower than the fifth that was quiet again.

BB

B.B.,

I have mulled the higher MV just after the detonation all day…left over heat from the explosion?

You were there…and have spring experience that i sure don’t.

What do you think of the Dark Sider’s mulling?

shootski

shootski,

That might be. I don’t really have a clue.

BB

I had to go to work pretty early yesterday, my last Monday by the way, and missed giving you poor folk my two cents worth on the Avenge-X. You lucky dogs.

I guess I am not much of a fan of this particular attempt at increasing the power output of a sproinger like this. Ether? Really? This only encourages those intellectually challenged folks on YouTube to attempt using various combustible propellants in their sproingers and blowing the seals out. I had that happen unintentionally with my Gamo CFX and neither Pyramyd Air nor I was very thrilled about that.

I never did find the chamber handle.

Oh, just so you folks know, I shot the 34 this past weekend. I was not impressed with its performance but will be trying a different hold and telling you about this past shooting experience and the new one in the near future.

RidgeRunner,

I ran across your name while I was doing some research on spring gun shot cycle. https://www.ctcustomairguns.com/hectors-airgun-blog/shot-cycle-dynamics-in-3-spring-piston-airguns-chap-1#:~:text=However%2C%20in%20the%20roughly%2010,as%20the%20piston%20stops%20its

I had read some comments on various TX200 owners trying to use an o-ring for the piston seal with various comments mostly regarding lack of durability. The gist of why is the recommended shaft speed for a dynamic seal (sliding piston) is less than 200 fpm. I thought it was reasonable piston speed until I read thru that post above. The Walther LGV based on his data is ~1400 fpm which is why the o-ring fails so quickly and is unreliable in that use. The other contributing factor is the recommended surface finish is ra of 16 (micro inches) or better for the sliding surface. This is very close to a mirror like finish.

No wonder the o-rings fail and the OEM design a different method of sealing the piston.

Mike.

bmwsmiley,

Hector regularly applies engineering to spring piston airguns. I have learned much from his writings. I am also fortunate to live near Lloyd Sikes (the inventor of the original Benjamin Rogue, Disco Double, etcetera). These gentlemen and others devote much time in advancing the world of airgunning. I am but a neophyte in their presence.

I like to “collect”, “restore” and shoot various examples of airguns that overcome some of the issues encountered in the past. I do have a few “modern” airguns, but I find myself more and more drawn to these “old gals”.

As to the issue with using o-rings as seals for the sliding pistons, I myself have not used such previously, but I can certainly understand why so many of the “old” engineers would not use such.

With the present advancements in polymers, it may be a subject to revisit in the future. I know of at least one gentleman who replaced the piston ring of a FWB300 with o-rings and was able to boost the power output of this air rifle considerably. As for the durability of such, I do not have such information.

The main issue I find these days is cost versus profit margin. There are some superb engineering solutions available, but the cost of doing such is a limiting factor with many corporations. If you are concerned with making large profits quickly, this is not the field to go into. Those who truly understand what it takes to overcome some of the issues encountered to make a truly superb airgun are not that many. Even fewer still are those willing and able to “pay” for such.

I do not own a Sig Sauer ASP20. When they were introduced, the price was beyond my “range”. Then the company suddenly decided they could not devote so much to so small a market and the ASP20 came to an abrupt end. The Diana 34 EMS met a similar fate. Fortunately for the EMS, Vortek has picked up the ball and with the new Diana owners’ blessings is able to run with such. I do hope it is a success.

Golly gee whiz, I can be quite long winded at times. I do hope you are able to glean something my ramblings.

I’m just happy to know another person who uses the word “glean.”

Merry Christmas, RR.

B.B.

Great shot strings! Yes, tight velocity spreads leads to tight groups.

On a different blog you once mentioned that a gun had a spread of 25 fps. Not bad you said.

However, when I put the numbers in a calculator at 35 yards, the difference between the high and the low spreads equalled a 1/2 inch drop just due to velocity differences.

Velocity differences greater than 2-3% make a gun inaccurate at range.

-Yogi

The lower velocity on shot #4 indicates that the compression ratio appears to be such that this rifle requires ether instead of pellgun oil. (Similar to a high-performance car engine that requires high-octane fuel.) Just kidding of course. But it does seem odd that the detonation didn’t increase the velocity.

B.B.

Just thinking: if instead of leather piston seal, they put bronze rings like in old BSA’s, it can work just fine. At least it will not blow out the seal after few dozens of shots.

Of course, it is still dumb, useles and impractical idea from the beginning to mix decent springer with a potato gun. If people want bang, they go to powderburners, they are just better with going bang.

I can’t wait for the accuracy test, but as we see it is a decent airgun with stupid appendage- so i bet that it is as accurate, as typical hw 35.

-Rafał.

Rafal,

I’m thinking it will be accurate as well. In fact, tomorrow’s report will touch on that.

BB

Rafal,

When did BSA go to the bronze rings? I have a 1906 that used a leather seal. I do have a Webley Service Mk 2 from the early 30s that has a bronze ring and the FWB300s I used to own had bronze rings. I have not encountered any in anything else yet. I do like knowing about these old gals and how they are put together.

Ridge runner,

My mistake, i was thinking about webley mk I. I am not sure if this design was ever used by BSA, but i promise to check it in the depths of internet.

-Rafał.

Rafal,

No problem dude. Yes, the bronze piston ring is very common with the Webleys and as I had mentioned, was used in the FWB300. Most of the others do not as a pad on the end of the piston is then needed to keep from having metal slam into metal. That is why most sproingers have the piston seal on the end of the piston. It also happens to provide for a better compression.

Sorry for the late response. Interesting to see another shooter’s experience with the same rifle. I look forward to the accuracy results. Hopefully, the trigger repair and other fixes will improve your results.

B.B.

Yes a tight velocity spread and a decent shooter and a decent barrel will enable accuracy.

I bet you shoot groups that surprise even you.

The Godfather with a million trigger pulls,

-Yogi

BB,

There have been several comments about how large of a springer this is. Having never actually held one, how big is it (or an HW 35) compared to an R1? An R9?

I am just trying to figure out a scale that I can visualize.

Thank you.

Bill

Bill,

It’s about as large as an R1, and the ether injector adds mass at the rear of the spring tube.

BB

BB,

I’ve been shooting some of my better air rifles to keep them in rotation, and I notice how nice some feel in the hand and while taking a shot. The shape of the pistol grip on my HW35E is better than many rifles and the rifle is very comfortable to hold. The grip fills my hand nicely. Many rifles leave my trigger hand holding air, because the wood isn’t where my hand thinks it should be. The HW35 is a luxury fit.

Will

Will S,

“Many rifles leave my trigger hand holding air, because the wood isn’t where my hand thinks it should be.”

As I see it you have four choices Will:

1. Rasp to stock and make it fit.

2. Putty to stock and make it fit.

3. Do nothing and live with it.

4. Hand surgery to make hand fit stock.

I only recommend choices 1 and 2 or perhaps a combination of those two.

I can never understand how most shooters choose number 3.

shootski

On that note, the setback trigger for Weirauch air rifles is probably worth looking into. The stock trigger can be wite a stretch to find.

shootski,

Yep, you’re right about being the boss of your airguns. The place I’m holding air is behind the trigger. I did change a stock and showed it in BB’s blog four years ago. It even has a nice dimple for the thumb along the spine of the grip. The paint has survived pretty well and I like the rifle much more than it was originally. The project gave me more to consider for the next one. Here it is again, just for fun.

As Roamin points out, a setback trigger can be a good resort in some cases, when available.

Cheers,

Will

I think that’s cool! Reminds me of a WWII fighter plane.

Thanks Roamin,

It does bring a toothy smile to my face.