by B.B. Pelletier

Part 8

Part 7

Part 6

Part 5

Part 4

Part 3

Part 2

Part 1

Getting ready to test

Today, I want to mount a scope on the 124 to get ready for the long-range accuracy test. Normally, I would just mount the scope and gloss over it in the report, because scope mounting is usually not a big deal; but the 124 is a special airgun that needs special scope mounting considerations. So, I’m making a separate report about it.

A strange scope stop

What makes the 124 special is the way Feinwerkbau went about providing a scope stop. You must understand that Feinwerkbau is a target gun company. They understand rear aperture sights very well, but they don’t appreciate scope sights nearly as well. And, in the 1970s — when the 124 came out — scope mounting was still very new to the hobby. They provided a scope stop system that works well for rear aperture sights but not so easy when working with scopes.

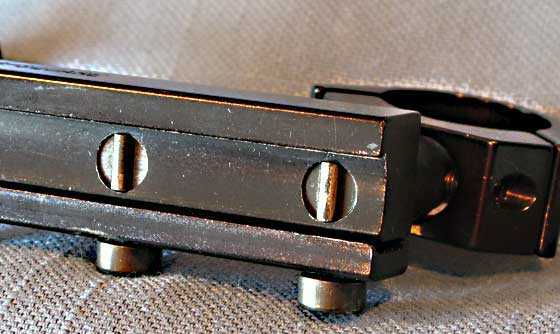

Their system consists of half-round grooves cut across the 11mm dovetail scope rails. The plan is for a round steel pin in the base of the rear scope mount or in the rear of the one-piece scope mount, if that’s what you use, to fit into one of those grooves. Once it’s in, the scope mount will stay put under recoil. It’s a simple system, but not one that’s widely used. Webley used it on the Patriot, and CZ used it on some of their rifles. Most airgun manufacturers use something else.

Pick one of those four grooves to accept a steel crosspin from the base of one of your scope rings or the rear of your one-piece scope ring. Once the base is tightened on the dovetails, the groove and pin prevent the base from moving under recoil.

Because of the low usage of this kind of scope stop system, there aren’t a lot of scope mounts with the necessary crosspin. Beeman sold them while the 124 was selling well, but they stopped offering them in the late 1990s. B-Square also made some just for 124s, plus they made a mount with two crosspins that was to be used on a Webley Patriot. You could always grind off or remove one of those two pins to make their mounts fit the 124.

This old B-Square one-piece scope mount has two crosspins to interface with the grooves on a Webley Patriot rifle. By removing one of the crosspins, this mount can be fitted to a 124.

Forget this!

Forget trying to just tighten the base screws to hold the mounts in place by friction. The 124 is a long-stroke spring-piston rifle that will walk any standard mounts — aluminum or steel — that you try to do this with. And, you can forget something else, too.

Some guys get the bright idea of taking a standard vertical scope stop pin and rounding it to a crosspin profile. Forget it. It doesn’t work. All it does is rip a wide groove straight back through the top of the steel receiver tube as the mount slowly walks backward under recoil. It may take six months of steady shooting before you notice it, but you’ll ruin your gun this way. There’s just not enough bearing surface on a single, thin vertical stop pin that’s been profiled in this way.

I have been testing airguns for a very long time now, and I have a drawer filled with exotic scope mounts, including some prototype units that never made it to market. There aren’t many airguns that I can’t scope, but my situation is not the norm. Most guys have to find a mount that works from what’s available today, and that can be daunting when the gun is an old-timer like the FWB 124.

Bring on the BKLs!

There may be a bright light on the horizon, though. Back when I was messing with 124 rifles, BKL mounts didn’t exist, but they do today and we’ve tested them on other spring rifles that recoil a lot harder than the 124. For those who aren’t aware, BKL mounts are the one mount on the market that can hold tight by just clamping pressure, alone. And, here’s the best part — they’re made from aluminum! So, as tight as you can make them, they’ll never damage the sharp edges of your rifle’s dovetails the way they would if they were made of steel.

For this test, I’ve installed a set of BKL-363H-MB scope mounts with double straps. Man, I wish these things had been around in the late 1970s!

I also found out something extra-cool about these double-strap BKL mounts. There’s no special torque pattern to be followed! Instead of tightening the scope caps by a prescribed pattern like you would the main bearings on a crankshaft to get the force evenly distributed over all four screws, these caps go down in a straightforward way. Tighten one side and the other. As simple as that. Because each strap has only two screws, there’s no way to screw up — pun intended!

I’ll watch the mounts to make certain they don’t move, but the groups I get should pretty well tell the whole tale without the need for any special testing. If I shoot tight groups, there can’t be any scope movement.

Leapers scope

I chose a Leapers 3-9x50AO scope with illuminated reticle. I didn’t need the illuminated reticle, but this particular scope comes with a fine crosshair that will aid in getting a refined aimpoint. As long as the light’s good, I should be able to get great results with it.

The 124 accepted the Leapers scope with ease. I could easily have installed a much longer scope on the rifle, but I wanted to keep the weight down.

So, that’s the saga of mounting a scope on a 124. It’s not any harder than installing a scope on any other spring rifle, but the mount situation is different enough to cause concern. Remember this — the FWB 124 was the very first air rifle to get a reputation for scopes slipping and even breaking. Though we have much more powerful rifles today, don’t underestimate the 124.

Feinwerkbau’s products are Fein indeed. I love the old 300S myself. But they are all good. The 600/601/602 were “the” Olympic rifle for a long time. I even saw a 602 on Craig’s List, yeah yeah guns and even stuff like scope rings are verboten on there but do some searches, some Fein finds on there these days.

B.B.

I’m back and OK, I hope you also got much better since my last comment.

Spent the whole evening yesterday cleaning my rifles – I lubed them for storage and just to get back the feeling. Waiting for weekend to revive the experience 😉

duskwight

Duskwight,

So, how was Portugal?

B.B.

Nice, very nice.

I made 600 km around country and everywhere I found kind people, beautiful sights and pieces of history, excellent wine and wonderful food, and, of course, the ocean. Unknowingly, I also visited Spain – those old Roman roads cross borders without any notice, you know 😉

Brought some 12 Gb of photos, I hope I’ll work them down to more common 4-5 Gb.

duskwight

B.B.

That really is a strange scope rail setup.

Most people I would guess would like Weaver type mounts on airguns. Particularly the springers. Sure would eliminate the problem of holding the scope in place.

twotalon

Morning B.B.,

I’m with twotalon–it would be nice to see airguns made to accept Weaver scope mounts. Do you have any more news on AirForce’s proprietary chemical/powder that will keep scopes from slipping in their rings?

Bruce

One thing that I think would help a lot, but have not proved for myself yet……….

Use rings that mount with two bolts instead of one, and have four bolt caps. Tighten in the pattern B.B. described quite a while ago.

twotalon

Bruce,

I don’t have anything more about it, except to say that it works.

B.B.

BB:

I was always partial to a one piece scope mount on my springer rifles.

My logic being that the more contact area between mount and rail the better the grip.

It did seem to hold true but in fairness the two piece mounts I had were cheap,so maybe not a good comparison.

DaveUK

There are two quirky things about the FWB 124. The trigger and mounting a scope. Neither are a big deal to address.

The factory trigger can be worked to be very good by someone that knows what they’re doing. The first FWB 124 I owned was sent to Paul Watts for an ADV tune and trigger work. After his work the trigger was terrific. Another option is an aftermarket trigger. Although Beeman offered an aluminum replacement trigger to address the outcry from the public that the original trigger was plastic the design is the same as the factory trigger. It’s just metal vs. plastic. Jim Maccari has a drop in replacement trigger for FWB 124’s and FWB 127’s that he slightly changed the design on. It significantly improves the trigger pull weight and is safe. Although he’s currently sold out of these wonderful triggers they should be back in stock in two weeks.

As mentioned by B.B. the FWB 124, Webley Patriot and others have the cross cut slots and require a unique mount. I really like BKL mounts and they’ve given us many options for mounting scopes on airguns. Since they don’t have a stop pin they need to be tightened with force. They’re well made and can take it but some guns with thin walled compression tubes (like the new HW50) have been crushed (bent out of round) by airgunners using BKL’s. The majority of airguns, like the FWB 124, can take the clamping pressure without a problem. Sportsmatch is the company that made the Beeman mounts specifically designed for the FWB 124, Webley Patriot, etc. and although they no longer make mounts for Beeman, they still make this mount. Sportsmatch mounts can be purchased in the UK and Mike has shipped items to me here in the USA within a week.

The one review on the Pyramyd AIR website for the BKL-363H-MB mounts complains that they would not stay in place on his TX200HC. He didn’t tighten them enough. They do work.

On guns without a dramatically raised cheek piece I prefer smaller objectives than 50mm since I don’t like high mounts that usually force an artificially high cheek weld. Low to medium mounts with a scope that matches is my preference. Just me.

kevin

What is the function of that big turret at the end (shooter side) of the scope? Fortunately, I’ve solved all of my scoping problems except for one, and now is the time for my open tirade/letter to Leapers.

rant

What are you guys thinking of with that turret locking mechanism on the 6-24X50mm scope which is otherwise a fine piece of equipment with great optics at the usual super price? For those not familiar with this mechanism, in order to change the settings on the turrets, you need to use a small Allen wrench to unlock them. The turrets have to be raised a few millimeters until you can see a truly microscopic white line etched on an inner column that the turrets ride on. Then you adjust and reverse the process to lock the turrets. Well, I can say that the turrets do really lock so that they will not move from zero. But otherwise, everything that can go wrong with this set-up will go wrong. If you misplace your tiny Allen wrench you are dead in the water. If your eyesight is not first-rate and you are operating in any lighting conditions that are not perfect, you will not see the white line. If you are under shade as at many shooting ranges, you will not be able to see the white line, and if you are out in blazing sunshine where you have to squint you might not see it either. Woe to you if you do not adjust the turret to the exact right height just above the microscopic line. The turret will not move if you are too low. If you are too high, the turret will spin freely and you will not get any change. It is rare if not impossible to get the exact right height where you get positive clicks. More often you get a mushy feeling, so you are often not sure of how many clicks you have moved and lose track of where you are. What scenario is this locking device designed for? For competitive target shooting, no one will have the time or inclination to fool around with this. For hunting, even worse. Nobody wants to fiddle around with a tiny Allen wrench and adjustments like this in the field. I don’t get it. Why don’t you just have positive clicks like the Air Force scopes or a sensible locking mechanism like the Centerpoint scopes (dial at the base of the turrets that does not require a wrench). Then we can get back to enjoying your fine products.

/rant

B.B. that Sundowner’s is pretty intense. And to think I was bothered by a little cognitive fogginess and inability to remember. Don’t forget to retain any alien symbols you bring back from these experiences.

Slinging Lead, I’m so glad to hear that the brother relationship was merely a pose for A Fish Called Wanda. I had a look at some Kevin Kline excerpts from that film, and I must say the business of shooting guns around the home and striking martial arts poses in the mirror does strike a little close to home….

All, take care. I just received the Yur’yev book on shooting technique through interlibrary loan. What a tome….

Matt61

Matt61,

I emailed your comments to Tina and David Ding at Leapers. They’re VERY interested in customer feedback. Tina provided the following feedback for you:

He certainly has some valid points. This is why we never stopped the development effort after painstaking incorporating the zero locking and resetting features in target turrets, which is no small feat, but certainly has room for more advancement. We have moved forward on 2 concurrent fronts in terms of adjustment turrets. One is to migrate the tool-free locking ring to our recent introductions such as SCP3-U3124AOMDL, SCP3-UM3124AOMDL and more to come. The other is introducing the Tool-free TF2 turrets with Pull-up to Adjust and Push-down to Lock type of mechanism. Some examples are SCP-394FW, SCP-M312L1, etc.

Edith

WOW. Edith your efficiency never cease to me. I’ve rarely met, seen or heard of someone like you and it’s even more rare in business and even more in web based business. I don’t know how much your getting paid but you deserve a raise or at least a bonus, because YOUR GOOD.

J-F

J-F,

There are many blog comments being forwarded to Pyramyd AIR and mfrs. What sense would it make to do otherwise? Pyramyd AIR is pretty darned responsive. Some manufacturers are not. Some, don’t need me to forward the comments because they regularly read the blog and know what you like, don’t like and want.

Don’t be surprised when your dreams come true 🙂

Edith

Edith knows all the RIGHT people!!! Don’t cross her or you and your gun may be swimming with the fishes! 🙂 🙂 🙂

rikib

LOL

Edith

May I second – Leapers 3-12×44 SWAT with 30mm tube – my scope of choice for most springers. Very durable, cheap, with nice picture and great no-tool turrets.

duskwight

Hi, Matt. I have a Leapers 4-16×50 (SCP-416AOMDLTS) that I think has the same turrets as your 6-24×50. I’ve always just left the turrets unlocked. They’ve never given me any trouble with unintended changes, so I’ve never felt the need to lock ’em.

I haven’t tried any of the newer-fangled models with the various tool-less turrets. They do sound handy. On the other hand, I wouldn’t want it to be too easy to put the things in zero-resetting mode. That could make for some major hassles!

BB: Hope you’re feeling well!

-Jan

Advice on pistol calibre… I’m interested in the new Webley Alecto pistol, but not sure which calibre to go with. I like the higher fps of the 177, but 22 tends to retain more energy and hit harder. I tend to shoot 10m at the closest, but enjoy 25m as a good challenge. With the 22 dropping to 410 fps (or lower), I’m not sure how well that’ll handle 25m. That’s not bad for a pistol, but seems pretty low. If a gun isn’t accurate, it isn’t interesting. Accuracy is important.

177, faster fps at 550 fps; more impacted and slowed by wind

22, slower fps at 410 fps; less impacted by wind

I’m sure lots of you have had to make this choice on the HW45/Beeman P1 and other pistols; any tips?

Bristolview,

I did go for the .177 in the Beeman P1, as you suggest, and for the same reasons you listed.

B.B.

Thanks B.B. Any chance you could list some of the pros and cons of the two options at these lower power ranges? The reason I ask is that I’m just not sure about the differences as we get into lower power pistol power plants.

I have a low power 177 rifle and a fairly high power one. The low power is a tack driver at 10 meters in my indoor range (no wind), but the groups open up substantially outside at the same ranges. The higher fps 177 rifle does not change as much, with it’s groups being fairly consistent indoor or out. My guess is that the higher fps is less impacted by wind, but I’m just guessing.

If my guess is at least partially correct, the pistols are in a moderate to low fps range, which would mean that they’d be fairly susceptible to wind. If that were the case, perhaps the 22 would work best to overcome that issue. That of course, moves the fps down even more, perhaps negating that advantage. I don’t have much experience with these lower fps ranges that the pistols operate in, and would like to learn the pros and cons, any tips? Any and all advice is welcome on the topic (but I’ll order the 177 for the Alecto as it has similar power ranges to the P1).

Did I miss something? Why not the 2240 rated at 460 fps.?

rikib

I do realize the Beeman P1 is a $500 pistol compared to a 2240 at $55. But for me $500 would buy a nice firearm. I guess I’m not fully into airguns yet, sorry.

rikib

The 22xx series are fine pistols, but I’m looking for a self contained pistol right now. I have a Crosman Custom Shop Carbine, which I absolutely love so it makes sense to get a 22xx pistol like you say, and someday I most likely will. Right now though, I’m looking for a self contained 25m pistol.

As for the cost, yes the $500 for a P1 or even the $360 for the Alecto could buy a decent firearm. The reason for me, as to why I’d pay that much is because airguns allow me to shoot every day. I enjoy my firearms as well, but must hike out to the woods or drive down to the range to shoot. Either option isn’t going to happen if I only have an hour free here and there. With airguns, I can shoot right at my house which allows more shooting opportunities than I have with my firearms. I work from home, so I can quickly run out and shoot during my lunch hour. If I had to drive down to the range or hike out to the woods, I’d not have enough time over my lunch hour. Air also allows me to move into my 10m range downstairs during the winter, a good distance for pistol shooting. So the answer to your question of why? Airgun shooting, for me, offers many more shooting opportunities than firearms. For me, that justifies some investment in the hobby. I shoot some form of airgun almost everyday, I shoot my firearms perhaps once or twice a month.

All valid justifications. My being in SW Georgia winter is not really a factor nor is land area. I was just wondering about your choice, that’s all.

rikib

No worries, valid question too. I asked the same question before I caught the airgun bug.

A friend of mine, who is an avid shooter of a range of firearms brought up airguns. I was floored, a sniper trained guy who is into airguns? What the… He introduced me to the Benjamin Discovery, which was very affordable and very good for what it is. I bought one, and by that afternoon was completely in love with airgunning. Time lapse about a few years… now I have a 10m range in my basement, a small set of rifles from low to fairly high power, and a couple of basic pistols. The best part, is that my daughter has taken over my IZH-61 and is shooting with me.

The set of airguns I have now was needed to really see what I liked and didn’t like as I explored this hobby and myself. Now that I’ve got a good idea of what my airgun tastes are, and learned a lot about airguns, I can focus on getting a really good pistol and a really good rifle. I’ll keep some of my current collection, and sell others. I’m really liking the new Alecto pistol, it has the aspects that I thought were missing from the P3. In Europe, it is sold as the Tokino (I think that’s right), and the reviews are pretty positive.

Now, if you really want to see some serious coinage for an airgun, check out the FX Monsoon (about $1500 in synthetic, more for wood). It’s a semi automatic with blowback, and she’s a beauty. I’d love one, but that’s is really hard to justify.

The six-screw, one piece BKL mount will hold on the FWB124 (it has on mine). Just like it did on my RWS 350. And does no my Patriot. And it will on the (insert magnum springer name here), too!

A friend of mine has come upon a pellet gun we are looking for information about it. It is a Feinwerkbau 124-cal. It also has Oberndorf/n and the number 51089 on the rifles. Can you tell me where it was made and where to find out about the company who made it, also do you have an estimated worth of the weapon. Its is in new condition and has a beeman scope.

Don,

How is it that you are reading this blog and don’t know exactly what you have? The information is all here. At the top of this report are links to the first 8 parts of the same report. Have you read them?

There are a total of 15 parts to this report.

The FWB (shot for Feinwerkbau) 124 is a .177 caliber air rifle. There are no 124-caliber airguns.

It was made in Germany in Oberndorf on the Nekar (river).

In the excellent condition you describe, if it has the original open sights, it is probably worth around $350-450.

B.B.

B.B.

I’ve read your articles about scope mounts for the FWB 124 and the issue of barrel droop. I want to get scope mounts for my rifle but do not know if it has droop because I have never mounted a scope on it.

I think I might prefer a 2 piece mount like the BKL 263 or Sportsmatch TO3S, but am wondering if I should get the BKL 260D7 to compensate for droop in case the rifle does have it. What would be your advice?

Thanks very much.

Gatwood,

I can almost guarantee that a 124 will have barrel droop. Beeman used to sell them based on how much droop they had. Buy the mount that compensates for droop.

B.B.