by B.B. Pelletier

Today you’ll read part 2 of Vince’s guest blog. As usual, he’s done an extremely thorough job.

If you’d like to write a guest post for this blog, please email us.

Bloggers must be proficient in the simple html that Blogger software uses, know how to take clear photos and size them for the internet (if their post requires them), and they must use proper English. We’ll edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

by Vince

You’ve loaded the magazine, and now you’re ready to shoot. Almost.

Lock & load!

Suppose the rotary mag wasn’t indexed quite right when you put it back into the gun? That could be a problem. To make sure there isn’t a problem, get into the habit of pulling back on the cocking lever after reinstalling the mag, as if you’re trying to reset the sear. As mentioned in part 1, this last little bit of travel is what indexes the mag, and the action will rotate it to the next position and line it up properly. If the mag is halfway between pellets, the feeding pin is going to be blocked from going forward. This means that the lever is not going to want to move toward the firing position. But only a little. Because of the immense amount of leverage in the cocking lever, there won’t be much resistance, you might force it and break the pin without even realizing it.

Now you’re ready to start making holes…and making holes is something the 300R does rather well.

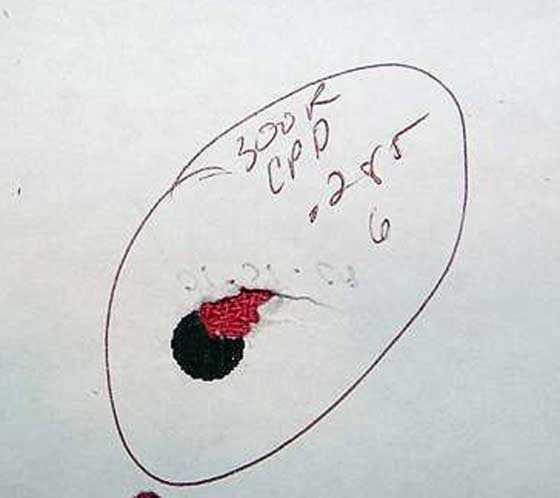

Pretty good 6-shot group with Crosman Premier hollowpoints.

The above target is a quick 6-shot group at 10 meters with open sights using Crosman Premier hollowpoints. It can do even better — and I’ve done better. More on that later. The rifle is about as hold sensitive as any other non-breakbarrel Diana springer, which is to say not too bad. Just remember that you have seven shots with no indication when those seven are done. To make sure the mag is empty, you’ve got two choices: dry-fire the gun (a no-no, although it will happen by accident on occasion) or remove the mag.

making holes is something the 300R does rather well

Fortunately, you don’t have to completely cock the gun to do so. Back when I described the picture of the pin retracting, I pointed out the position of the cocking lever. I was only starting to pull it back, but the pin was retracted almost all the way. Fact is, the pin is out of the way well before the lever is even halfway cocked. So, you CAN remove and replace the mag without cocking the gun if you hold the lever in the partially cocked position. Familiarize yourself with exactly where this is before making a habit out of it. Don’t let the lever go while you’re in the process of removing or reinstalling the mag.

So far, I’ve described how this gun is supposed to operate. What goes wrong and what do you do when it does go wrong?

The most obvious boo-boo is to try to remove the mag with the lever all the way forward. A real easy mistake to make. What does this do? Well, first of all the mag doesn’t want to come out because the pin is running through it. Second, the thin, brittle pin probably breaks. The next real easy mistake to make is to say to yourself “Oh! Right! I forgot to cock the gun!” So, you cock the gun, but the now-broken pin is still lodged in the rotary mag and won’t let it index to the next position. Again, you’ve got so much leverage in the cocking linkage that you don’t notice the increase in resistance. You force it without realizing it, and you break the magazine. Yet, it still doesn’t want to come out. Since you’re probably holding the gun muzzle up while you shake the gun, pump the lever and fiddle with the mag — that broken pin will eventually come loose…and fall into the guts of the gun.

Hoo-boy. Now you’ve got three major problems, and you’ve collected them all in the space of about 45 seconds.

Some time ago, I wrote up a sheet of cautions and procedures to follow with this rifle, and I tried to cover every contingency. I’ve listed those instructions at the end of this blog, so I won’t rehash everything here.

The last thing I want to talk about, though, is what happens when the gun is operated without that pin. In that case, the air will blast the pellet out of the mag. The cylinder pellet holes are sealed pretty well at the front and rear of the magazine.

Front and rear seals help stabilize the rotary mag.

That rear seal is on the end of a spring-loaded plunger. When the lever is forward, the rotary is firmly sandwiched between these seals. Combined with the relative power of the rifle (compared to an Umarex pistol or a Crosman 1077), it should make for a nice, strong burst of air that will reliably feed the pellet from the cylinder to the breech…pin or no pin.

The only possible fly in the ointment, as far as I can see, is that the rapid blasting of the pellet into the breech might be more inclined to damage the pellet if there’s a significant mismatch between the hole in the cylinder and the barrel bore than if it was gently fed by the loading pin. Theoretically, this could affect accuracy. I’ve tried it both ways and could not detect any difference. In my basement range, I managed to shoot a .18″ group (don’t remember if it was 5 or 7 shots) at 12 yards with a pin-less gun with a scope. Frankly, I just don’t do any better than that. So, no, I don’t think the accuracy issue is a significant one.

That wraps it up for the 300R. It’s a unique experience that definitely keeps you on your toes. Like many unique relationships, it’s frighteningly easy to mess things up, but there’s no need for despair. One way or another y’all can patch things up again and literally find yourself repeating the experience.

Below is my list of things to remember when shooting the Diana 300R.

Read all factory instructions. The RWS 300R has a unique mechanism that can be accidentally damaged by mishandling.

The pellet is loaded from the magazine into the breech by a very thin, brittle pin that cannot tolerate any significant side loading. This pin is retracted when the cocking lever is pulled back and pushes the pellet forward as the cocking lever is returned to its normal (or firing) position. With the cocking handle in its normal position, this pin runs through the magazine.

Never attempt to remove the magazine unless the gun is cocked and the cocking lever is to the rear — or you will probably break the pin.

If the mag holder is inserted when the cylinder is not properly lined up, the feed pin might hit the cylinder between two pellets — or it might hit a pellet off-center and jam or mangle the pellet on loading. Here’s how you prevent this: After reinserting the magazine, pull the cocking lever all the way to the rear as far as it will go (just as you would when cocking the gun). This ensures that the magazine is indexed properly.

A cocked gun may be uncocked without firing and with the magazine installed or removed. Pull the cocking to the rear until it just reaches the point of meeting resistance from the piston and spring. Holding it firmly (just as you would while cocking the rifle), push in the safety and pull the trigger. This should release the handle. Let it return, under pressure, to the uncocked position.

The rotary magazine is indexed (rotated to a new position) during the cocking cycle just before the trigger engages. If the rearward part of the cocking stroke meets with unusual resistance right before the trigger catches and doesn’t want to fully cock, stop pulling the lever or the magazine might break. Something has probably jammed the magazine and won’t let it rotate.

Try to remove the magazine with the lever pulled back MOST of the way. If it’s difficult to remove, stop, reseat the mag, allow the lever to return to its normal position and service the gun (or have it serviced). The 300R is not a particularly difficult gun to disassemble, and the powerplant does not have a lot of spring preload (about 50 lbs.). If you’ve disassembled other spring-piston air rifles, you’ll probably be able to service this one.

If the magazine does come out, let the lever return forward. Is the loading pin visible in the magazine port? If it is, try recocking and decocking the gun without the mag. If it feels normal, empty and reload the magazine and try again.

Never attempt to remove the magazine unless the gun is cocked and the cocking lever is to the rear — or you will probably break the pin.

If the pin is not visible, it’s broken. Sometimes, the 300R will feed and fire just fine without it, but the owner must first make sure that the broken pin is not inside the barrel or inside the gun (trapped in front of the sliding cylinder). The barrel bore can be visually inspected. In order to check the cylinder, bring the cocking lever all the way forward and lock it into position. Look in the magazine port, and you should see the air nozzle with a blue seal protruding into the rear of the port. The outside metal shell of the nozzle should be protruding into the mag port by about .050 inches. If it’s much less than this or not protruding at all, the pin is probably in the gun and it needs to be disassembled.

Otherwise, the pin probably just fell out or was discharged behind a pellet. You may try operating the rifle without this pin. If it functions properly, go ahead and use it. The only risk is that if the pellet doesn’t discharge it might be lodged halfway into the breech. Given the relatively high power of this gun, this isn’t very likely, If you think it happened, do not recock the gun. Pull the cocking lever back slightly and try to remove the mag. If it comes out, you can easily check the mag and barrel for a damaged or jammed pellet. If it doesn’t want to come out, go in from the muzzle with a cleaning rod and push the jammed pellet back into the mag.

This comment comes from personal 🙂 experience, my wife is sitting at her laptop, me on my netbook. She is playing “farmville”, I’m watching the blog and TV. She asks me if we have any chocolate, so here is a quote:

“After about 20 years of marriage, I’m finally starting to scratch the surface of what women want. And I think the answer lies somewhere between conversation and chocolate.”

Mel Gibson

Thankfully, earlier today I had purchased some of her favorite dark chocolate. Don’t know why, but I seen it in the store and thought she would like it, not knowing she would ask for it tonight. Thank God I bought it!

rikib 🙂

Yes, women. Marriage is one of those things that seemed like a really good idea at the time.

Mike

rIKIb,

it’s more scary than you think. After 20 years of marriage, you and your wife will start to think alike. THAT’s why you bought the chocolate. Happens to me all the time!

Fred PRoNJ

And of course, “do we have any chocolate,” really means, “bring me some chocolate.”

Lloyd

From the old Roseanne TV show:

Friend: Wow, you have a great husband.

Roseanne: You know, they don’t come that way. You have to train them.

Yes, training takes place and eventually it sticks 🙂

Funny story on Tom:

Because we don’t always know what to buy each other for Xmas, we now provide lists of things we want (and often places to buy them). Using written lists was a lesson learned the hard way during Xmas 1987.

I told Tom exactly what I wanted. Brand, name, price and even where to buy it. There were similar items that I absolutely did not want, and I made sure he knew what they were so he wouldn’t buy those by mistake. Of course, he remembered only the things I did not want…and that’s what I got for Christmas in 1987 🙂 Starting in 1988, we went to written lists.

Edith

Lolz, I thought marriage was SUCH a good idea, I did it twice! With a 14 year cooling off period in between them! First one lasted 18 years, so far this one is 15+ years with much better prospects than the first!

Rikib, I’d say Mel Gibson’s reputation for relationship advice is currently in the tank….

How is this for a bit of husband training. I know of a relationship where if the wife doesn’t like the husband’s gift, it gets returned. The husband would ask: “How was I supposed to know what you wanted.” And the reply: “If you had paid enough attention to me, you would have known”…..

Matt61

Matt61,

I expected something about “Mel’s” reputation, I just don’t believe all the hype I read. Maybe true may not. I was merely providing a quote.

Don’t Kill The Messenger! 🙂

rikib 🙂

Rikib, the messenger is safe by me. 🙂 But I did think Gibson’s telephone recordings were just about the darnedest things I’d ever heard.

Matt61

Thanks for the report Vince.

Not too hard to see why they were discontinued rather quickly. They probably had them coming back broken as fast as they were selling them. Not enough ‘gorilla proofing’ built in.

twotalon

It’s not even a matter of gorilla-proofing. I mean, come-on, you can’t pull the mag out of an uncocked gun? That is so counter-intuitive. And then there’s no interlock to hold the mag so that if you try you don’t break anything?

As usual for a Diana gun it’s is well made and very accurate. But when it came to user-engineering – man, they REALLY dropped the ball on this one.

I’m thinking that it could have been much better and much more user friendly

1) Get rid of that pin

2) Allow the rear plunger/seal to hang back a bit and not put pressure on the mag. When the gun is fired let it then slide forward that last 1/16″ and seal it up

With those 2 mods – which I wouldn’t think would be all that difficult – you’d have a gun that’s a lot easier to use.

Vince,

A very interesting gun. However the way my poor old brain sometimes does not work means that I’d get very good at R&R this gun.

What do you think Matt61? Is this the springer for you–a repeater and she shoots?

Bruce

Mr. B, it doesn’t sound like she shoots for long, especially not with me running it. It sounds more like a nervous breakdown kit. You may not recall my agonies in the early days of my IZH 61 when I jammed four pellets up the barrel by accident and shot them all off. I thought my pride and joy was destroyed by my own hand. But that was just the beginning as my mind and will were forged repeatedly in the fires of stupidity as I miscounted and double-loaded again and again over the years. But the rifle shows no ill-effects whatsoever. That wouldn’t be the case with this rifle. I have a horrified fascination with the Whiscombe–the custom rifle that can be destroyed with a single dry fire. I believe that I could never relax enough to enjoy that rifle.

Matt61

Matt61,

I’d totally forgotten your mishap with the IZH 61 or I never would have made that suggestion.

Bruce

Vince,

Nice blog. Excellent work. But no way I could or would own one of these. With my level of forgetfulness it would be broken in 10 min.

Good luck man. Keep those wonderful blogs coming.

Have you guys seen the new Air Force Talon Pistol ???

http://www.airforceairguns.com/Articles.asp?ID=252

J-F

It has probably been done already. Guys do all kinds of things to Talons and Condors.

Drop in .25 barrels are not new either. A lot of guys say that the Condor is overpowered in .22, and that .25 is just about perfect for the power plant.

twotalon

TT… has anyone developed a multi-shot mod for the AF guns? Or does the breech design/shape not allow for it? Seems that AF has not gone down the multi-shot development road yet?

I think there have been some attempts, but the design of the rifle would need some modifications to make it work.

The way the rifle is put together it does not lend itself to multishot operation. Would not be easy.

twotalon

J-F:

Another jaw dropping moment 🙂

DaveUK

Wow, that Talon pistol is something. Now, if they’d only make a wire stock for that you could turn it into a carbine. (….)

-Chuck

Stick a 12″ barrel in a Talon, or stick a Talon tank on the pistol.

twotalon

Chuck,

Now THAT qualifies as a wry comment! And you didn’t even put a smilie after it.

I guess this blog is growing up!

B.B.

Thank you Master! Now, will you quit calling me grasshopper?

-Chuck

Vince:

So this is one of those rifles you don’t lend to a buddy.

My old MKI Logun S16 PCP had issues indexing the rotary mag.You had to adopt a very positive back/forward stroke with the bolt.

After discovering that,it worked a treat but let a mate shoot it and a lot of hassle would result.

DaveUK

Thanks Vince for a great review and all of the detail.

I wonder if the Theoben SLR rifle has similar, potential hazards in it’s operation?

A neat air gun. Now that I know about it and how to deal with it’s “Issues”, I would probably buy one if I ran across one at a good price.

Mike

Vince,

Great job as usual. That’s some good shooting. How difficult is it to find a replacement magazines and replacement pins for the diana 300R?

kevin

Wasn’t too hard a year ago. I don’t know about now, though…

You can get all of the parts: Pin assy ,rotary mag assy, and parts for the rotary mag from Umarex.I know because i just broke my rotary mag lever trying to cock my 300 with a pellet half way in the breech a couple of weeks ago.

Pellet halfway? Do you know how that happened?

Vince

So the perfect storm leading to breakage of cartridge rotate pin went like this: First there was no pusher pin on this gun. Next i had loose fitting pellets installed in the mag. i cocked the gun just to feel how things moved together(new gun thing i cant help doing). in the process of cocking the gun a second time i felt a brief resistance (rotator pin breaking) i noticed the magazine holder wouldnt come out( pellet stuck half way between breech and mag) i then fired gun expelling the stuck pellet and pulled my now broken holder out.

its all fixed now with fabricated pusher pin installed (could have purchased pusher, but made a slightly thicker pin)and ordered rotator pin from Umarex for mag holder.

So after you cocked the gun the first time the pellet slid partially into the barrel. OK, so that’s another scenario. What particular pellets were these?

Looks like I’ve got a few more caveats to add to my list…

Vince

Correct. it slid half way in and jammed. Cocking and not firing is just something you dont do with a loaded mag in this gun; especially with the pin pusher installed LOL. You’d end up loading 3 o 4 pellets at a time into the barrel. The pellets i used were cheap Walmart flathead Daisys. I use them in another gun i own that is also a repeater and it works well with that gun because of the flat faced shape and diameter. I didnt like the way the gun shot with these pellets anyway (small Ø and light weight =poor grouping)

B.B.,

Is a review by you of the new Air Arms Twice in the queue?

kevin

Kevin,

As soon as the Twice guns come back from the SHOT Show, I’ll order one for Tom to test.

Edith

Mrs. Gaylord,

Thanks. I’ve read the specs and have viewed the numerous photo’s on the Pyramyd AIR site. It will be interesting to learn if the represented shot count is for real and whether it’s more applicable to .177 or .22. I’m also interested to know B.B.’s take on the ergonomics of the forestock since it’s now forced to accomodate twin reservoirs and his take on the stock fit in general since it’s a new design.

kevin

Kevin,

If you look at the S510 rifle images and compare them to the Twice images, I think you’ll see that the rifle stock is the one they used for the Twice. It looks like they cut out the top part of the forearm of the rifle stock (removing the area that would have been checkered) to accommodate the twin reservoirs, which are now made of aluminum & therefore add no extra weight to the gun when compared to the S510 rifle. Here are the links:

S510 zoomed images:

/product/air-arms-s510-xtra-fac-pcp-air-rifle-poplar?m=2279

Twice zoomed images:

/product/air-arms-s510-tc-pcp-air-rifle?m=2386

Edith

Mrs. Gaylord,

Exactly. The necessary removal of the wood on the forestock of the Twice vs. the traditional checkered area on the S510 is one of the things I’m curious about. Appears that your support hand must lay flat or your fingers will be laying on the aluminum reservoirs. Ergonomics. Thanks.

Must assume you’ve added one more role to your repertoire. That of drill sergeant. Let us know how your soldier does under your supervision while revisiting basic training. 😉

kevin

Vince,

Another excellent article, thanks again.

I am pleasantly surprised that you didn’t notice a drop in accuracy when the pellet was “blasted” into the rifling instead of being pressed in by the tiny pusher pin. The mag looks to be made of die cast parts, so there must be at least a little misalignment. Did you notice any shaved lead around the breech or mag. It would have been nice if they had incorporated an additional auxiliary mag lock pin so that the pusher pin wouldn’t take any abuse.

Lloyd

Almost certainly there’s some flaring at the mouth of the breech to help that along, like the forcing cone on a revolver.

I’m going to be on the lookout for one of these.

I have the XS-B9 (the chinese bullpup that is a 10 shot repeater). Gotta admit, it’s a fun gun because of its looks, especially with a red dot attached…but I now only use it single shot. As spoken about here the pellet is forced into the barrel by air pressure and I was to many flyers which I eventually realized were the result of the pellet not entering the barrel cleanly and being forced out of shape.

But used as a single shot it is very accurate at 30 yds, easily putting 5 shots in an inch.

The other thing I didn’t like, and would be concerned about with this rifle (and am hoping you can answer Vince) was that it was easy to forget you had fired your 10 shots and then ‘bang’, I’d fire a shot with no pellet. Luckily it is not a powerful gun so no broken springs resulted.

Is there any kind of a mechanism on this gun to prevent firing on an empty magazine?

Your ability to count and the assumptions that you still have at least 7 fingers available for keeping track.

Just what I wanted vince…a snarky response to a simple question.

Thanks 🙁

Sorry, wasn’t trying to make a statement about your question. It was more a comment on what must have been Diana’s reasoning when they made the gun the way they did. Making a springer repeater with no ’empty mag’ indication is just inviting trouble, or at least when you’ve got a springer with some power behind it.

Sorry for taking it the wrong way Vince.

One of the issues I have with the ‘net…without face to face interaction sometimes things can be taken the wrong way.

I owe you a beer…but only if it’s German or Belgian.

i consider this gun a six shooter and never shoot seven just to be sure. haha

I’ve just gotten an email that says the Pyramyd AIR website will have some maintenance done in the middle of the night. It could temporarily affect access to their retail site. As far as I know, it won’t affect the blog or anything on this site.

Edith

Hey out there all you air gun nuts;

I’m on cloud nine, I just got a phone call from Air Force Air Guns. I won the the BKL drawing for the Condor any caliber, it’ll be 20 cal. for me. Haven’t decided on the color yet black red or blue. I all ready have a black talon ss. Although I have four or five sets of BKL mounts I only had one receipt to send in.

I’ve never considered myself a lucky man,but I may have to take a trip to Georgia tomorrow for lotto tickets

Loren

An actual lottery winner. Congratulations. I understand that the lottery odds are usually very much against. Enjoy your rifle.

Matt61

Loren,

Not so quick there, pardner. You realize you now owe us a review of your experiences from day one to at least day to day five, or at least until you start shooting those .5 inch ten shot groups. Dang!! You lucky Dog!!

-Chuck

Welcome to the ‘2x4s do not make good backstops’ club.

twotalon

Now that’s funny, man I have had that experience once or twice!

Good for you Loren so… what’s the first modification going to be?

Brian in Idaho;

Just a little trigger work if it needs it like my Talon needed and and a trigger stop screw.Thats all it should need.

Loren

Loren,

Congratulations@!! Have you considered one in .25 caliber?

Bruce

Mr B.

Yes I have considered the 25 cal. but they don’t have it stock right now and I have a thing about 20 cal. airguns. But I may just order the 25 barrel when Pyramyd gets them in.

Loren

Loren

Many Congrats. I love it when good fortune befalls those in the PA community. What made you opt for .20 cal? If you don’t mind my asking.

I myself just purchased my first two guns in .20 after two years of enthusiastic involvement in airguns. It seems a bit of a compromise in terms of pellet selection and price, however it sounds to me like the perfect compromise (if there is such a thing) between .177 and .22. Certain guns are legendary in that caliber.

Yippee! The odious California ban on mail order purchase of handgun ammo AB962 is struck down as unconstitutional in the very nick of time before going into effect on February 1, 2011. Let us have a rendition of the song from the film Babe: “If I had the words to make a day for you….” We just need the word “unconstitutional”! Do I feel upset at the five years worth of Wolf target ammo that I’ve stockpiled? Not a bit of it! Since the state will no doubt appeal, I will just stockpile some more. But that worry has taken a backseat to the predictions of a super storm over California which is supposed to cover the whole state–or at least the central valley–in 10 feet of water.

Matt61

Matt 61

Where in Cali are you?

Was that decision from the 9th circuit court? If so, it is hard to believe that prestigious group doing anything to help the 2nd amendment remain intact! Still, good news regardless.

The ruling came from the Fresno Superior Court. I don’t know what if any relation that has to the 9th circuit court. They’re good blokes in my opinion. I’m in northern California outside of Sacramento.

Matt61

Guys,

since we’re talking about repeaters, has anyone on the blog tried out QB Mags conversion of a Disco from single shot to repeater? How did it work out? I’m tempted but have no one to do the machine work on the barrel (O ring placement necessary). I know – it’s a repeat as I posted on yesterday’s blog today, by mistake.

Fred PRoNJ

Same here Fred only for the TF79 or QB78 guns. Anyone have one of these installed?

Fred, I believe that QB Mags offers a barrel machining service too. Check out their site.

Fred, on their New Products page, they offer machining for the QB guns but, I’ll bet that they will do the same for your Disco.

BB and all,

I seldom post anymore. But I still read the blog.

Good stuff,

DB

DB,

It’s nice to see that you’re still reading the blog. Please let us know how you’re doing and what you’ve been up to.

Thanks,

Bruce

I own two RWS300R rifles and thoroughly enjoy shooting one. I have a NIB 300R, never been cocked, that I purchased for a measely $236.00 from Mid South during a closeout sale.

I am very careful with my shooter 300R. The instructions laid out in the article will promote a long, trouble free life. I count my shots and reload after five pellets have zipped out at 796 fps. This is

extremely accurate. I have no trouble knocking down field targets 50 yards away. Thus far, after nearly

3,000 shots, I have had no problems with my sleek 300R.

I am thankful for resources like this one that educates air gunners.

As my groups show the 300R can be an EXTREMELY rewarding gun to shoot. It’s not terribly efficient (the somewhat tortured airflow path makes sure of that) but it’s accuracy really makes up for a lot of that.