by B.B. Pelletier

Announcement: Pyramyd Air’s facebook site was running a special Father’s Day Edition of the Big Shot of the Week contest. The winner is Holly Thoman Hearn, who posted the following, which we assume is her husband and son. Holly will receive a $100 gift eCard from Pyramyd Air.

With the above photo, Holly Thoman Hearn won the 2011 Father’s Day Special Edition of the Big Shot of Week contest.

Today’s guest blogger is Fred. If you’ve spent any time at all reading this blog and the comments, you already know that Fred is deeply involved in airgunning and loves to modify and improve his guns to get the most out of them. This time, Fred’s going to show you how he glass-bedded one of his Nitro Piston rifles.

If you’d like to write a guest post for this blog, please email me.

Guest bloggers must know how to take clear photos and size them for the internet (if their post requires them), and they must use proper English. We’ll edit each submission, but we won’t work on any submission that contains gross misspellings and/or grammatical errors.

Take it away, Fred!

by Fred of the Peoples’ Republik of New Jersey

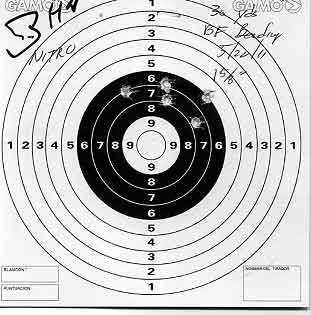

In my last blog, I detailed how I did a recrowning job on my Benjamin Trail NP XL. This is a gas-spring rifle made in China for the Benjamin Company. I was able to reduce a 5-shot group from .80 inches to .40 inches. That was at 28 feet and was considered a successful modification by many who read the blog. However, at 30 yards, I was getting 1.50-inch groups. Not quite good enough for hunting at this distance.

A representative target of what I was getting with the Benjamin Trail NP XL at 30 yards.

Our favorite Russian blog reader, duskwight, who has designed his own air rifle and is hoping a manufacturer will decide to take his design and bring it to life, suggested that my next step should be to glass-bed the rifle to prevent any movement between the action and the stock. Due to manufacturing tolerances, there’s normally ample room for play between the action and stock. The cheaper the rifle, the less care is taken in holding manufacturing tolerances to the engineers’ specifications and the less accurate the rifle. The process involves introducing a liquified fiberglass compound to the rifle stock and allowing the action to bed in as the compound flows around it and hardens, creating a custom fit that prevents the action from moving within the stock.

I started my research by going to YouTube and watching different gunsmiths – some pros, some amateurs, glass-bed their rifles. Next, I researched the glass bedding kits. After reading product reviews and the product manuals, I decided on Miles Gilbert Bedrock kit from Battenfeld Industries. I selected it mainly because of the claim that their kit contained “the most comprehensive, illustrated instructions ever offered to take you from start to finish with your bedding project.” I was sold on this kit when I read that their kit included everything I could possibly need to bed my rifle.

To remove the Trail’s action from the stock, I have to remove 3 screws, one on either side of the stock, plus the rear triggerguard screw. With the screws out, the action fell out of the stock and my first confusion arose. When glass-bedding a centerfire rifle, all the YouTube videos showed the action typically resting on the bottom of the stock. There were no moving parts to be concerned with. Not so with the Trail. As with any breakbarrel rifle, you have a cocking lever and a guide for the lever moving within a channel carved into the bottom of the stock. In the Trail’s case, there was an additional lever connected from the end of the cocking link to the trigger assembly, which serves as the anti-beartrap device. The stock has a semi-circle inlet above this channel, and that’s where the action rests.

The curved part of the stock where the action rests. Below that is the channel for the cocking lever.

Most centerfire rifles have a recoil lug on the action that fits into the stock. This air rifle doesn’t, as there’s no place to put it due to the cocking linkage. Benjamin put a removable recoil lug at the end of the stock. The trigger lug fits into the stock just below the compression tube.

The rear of the triggerguard screws into the bolt that is holding the trigger unit in the rifle, drawing the action down to the stock. The recoil lug fits very loosely around the bolt and within the stock. This looseness could allow the action to move around within the stock and affect accuracy.

The rear of the action with the bolt that secures the trigger group. Foreground is the recoil lug that fits around that bolt and then slides into the rear of the stock.

A closer look, front to rear, at the inlet for the cocking lever.

Where to put the bedding compound?

Another question. Many of the YouTube videos talked about pillaring the action. What this entails is drilling out the screw holes and inserting a piece of aluminum roundstock with a pre-drilled hole in it, with the end curved to fit against the rifle action. If you look again at the screw holes, only one — the rear trigger hole — has any potential for this improvement. The forearm screw holes are too thin for a useful pillar.

That rear screw hole is the only place to put an aluminum pillar.

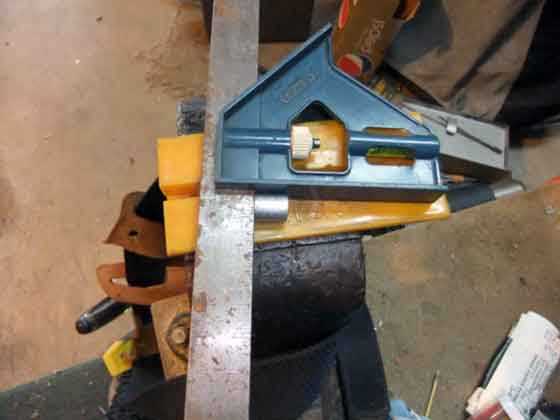

First, I drilled a half-inch hole to enlarge that screw hole. Of course, the wooden piece forming the right (forward) part of the hole fell out. Next, I cut a piece of half-inch aluminum round stock using a mitre box to keep the cut end as square to the length as possible.

Aluminum round stock cut with hacksaw.

Using my handy dandy mill file and a T-square, I filed the end as flat as possible…at least within my set of skills.

I actually got pretty close to making this surface perfectly perpendicular to the axis of the round stock.

Finally, I drilled an off-center hole (not by design), and my pillar for the rifle was complete. Using some epoxy, I glued the pillar into the enlarged screw hole in the stock. I figured I could always make another pillar and this time drill that hole centered — but wonder of wonders, everything fit!

I used JB Weld to hold the pillar in the stock. Darned thing worked. Notice on either side of the pillar and toward the rear of the rifle is a slot for the recoil lug to slide into.

On a springer the recoil block should be *forward*.

I’m guessing that bedding does help accuracy. Anything that helps firearms should help spring-piston guns more, with their weird recoils and long lock times.

Flo,

on this particular configuration, there really is no place to put a forward recoil lub. In fact, the other rifles I have taken out of the stock all have the same problem – due to the cocking slot in the bottom of the action and the stock, there is no room for that recoil lug configuration that is common on the Remington 700, for instance.

Fred PRoNJ

Good evening everyone. First let me say that this is something I have been wondering about for a bit too. I don’t think it can hurt. Thank you Fred for being the “first” to publish this idea. Wouldn’t you know it. It’s on B.B.’s blog too. Forward thinking. It can only benefit our sport.

As for the time you see, it is actually 10.36 p.m. as I write this. I believe Eastern Daylight time is displayed.

One more thing. Forgive me if anyone has checked this out. There is an excellent 20:00 min. video of a tour of the new Weihrauch factory at airgunshooting.co.uk/vidios . Parts made by cnc machines, and assembly by Man or Woman power. There is a good view of a guy truing a barrel too. I believe this was brought up a week or so back. Well must hit the sack. Enjoy.

Titus Groan

Fred….

I don’t remember if you have said or not…

Have you had this thing apart and looked at the guts? My Titan had a wasted compression chamber and piston seal. Not exactly a smooth shooter.

I went after the compression chamber with a brake cylinder hone until I got most of the pitting out, replaced the seal with a quest seal, and moly lubed the pig. The Quest seal fit very tight and probably should have been sanded down a bit, but I decided to just let it squeeze down and rub it’s way to a fit. It does shoot well now…smooth and an accomplished starling killer in spite of the sucky trigger.

twotalon

TT,

no I didn’t dismantle my rifle that far but that is a good idea. I’ll pull the action out again and look into the compression chamber through the cocking slot. However, mine is a smooth shooter and does make good power. What confounds me or confounded me was that the first pellet I fired would hit almost exactly at the Point of Aim. The next several pellets might or might not do the same and then there would be a flyer. Or, the pellets would seem to move all over the target independently from the POA. It seemed to me something was moving around – action or scope. There may be a part III coming but I’ll know after this Sunday.

Fred PRoNJ

TT

I don’t know if you have addressed this before, but have you considered the Charlie da Tuna drop in trigger for your Titan? I have no experience with either the trigger or the rifle, but once adjusted correctly, I read it is a very good trigger. I believe that is what is pictured in Fred’s photos, Fred correct me if I am wrong.

I can draw a comparison to the Discovery trigger. I performed the ‘three screw modification’ to mine, and initially I felt it made it moderately if not barely perceptibly better. Then I read a post somewhere that someone explored every combination of adjustment, and how much better it got. I did the same, and got the same results. Despite the overwhelming amount of plastic (trigger, and guard) it is now crisp, and you always know when it will break.

There is more wrong with it than can be fixed with a blade replacement. The sear is soft and does not release right if it is left cocked too long. Click………bang.

twotalon

SL,

you are correct that the GRT III trigger was a modification to this rifle. However, unlike the three screw modification to the Disco trigger, the Nitro trigger is probably the worst trigger in my airgun collection. I can’t tell the difference or even if there is a Stage 1 or II. I just keep pulling and pulling and pulling until the shot suddenly releases. I have no idea when it will break even with Charlie’s trigger. The GRT III trigger did make the entire operation much smoother but as for giving me a definitive Stage I and a crisp Stage II, no dice.

OTOH, the Disco mod was on par with a miracle. A great modification and very easy to do.

Fred PRoNJ

Fred

Thank you for that objective opinion. Some people, once they have invested in something, must brag about it. Your opinion carries water.

Great idea Fred. I was thinking of doing the same thing using clear silicone. Do you think that would work??

It has done wonders for Hollywood so perhaps it might help air gunners too.LOL!

Pete

Well, I love the way silicon looks (looked?) on Pam Anderson but it moves and jiggles. I don’t think it would be very helpful on the rifle action as that appears to be the problem to begin with. 🙂

Fred PRoNJ

Fred

You noticed that too?! I thought I was the only one. Or maybe it was the whole point of the show. IMHO she was much more appealing when she was on Home Improvement.

Great blog. And its a cliffhanger! I’m on the edge of my seat.

I take it she was at the beach, if covered with silicon (major component of sand and glass, somewhat crystalline)… Where she’s hiding silicone (a stretchy fluid polymer) I won’t bother to hypothesize.

Nooooo, you can’t stop here! No fair doing a multi parter (I’ll bet BB, the master of clif hangers, had something to do with this). Boy, I’m sure glad it isn’t Friday. This is going to be enlightening.

Chuck,

it was actually my suggestion to Edith to break this up. The original blog ran over 2,000 words and I thought it would be too long for this venue. Edith and Tom agreed apparently and after reading it this morning, I want to publicly thank Edith for her deft editing. Edith, you really cleaned up some of the areas that were wordy or might have been incorrect or offended lurkers. For those wondering what I’m talking about, as an example, in one part I playfully called Duskwright our only Russian blogger in addition to our favorite Russian blogger. Might not be the case. But he’s still my favorite Russian Blogger and the one that gave me the idea for this project.

Fred PRoNJ

Fred,

You’re doing a great job, anyway, and 2,000 words is a good start. Can’t wait to read more.

There does seem to be a lot of other countries represented on this blog and it is soooooo refreshing to hear from them. I hope they keep reading and sharing. A lot of the good stuff we enjoy comes from their countrymen.

Great post Fred! You are a bad influence on me. I’ve already started thinking about how much fun it would be to do this. I might need to buy an economy springer just to have an excuse.

Wait for part II and there might even be a part III after another revelation I made the other night. Unfortunately, I have to wait till Sunday to see if what I did the other night was “the answer”. That’s when the public range is open and I can shoot at a 30 yard distance.

Fred PRoNJ

Fred,

Great topic!

I have often considered doing this for my Ruger Airhawk in hopes of taming some of it’s hold sensitivity. Faced with the daunting task of containing the bedding compound and keeping it out of the gun’s action, I have to date held off on that project. It just looked like a bridge too far every time I gave it thought. If you get good results, however, I could see some JB Weld getting slung this weekend 🙂

Bobby

I don’t know if the Airhawk is anything similar to a Black Hawk, but have you considered a Vortek kit for that gun? They have a Black Hawk kit, and I read very good things about the Vortek kits.

I think that the BlackHawk and the AirHawk have the same action but different stocks.

I did consider the vortek kit but instead went with a kit from Target Tune India, as I was curious about their products and workmanship. Unfortunately, I still haven’t installed it yet as squirrel season just ended a few weeks back and my projects list is rather long at the moment. I’ve had the gun for about 3 years now and did a home tune on it early on that did smooth out the shot cycle a bit.

It’s due for another tune, though, so that’s on the list.

May be messy, but I’d think the solution would be modelling clay… You’d wrap the moving parts of the action with a layer of modelling clay shaped to maintain just enough clearance in the bedding compound after it hardens (and the clay has been removed)…

Granted, this is all hypothetical as I’ve not done such (glass bedding an RWS Diana mod 54 would be an exercise in stupidity, and the plastic stock of the Gamo NRA 1000 is just too flexible on its own — the bedding compound, if it would even stick, would tend to flake off from flexing; the Marauder already has a free-floated barrel, and what could one do with a Condor but gum up the swappable barrel system).

I have often wondered about the glass bedding thing too. Like you, I can’t see a whole lot of area where the stuff could be applied without possibly interfering with the normal movements of the action, like cocking or the anti bear trap bar. I often wondered if some of the voids could be filled in carefully and if that would make a difference. I’ve never used the bedding kit, mostly out of fear of permanently screwing something up. The finality of expoxy worries me..

Here is an idea and don’t laugh too hard.. could you use a hot glue gun? The glue dries and sets relatively quickly, when dried it’s not as flexible as silicon and (I think) would be a lot easier to remove from the wood and metal should it go where it’s not wanted.

Maybe a cheap rifle would be an appropriate test bed for a hot glue treatment

Great Blog and Photo’s Fred.

Glass bedding,I get the idea.

When I used to be in the denture trade,to remedy a loose fitting set of teeth and save making new one’s,we used to do a ‘reline’ on them.

If you had plenty of money a ‘soft lining’ could be had on the lowers.Mmm comfy.

I know it works on teeth,why not rifle stocks?Go for it.

DaveUK

Fred,

You rascal — a cliffhanger! Will I have to stay up late to find out how it works, or should I get up early so I can find out before getting to work…

On pillars for the front of the action, how about a large washer or thin plate with a tube welded in. You could epoxy the washer to the inside of the stock.

BG

I didn’t catch your post yesterday until this morning.

For anyone else that missed it, here is BG’s muzzleloader that he built.

https://picasaweb.google.com/BGFarmer0/GBI_rb?authkey=Gv1sRgCPyUsb7406GwxQE&feat=directlink

Absolutely incredible.

How did I miss that too? Stunning work BG Farmer.

kevin

Everyone missed BG_Farmer’s comment because it got caught up in the spam filter. He tried to post it several times. When I went online this morning, I saw all the attempts & approved his comment, which was posted on yesterday’s blog.

BG_Farmer is on the approved list of people who can post. In fact, he was the first person I ever put on the approved list. If he gets caught in the spam filter again, I’ll ask the IT department to work on the issue.

Edith

SL, Kevin,

What Edith said — it wasn’t showing up yesterday. Glad you all like it.

Edith,

Thanks again. I didn’t really take it personally — my posts are so random sometimes that IT may not be able to figure out the pattern, anyway. Mainly, Matt seemed to be casting aspersions on my caplock only status many months ago, and I wanted him to see this one :). Just kidding, Matt.

BG_Farmer,

You make ’em and I destroy ’em. Seems like a fair distribution of the work. 🙂

B.B.

BB,

Aside from possibly the “Bronco aperture sight incident”, you haven’t done anything destructive that I’ve seen, or is there an adumbration of an upcoming blog in your comment :)…? I hope the Ballard is OK!

BG_Farmer,

The Ballard is fine. Just had her out to the range today, along with the HW 100 for the blog (gotta do my work, too). I would never touch the Ballard, except to shoot it and clean it.

And, you, sir, are a craftsman!

B.B.

BG,

this is one stunning piece of work. You are a real craftsman! My level of work is not anywhere near yours as is evident by my off-center hole drilled in that piece of Aluminum round stock! Perhaps I can send future pillars to you for driling?

My reason for not doing the forearm pillars was (a) the forearm is pretty thin at that point and I was worried about damaging the mystery wood and (b) I would have had to curve the end of the roundstock to match the curve of the compression tube and filing and fitting and filing more didn’t appeal to me.

However, Matt61 has brought up a very good question and I need to think this through – why pillar if you glass bed and vice versa?

Fred PRoNJ

I’m lost on the pillar versus/in addition to bedding thing, also. At least we don’t have to worry about free-floating. I’m looking forward to seeing the results of what you did. It is a very methodical approach to test one improvement at a time.

Fred,

Admirable undertaking. Can’t wait to hear about the results.

Anyone/Everyone,

Who makes the current Browning Gold Air Rifles?

kevin

Kevin,

Turkey, as in Hatsan, I think.

B.B.

B.B.,

Thanks. Gotta pass.

kevin

I’m frustrated. Again.

It seems everytime I find something that works well and is priced fairly it’s discontinued.

I really like the tech force, 2 piece LOW rings for mounting scopes because:

1-They’re the lowest I ever found (11.3mm saddle height)

2-They have two screws and a stop pin for affixing to a 3/8″/11mm dovetail rail

3-They have 4 screws in the straps

PA has discontinued these

/product/tech-force-1-rings-low-9-5-13mm-dovetail?a=3455

and it appears everyone else on the internet was drop shipping from PA.

Does anyone know of a LOW mount for 1″ scopes that fits all the rest of my criteria?

kevin

Kevin,

You’re right. I compared the discontinued mounts with images of the others, and they do look much lower. I’ve forwarded your comment to the movers & shakers at Pyramyd AIR who make things happen. Let’s see what they say.

Edith

Edith,

Very kind of you. For the record I did not intend for my plea to turn into a work order for you. Gotta luv ya though.

Anyone have an alternative in the event that PA is unable to re-stock the tech force?

kevin

Kevin

Give these a try:

/product/leapers-accushot-1-rings-medium-3-8-dovetail-4-screws-cap?a=793

They are listed as medium height rings, but a 32mm objective will barely clear the receiver with the caps mounted. 4 screws per cap, 2 screws on each rail mount, and a scope stop pin.

SL,

I compared every set of rings with the discontinued ones. While the Leapers ones you linked are pretty low, they’re not going to be as low as the TF version. On the other hand, I don’t know how crucial the height may be for Kevin.

There’s a possibility Pyramyd AIR may have a set of the TF rings hanging around that can be shipped to Kevin. At least, that’s what I’m hoping they’ll tell me 🙂

Edith

Slinging Lead,

Those are good rings. I have some of them. Thank you. Looking for something really low. Greatly appreciated.

kevin

Kevin,

The staff in the Kentucky warehouse is looking for the rings. They may have a pair to sell you 🙂 I’ll let you know.

Edith

Edith,

You’re the best. Thanks so much for this extra work. I’ll buy all they find.

kevin

Kevin,

I know that a set of BKL special low rings will soon be coming to market.

They are a new design.

B.B.

B.B.,

Now that’s some good news. Seems that the python has digested the elephant if they’re back to new designs.

Not sure how you keep up with all the new developments. New pellets on the horizon, competition for the shoebox, all the new gun introductions, testing, etc. etc. I will, reluctantly, take over the ballard testing since you can’t possibly have anymore time to devote to that project.

kevin

Kevin,

Okay, you can take over testing the Ballard! I’ll need the deed to your primary residence signed over and a DNA sample for security. Do you think you can finish it in 48 hours? 😉

B.B.

If I didn’t know better I’d assume that you spent some time working for the IRS. LOL!

Fred, now this is fascinating and brings me back to one of my very first questions on the blog many years ago which was why the many accurizing techniques for firearms are not used for airguns. It seems like tuning is used as a substitute, so the derivative question then was whether tuning could accurize an airgun to which they answer was equivocal although Mike Melick’s work on my IZH 61 has me inclining to yes. Anyway, here Fred is pumping life into the original question. I’m on the edge of my seat believe me. I give you a lot of credit for sailing in to tackle the glass-bedding from scratch. I ordered Clint Fowler’s book on how to glass bed your M1 Garand using acra gel and was fairly flabbergasted at the level of technical detail. I also read Bryce Towson’s book on amateur gunsmithing and was amused at his stories about the different ways he screwed up the glass-bedding process. One of them had to do with giving the finished product a good shake and having the action fall right out onto the floor. It was all-around encouraging, but I’ll let you tackle the job all the same. I’m well-disposed towards pillar bedding since that is how the Savage rifles are bedded, but here a question arises. Aren’t the pillar and glass bedding exclusive? If you have the action resting on pillars, why worry about the glass?

Edith, are you saying that the paintballers have stabbed us in the back by supporting this bill? Ha, no paintball for me. That’s depressing that the bill may be back soon, but as the saying goes, you can’t fix stupid, and what is stupid and illogical now will still be when the bill reappears. Yes, the zombie analogy works I think. In The Night of the Living Dead, my favorite zombie attack technique was used by the renegade motorcycle gang whose members would use sledgehammers and send those zombies sailing. (Second place was the policeman who would flatten the zombies with a forearm and cry out, “We’ve got this by the a—.”) 🙂

BG_Farmer, I was all set to congratulate you on assembling a parts kit, but to hear you fabricated that flintlock is just incredible. You should go into business. And you are fully self-sufficient and ready for the apocalypse. The history of guns is something that I happened to be very concerned about right now as I will explain later, but what’s the story with your model and how did you select it to build? How does it shoot? As a man who has built his rifle from scratch, you are ideally situated to answer my questions about gun safety. So, how do you know that your rifle won’t blow up on you? Were you trusting the specs of your plans? Were there standards of tempering or forging that you followed? I’ve been asking my question of military surplus gun dealers over the phone and been met by puzzled silence and, in one case, loud laughter. They don’t seem concerned about this question at all.

Matt61

Matt,

pillar bedding and glass bedding – are they mutually exclusive? Darn good question. The answer is I don’t know. If they are, then I did a lot of extra work for nothing.

Let me think about this as the theory is if you’ve done a good glass bedding job and the action doesn’t move within the stock, why pillar? I thought that this removed the possibility of compressing the stock or having the action slightly move under recoil but if the glass bedding is done properly, how could the action move? Well, when you read part II, you’ll see this is not as difficult as it seems. Did it reduce my groupings? You’ll have to wait for that….. zombies not withstanding.

Fred PRoNJ

My concern with the screw pillar is that after your drilling it is unsupported on the front side… Given that spring guns have that nasty forward slap on the action you might actually have weakened that support point (though drilling a small gauge transverse hole through the stock and the “unintentional” thick section of the post, and fitting a long pin through the assembly would lock it in place… until the stock holes wear from recoil and you have to counter sink metal posts to spread the pressure… To (mis)quote the Comcast turtles “When does this stop?”

Wulfraed,

I had worried about that after it happened but if you look closely, the original hole in the stock is still three quarters present to hold the pillar in place. Also, the pillar itself is glued to the stock and when I took it out the other night to check on a different item, it was still solidly in place. JB Weld, the answer to making things stay put. Quite frankly, that small cross bar of wood really didn’t have the strength to stand up to any real force. I also hoped the two forearm screws along with the glass bedding would prevent the action from moving as a result of that enlarged hole. I guess only time will tell.

Fred PRoNJ

Matt,

I don’t want to take too much credit, the barrel and breech plug were standard parts — they just have to be fitted (via filing and testing) so that the face of the breech seats tightly against a rim where the rifling stops and lines up with the proper flat on the barrel. That is about the only part that could blow up, and all I could do is follow the best practices as far as I could find them. The barrel is a Green Mountain, which is made of certified gun barrel quality steel and not likely to fail. In the old days, they used wrought iron, which is an even better material for a barrel because it tends to swell rather than burst under pressure, and they used a lot of it at the breech where the pressure was highest. BP pressure with round balls is somehwere around 10-12,000 psi if I remember correctly, so not as demanding as a centerfire barrel. I did have to (re-)harden and temper a spring or two, but the hardware in general is fine without any treatment beyond cosmetic, if you keep in mind that brass does the same job. Ideally, I could have hardened the lock plate and some internals, but you can easily warp stuff and it is not strictly necessary.

I followed an original rifle fairly closely in architecture and blended in some regional variations. A friend of mine who shares my interest in stepped wrist SW Va. rifles first showed me the original and I really liked it. These were made in and around the areas some of my family comes from and at an exciting time. Initially, I was going to make an exact copy, but I didn’t feel I had the necessary skill, nor could I justify risking money on a custom profiled barrel. Maybe someday I will do it that way, but for now, I was happy learning what I did and picking up some experience. It shoots very well, although I had a minor problem getting the homemade sights aligned properly at first (blade as perfectly perpendicular to top flat as possible, rear sight level), but that’s fixed and they work well now; just like a scope, I suppose :). The lock is really fast (which is good luck because I chose it on the basis of styling) — I can shoot just as well as percussion, and the long sighting plane and substantial weight out front help, also, in conjunction with the set trigger. Probably airguns help again, because of the similarities in lock+barrel time.

Wow I read this too fast last night and thought as usual the article’s by BB.

Where’s BB these days? I don’t see any posts by him here. I hope he’s OK.

Good article Fred der Pronmeister!

flobert,

Sometimes, B.B. has to actually go to the range to shoot 🙂 That’s where he was this morning. He’s hale & hearty and living the good life.

Edith

BGF…

Thet thar be a right purdy raffle what you made yer ownsef.

You done put them Hawken boys to shame, you did.

twotalon

Twotalon,

Glad you like it. The Hawken is quite a different concept, but I like them also. One practical issue with this one that a Hawken doesn’t have is that the cleaning rod can bump the ceiling quite easily, even with the barrel out of the stock :).

I think I ran into that problem too.

They don’t fit into gun cabinets well either.

twotalon

twotalon,

I was unaware that BG_Farmer’s rifle was up for raffle. Please enter me for ten tickets and I’ll send the money as soon as the results are announced. 🙂

B.B.

I promised some photos of my pellet trap. This is my first attempt at using Picasa, so bear with me.

https://picasaweb.google.com/114513424174340662506/SLSPelletGunTrap?authkey=Gv1sRgCKHnic2f-M_qwgE&feat=directlink

SL,

Holy truck box, Batman! That’s no pellet trap! It’s a safe with the door missing.

B.B.

Thanks! I wish I could take some credit for it.

I hope you had fun at the range today.

SL

Now I know who steals tanks 😉

duskwight

Slinging Lead,

Nice trap. Where you got that target stamp?

Victor

Fred,

You give me waay too much credit 🙂 I didn’t design it, I just brought some well-known solutions together and made an attempt to make them into one working piece. And all I do – is just playing with engineering software, ordering parts from several manufacturers and putting them together. Ah, yes, there is a part designed by me – a safety switch, a great deal of job 🙂

From what I understand on your Benjamin Nitro you gained 50% accuracy improvement on your rifle just by recrowning it. That’s very nice. Maybe you’ll get some more by bedding. We’ll see soon, I’m sure 😉

I still feel that this rifle is a bit overpowered, and a bit too light for its power, so maybe you should test it with heaviest pellets in your posession, to keep it subsonic all the way. Or, if a Nitro spring is possible to fine tune, I would drop some kilos of its power down.

And one more thing on overpowered Chinese springers – check out the seal. They seem to make them from some unknown to mankind stuff, so it starts to burn out even on normal springers. Burnt seal makes no air cushion in the end of a working cycle, so your rifle kicks more than it should, loses power and accuracy too.

If you see some sort of “licks” on its sides – that’s it, you need a replacement. Rub your cylinder dry. All the oil you’ll ever need is already there. Change the seal, and apply some synthetic motor oil – by your own finger, just dip to have a little drop on your finger and distribute it around the edges of the seal, to create a thin film.

I’m always distrustful of breakbarrels, just because they are breakbarrels. There’s always some chance of barrel wobble or rock, so check that every time.

If I were you, next step would be adding some mass to the stock. E.g. drill some holes in the stock, under butt pad and glue in there some old Crosman 12g bottles, with their top parts cut off and all the rest filled with lead (I guess you know the safety on working with molten lead).

Wishing you and your rifle all the best.

duskwight

Only by the eventual leakage of nitrogen gas past the internal seals with age… These are essentially the same thing as the struts that hold lift gates up at the back of an SUV (My Jeep managed to go over 7 years before I had to replace the struts — though I did have to warm the old ones up if the temperature was below 55degF [by pumping the hatch up and down at a “rapid” rate for 15-20 seconds, then they would hold the tail up])

Heh.. an excuse to sort tins of pellets for any minor damage (along with emptying the pellet traps).

Wulfraed,

Thing is that gas springs I use (they are in fact made from automobile door struts) have the ability to be “discharged”, re-lubed and then filled up to a certain pressure. I check it every 3000-4000 shots, for accuracy reasons. And a man who services them has a well-written table of pressure/force at 20C so adjustments are as fine as 1 kilogram.

I thought Nitro spring has the same capabilities for adjustment.

duskwight

Hmmm, I’d not encountered serviceable versions before… So can’t confirm or deny…

Fred,

A lot going on here: pillars; recoil lugs; bedding…..hmmmm. Confusing nomenclature and I bet pretty universally misunderstood. Are you going to be able to give “The” authoritative descriptions as they apply to springer airguns? I think you are up to the task.

So we have to wait several days to find out if it worked? I hope you are not going to give us some “kinda maybe” answer! Like getting socks for your birthday.

Lloyd

PS. It will be ok if the test is inconclusive…kinda maybe.

Lloyd,

a new wrinkle came up last week after I had sent the entire blog to Edith. I asked her to holdup on running the second part until I get to the public range here and test out the change I made. Sunday will tell. This will either be a two parter or a three parter. I’ll know Sunday. The rest of you will know next week…..

Fred PRoNJ