by B.B.Pelletier

Today, I’m going to do a fundamental report that I promised some time back. I’ll show you how a spring-piston powerplant works. I’ll also show you how to measure mainsprings so you can find replacements when yours wears out. We had a question yesterday morning from a blog reader named Peter:

Hi Tom! Been trying to locate a replacement spring online for about the last six months. What I have is a pre-war Diana model 45 underlever. I have read on different blogs that springs from other guns can be used; but when contacting these spring suppliers, they say that if it’s not in their online catolog it’s not available. At any rate, there must be someone, somewhere that would be willing to sell a spring that would work in this gun. What baffles me most is there must be hundreds of other people who have located springs for their old airguns, but in six months of searching have had no luck in locating their source. Tom, I need your help before I go completely bazonkoos!!!

Well there’s not much chance of a pre-war Diana airgun mainspring being available anymore, is there? World War II ended in 1945, which was 67 years ago, and the chances of finding a new old-stock mainspring are virtually impossible. However, all is not lost. There are plenty of mainsprings around today that can be made to work. All you have to do is measure the old spring, so you know what’s needed. I’ll come back to this, but first I want to discuss how the spring-piston powerplant works.

The spring-piston powerplant

There are a number of ways they can work, but the basics of the spring-piston powerplant is a spring pushing a piston that compresses air that then pushes the pellet. That’s it in a nutshell. There are no valves or moving parts, other than the piston and mainspring. The air is compressed ahead of the piston in a part of the spring tube called the compression chamber.

In the end of the compression chamber, there’s a hole called the air transfer port. It’s where the compressed air leaves the compression chamber and gets behind the pellet, because the breech is in line with the transfer port.

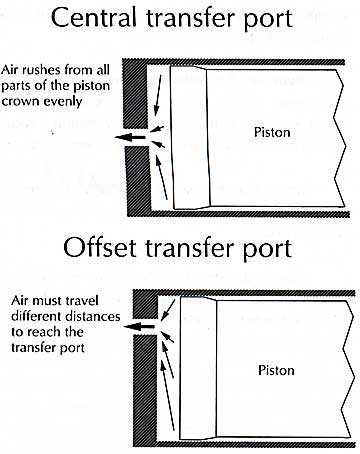

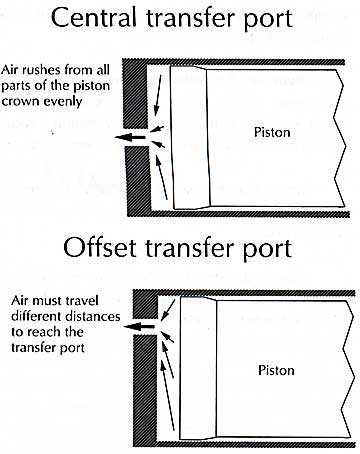

This side view of two air transfer ports shows how they work with the piston to channel high-pressure air behind the pellet. The port may be offset compared to where the breech is located in relation to the compression chamber.

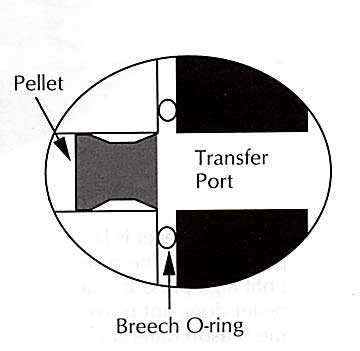

This drawing shows how the pellet seals the end of the compression chamber, which is on the right in this view. The compressed air has nowhere to go, other than behind the pellet.

This Beeman R1 rifle has a special replaceable transfer port installed. That’s the reason the Allen screw is on top of the spring tube. But the transfer port here looks like most breakbarrel transfer ports.

When a spring gun is fired

Most spring guns, including those with gas springs, work the way I’m about to describe. When the gun is cocked, the mainspring is compressed by the piston, which is held in the rearward position by the sear. When the trigger releases the sear, the piston springs forward, compressing air as it goes. When the air is fully compressed it stops the piston before it hits the end of the compression chamber.

On some guns that aren’t properly designed or guns that have been tuned incorrectly, the piston actually slams into the end of the compression chamber because the air pressure isn’t high enough to stop it. This is why some pellets feel much harsher than others in a spring gun — because they either move too soon and are unbalancing the powerplant (allowing things to happen that shouldn’t) or they remain in place too long, allowing the piston to rebound off the high-pressure air in the compression chamber.

The powerplant

This is the question that started this report. A reader asked me to show what a spring-piston powerplant looks like. This is it, except for the outer spring tube.

These are the major parts of a spring-piston powerplant. They fit inside the spring tube and the mainspring fits inside the hollow piston. It also fits over the spring guide, which is shown in front of the trigger. Some guns also have a shorter spring guide at the front of the spring that fits inside the piston. Because of its shape, it’s called a top hat — shown above the end of the spring.

The piston is hollow, as you can see here. The mainspring fits between the central rod, which is used to engage the sear and the inside of the piston. The better the fit here the less the gun will buzz. A tin soda can could be cut to make a liner to fit inside the piston and take up any slack between the mainspring and the piston.

Here you see the piston in the cocked position. The trigger has caught the piston and will hold it in place until the trigger is pulled. The spring guide is not shown here so you can see this relationship, but it would be against the front of the trigger and extending into the hollow piston, inside the spring. The piston rod that you can see passes through the spring guide.

How to measure a mainspring

Pete asked where to get a mainspring for his pre-war air rifle. I told him he’ll have to get one that is close and make it work, Let’s take a look at what that means.

There are several measurements you need to know when measuring mainsprings. One is how fat the spring is on the outside, so you can determine if it will fit inside a piston. Be careful with this one, though, as springs will buckle when they’re compressed and become wider than they measure at rest. Always allow yourself some wiggle room until you get the hang of it.

The second measurement is the inside diameter of the spring. It has to fit over the outside of the spring guide and top hat, if there is one. You want the fit of the spring over the rear spring guide to be very tight or “nailed on” as Jim Maccari says. The spring will get a trifle wider when it’s compressed, so don’t worry if it’s very tight — as long as it fits over the guide.

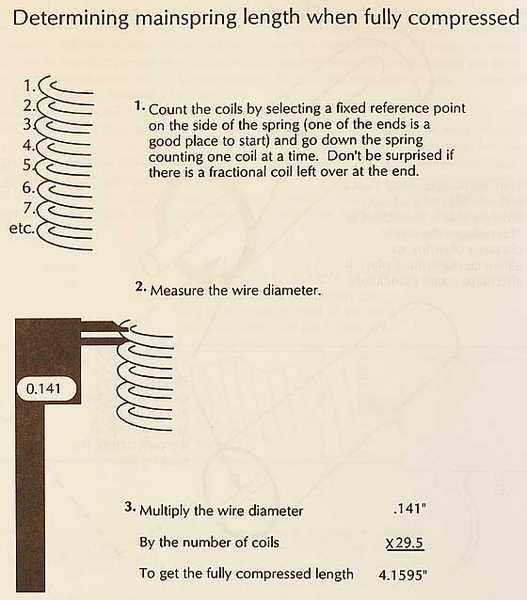

Lastly, you need to know how long the mainspring will be when it’s fully compressed. That helps determine if you’ll be able to cock the gun or the spring will become coil-bound before the sear grabs the piston. Look at the picture of the piston in the cocked position above. The compressed mainspring has to fit in the space provided when the piston is in that position and the spring guide is in place.

This graphic tells you how to calculate the compressed length of a mainspring.

What if the spring is too long?

You can live with a spring that’s too long, as long as all the other measurements work. When the spring is too long, you cut off some coils to make it fit. I use a Dremel tool with a cutoff wheel for this, and I cut with the wheel at 90 degrees to the axis of the spring wire. Then, if I want a beveled end, I can grind the end of the spring on a bench grinder to get it flat again.

I don’t bother to collapse the last coils of the spring the way they come from the factory, but if I wanted to I would heat them red hot and whack them with a hammer until they bunch up. I would have to use heat-sink paste or a good wet towel above the spot where the spring was heated to prevent more of the spring wire from softening this way. Then I would quench the job in water when it was completed. But like I said, I don’t bother doing that and my springs seem to work fine.

Where to get mainsprings

Now that you know how to measure a mainspring, you probably want to know where to buy them. I know of three possible sources. First is Pyramyd Air, which sells many replacement springs for current and obsolete models. Some of the old Weihrauch, FWB and Diana mainsprings can be modified to fit many older airguns. The HW55 mainspring and the FWB 124 mainspring are both quite long and can be cut to fit many other guns.

The second source is John Groenewold, of JG Airguns. Contact him at https://www.jgairguns.biz. John buys vintage parts in the UK for many old classic airguns and often has parts for those oddball guns. He may even know if he has a spring that will work for you, even if it isn’t commonly listed anywhere.

Third and perhaps the best of all is Jim Maccari, also known as the Springman. Visit his website at https://www.airrifleheadquarters.com. Jim makes springs for many older airguns, plus he can sometimes find a spring that will serve for something other than what it was made for.

So that”s what they look like without all the grease. Kinda pretty that way.

Where did you find a spring that does not look like a pretzel ? I want one of those.

twotalon

TT,

You can buy springs for future use and store them until you need them. Maccari used to sell sets of a dozen or so.

B.B.

Lots of good info here. I just cut a spring last week for a RWS93/Cometa300. I had a new Crosman Storm XT spring and only needed about 1/2″ cut off. I had a couple of these as they fit so many rifles.

I tried both ways, first I cut and put the spring back in with out heating and compressing the last coil. I then took it out and heated and compress and ground flat the last coil. It worked fine both ways and couldn’t see any difference.

Bob,

There wouldn’t be any difference in compressed length if the ends weren’t collapsed. Most shooters like the ends ground flat, though I have used them rough and flat and see no real difference. But in a smooth tune I think flat is needed to keep the spring base from digging into the spring guide base.

B.B.

For those who want to mess with it….

If you just grind a somewhat rounded bevel on the cut end of the spring, being careful not to burn the temper out, and put a thrust washer with grease in between it and the spring base, it works great. You may have to make the thrust washer from a regular washer who’s imer diameter fits close to the spring guide. Then just grind the outside diameter of the washer to the spring OD.

I have had trouble trying to heat and collapse the last couple of coils. They tend to break adjacent to the heat affected zone because without re-heat treating the whole spring, it’s hard to even out the temper. Just grinding a bevel and using a thrust washer with it does about as good.

More info about spring winding can be found on Macarri’s site and in Google…

/Dave

There are more places to get springs. I get mine from McMaster-Carr. Their square section (the wire is square) die springs are rated for hundreds of thousands of cycles. You can also buy them coated, eliminating the need for lube on the spring. If I remember correctly, they come in 3 ft lengths so you’ll need to cut them to size.

/Dave

/Dave,

That’s a new source for me!

Thanks,

B.B.

Mc-Master-Carr is EXCELLENT.

I wonder if there’s any demand for gas pistons to replace the springs in spring guns? As in, direct replacement?

There is a market for such a thing, in fact we just did a group buy on a forum for some gas piston for IZH-60/61. I haven’t had time to fit mine in it yet but report from some of the other buyers confirm the great quality of the part included, it makes for a sweet, all day, smooooooth shooter. Can’t wait to try mine out once the weather is a little warmer as these are my favorite kind of rifles.

J-F

Golly. Is there anything McMaster Carr doesn’t carry? Love that place. Now, would you like your esoteric machine screws in tin, stainless, or titanium? Great tip, Dave!

-Jan

B.B.,

How do you fit all this into your head?

Why is the sky blue, Dad?

se mn airgunner,

You start out telling everything you know, then smoothly transition to making up what you don’t know. It’s the transitions that are rough. 😉

B.B.

That is so funny b.b.

But don’t you hate it when you’re trying to buy something and you can just tell when the salesperson has reached the limit of their knowledge.

The good ones of course say something like…”I’m not sure let me find out for you”

But sometimes I love the line of B.S. that starts coming out of them because they’re just too proud to admit they don’t know everything 😉

cowboystar dad

Oh yes, you’re 100% right 🙂

Once a very wise man told me – “One’s grown-up when he knows when he can say “I don’t know” – and isn’t shy to say so. And this is called maturity”

duskwight

Yeah, whenever I come up with some arcane fact, my wife says “You’re just making that up.” About 50 % of the time she’s right….

Mike U,

In our house, I’m a stickler for facts. When Tom writes an article or the blog and has “facts” he quotes, he has to prove to me that they’re legit 🙂 In many cases, he’s got the books open and ready to prove his points. In some cases, he misread something…and I’m there to say, “I told you so!”

Tom has visual agnosia (we’ve discussed the hilarious issues with that in previous blog comments) and is also somewhat dyslexic. Put those two together, and you’re in for some fun times 🙂

Edith

Sorry for being late to the party, today was kinda ectic.

I think smart phone and easy internet access was invented for this purpose. When someone asks a question no one has the answer too it’s nice being able to get your phone out and just search it on the spot. 😉

J-F

Edith, it has been my understanding for many years that Zane Gray only had one manuscript returned by his editor, the one he sent in while Mrs. Gray was out of town.The stories were all Zane’s but Mrs. Gray applied the polish.

Ken

ken,

Glad to see you adding comments, again 🙂 Before you know it, your surgery will be a distant memory.

All those months that Tom was ill seem like a distant memory.

Life returns to normal. Forget the bad, remember the good 🙂

Edith

Thank you, Edith. I don’t feel great, but I do feel hope.

Ken

BB

What powerplant did you use for the photos? Judging by the safety it looks like a Diana of some kind.

SL,

Diana 34 with T05 trigger. The way the trigger works, this is the easiest powerplant to show this way. It’s more difficult to shot a Weihrauch trigger and piston cocked — even if I had a spare one to use, which I don’t.

B.B.

Thanks for the fast response.

I don’t facebook, but I found this PA facebook link on the yellow, and it is just priceless.

http://www.facebook.com/photo.php?fbid=343162135728185&set=a.196562423721491.49635.173426952701705&type=1&theater

I share that link with everyone I know, it’s priceless.

J-F

Minor, not quite typo, in there…

I think you mean “cut the spring at”

Wulfraed,

Good catch.

Thanks,

B.B.

I think what he meant to say was: “…and I cut with the wheel positioned 90 degrees to the axis…”

-Chuck

When the Good Lord put me together he left out all the AT (Airgunner Tinkerer) genes. Good info for those that have these genes though.

Anyone on this blog planning a trip to Asheville, NC the end of next month to attend the big airgun auction (estate of Cecil Whiteside)?

kevin

I actually have a full day of weeping in the corner planned Kevin.Why couldn’t this auction have happened about $50K ago?? I really expect to hear about some very very good deals after this one takes place.Unlike the big airgun shows,this has had very little “ramp up” time……so I would think with 800 airguns on the block…..the sheer volume might keep the prices reasonable on the remainder after all the top eschelon are fought over.I’m out of “rainy day” money,or I would be there with a vengeance…….hence,the weeping.Best of luck if you attend……I’ll anxiously wait for the report!

Frank,

I can’t go. Although bidding online is allowed I was hoping for a pair of eyes at the auction since the pictures suck and are incomplete. The little girl that answers ramseys phone has no idea when or if they will have a catalog or even a complete listing of guns.

I think you’re absolutely correct that there will be some great deals but fear you’ll need to be there in person to verify. Really wish I knew someone that was going.

kevin

So, what makes Macarri springs so good? I’m still holding out for chromium steel springs like those used on racecars to take performance to the next level. If someone has venture capital to give someone else to develop this, I would be glad to watch…. What would be the weight of some of the higher-end mainsprings? I understand that the recoil spring for my 1911 is rated at 16lb. My IZH 61 mainspring appeared to be just about incompressible with bare hands and that is one of the smaller ones out there. On the other hand, I’ve been reading about the traditional English longbows with a draw weight of 190lbs which is at an extreme upper limit of the force one could generate. So, how to fit spring guns into this spectrum where my B30, for instance, requires something like 30 pounds of force to cock? I don’t think this is the same quantity as the longbow or even the 1911 mainspring. Does 30 pounds refer to the actual compression value of the spring or what is felt in the hand as you compress? Perhaps to convert, you need to use the equation for torque T = rF where r is the length of the cocking arm and that could bump up your actual spring force quite a bit.

Wulfraed, you’re back! Where have you been? Regarding the coffee can, I suspect that the can was upright rather than lying on its side with an end exposed. In any case, shooting into 6 inches offhand at 100 yards with a spring gun seems like quite a feat of shooting to me. I believe that Olympians hold something like 3 inches in those conditions with firearms.

Victor, yes, Karate training can be very brutal. But it’s been my observation that those who approach martial arts training with the most violent mindset are the ones who tend not to stay. They will go hard for a few sessions and then their own high standards put them off and they never come back. At one place, I watched a “student sport sparring club” form. Everyone whaled on each other for a session or two, and then no one showed up again. The hardcore approach will sift out the people who are into it, but the attrition rate is heavy and the path is narrow. I myself did not respond well to my Karate class and was resentful and confused. The shouting, the rigid postures, and the aggression just never felt natural. I gravitated more naturally to the softer styles with the throwing and maneuvering. This is actually one of the reasons that I’ve found Systema so interesting. Their method is informal and relaxed in the extreme, and it is not uncommon for people to laugh in the midst of training. (Not what I associated with the most militant realms of the former Soviet Union.) This was new to me and more congenial, especially when it seemed like they could still deliver. Vladimir’s explanation for this is that if you go 100% in a training situation you’ll have nothing left to call on and nowhere to go when you’re in real danger. Interesting point which is certainly a departure from the adage about fight like you train. His teacher Mikhail Ryabko claims that the ideal mindset for fighting is the same as when you are buttering your toast in the morning. What can this mean?! My mornings are a little more frenetic and hurried than I would like. But the point seems to be total relaxation and composure (like my splendid indifference to results in shooting at its best). Mikhail goes on to say that he had met people “whose business was to kill people in the war” and he said it was not their method to distort their faces or yell or adopt unusual body postures of the kind that people associate with Bruce Lee. What is more interesting is that Mikhail himself is probably one of those people. His bio says that after intensive training from the age of 5, he went on his first mission with the Spetsnatz at age 15! I thought this was preposterous. But then I was reading a memoir of a German soldier on the Eastern Front and he says that the Russians would send tanks into battle with teenage kids mounted on them who would throw grenades and then jump off to engage in hand-to-hand combat. I guess the kids were chosen to fit better on the tank. But the writer said that they were “tough and agile as cats” and that anyone who underestimated them paid the price. So, maybe there is really a tradition for using kids in combat. Anyway, I would say that these tank-mounted teenagers certainly have their credentials, and any method attributed to them is a viable alternative.

I have studied Ulysses S. Grant, one of the greatest warriors of all time for sure, and it was his observation, like you said, that there are some people who are just not cut out for violence. This was not necessarily a character flaw since some of these people were of the highest morality and principles, but in the event, they just could not function. “Not temperamentally suited for fighting” were Grant’s words. Another person commenting on this same trait says that it is probably to their credit as human beings. Anyway, along the same lines, I think that temperament probably guides one to their particular style if they are minded to do martial arts in the first place. You seek the style and the style seeks you. And perhaps they are not so different in the end. I was all black and blue after my Systema sessions notwithstanding all of their good humor. And I believe that the founder of modern Karate, Gichin Funakoshi wrote to the effect that everyone has a mixture of fear and courage, and everyone has their way of trying to make sure that the courage has the upper hand at the right time. (His way involved doing his forms in the middle of a hurricane!)

Matt61

Matt61,

In formal Karate (that I know of), students are neither taught, nor encouraged to whale on each other. Form is EVERYTHING, so the first clean punch ends in a point. IF two students cannot connect cleanly (with perfect form), then they are taken aside and lectured. In my experience, it wasn’t brutal because of excessive violence, it was brutal because a great deal of discipline and hard work was required. However, in non-point sparring (i.e., learning how to spar), if you failed to block, then you were not allowed to block for the remainder of the session. If you failed to throw punches, then you were not allowed to throw punches for the remainder of the session. Students who failed to execute in either of these two areas learned VERY quickly, so it wasn’t something that you saw often. Yes, the demands were very great, and yes, the turnover was very high, but not because of brutality. It was either for you, or it wasn’t. About 1 in every 32 students got their first colored belt. Obviously, it was not done for a profit. This training was passed down over many generations, through a direct and unbroken lineage, with very high standards. There’s no way that it could be done as a business, because little money could be made this way. In this regard, it is a very special program, and one (experience) that I cherished. Put it another way, it was truly practical Karate.

Imagine any program with very high standards, where you have to perform up to a certain level, no if’s, and’s, or but’s. Only the most ambitious students will do well.

Victor

One last thing. We were not allowed to spar until AFTER the first belt. By then we had passed the conditioning requirements, and knew all of the fundamentals. But once ready, the punches and kicks absorbed were very real. How else can you truly prepare for a real fight? It’s like training with a gun for self defense. By shooting it, you help to reduce the “shock” element.

I like that dialogue from one of the Kung Fu tv episodes “One cannot speak convincingly of peace and go forth armed. One cannot speak convincingly of peace and go forth weak.”

Matt61,

If there is one thing that I’ve learned about martial arts training is that training is super critical. The reason I have to much respect for the particular Okinawan style that I studied is that it proved to be very effective in actual combat. At least a third of each training session was heavy conditioning. At the end of the floor exercises (mostly for core strengthening), while lying flat on our back, we were forced to get up as fast as possible. By then our bodies were already exhausted. A lot of our training was like that. They would wear us out, AND THEN demand our best and hardest effort. If we showed even the smallest bit of being tired, they’d bark at us, saying “What are you going to do when you’re really tired during a real fight! Tell your opponent that you’re tired!?”

Anyways, this practice of getting up as fast as we could was a daily thing, so we got really good at it. For me, the significance of this was that during my very first serious sparring match, during a grading, I was fighting a guy who was MUCH bigger and stronger than me, and he had a much higher ranking than me. I found that my body reacted instinctively and powerfully. The most obvious thing was when this man with much longer legs swept my legs out from under me. I went down fast, but more importantly, got up so fast that it was as if gravity had no real significance to me. The hard and consistent training MADE me a better fighter.

I’ve seen some very ugly fights where one guy will go down and not have the capacity to get up, or out of a dangerous situation, and seriously pay for it. There are some very nasty and mean people out there, so you have to use everything in your arsenal. Some people won’t stop just because your down, or even already seriously injured. Knowing what to expect from the “real world”, you have to either avoid danger altogether, or train harder than your potential enemies.

Way back when the UFC was just getting traction, I saw a fight in which some guy who had trained entirely in a kicking style of Karate got pinned own. The opponent sat on top of him, leaving the kicker’s arms free by his side. The guy on top started to pound the Karate guy mercilessly, and the Karate guy didn’t have the instinct to raise his arms to protect his head. That was an amazing thing to watch, because it highlighted the point that training is everything. This Karate guy had effectively trained defense of punches OUT of his system. He may have been a world champion when fighting against opponents who only threw kicks, but he was practically unarmed against any other style.

Well-trained boxers will defend themselves even when knocked out. That’s why the referee sometimes has to step in to look more closely to see if the boxer is still coherent or conscious. Again, there’s no real shot-cut to becoming an excellent fighter. Fortunately, your average thug isn’t trained, so most self-defense training is sufficient. A well-trained fighter is not likely to go around threatening people.

Victor

B.B.

Great article. Simple facts, but some people don’t even know the basics. And behind every few words are technology and tweaks and tuning – things to upgrade, to polish, to sand, to squeeze maximum performance out of the metal.

BTW, are there any custom aftermarket seal solutions for seals in US? Here people experiment with different types of grooves on a seal’s face, to control the airflow and make it smoother and more effective. They state that this helps to increase performance especially on offset transfer port springers – the say some 10 m/s and less felt recoil. Any experiments on that to prove or disprove that?

duskwight

duskwight,

I have tested many seals with custom shapes to their face. Most of them were from Theoben, and there was nothing to test them against. I do know that they work very well.

I have tested a couple American custom seals in the past. Vortek used to sell them and they seemed to be at least as good as the best, though I could never measure any velocity difference above what other premium seals were giving.

B.B.

B.B.,

Offhand, can you think of any guns where the piston actually slams into the end of the compression chamber? Or is this something that we should expect with a magnum springer and light pellets? I’m thinking that my Ruger AirMagnum must be doing something like this because I can’t seem to tame this beast.

Victor

Sure, Victor. Any gun with poor sealing will do that… which will show up (of course) as low velocity and powerplant efficiency.

Vince,

That makes perfect sense. Thanks!

Victor

Victor,

Vince beat me to the punch and his answer is exactly what I was going to say. I will add that a heavy piston and light pellets can cause a piston to slam, too. It isn’t the power of the mainspring as much as it’s the weight of the piston that makes the difference.

I remember testing a TX 200 that Jim Maccari had installed an experimental plastic piston in. The thing buzzed like a bottle of hornets! It stung my face, just shooting it.

B.B.

Maybe it needed to be buttoned?! LOL…….some steel buttons,maybe? 🙂 This is another of those posts that should be mandatory reading for new enthusiasts,and easy for them to find.

B.B.,

My Ruger AirMagnum has plenty of power, so I don’t think that there’s an issue with the seal. I do wonder if it’s the heavy piston, because heavy pellets definitely shoot better, but still not nearly as well as what was tested here on this blog. It literally shattered the lens of one scope, just to give you an idea.

Victor

Victor,

Frank’s suggestion of buttoning the piston of your Ruger is pretty good. Actually what should happen is a qualified airgunsmith should go through the action and tune it for you. There are probably multiple issues mostly relating to loose tolerances that are causing it to be so rough. Maybe no one thing is at fault, but the combination of everything causes a cascade of errors.

B.B.

What’s “plenty of power”? Do you have any numbers?

Sorry to be late (the new blog will be live in less than 5mins) but how about fitting a gas ram to replace a spring? You need it to be the exact same length right? Is anything else special needed?

J-F

Hi All, I am looking forward to reading the blogs from Monday, Tuesday and Wednesday. Well, it has been nine days since the surgery on my neck. Two discs replaced. Of course it was easier to be optimistic on the other side of surgery. Not that I have lost optimism; I just hurt. Vicodin makes me nauseous so I have shifted to plain aspirin. Dr. Kraus anticipates I can return to work on April 2nd (got to get passed April Fool’s Day). I will see him tomorrow for my first follow up. I’ll know more after that. In the mean time I’ll be content to read about the airgun experiences of others. It actually gives me something to look forward to, first to read and hopefully to get back in the field before too very long. That will still be a while to come, but there is hope 🙂

Thanks to all of you,

Ken

Ken,

Welcome back!

B.B.

Thank you, B.B. It’s good to be able to check in, even just to read some. Hi to Edith, also.

Ken

Ah, vicodin… The supposed end-all of pain-killers…

But how much of the population really gets a benefit from them?

I had surgery a few years ago, and found that the only effect vicodin had on me was as a sleeping pill; it did nothing for the apparent level of felt pain. Not to mention that the tylenol component is a liver killer for someone with my tastes…

Of course, the problem with using aspirin for surgical pain is that it is a blood thinner — increasing the likelihood of bleeding.

Wulfraed, you are so right. Hydrocodone is mostly good if your in need of a little nausea, acetaminophen if you think your liver is too healthy, and aspirin if you think you need more internal bleeding. The only left is therapeutic suffering. The neurosurgeon believes everything is proceeding as expected. I will see him at the end of March if nothing requires a sooner visit.

Thanks for saying, “Hi”.

Ken

What about 800mg of ibuprofin? Good pain reliever.

-Chuck

chuck, I agree about 800mg of ibuprofin. However, the doc doesn’t want me taking any NSAIDs. Thankfully, pain hasn’t been as bad as I thought it might be. So, I won’t complain much. The hard part is making sure I don’t hurt myself. I almost picked up my Titan earlier, but I realized it is only about 9 times heavier than the heaviest thing I am supposed to pick up for a while.

Ken

Wish I had this great article when I got my first gun. Any chance a similar pcp tutorial could happen? …and add my Get Well wishes to the list, Ken!

calvin

Calvin,

What sort of things would the PCP tutorial contain?

B.B.

Suspect it would have to be a multipart series… Though the first part wouldn’t have too much — fill system, basics of valve operation…

Then come the more complex addendums: the interactions between the three adjustments on the Marauder (maybe compounded with selected fill pressure). The two adjustments on the Silhouette pistol; the one (or two if “top-hat” is adjustable) of the AirForce models… (just to pick three classes off the top of my head: striker pre-load, striker travel, transfer port vs just striker pre-load/travel vs striker pre-load)

Wufraed,

I’m not going to go that far, because every new PCP is another potential “procedure,” and there are endless possibilities. So nothing complex — just the basics.

B.B.

This youtube video regarding hammer bounce may stimulate more ideas for a pcp tutorial:

http://www.youtube.com/watch?v=J_rrZWaFqbI&feature=digest_sun

calvin

calvin, thank you for your good wishes. It is people I have met and some I have not who have helped me plan for the long haul. Learning what B.B has been through and others who blog here has been a serious encouragement. In fact, I was seriously disappointed that after picking up airguns again after a long absence it looked like my enthusiasm would be crushed. Somewhere, I hope, I still have my old Air Rifle Headquarters catalogs and articles, my old Airgun Digest and my Beman’s catalogs (as well as a few rare magazine finds). There was no Internet available to me back then.

Although I have found some other sites on line that I will visit, this site has proven to be the one that has meant the most to me. As Edith has mentioned, it is nice to find a place where you feel welcomed and can join in. And so much to learn; not only the bear facts but the nuances and the “aha” moments.

Have a good one,

Ken

Ha ha if i knew that, i would write it myself…hmm, a block diagram of air tank which has a pressure gauge and two one-way valves (one lets air in, one lets air out if and only if temporarily opened by a spring-loaded(?) hammer into a lost volume and through a transfer port onto a pellet skirt); relationship between spring constant, hammer mass, hammer length, port diameter; why and how is a plot of tank pressure v fps curved, what is done to widen and flatten the curve?; how does a regulator regulate and where is it located (upstream of the outlet valve?) and why don’t all pcp’s have them?; what is ping, why don’t all pcp’s ping, and how is depinging done?; there seem to be a couple of ways to chamber pellets from multi-shot magazines; how do depressurizers work?; is it bad to dry fire a pcp?; are special tools needed to home strip a pcp?; are solenoid activated valves being used in state-of-the-art digitized pcp’s?; are barrel bands functional or cosmetic?; why does PA give same loudness rating to both Falcon Prairie and Benjamin Trail NP (not XL) when i can attest that, despite both being shrouded, they are Nowhere nearly equal? Stuff like dat plus what i missed! Terminology, nomenclature. A Pcp’s-For-Dummies type thing. Thanks for listening. 😉

calvin

Calvin,

I knew you would think that, but you actually told me a lot in your answer and I copied it so I could use it as a guideline.

Thanks,

B.B.

THE POWER PLANT ILUSTRATED IN THIS ARTICLE- I DARE GUESS IS A RWS- LOOKS IDENTICAL TO THE POWER PLANT OF A RUGER MAG .177 I DISASSEMBLED. IS THE RUGER POWER PLANT ANYWHERE AS GOOD AS THE RWS? AFTER A BASIC CLEANING AND LUBE THE RUGERS PERFORMANCE AND ACCURACY INCREASED NOTICEABLY.

Primo,

Once again, please turn off the caps key.

The Ruger powerplant may be made well, but if the tolerances are too great it may not perform as well as it might. The real key is the tolerances between the moving parts — if we can assume that the parts are all made from the correct material and hardened as needed.

B.B.

I love to plink a whole bunch with my spring piston rifles , Gamos ,rws ,etc. is there a recommended amount of continuous shots that should be taken into account in regard to avoiding spring fatigue? Should one give the rifle a rest after a certain amount of continuous shots?

Primo,

There is no need to stop shooting spring-piston guns. They don’t need to rest. Only firearms need to cool down when shooting, and only until they are cool again, or if they become too dirty they need to be cleaned. But you can shoot airguns as many times in a row as you want.

B.B.