by Tom Gaylord, a.k.a. B.B. Pelletier

This report talks about bending and straightening airgun barrels. Sometimes, airgun barrels are bent and need to be straightened to work properly with their sights. While there are many home fixes for doing this, I wanted something more precise that I could control more closely.

Today is the beginning of a very large 2-part report that’s nestled within this larger ongoing article. There is too much information to get into a single day’s report, yet everything should stay together, so I am running it sequentially over the next two days.

I am about show you the barrel straightening/bending fixture I built and will describe how it works. Then, I’ll show the results of using it.

In the last report, I tested a breakbarrel that had been fired with the barrel open. The barrel was bent up, so with the scope adjusted as low as it would go, the gun still shot about 9 inches too high at 10 meters. Obviously, that’s way too far out of the range that the scope’s adjustments can accommodate, so something had to be done.

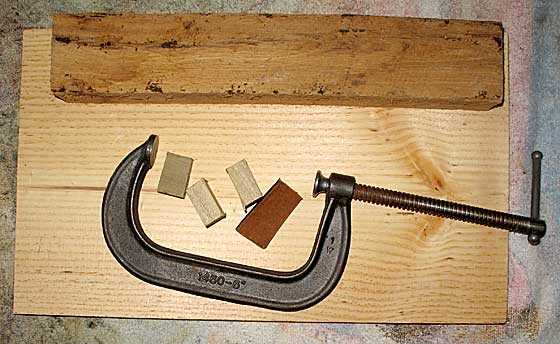

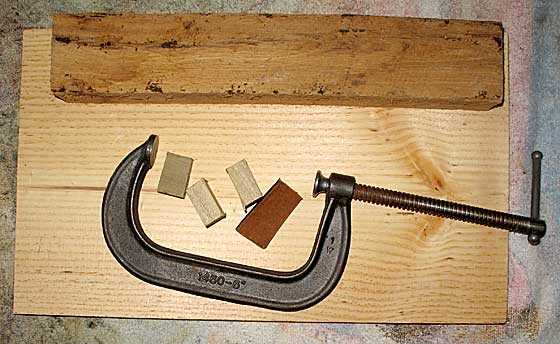

Let me show you my simple barrel-bending fixture. I built it in 20 minutes at no cost; but even if you had to buy everything, you’d still spend less than $20. Actually, you would probably spend less than $10 for this fixture. Once I show you how it works, you’ll probably see all sorts of ways to improve it and further reduce the cost.

The fixture

The fixture is a plank with a 4″x4″ post of oak lumber attached to it horizontally with wood screws. The base was made from a 1-inch pine plank that’s 12″ wide by 19″ long. The length isn’t that important, but I think I got it right for my needs. I made the 4×4 wood post a little shorter than the base for no particular reason.

I attached my 4×4 oak post to the base with 8 wood screws. These were 2.5″ long, but all I cared about was making their heads flush on the bottom of the base and ensuring that the screws didn’t come though the post on the other side. The oak post was left over from a pallet I disassembled years ago to make a workbench. It isn’t good wood, but it served the purpose I needed perfectly. The only reason for the post is to give a clamp something to bear against. I do think hardwood is best for this application, though pine would probably also work.

This is the barrel-bending fixture. The darker wood post at the top is a 4″x4″ oak post cut from a pallet. There are three small wooden blocks cut from 1″x3″ lumber. You’ll see how these are used in the next picture. There’s also a piece of thick leather belt that I used to keep the clamp from scratching the barrel when I pressed directly against it. And the clamp is a Craftsman 6″(150mm) c-clamp.

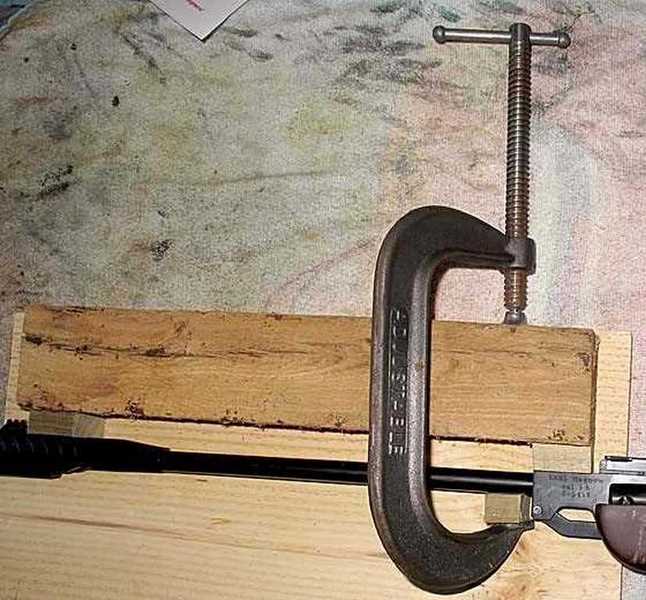

Barrel bending fixture in operation.

The above picture shows everything. The top of the barrel is supported by two wooden blocks, and the clamp pushes up from the bottom. When the clamp is tightened, the barrel will bend down. By allowing the clamp to flip on its side and contact the post, all sideways movement stops and the pressure stays in a straight line.

As you can see, the wood post is under no sideways pressure from the clamp. The base isn’t even required! I just put it there to keep the post up off the surface of whatever table I was working on.

The gun extends to the right, out of the picture. It’s laying on clean rags to elevate it to the same level as the barrel and to keep it still. The scope is still mounted on the gun, so I can take the rifle from the clamp and test-fire it immediately after a bend.

Problem with the clamp

After I’d tightened the clamp as far as I could, the barrel still was not bent enough — so I used a 6″ cheater bar to extend the clamp pin for better leverage. With the extra leverage, it was possible to bend the barrel much more so the bend was visible.

Here the barrel is really bent. Even with this much of a bend in it, however, it still sprung back to almost where it had been. I’m using a lead ingot here instead of a wood block for pressing on the barrel.

Don’t let anyone tell you that airgun barrels bend easily, because they don’t! They also spring back after the pressure is released, so even when they appear to be bent in the fixture, it probably won’t be enough at first.

Test firing

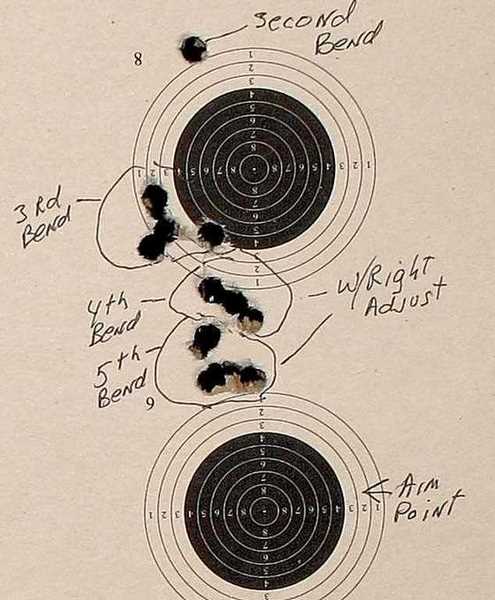

I took the rifle from the fixture and fired it at 10 meters, as before. You’ll remember that it was shooting 9″ high after the barrel was initially bent by firing the gun with the barrel open — and that was with the scope adjusted as low as it would go.

This time, after the first bend made in the fixture, the rifle shot about 4″ high at the same 10 meters. I was getting somewhere, but had more to do because the scope was still adjusted as low as it would go and the gun still shot high.

The scope was centered on the aim point for all shots in this picture, and the pellets shot after the first bend struck about 4″ high at 10 meters. I’d eliminated over half the bend in the barrel with the first use of the fixture.

I put the rifle back in the fixture and bent the barrel again. This time, I had to use even more effort to get the barrel to bend — so much more, in fact, that I bent the handle on the c-clamp. I would have to use something else to apply pressure in the future.

With the cheater bar, I applied too much force to the c-clamp handle and bent it. That’s the end of using this clamp.

The second bend lowered the shots only about a half-inch. The barrel had to be bent more, and I needed a new c-clamp or something else to apply pressure.

I was frustrated at this point, so I stuck the barrel in the bottom space of my workbench and applied corrective bending pressure with my weight, alone. This is the way others say they bend airgun barrels. I found it very difficult to control what I was doing this way, and I had to apply as much force as my weight permitted — but the barrel did continue to bend. The next picture tells the rest of the story.

This target was fired with the center of the lower bull being the aim point for all shots. The single high shot is a confirmation shot from after the second bend. Then, using the leverage of the workbench, I bent the barrel a third time and got the rise of the pellet down to about 2.25 inches above the aim point.

Back to the workbench I went, bending the barrel a 4th and 5th time. You can see the progression of the groups as they drop closer to the aim point after each bend. The problem was that I wasn’t controlling the bend like I wanted, so this was all guesswork. It went fast enough, because the gun could be shot immediately after each bend. But I couldn’t see what I was doing as I did it.

You can see the results of the 4th and 5th bends. By the 5th bend, the groups were landing just 1″ to 1.25″ high at 10 meters. But the scope was still adjusted as low as it would go, so more adjustment (of the barrel) was needed.

More to come

As you can see, I really put in the time on this test! There’s a happy ending coming, but I need another full report to get to it.

At this point in the exercise, the barrel was much closer to where it needed to be, but I had lost the use of my c-clamp…and with it, I lost the control I wanted to have. I now know that airgun barrels can be bent, and it doesn’t take that much equipment to do it. But bending them with leverage, alone, is too crude a method for me. I want some control over the process.

Tomorrow, I’ll finish this report and will show you a solution that works quite well.

Tom,

It’s a comfort to see accuracy not being affected since the bending doesn’t appear to affect the group sizes.

-Chuckj

Tom,

That jig is brilliant in its’ simplicity.

That’s high technology in my neighborhood. My barrel bending is done between the two large forks of a 100 year old cottonwood. Redneck style LOL! We hicks cun lurn a thin ur to frum yuums citified folk.

Here’s my redneck observation on your high falutin rig….A wooden/lead insert is missing on the jig between the end of the barrel wooden support and the wooden support at the breech block. It seems that a much taller, half moon shaped block, that is MUCH taller than the other two blocks used at either end of the barrel would allow for the spring back of the barrel. As in an arch in any bridge. In other words your jig is like trying to bend a car frame back into straight by by only supporting the front and rear. You can’t do it. You need adjustable support in the middle and various points inbetween to affect controlled manipulation.

Your C clamp is not done. Bend it back. For future use in this appication it just needs a cheater bar that will evenly distribute force. A one inch piece of aluminum or steel pipe with a segment in the middle cut out to fit over the top of the C clamps adjusting arms will give the leverage necessary without re-mangling the adjusting arms on the C clamp. Aluminum pipe is easy to cut with a dremel with the right blade. Get a 24″ piece of aluminum pipe, notch it to fit over the clamps adjusting arms and twist away. “Give me a long enough lever/fulcrum and I can move the world.”

Wish I would have thought of that jig. If the barrel is bent downwards with your jig it’s easy to just turn the airgun over and adjust the other way. Simple. Cheap. This speaks to me. Thanks. Great idea.

kevin

Kevin,

I know I can fix the c-clamp. I only meant that it is finished for this application.Tomorrow I will show something better.

B.B.

Trees are great for redneck bending projects. I used to straighten the bumper on my stock car by running it into a large walnut tree in my front yard.

It looks to me that this bending jig may be able to be powered by an hydraulic floor jack. The post would have to be placed tight against something pretty heavy (like the frame rail of a truck). Probably a redneck idea in itself.

Les

Hello B.B. and Fellow Airgunners. I must agree with Kevin’s assessment, as usual. When I was into competitive archery back in the early eighties, a good friend had a slogan on his tackle box. Keep It Simple Stupid. Or the KISS method. This applied not only to his equipment, but also his shooting technique. He became one of the better unlimited amateur archers in British Columbia and eventually, Canada. Finding no fault with his methods, and subsequent success, I too adapted the kiss method for archery, and much later, air guns. And many areas of everyday living. Your barrel bending apparatus is the definition of simplicity. I have to conclude you and Kevin, and a quite a few other blog regulars, must be familiar with Kiss, or some equivalent term. “A rose by any other name”. I find a few companies seem to try too hard to make their product as complicated as possible. Very frustrating for a newbie such as I was almost 4 years ago. Proving the value of this blog when trying to make knowledgeable decisions about that first and second air rifle, and or accessories. Four years. My, how time flies when you are having a good time. I am looking forward to tomorrows blog. This, along with the two Cometa’s currently under the microscope, so to speak, is turning out to be a most entertaining week.

Caio—-Titus

Titus,

I sometimes listen to KISS, but the guy with the black star on his face and the long tongue scares me. 🙂

I have been thinking about this for many years. I knew I could bend barrels, but not how I could control the work. I also wanted a device that could do the job without disassembly, so the gun can be checked periodically.

B.B.

If you wanted to take the time, and had the equipment find a nut that would just fit over the end of the jack screw of the c clamp and drill through a flat and use the existing hole in the jack screw to pin the nut in place and weld the nut to the top of the jack screw so it could be turned with a socket and ratchet. The other solution might be a harbor freight hydraulic Porta power depending on how much cash you want to spend on the project.

David,

It all comes home tomorrow. And the tailstock of a bench vise also works.

B.B.

B.B.

It looks to me like you are trying to apply force from the wrong point. It looks like what you should do is modify it so that you pull the end of the barrel down (your highest point of leverage).

twotalon

I thought so too at first, TT. But, when you think about where the center of the bend is from remembering how it was bent in the first place, you realize that the bend’s smallest radius is about where BB has the clamp. If anything, I’d just change to a 10″ clamp for more strength. A guy could also weld a nut on this 6″clamp screw and just use a wrench for the handle. I’ve done that on more than one occasion.

I have a 20 ton hydraulic press that I use, but this is an excellent, simple jig for anyone doesn’t have access to a press!

/Dave

/Dave,

I was considering using a hydraulic press, too, but I found the perfect solution that I will show tomorrow.

B.B.

I guess you didn’t understand….

The basic theory looks good, but applying pressure at the bend point requires a lot of brutality on that clamp handle. The barrel got bent because of the leverage the muzzle end of the barrel had.

Leaving everything the same, but NOT cranking on the clamp, if something was rigged on the muzzle end to pull that end of the end of the barrel down you could use the same leverage in reverse of what originally happend without needing to apply a great deal of force…..

Let’s say you built a bridge over the muzzle end and used a clamp to pull the muzzle toward the top of the bridge. The clamp there would not have to work as hard. The one down by the breech block only needs to hold the barrel at that point.

twotalon

That makes a lot of sense, but you do not want to wind up with a barrel with an S curve in it.

It goes to reason to apply the corrective force at the point of maximum leverage.

Les

Totally off topic. My daughter, who returns from Kabul in a few days, God willing, wrote this.

http://atwar.blogs.nytimes.com/2012/09/13/the-death-of-a-butterfly-in-kabul/

Pete

The story is a beautiful as the little girl in the picture.

Well written.

J-F

Pete,

That’s a moving article. It make me wonder what cause is worth so much that children have to die that way.

B.B.

I hope everyone here reads that.

Les

Pete,

Hard to read, but important to read.

It is difficult enough just to ready about this tragedy. I cannot imagine what your daughter must be feeling.

Thank you for sharing this.

Edith

Pete,

I will be holding my breath for the safe return of your daughter – a wonderful gift just before the High Holy Days of Rosh Hashanah.

Fred DPRoNJ

Pete,

That really touched me. Thanks for sharing that.

-Chuckj

Pete. Thank your Daughter for us for writing such a moving article. Too many times we read of how things are so much better in Afghanistan and other war torn countries. It makes one wonder if the reporter was in the same country when they wrote it. Your Daughter has a special gift. She is a true Humanitarian. This world needs more young people like her. I hope she returns safe and sound.

See this from the Friday Washington Post. The story continues.

http://www.washingtonpost.com/world/war-zones/friends-mourn-four-young-skateboarders-killed-in-afghan-suicide-blast/2012/09/13/659d90d6-fde1-11e1-98c6-ec0a0a93f8eb_story_1.html

Pete,

Thanks so much for sharing your daughters story and that of the children that touched her. Today I took my granddaughter, Arianna, to a petting zoo. Experiencing Arianna’s joy and new experiences are among the greatest experiences of my life. However, when I think of war I think of it in terms of my own family, including Arianna. As much as I hate the idea of me, or anyone in my family, including myself, suffering I hate what happens to innocents in places like Iraq or Afghanistan. I personally have suffered unimaginable pain and suffering, but am keenly aware that innocents in war-torn countries suffer even more. None of what I, or your daughter, are saying is political. Rather, we’re talking about humanity and that fact that we are called upon by our (various) faiths to have compassion for the lessor of our brothers.

I have always felt strong that war must always be a last resort because of what I do know about it’s lasting effects and the helpless victims, including long after the conflict. If there is one thing that bothers me more than anything is that fact that it always seems to be much easier to spend enormous amounts of money on war when often a fraction of that money could have been used to truly help and make a difference. These days we read lots of comments about how so much violence and brutality comes from Islamic states, and question that “Islam is suppose to be the religion of peace?”. Beyond the surface, it’s clear that there’s plenty of blame to be shared by other faiths, including people of my own.

I wish your daughter peace,

Victor

It’s truly gratifying how many of you she touched. And the fan mail she got personally and the NYT comments have been great.

Thank you so very much! Less than 2 days until wheels up for Paris. She & boy friend wanted to see Tuins for adventures. But when I told the AM-EMB-TUNIS, as we say in cable speak had been raided and reduced to a skeleton staff, tickets got changed quickly! Sensible kids. Esp the boy friend.

But one day after she posted, she got her first hate letter that was so bad she can’t bear to send it to me. Little does she know how much of that stuff I’ve gotten; death threats included.

And you thought being a professor and security pundit were safe careers. Once got a packet the postal inspectors thought was a large bomb. I let THEM x-ray and open it. Turned out innocent. But the x-ray pic was vy suspicious.

“remembering how it was bent in the first place”

Also remembering the physics of center-of-mass and of angular momentum during the bend in the first place. During the original incident, the barrel/breechblock assembly rotated upward (as viewed from the side). Once locked up, the breechblock could no longer rotate but the barrel-only portion could and did. The center of that continued rotation lies at or near the center of mass of the barrel, namely at or near the midpoint of the barrel. Therefore, to negate that unfortunate occurrence, I would reposition the block (shown at the muzzle) from the muzzle toward the midpoint…keeping all else the same. Yes, it will require more force but it will be a more accurate reflection of the original bending, imo. But i think any difference in the final result (due to change in block position) is insignificant; we know that once the poi is back down to the poa, any minor deviations from barrel straightness are unimportant (as shown by that now well-known cork-screwed pistol barrel). Just thinking out loud.

John,

Actually, it leaves a more parabolic curve with its tighter radius closer to the beach block. This is due to the center of mass and its inertia being located closer to the center of gravity of the barrel, not near the muzzle. Although it moves, for all intents, the breach block might as well be considered solid. As the bend progresses, the retained energy from that inertia is absorbed by the bending of the barrel, which in turn pushes the center of the still moving mass further towards the muzzle. Energy is still being bled off and the bend becomes shallower as its center rolls up the length of the barrel, eventually the strength of the barrel is more than the force it takes to permanently distort it. Try a similar experiment with a piece of pipe and tell me what kind of bends you get.

/Dave

I can’t derive the curvature…maybe a catenary…but i have applied an equal and opposite unbending force. Described at the bottom of this thread:

/blog/2012/07/bending-airgun-barrels-part-1/