by B.B. Pelletier

A couple weeks back, we talked about straightening bent airgun barrels to improve accuracy. We want to do that so we can hit targets with the sights that were installed. There is, however, another reason for bending barrels. Some guns have sights that do not coincide with where their barrels are pointing, even when they’re not bent. For this situation, we also need a fix.

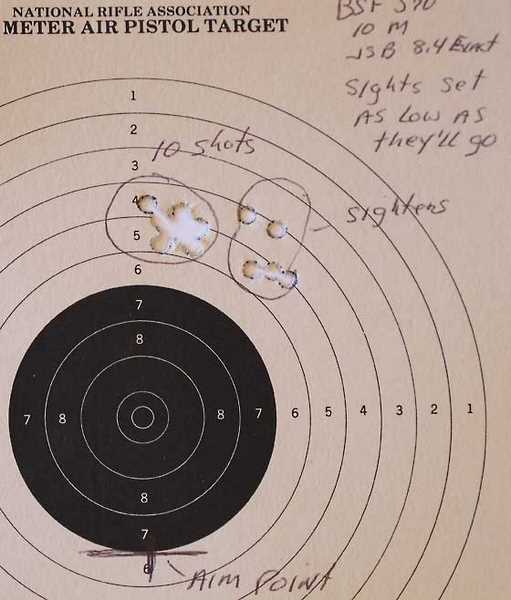

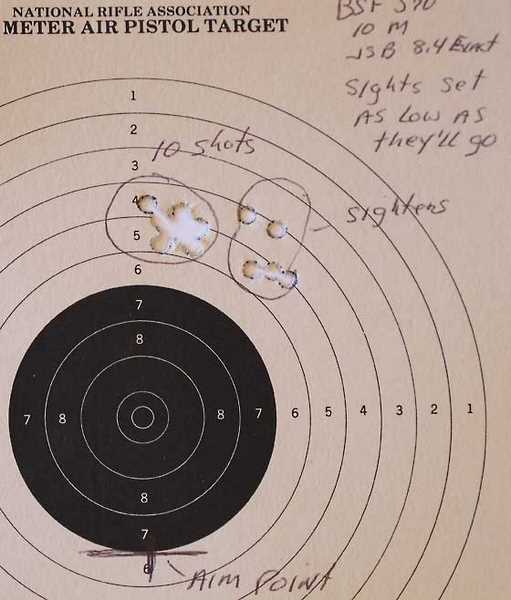

Many guns have replacement rear sights. I own a BSF S70 breakbarrel rifle that has a Williams peep sight that was either installed by Air Rifle Headquarters (the original company in Grantsville, West Virginia) or was a sight they sold for owners to mount. ARH did inform the customers of the necessity for the rear sight to have a complimentary taller front sight installed, and on my rifle that didn’t happen. I think this was an owner-installed sight that they probably hated ever since.

This is the problem I’m faced with.

The special Williams peep sight is low and fits the rifle well. It looks good, and I want to keep it.

I like the vintage look of the original front sight. Bending the barrel is the only solution!

In either case, the rear sight cannot be adjusted low enough for the rifle to strike the target at 10 meters. Since 10 meters is such a common shooting distance for an air rifle, this is not handy. The other possibility would be to raise the front sight higher, but I don’t want to do that. I happen to like the look of the front sight that’s there and want to leave it as installed. My only option is to bend the barrel.

Several blog readers, including Kevin Lentz, commented on having bent many airgun barrels and how easy it is to do. My buddy Mac has also bent a number of airgun barrels to get them on target.

While a barrel may be bent in any direction, up is by far the most common direction you’ll have to go since the majority of breakbarrel rifles shoot a little low. The second most common direction is down, which is what I need to do to fix the kind of problem I have.

I was in my reading room a few days after that; and from the pile of literature lying on the sink, I picked up the 2000 Edition of The Gun Digest and stumbled across an article by Todd G. Lofgren titled, Sighting In Single-Actions. The author describes, shows and tests the results of bending the barrels of numerous Colt Single Action Army revolvers to get them to shoot to the point of aim at 25 yards. He knew that the traditional way of doing this is to either file down or add to the front sight for height and to bend it (the front sight blade) in the direction opposite of where he wanted the bullet to go, but that didn’t appeal to him. He built a jig and used a 12-1/2 ton hydraulic press to actually bend the barrel in the direction the bullet needed to go.

He fixed guns that were off in all ways, but by far the most common directions were to the left and low. And then he shot three groups at 25 yards to prove the guns now shot to their point of aim. Before bending each barrel, the extractor housing was removed; and in every case, it was installed after the bend without a problem, thus proving that the bend itself was only a very small distance.

Lofgren commented that the first-generation Colt barrels are easier to bend than the barrels of guns made today. That means their metal is softer and more ductile, and lends itself to slight deformation better than barrels made from harder steel. That bodes well for airguns, because they’re also still being made of soft steel that should deform easily.

Lofgren also happened to favor the short 4-3/4 inch barrels, and all of the guns shown in his pictures have barrels of that length. Compared to that, bending a 12-inch or longer air rifle barrel made from thinner steel stock should be a piece of cake!

While he uses a hydraulic press to bend his barrels, I think that bending an air rifle barrel that’s sitting between two blocks 12 inches apart will be easy enough to do with a common screw like the kind found on a C-clamp. If the jig is constructed correctly, it should be possible to control the amount of pressure very precisely, which is desirable for collectors who don’t want to ruin their fine guns.

What about guns with fixed barrels?

It should be possible to bend guns that have fixed barrels, as well, provided the barrels are solid. This process will not work on barrels inside jackets or shrouds, which lets out many airguns of modern design.

Don’t over-think this!

Some readers might think this operation through and wonder if bending the barrel in the direction you want the pellet to move is correct. If you bend the barrel, you also move the front sight — and we know that the front sight is supposed to be moved in the opposite direction that you want to pellet to move. But Lofgren cautions his readers not to over-think this and just bend the barrel as they want the strike of the round to move. It’ll work out perfectly that way.

This fixes bent barrels, too

The initial reason for bending barrels was to straighten them after they’re bent from an accident or from their manufacture — not because they weren’t hitting where the sights are aiming. But one bend is the same as the other. It’ll work for both problems — I guess. At any rate, seeing a man bending the barrels of collectible first-generation Colt revolvers and getting the results he was after has given me the courage to try the same thing on this air rifle.

The next step is to damage a spring-piston barrel and then try to bend it straight again. If I can do that, then bending the S70 barrel shouldn’t prove too difficult. In the process, I hope to construct a simple low-cost barrel-bending fixture that will serve all my future needs. It should be a fun experiment!

I have bent a few barrels successfully using my 20 ton press. While I obviously don’t need 20 tons to bend a barrel, I like the control that it gives me with its small movements. I think you should get the same kind of repeatable control with a large c-clamp and v-block setup.

I’ve cured 3 problems doing this. One had a ranging bore that I straightened. Looked a bit od when I was done because the outside of thebarrel looked bent while the bore looked straight.

Second, was a barrel that was truly bent.

Third, was one that I bent to get it on target without taking up all the adjustment in my scope. That one is my TF99 that came from the factory with a lot of droop built in. I actually had to tweak the receiver about .010-.015″ to finish up the alignment.

Go slow. You won’t work harden the barrel if you miss by a bit a few times. Too many times and the barrel will work harden, leaving you with a bore that shoots straight, but looks like a corkscrew.

/Dave

/Dave,

Thanks for your experience. I have a jig in mind that is so simple anyone can make it. Control should be very easy to maintain.

B.B.

Gee whizz B.B. ….

You are going to wreck one or do you have one that has already been pretzeled ????

If you are going to slam fire one or deliberately bend it up in a different way, are you going to make us wait to find out what it is ???

twotalon

TT,

Yes, I am going to deliberately bend a rifle barrel by firing a breakbarrel when it open. Then I will try to straighten it.

Don’t worry. This one is a gun that is on the destruction list, anyway. It’s donating its life for science.

B.B.

BB & Edith;

I see on my tracking for the FWB 124 I send to Pyramyd AIR that it arrived there on Saturday. Of course, being closed for the weekend, they did not deliver it. Will USPS re-deliver today? Does this happen normally? Do I need to contact USPS to have them re-deliver it? Thanks.

Mike

Mike,

If it’s a gun, it was delivered via FedEx, not USPS. If it’s a part, then it could have been delivered via USPS. You’d have to contact the company that’s got the package.

Edith

Edith,

While it is illegal for the Post Office to transport handguns, they transport long guns all the time. Even firearms are legal to ship by the USPS.

B.B.

B.B.,

I wasn’t speaking about what’s legal or illegal. I was speaking about which delivery services Pyramyd AIR uses. As far as I know, they never use USPS to ship guns of any kind.

Edith

Edith,

Mike was asking whether the Post Office would deliver to PA a second time after trying on Saturday. He didn’t ask how they would return the gun.

B.B.

Ok. I’m officially out of this conversation. I’m too tired to figure out what you said, Mike said…or even what I said :-\

Edith

BB is right, I sent it USPS. Edith, thanks for letting me know that it will return on FedEx.

I always try to use USPS when I can since they are most often less expensive.

Mike

This is quite wild. Last year when I ordered my Steyr LP-10 from Germany it was shipped by Deutsche Post/DHL, and was delivered by USPS at this end. It was clearly marked that it was an air Pistol!

pz

Thanks. Delivery will be now be made today.

Mike

Here is a comment that was sent to the wrong address. Im posting it here for the sender,

Tom/B.B.

/blog/2008/9/bsf-s20-match-part-1-germanys-rifle-pistol/

/blog/2008/9/bsf-s20-match-part-2-germanys-rifle-pistol/

Thanks for the wonderful above articles. I found one at an antique

store and while it is in great shape I have no experience working on

them, and would like to give it a basic lube/overhaul/checkup. I

imagine the leather needs oil (it generates some friction-related or

compression-related smoke with a slight burned smell) and the seal at

the back of the barrel probably needs something to seal better (a piece

of tissue paper set across the joint jumps off when I fire it). Can you

recommend someone(s) who does this kind of thing professionally?

Thanks,

Steve

Steve,

You want the S20 to smoke when fired. It tells you the seal is properly oiled. It’s not a bad thing.

Why do you think your gun needs an overhaul? What velocity does it shoot Hobbys? If it’s in the mid-400s, leave the gun as it is.

If the gun is too slow, then you might contact this man to overhaul it:

B.B.

BB,

Do you plan on writing any about the on-going 2012 Olympic air pistol and rifle matches?

Chris,

Not really. I don’t see what I can add to the coverage.

B.B.

Chris,

Did you have any particular questions? Lots of people question the validity of air-rifle as an Olympic sport, but that’s only because they don’t understand how mentally and physically challenging it is. The same goes for prone and 3 position shooting. VERY TOUGH to compete at this level.

Victor

A couple weeks back, we talked about straightening bent airgun barrels to improve accuracy.

Sorry to be a stickler BB, but I believe that statement is a little misleading. Bending the barrel doesn’t improve or degrade the accuracy of a barrel, it only changes the point of impact.

I’ve been bending barrels (especially on Diana’s) for many years now to compensate for “barrel droop”. All I use is a securely mounted bench vise and some carefully applied force. Barrel bending is not often needed now, with the availability of more brands of adjustable mounts and droop compensated bases.

Depends on your definition of “accuracy”. If by that you mean “consistency”, then no, not really. But if you mean “hitting the target” then BB’s right.

Sometimes a bent barrel will make it impossible to use open sights, for example, because they cannot be adjusted sufficiently to compensate. At that point there’s no matchup between POI and POA, so hitting the target becomes difficult.

There is a partial self-compensating effect because the front sight moves with the barrel, and moves the sight radius in the same direction as the POI shift. But the effect depends on how far the bend is in front of the rear sight, and I have seen a number of instances where the it didn’t really help.

When you’re right, you’re right!

Good call.

B.B.

For what it’s worth, if a gun will print dime-sized groups all day, but cannot be made to print them where you want them to print, then it is not an accurate gun. This is well-defined by the scientific community already: https://en.wikipedia.org/wiki/Precision_vs._accuracy

Well, in that case, B.B.’s statement is accurate. 🙂

Bending Barrels.

Great topic. Although adjustable scope mounts, shimming, riser blocks, etc. can compensate for a bent barrel B.B.’s BSF S70 with period correct williams peep sight is an example where barrel bending is the only answer.

Barrel Bending is not a kitchen table idea thought up by a desperate airgunner. Todd G. Loffgren is a very well respected gun enthusiast. One of my favorite writers when Guns of the Old West was still being published.

Gun manufacturers bend barrels. Here’s a link that shows a press specifically designed to bend a barrel.

http://www.network54.com/Forum/405945/thread/1305980933/%26quot%3BOnly+a+fool+and+a+watchmaker+works+on+a+watch%26quot%3B

Don’t be afraid of this technique. Keep it in your arsenal of potential solutions.

kevin

This is going to be fun to follow. I think most of my guns are tubes inside tubes or shrouds but this topic may come in handy sometime. External droop compensating mounts, etc. are safer for us unsure of our abilities but some of those solutions, i.e. B-Square adjustable mounts or raising the front sight too much, in some cases, can detract from the natural look of the gun. Especially correcting for windage by bending a front sight. That drives me to distraction when I have to look at a blade slanted to one side.

-Chuck

Chuck,

You know how writers always say you can drift the front sight blade to compensate for a barrel that doesn’t shoot straight? Well, I once owned a Winchester-made 1917 Enfield that was produced BEFORE the contract was signed. It had a serial number in the 12,000 range. It was in pristine arsenal refinished condition, but whoever reinstalled the front sight assembly did it on about a three-degree angle. To get that rifle on target at 100 yards the sight blade had to be drifted way over to the side.

I got so sick of looking at it that I sold the rifle, rather than continue to lament over a fine rifle made bad by a sloppy job during the refinish!

I hate sights that are bent!

B.B.

Agreed! I can safely say that, in my case, bending the front sight at an angle to bring it in-line to the bull destroys accuracy – whether real or imagined.

-Chuck

I know what you mean BB. I had a really nice Savage Built No. 4 Mark 1* that need to have the front sight as far to the left in the dovetail as it would go. I too traded that one off.

Mike

I’m waiting to see if BB tries to get fancy with this bending… Like a minor S-curve so that the majority of the barrel remains parallel but raises the front sight by the amount needed to match the rear sight height — rather than just a generic arc from chamber to muzzle.

Wulfraed,

You didn’t read the whole article. To make the pellets go down you bend the barrel down, not up.

B.B.

As I recall, at least part of the affair is that the rear peep site does not go low enough to match the original front sight. You also don’t want to modify the front sight to raise it relative to the bore.

My fanciful S-curve would keep the main length of the barrel parallel to the existing bore line, but result in raising the bore AND front sight into alignment with the higher rear sight. Pity one can’t do drawings in blog comments…

What I visualize is that, at present, you have a bore that is, say, horizontal. You have a sight line which is descending from rear to front to target. Your simple downward bend will, to a minor extant, increase the downward sight line — but will also change the bore line to release pellets in a descending slope rather than the horizontal plane.

The complex S-curve would leave the bore line horizontal but lift the bore and sight upwards so the sight line is also horizontal.

As I said, a rather fanciful solution; looking through the barrel would reveal the dual bends.

Wulfraed,

Again, this is in the article. You do not concern yourself with where the front sight is going. You simply bend the barrel in the direction you want to bullet or pellet to go. I didn’t write that. The author of the article I read did.

Read the paragraph under the heading, “Don’t over-think this”.

B.B.

BB,

Bonus points for bending barrel into any of the classic knots — as long as it still shoots:)! One thing I’ve read about barrel bending in discussions is that you need to bend it a little bit past where you want it, since it will bounce back. My only concern would be setting up stresses in the barrel that might make it “act funny”, but that should be minimal with air rifle!

BG_Farmer,

The beauty of this is you shoot as you bend the barrel. Bend a little and shoot and so on. And since airgun barrel don’t heat up when firing, they don’t change their zeros like firearms do. Once zeroed it should remain there.

But I will test it to make certain.

B.B.

Okay, dumb question.

Just out of interest, can you do the same thing if needed be with a powderburner barrel?

csd,

Yes.

Did it on my remington 550 because of an accident that bent the barrel. Softer barrel than some airguns I’ve bent.

kevin

Hey Kevin I’m replying on an old post, but I wanted to let you know I straightened the barrel on my Titan GP and it was a complete success! Very easy thanks for the advice.

Coduece,

Thrilled to read this. I’m so glad that you executed this tried and true method. Many airgunners take bending barrel advice as heresy but the fact of the matter is that this is also done at the factory.

You’ve taken a big leap in your airgunning journey. Congratulations.

Coduece,

My picture didn’t post. This is a barrel bending fixture used by Weihrauch.

So it looks like he is sighting down the bore?

You are correct about the fixture pictured. The operator is looking for “concentric rings” in the bore which are actually reflections of the muzzle off the side walls of the bore. A crooked barrel results in those rings being bunched together on one side and spread on the other and since it’s impossible to bore a perfectly straight hole of that aspect ratio, the barrel is bent to cause the bore to be straight so I contend that barrels which shoot to a POI that is not aligned with the centerline of the exterior of the barrel are actually crooked, no matter how straight the outside is.

There are of course other causes for barrels to shoot “crooked” but a crooked bore is certainly one of them. Indexing the barrel to provide a 6 o’clock trajectory seems to be the preferred method for mounting a barrel but if it’s impossible to index (which is often the case after porting, etc.); I prefer to bend the barrel to provide the desired trajectory.

For those that are timid about barrel bending I offer this factory FWB pistol that has legendary accuracy.

Ok that’s crazy,ok you’re obviously very knowledgable so hw50 in .22 for back yard plinking yay or nay?

And my take on the pistol is evidently the most important part of the barrel is the last inch.

My take on the pistol barrel is the last inch is the most important.

CSD,

Did you read the article? I got the idea from a guy who was bending Colt SAA barrels.

B.B.

Sorry b.b., I specifically meant rifle barrels.

I’ll try and be more attentive in the future.

My FWB 124 is now happily with Pyramyd AIR. All is well 🙂

Mike

Question about barrel hardness: does there appear to be any significant differences in hardness between the Crosman discovery/marauder, diana 34, and HW 95 barrels? I read a comment on another forum saying that Crosman discovery/marauder barrels ”wear out” and become inconsistent after 6-12 months – especially if cleaned with JB paste. The poster argued that the chinese barrels were softer or put metal. Are the diana or HW barrels any better?

JohnG10,

This is news to me. I’ve not heard of a Crosman barrel being worn out with JB paste, but I suppose it could happen. I know benchrest shooters clean their barrels with JB paste sometimes, so I wonder what the truth really is.

One thing we should think about is the depth of rifling. Airgun barrels are rifled much shallower than firearm barrels.

As you can tell, I am not the one to comment of the wear rate of a Diana or HW barrel.

B.B.

Johng10,

Re: Internet guru’s saying that Crosman discovery/marauder barrels ”wear out” and become inconsistent after 6-12 months.

There have been some barrel problems, especially with the early .22 caliber Marauders. Very, very few problems with the discovery’s, .177 Marauders and almost none with the .25 caliber Marauders since they have green mountain barrels. Don’t know for certain what the reason(s) were/are for accuracy problems with the early .22 caliber Marauders. IMHO, it has nothing to do with whether jb bore paste was used or not in the barrels since many had accuracy issues without the owner using jb bore paste. IMHO, you’re not going to wear out a barrel in 6-12 months. You have other issues if accuracy falls off.

Based on my experience with a friends early .22 caliber marauder, much reading and dialogue with other .22 caliber marauder owners and several conversations with Greg Davis I am convinced the more common problem was the rough finished inleade and lands.

The sometimes fix for lands was either taking jb bore paste or mothers mag (Greg Davis’s choice of products) and polishing the barrel. A .177 cal brush wrapped in paper towel and run back and forth in your .22 cal marauder barrel 20-25 times was Gregs advice since it worked on many of his customers guns. The sometimes fix for the inleade was a dremel with a hard felt cone, sized for your inleade on sandpaper, then smeared with jewelers rouge. Polish the inleade to a mirror finish and just enter the lands and grooves. These fixes worked many times but on those guns that it didn’t the owners usually replaced the barrel with a Lothar Walther.

kevin

Green Mountain barrels are very good. I have one in .54 Cal with a round ball twist for my T/C Hawken Muzzle Loader.

Mike

BB

Can you post a graphic or photo of the barrel straightening jig when you make it?

Ton,

I will give complete instructions on how the jig was made and how to use it. There will be plenty of photos.

If this goes like I think it will, the jig will be very simple and easy to make. No special tools needed beyond a hand drill, and a saw.

Of course at this point in time this is just an idea. I haven’t made anything yet, so I could be wrong about it.

B.B.

This video of barrel-making at the Pedersoli factory shows an employee using a barrel-bending jig at 6 min. 11 sec.

https://www.youtube.com/watch?v=eOo-muzMRp0

Steve

Steve,

Thanks for that link!

B.B.

I posted the following recently in a thread re straightening:

…the barrel snapped shut so hard that it bent the barrel UP, just forward of the breech block…

I submit with respect that the barrel straightener is fine for certain types of bend but not ideal for YOUR bend. The proper way to unbend is to apply a force equal and opposite to that which caused the unfortunate bend in the first place. Here is a very simple way to apply that very equal and opposite corrective force. Replace the alive jam spring temporarily with a metal dowel to prevent the alive jam from receding into its hole. Chuck up (edgewise, i.e. with a narrow edge sticking upward) a block of hard wood (i used a 3/4″X4″X8″ piece of laminated plywood from my scrap pile) in your bench vice. Remove the stock. Stand flat footed with knees slightly bent. Holding the action upright (stock removed) and pointing upward, swing it down so that the bottom front of the compression tube hits the top edge of the wood block. This is not batting practice, but adjust your stance as needed, relax, think it through, and don’t be in a hurry. The wood is hard enough to withstand repeated blows and soft enough not to damage the metal action. Repeated impacts will straighten the barrel where it needs to be straightened. Merely dropping the action down will probably not be forceful enough to do the job, so swing it down firmly and accurately enough so as not to miss the wood. Repeat as needed until the barrel is straight enough. A straight edge (such as a metal meter stick) along the compression tube can be used to monitor the misalignment of the barrel. I did this to my breakbarrel after a similar incident; canceled out some unwanted droop at the same time. It is conceivable that the alive jam will bend the detent during this process; that did not happen to mine but even if it had, the detent is relatively easy to replace.

John,

We shall see.

B.B.

Interesting blog. I have three Diana 806 rifles and all three are slightly bent upwards. Is this common in this rifle because of its inexpensive two-piece barrel design, or maybe because kids are rough on pellet guns?

Eric,

Welcome to the blog.

A bent barrel happens in one way, only. Someone fires the gun when the barrel is broken open.

This is a 5-part blog and it has a lot of information in it. You should read all sections. Here is the last one, where the links to all others are given:

/blog/2012/09/bending-airgun-barrels-part-5/

B.B.