by Tom Gaylord, a.k.a. B.B. Pelletier

Announcement: Jedediah Strong Smith is this week’s winner of Pyramyd Air’s Big Shot of the Week on their airgun facebook page. He’ll receive a $50 Pyramyd AIR gift card. Congratulations!

Jedediah Strong Smith submitted this week’s winning photo for BSOTW.

Do you see that there are two people in this image?

As promised, today is a continuation of the barrel-bending exercise I’m doing with the fixture we looked at yesterday. When we left things, I’d bent the handle on the c-clamp I was using and couldn’t get the barrel to bend enough to shoot to the point of aim at 10 meters. After that, I used the cross-members of my workbench for leverage and bent the barrel some more. I did get it closer to the aim point, but not close enough. And the scope was still adjusted as low as it will go, which is not what I wanted.

Today, I’ll tackle the job with a slightly different tool. Remember that the goal is to straighten (or bend) a barrel enough that the gun shoots to the point of aim at 10 meters.

I needed some kind of pressure-generator that didn’t get ruined when I put some serious torque on it. The screw on the 6-inch c-clamp I used is strong enough for the job, but the soft steel T-handle can’t take the strain that had to be put on it. What’s needed is a c-clamp that isn’t prone to bending.

I talked it over with a shooting buddy who told me he might have the perfect tool for the job. It was a 6-inch c-clamp that has a hex nut on the end of the screw. Instead of a sliding T-handle, you tighten this one with a socket held in a ratchet wrench. But it was also a different type of c-clamp, altogether. It was obviously designed for pressing out a large pin of some kind. That didn’t bother me, and the fact that the screw accepted a socket wrench seemed like exactly what I wanted. I envisioned adding pressure in small amounts with the ratchet wrench, so the control I was after would be even greater than with the first c-clamp. But there was also a problem.

The end of the c-clamp screw came to a sharp point — what was needed to press out large pins, but not good for pressing against wood — even oak. That would have to be changed.

My buddy said he had bought the clamp for two dollars in a pawn shop years ago and had never found a job for it. This sounded like the perfect application to him, so he donated it to the cause. He also made a flat cylinder to cover the sharp point on the end of the screw so it wouldn’t bite into the oak post too much.

He ran it by my house a few days later, and I resumed the barrel bending (straightening) exercise. You will recall that when we last looked at the gun, the barrel was shooting about 1″ to 1.25″ high at 10 meters with the scope adjusted as low as it would go. I wanted it to shoot below the aim point at 10 meters so I could crank a little elevation back into the scope. That was just so I could go both ways with the adjustment knobs — not that I really needed to sight the scope for anything less than 10 meters.

I put the rifle back into the fixture, put the new clamp in place and began applying pressure. Immediately I saw that this was going to work much better than the other c-clamp, because I could get a lot more torque on the ratchet handle than I could on the c-clamp T-handle with my makeshift cheater bar. So the first time I used it was the only time I needed to use it — it finished the job in a single try!

The new c-clamp worked better than the first one. I was able to bend the barrel exactly like I wanted the first time! The bend seen here sprang back when the tension was released. That’s a piece of leather between the clamp and the barrel.

I knew the barrel would spring back after it was released from the fixture, so I bent it a little farther than seemed necessary. Sure enough, when the pressure was released, it did spring back. I could see a slight downward bend in the barrel for the first time since it was slammed shut, so it was time to shoot the rifle again.

Complex picture

The next picture is complex because a lot is happening. I’ll explain it in the text, rather than the caption, so it’s easier to follow.

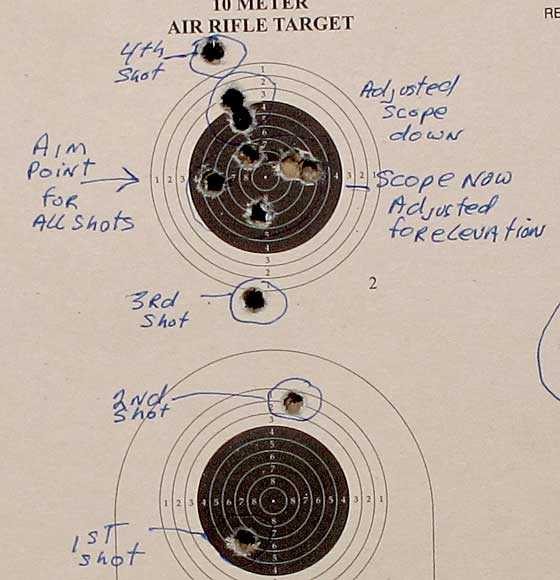

This is the first target after using the new barrel-bending clamp. Read the text below for an explanation.

The aim point for all shots on this target is the center of the top bull. The first shot landed about 3.125″ below the point of aim. This was the first time in this test that the pellet landed below the aim point, and it meant the bend had finally been successful. I adjusted the scope up several clicks and shot again.

You can see that shots 2 and 3 are progressively higher on the target but are still below the aim point. The 4th shot, however, is considerably higher than the aim point. Now it was time to adjust the elevation back down and zero the scope.

The first down adjustment wasn’t far enough, but the second one was right on target. But look at the large distribution of shots. Had I destroyed the barrel’s accuracy by bending it? I didn’t think so, but I needed to shoot some more, to know what was happening.

The shots seem too scattered. The rifle was capable of better groups before the bend, and during it, too!

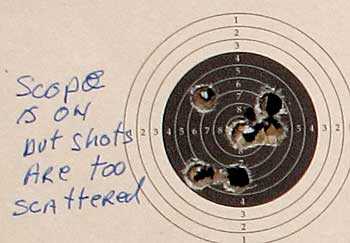

The next target just confirmed what I already knew. The shots were on the aim point, but the group was too large. What was wrong? I wondered if the scope was now adjusted too high and the erector tube was floating. Did I need to bend the barrel back in the opposite direction? I didn’t think so, but this open group was puzzling.

The answer

The way to determine whether the scope adjustment is too high is to adjust it lower and shoot another group. I did this, and it seemed to shoot a little tighter but was hard to tell for certain.

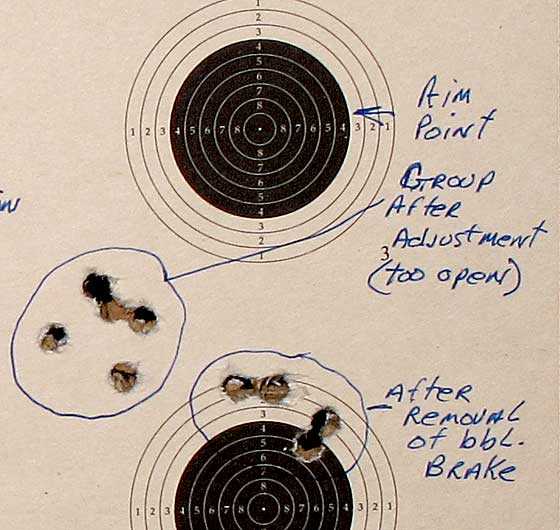

The scope was adjusted down for the first group on the left. Then the broken shell of the muzzlebrake was removed for the second group. The first three shots of the second group went into what looks like two pellet holes at the top of the group.

Then, I remembered the lengthy Pellet velocity versus accuracy test I did late last year, in which it was demonstrated that vibrations affect accuracy more than velocity. What I haven’t told you before now is that while I was bending the barrel by hand in the crotch of my workbench, the plastic front sight assembly broke and half of the sight fell off the gun. The hollow shell of the assembly was still attached, loosely, to the barrel. Could that be the cause of the scattered shots?

The lower piece of the front sight assembly fell off the gun after I bent the barrel using my workbench. That left the large hollow shell (above) still attached to the muzzle. I removed this piece, thinking it was creating accuracy-destroying vibrations.

I removed what was left of the front sight assembly, except for an anchor that seems to be epoxied on the barrel. It shouldn’t cause a problem because it’s very tight. Of course, it does change the vibration nodes just by adding a little extra weight, but I left it on the barrel because I didn’t want to fool with it.

Then, I shot a last group. The first three pellets went into a very tight hole and the last two went into a second smaller group to the right of the first. It isn’t the best group I’ve shot with the gun, but I’m satisfied the gun is shooting as it should. I believe it was the vibrations caused by the remaining hollow plastic muzzlebrake shell and not the elevation of the scope that caused the scattering of the shots.

At this point, I was finished with this test. The fixture had done everything I wanted it to, and I was satisfied that this approach will work. I don’t recommend doing this unless you have a real problem with a gun, because there’s always a lot that can go wrong. But I think this procedure is precise enough for this kind of repair.

Some thoughts on bending airgun barrels

First, let’s remember that I have been dealing with a severely bent barrel in this project! You’ll never get a production air rifle with a ski-jump barrel like this one. But you may get a rifle that doesn’t shoot to the aim point for a number of reasons — wrong sights, bore not drilled straight, scope base not aligned with the bore or perhaps somebody bent the barrel before you got the gun. You may never need to bend a barrel as much as I have in this report, and bending it very slightly to correct a couple inches of impact shift will be much easier than what you’ve seen here. But this technique works well and gives you wonderful control over the process.

Can you bend the barrel in different places? Of course! All it takes is positioning the bending blocks and the pressure point where you want the bend to be. Just remember that bending an airgun barrel precisely isn’t easy. Anyone can bend a barrel, but to get it the way you want it takes control over the process.

Next, I think there must be differences in the metallurgy of various airgun barrels. None of them are ever hardened purposely, but different steel alloys will respond differently to pressure, I’m sure. Different rifling techniques, such as button rifling and hammer forging, undoubtedly create different amounts of inadvertent work-hardening. You should approach any barrel-bending project as though it’s the very first time you’ve done it — because when you consider the metallurgy issue, it just might be!

I also think that once a barrel’s been bent in a certain direction, such as the corrective bending I’m doing here, subsequent bends in the same direction are easier to make. That’s just a guess. If I’m right, it means you have to go slower and be more careful on bends 2 through N.

What’s next?

This report began with my complaint that my BSF S70 doesn’t shoot to the point of aim. It has an aftermarket peep sight that cannot be adjusted low enough to get the point of impact to coincide with the aim point at 10 meters. And I don’t have a factory original rear sight for the rifle. So, I want to bend the barrel down to correct the situation. It won’t take anything close to the amount of bending I’ve had to do with this rifle, so I shouldn’t be able to notice the bend after I finish. That’s important because the S70 is in beautiful original condition.

An update from the Washington Post. Becky’s story continues.

http://www.washingtonpost.com/world/war-zones/friends-mourn-four-young-skateboarders-killed-in-afghan-suicide-blast/2012/09/13/659d90d6-fde1-11e1-98c6-ec0a0a93f8eb_story_1.html

KIDS murdering KIDS over issues none of them can understand.

Pete,

Reminds me of something I read on a billboard; “If you think education is expensive, try ignorance.”.

Without explicitly mentioning it in my reply to your first post, this is something that was on my mind and that I think about often.

Victor

Re the photo… I think I had a feeling there was a second person in the scene before reading the caption — then rapidly acquired the binoculars peering out…

Re the new clamp… You state that it appears to be meant to drive out pin (and is obviously too large for a bicycle chain tool)… Might it have been meant for opening links in a small caterpillar track?

Wulfraed,

That sounds very plausible. Maybe a farm tool?

B.B.

Hello B.B. and Fellow Airgunners. Quite an impressive result you obtained with your second incarnation of B.B.’s Barrel Bender 2.0. The ratcheted socket definitely increases your control over minute adjustments. It seems like you have an easier time of it with the initial adjustments too. I do have a couple of questions regarding accuracy after improving such a drastically bent barrel. The first is how do you plan to mount a front sight on this puppy, now that the original was broken? I believe you mentioned you were not able to adjust the rear peep sight low enough to aim properly because the barrel was bent too low. This suggests you want to shoot this gun without a scope. The second. Would the act of trying to straighten such a drastic bend in a barrel produce an ‘artificial’ choke at the apex of the bend? If my questions seem elementary,it is most likely due to the lateness of the hour which has addled my thinking process a tad. Thank you for a great series of articles. This is the only place on the web where I can obtain this type of information. Other blogs may have one or two “how too’s” a month. Here, I can learn something new every day. If not from you B.B., then one of the many knowledgable regulars and not so regular fans of this blog. The saying, “Birds of feather, flock together”, definitely applies here.

Caio Titus

Titus,

As I said at the beginning, this rifle was doommed from the beginning, so there was never any need to protect it in any way. Had I wished to preserrve the front sight I( would not have used my workbench to bend the barrel. The fixture makes it much easier to protect the front sight.

Is there a choke from this? All it takes is to push a pellet through the bore to feel it. I just did, and no choke can be felt.

The apex of the bend is several inches long, so it’s probably too gradual to influence anything.

B.B.

That clamp appers to be a ball joint installation tool. Also used to install u-joints, they come new with adaptors and are used on cars and trucks etc. Or in this case to bend barrels.

Bob,

That’s also a plausible explanation. Thanks.

B.B.

“Scope is on but shots are too scattered”…that looks like my typical group!

Can’t use the broken front sight excuse though, so I blame it on tremors from passing trains, low-flying aircraft, or earthquakes. Yeah, that’s it!

I have decided that I have trouble shooting a good group because the wind keeps moving the ground.

twotalon

The worlds most obnoxious invention has a practical use.

This is a dead one that we picked up at a garage sale a few weeks ago. Plugging them with a Nerf gun is almost as much fun as blasting tomato hornworms with a Steel Storm.

http://i189.photobucket.com/albums/z244/twotalon/001-3.jpg

On the down side, my blonde has a new one on order and may be here today. I hate Furby with a passion.

twotalon

BB,

(far as I’m concerned, you are now known as Tom “BB” Gaylord),

I guess I’m going to take that FWB 124 and try to bend the barrel a bit so the peep sight adjustment is centered more. Since I’m only talking a few inches of POI adjustment, I suspect my 8″ clamp should be fine. Or do you still want me to bring it to Roanoke for you to work your magic? By the way, an arbor press can be had for $48 from Harbor Freight – from reading the customer reviews. expect typical Chinese quality.

Fred DPRoNJ

You may want to just install a different front sight that is a the hight you need.

Mike

Mike,

you’ve missed the past history and communications on my FWB 124. In short, I’ve tried three different rear sights, finally settling on an FWB target sight thanks to Kevin of Colorado, which works. He came to the rescue after I had said I might carve a notch out of the stock so that the two different Williams Peep sights (one from Beeman, one from Williams which was flatter and lower than the Beeman) could go down lower and POA would equal POI.

I’ve also tried the Air Force adjustable front sight which ended up being TOO HIGH for any of the three sights! That is, the rifle then shot too low and none of the rear sights had enough adjustment to match that. By the way, the A F adjustable sight is a very nice piece of equipment with it’s range of adjustability and inserts. I even ordered clear inserts from another vendor on the web, which didn’t help but now I use those inserts in the stock front peep sight. It’s been “fun”.

Fred DPRoNJ

Fred,

I will do another trade with you anytime! Just let me know what you need.

kevin

Copy that. Fun indeed!

Mike

Fred,

The beauty of this fixture is its simplicity and potability. By Roanoke I will have corrected the barrel on my BSF S70, which has the identical problem you are having. If I can do that I can also fix your barrel — i9f you want to wait that long.

B.B.

And by potability I did not mean that you can drink the fixture. I misspelled portability.

B.B.

Thanks, BB. While I have a “few” other projects in the works, I’ll try my hand at this one later this month. If I fail to achieve results, I’ll get back to you.

Fred DPRoNJ

I don’t believe that even in this extreme case of barrel bending that it affected the accuracy.

If this were an airgun worth salvaging I would look at what else was damaged on the gun during the violent slam fire. Starting with the stock screws. They were pulled deeper into the stock which means that although they may feel tight with a screwdriver the action of the gun is probably not seated the same way in the stock. It’s probably “floating” a bit. Screw cups may fix this but bedding the action might also be necessary to tighten those groups.

kevin

Mr B,

Are you out there?

kevin

All right, it’s plywood time.

Brought my cutouts home from laser guys. Nice stuff, but I’m glad I left 3 mm excess – they smell a bit smoky and the edge is carbonized. 1 megawatt semiconductor laser – that’s something, I tell ya 🙂 It cuts through steel sheets just like pellet punches through paper – whooosh! – and there’s a nice hole with thin edges glowing white-orange.

My plywood sheets were cut under argon on lowest setting to prevent burning, and still exhaust fans were blowing their best. We all wore light gas masks with darkened faceplates – plywood is glued together with epoxy, so fumes are not very much of a benefit to one’s health. All in all, it took more time to change sheets and punch in commands than actual cutting. I must strengthen my ties with those guys as I see a great future for this technology in my plans – and lots of things cut out with that amazing CNC death ray 😉

Having done all that I can leave with light heart – my flight is tomorrow and I’ll be home very early morning of September 26.

duskwight

duskwight,

One megawatt! Wow. I’m used to 25 watt lasers that etch words and numbers onto metal. I have never see a megawatt laser in operation.

Charred edges sounds like my handiwork. Only I never leave the excess material for cleanup.

You’re getting close, now.

B.B.

Duskwright,

Comrade Pelletier and I say holiday is cancelled. We want to see results of the new Duskcombe! 🙂

Fred DPRoNJ

Comrade Fred,

Great Stalin said: “Faster that required and badly thought actions produce no other result than laughter”.

Everything is going according to plan, approved by the Cental Committee and my holiday is also approved by the Central Committee and by comrade Chairman himself. I cannot risk my health and psychological state for they belong to the Party and Motherland. So I must spend 10 days drinking only high quality vodka, watching fresh snow, reading Lenin and Kalashnikov and absolutely no wrestling with the bears or launching rockets – that’s what comrade Chairman said to me personaly – or else I’ll be considered a traitor to Motherland.

So, comrade Fred, my options are quite narrow, unless you put your considerations before the Central Committee on next year’s plenum.

duskwight

Tovarish, I should have known better than to try to ursurp Comrade Chairman.

Have a wonderful holiday. Try not to shoot all the squirrels.

Fred DPRoNJ

duskwight,

Here in America we have a saying, “Tongue in cheek,” when we don’t mean what we say. Your English is so good I think you must know that saying already. In this case I think you are pushing your tongue through the side of your cheek! 😉

B.B.

B.B.

One megawatt is, of course, is not an impulse power, it’s not Star Wars 🙂 Actual instant power in its beam is somewhat 4 kW on max settings and in my case it required only 500 watt, or else I woud have carbon stock. It can pump one megawatt into metal in one continious beam – that’s what I learned from guys and that’s why they name this class.

duskwight

1 MW being enough to power about 250-350 average homes and businesses, I’m sure glad he pays the bill for that and not me….! 😉

Can’t wait for pics of the finished duskcombe!

/Dave

Made another trip to the range today. Brought the repaired 880 and the new Gamo Hornet.

The 880 was shooting too low, beyond the range of scope adjustment. Shimmed the scope, still too low. Took the scope off, rear open sight needed adjustment, had no screwdriver with me that would fit. Sent it back home to await new scope.

The Gamo Hornet was being shot for the second time out. Scope wasn’t quite on target last time, needed only minor adjustment. Today was a total bust.

Shooting at 6″ target at 25yd. Twice, shooting at fresh targets, I would drill the bullseye on the first shot. Then, subsequent shots weren’t even landing on the paper. I was shooting 7.4gr. pellets, and the new gun was Dieseling heavily on each shot. I switched to 10.4 gr. pellets and at least could keep them on the target face. Gun shot more accurately out of the box last week. I shot three targets before I had one with enough hits to score.

The scope wasn’t loose, nor were the stock screws. Has anyone experienced this before? I think the Dieseling was spewing the pellets, and the heavier pellets were slower and therefore more stable.

I’m hoping this gun will turn out to be a good shooter after it gets the excess lube burned out of the compression chamber. This gun shot 279/300 last week, but no better than 255/300 today. I have not added any lube. I think it was over-lubed at the factory.

Les

Today the pellet target box finally was retired and replaced.

Curious to see what was going on inside, I opened it up. Lately, pellets have been flying clean through the box near the top.

The boards I had placed inside the box near the top (behind the bullseyes on the upper targets) have pretty well been shot into wood splinters. These splinters had worked their way down lower in the box, leaving the top layer empty space.

I spent some time recovering and examining the spent pellets. Strangely enough, some of them appeared unscathed.

My neighbor was shooting some gold-plated PBA pellets at the box, and these seemed to stand up very well with minimal deformation. They appear to be much harder than lead pellets.

Hollow point pellets are supposed to really mushroom, but from what I could see, they didn’t. With both .177 and .22 hollow points, the pellet head seemed to be the part most likely to remain intact. It was typical to find hollow point pellets with the heads undamaged, but the skirts flattened.

The pellets that experienced the greatest deformation were the Crosman Destroyer EX. The .177 pellets really tear themselves up on impact.

Oddly enough, some of the Destroyers were found with the pellet bodies all torn up, but the little pointed heads intact.

There were several thousand pellets in that target box, but I stopped examining them after filling one tin with spent pellets. My OCD only goes so far.

Les

What velocities are you achieving with those hollow points? Up to about 600-700fps I wouldn’t expect mushrooming.

Furthermore, wood slats aren’t going to respond in a way conducive to mushrooming. Putty and gelatin will spread sideways, making room for the projectile to expand outwards. A wood slat is not likely to flex that way, so you just get a plugged hollow point, at which stage it behaves much like something between a wadcutter and a dome pellet.

The box contained pellets that were shot by a variety of guns. Some in the 600/700fps. range, some faster.

The wood pieces were mostly pieces of 2×4’s and 1×4’s. One piece of 2×4 had a hole about 2″ diameter shot clear through it.

I haven’t done much work comparing pellets shot into different materials. Pellets shot against the end of reinforced concrete railroad ties will flatten into coin-like discs. Pellets shot into buffalo gourds often do not deform much (except for Crosman Destroyer EX pellets, which tend to rip themselves apart).

I agree that wood does not lend itself to expanding pellets.

Les

B.B. and others

Does anyone have any idea of what would be a fair price for a Diana BSA S20 ? I was looking at one that seems to be n fairly good shape. Did not fire it but seal seems new although pretty flush, and it seems to cock smooth and tight. It has both front and rear sights but it is missing the front globe.

Thank you

T.E.

TE,

A Diana BSA S20? Now I’m confused. Diana never built anything for or with BSA, as far as I know. And S20 is the model designation for a BSF (another company entirely) air pistol.

So, what is it?

B.B.

That was a typo, I meant BSF and it is the air pistol!

Ty

TE,

I thought so. Okay, a straight S20, not the target model, is worth $75-100 in good condition. The guy on Gun Broker has been trying to sell his for three years and has had bids as high as $60, but they never tripped his reserve.

I have put my own boxed S20 Target model in an ARH box with papers on my table at several airgun shows and gotten no bytes at $125. I decided to keep it, because I can’t find another one at the price. So I think the Target model must be worth a little more.

B.B.

B.B

Thank you. I saw one at a gun shop. I don’t think it is the target model because the grip has no thumb rest. I just wanted to make sure that at $85 I should not jump and get it

Ty

T.E.

TE,

At $85 the gun is a good buy if the finish is excellent. But if it shows wear then the gun is priced where it should be.

B.B.

Hi i bought a hatsan mod 135 yesterday. when i first shot the gun it gave a loud bang for 2 shots , thereafter i cleaned the barrel by pushing earbuds through the barrel with a plastic airsoft unjamming rod until it was clean. when i shoot the gun i stll get a little bit of smoke but no bang. Should I shoot the gun as it is or should i take it somewhere to be cleaned and relubed rather?

regards

Sameer

OK, off topic. I feel my career in .22 target bullseye competition is stagnating because my eyesight is not up to using the iron sights on my High Standard Victor expecially at night even with the targets well illuminated. I’m looking at red dots and have narrowed the field down to the Bushnell Trophy and the Tasco Propoint red dot. Anyone have any suggestions? Like to keep it under $100 if possible. Remember it’s going to be on a .22 rimfire pistol.

Fred DPRoNJ

Hm, do you use red dots for target competition? I was under the impression that red dots are more for quick acquisition than accuracy because the red dot can cover the target area.

Matt61

Fred,

1) Are you using any kind of corrective lenses, including possibly low-powered reading glasses? If not, then try low-powerd reading glasses that focus at about the distance of your front sight. I have a pair of progressives that I use for shooting pistol. However, I’ve not tried shooting in low-light.

2) Can you open up the rear sight so that more light (and space) is visible through the real sight?

3) Talk to other shooters, or retailers, about better alternatives to what you have, if that makes sense.

As I’m sure you know, when shooting pistol you’re really not focusing on the target anyways. Your goal is to deliberately squeeze the trigger such that the gun goes off without disturbing SIGHT ALIGNMENT.

Good luck,

Victor

OH, Boy. First, I don’t have any vision that’s useful in my left eye. My right eye prescription is about a -15 diopter, never mind astigmatism which I also have. I must have been behind the barn door when “God passed out the good eyes”. We shoot outdoors and the port line is kind of dark as the sun goes down. Most of the top competitors are using red dots and so long as they are 1x, they are allowed. It’s a fun league.

It’s possible that widening the rear sight will help but I’ve diagnosed the problem as not being able to keep the front sight centered in the rear – especially on the timed shooting cycle. I am concentrating on the front sight and squeezing the trigger but…..

FRed DPRoNJ

Le Ouch!

I thought MY prescription was bad… ~-5 spherical, another -4 cylindrical (astigmatism), and -6 diopter prisms (my left eye looks down, the right one looks up — makes using binoculars a pain as there is just one sweet spot for both inter-ocular distance and eye-piece position that allows both eyes to view through the glass).

Compound that with: Regular wear — left eye set for 20″ reading (computer monitor), right eye set for distance; Reading — both eyes set for the span of a dinner plate [I’m known to read leaning back with a plate balanced on my collar-bone and the wrist holding the book]; Sunglasses — both eyes set for distance (analog vehicle gauges can be read by position, so no need for sharp digits). My shooting glasses have the sunglass prescription but in clear inserts for an old pair of Gargoyles.

Fred,

Well, the good news is that we only shoot with one eye. But identifying that the issue is with sight alignment is useful. You need to do a couple things:

1) Perfect your natural point of aim. That is, make sure that when the gun comes up, it is pointing perfectly in line with the target.

2) Perfect your hold/grip so that the sights line up. In other words, make sure that you aren’t having to twist your wrists to force the sights to line up. You can practice grabbing the gun in high light as often as possible. If necessary, and possible, use puddy to cause your hand to grip the pistol consistently.

Again, you can work on these things in bright light. The good news is that you can do this anywhere.

One last thing. More important than having perfect vision or a super tight wobble area, you want to do your best to deliberately squeeze the trigger such that the gun goes off without disturbing your sight alignment. If you can do that consistently, then you’ll do about as good as you can. Practice this until you can do it and stay completely relaxed. Don’t think about, or worry about, things like score. Just practice executing without worrying about how well, or bad, you might do, and don’t try to “catch” bulls-eyes. Just bring the gun up, squeeze the trigger without causing your sight picture (however bad it is) to change during the shot, and then follow-through.

If you see your sight picture, or sight alignment, change during shot execution, then there’s probably something wrong with your grip. What matters most is that you can consistently execute each shot. The other details are less important.

Victor

Victor,

thanks for the pointers (no pun intended).

Fred DPRoNJ

Victor,

Wow! Between you and Tom I’m getting bu-cu dollars of training.

-Chuckj

This post makes me wonder about the ease of rebarreling airguns. You hear about this a lot with firearms but rarely with airguns.

I have finally recovered from my knife wound after a week, but it was a hard struggle. During my business trip, the wound kept reopening and the blood came pouring out. Once was right in the middle of an interview that I was conducting. I left splotches all over my notes and on my one remaining pair of pants (the other pair having split down the middle the previous day). Nevertheless, with the help of FrankB, I’m preparing to make my knives even sharper.

Also, I ended up picking up a book at an airport bookstore called something like Navy Seal Sniper. Despite all of the controversy about the Seal Team Six operator publishing his book on the bin Laden raid, this one seemed to have equivalent information. It was all about the training and tactics of Seal Team Six and even included photos and the name of the operator. I suppose the difference is that most of the action described occurred around the time of the Blackhawk Down, so it’s not as current and the Somalis are not as likely to embark on revenge assassination. Still, it would probably be my preference for these guys to keep quiet. I understand the ninja would purposely try to cultivate an air of mystery about themselves as part of psychological warfare. Seems like a good idea, and familiarity breeds contempt as the saying goes. But it was interesting to read. They’re all very impressive. But for all their great skills, their sense of humor is kind of juvenile, sort of like junior high school. I’ve got nothing against that. But for the self-described Jedi Knights of the U.S. military…it’s not exactly Obi Wan Kenobi.

Anyway, just to show that I’m being open-minded, I learned about some advantages of the CAR-15 which was an earlier version of the M4. The author was shooting it with one hand while driving a humvee with the other. That’s something I would definitely prefer to try with an AR-15 rather than an AK 47.

Matt61

Well, that’s an unfair comparison…

The similar cartridge to the 5.56/.223Rem is not the AK-47’s 7.62×39, but rather the AK-74’s 5.45×39.

I suspect the M-14/M-1A (7.62NATO/.308Win) would come off as “softer” relative to the AK-47 just due to the mass of the M-14. Heck, the M-14 probably comes off softer than my rather heavy HK-91 (which uses a roller-blocked delayed blow-back action — meaning one has to resist the initial recoil forces until the rollers unlock; M-16/M-14 use gas impulses to unlock the bolt, which means they don’t require resistance against recoil).

{Hearsay tells of a drill instructor showing how wimpy the AR-15/M-16 recoil is to recruits by putting the buttplate on the bridge of his nose, and firing one round}

Wulfraed,

I’ve shot an M4 and an AK-74 and I know I would never be able to shoot a either one handed, and I would not want to shoot the 74 again shouldered. That must have been a pretty big guy to do that.

-Chuckj

Previous reply meant for matt61.

-Chuckj

Matt61,

When I was a guide miracle glue (there are many variations now and I don’t know which is best) was a staple. Lacerations like knife cuts were best mended in the field with miracle glue. Surprisingly it breathes. I’m almost ashamed to admit it wasn’t my idea but the guy that cut my hair at the time that was always getting cut by scissors and straight razors that told me about miracle glue fixing his cuts that I took to the field.

My dentist buddy Dr. Dann years ago was with us when we had a deep cut on a horse. About 2″ deep caused by the knot head bucking off a string. He used stick deoderant that contains/contained some anticoagulant and smeared it on the inside of the cut. We then sealed it with miracle glue. In 5 days that horse was better than stitching (we couldn’t stitch since we didn’t have any numbing agent). Speaking of home cures for horses we had a paint that was at the end of a 40 mile that turned colic. Nursed that gelding back to camp. Wasn’t in our string. We wouldn’t tolerate a paint LOL! Luckily we had our local vet on that junket. Doc Van poured two fifths of vodka down that geldings throat. Old remedy for colic. We spent most of the night babysitting that paint but in the morning he was on his feet and lived. Google those and you’ll never find em.

Put miracle glue on your cut and let it heal. It won’t bleed in the meantime.

kevin

B.B.

Do you know how well Wonder Blue black finish works on LW barrels ? I have a LW on order for my AA 200T (or T200). I know that Perma Blue makes them purple.

twotalon

B.B.

Sorry….Blue Wonder.

twotalon

TT,

Blue Wonder is a photographic process in which a developer is used to create the color. The color has a lot of gold cast in it, due to the gold in the chemicals. The reason you get a purpleish cast to a color is from the hardness of the steel, but since Blue Wonder is chemical, I don’t think it will be an issue.

B.B.

Van’s Instant Gun Blue worth a try also. I have a procedure that makes it come out nice and black that I would be happy to share with you if you’re interested, but I’ve not tried it on an LW barrel.

That was for TT: typing on tiny keyboard I can’t control myself :).

I just screwed up the position of the post myself. Must be the booze.

twotalon

B-G……

I will keep you in mind.

I still have to get and machine the blank. Hope it’s a good one. It has to come from Germany.

The hard part will be the breech work. I can crown O.K. . I have to get the breech end fitted to the reciever, and the machining for the bolt probe and the transfer port. The roughest part may be polishing the breech end for a nice fit for the probe and O-ring, along with getting a nice inlead for a smooth and clean pellet seating. Going to go with a couple more inches of barrel than stock.

twotalon

The barrel will try to return to where it was to some degree. You have not effectively stress relieved it after just bending in on one direction. You need to bend it the way you want more than what you want and then bend it back to where you do want it. This will help relieve some of the stress but expect some initial movement and the groups may show it for a while.

This is true. I came across some old records someone found for one of the arsenals where they specified barrels had to be stored outside for one year after manufacture before stocking. Obviously to relieve stress. Annealing will do the same thing quicker, but not many people can heat the barrel to red and cool slowly without damage to the barrel or themselves. I am not 100% sure, but I think that a few cycles in an oven up to whatever temperature it can achieve (e.g. 550 or 600dF) and then cooled slowly (e.g. with the barrel in sand or on a tray of sand) would probably help quite a bit.