by Tom Gaylord, a.k.a. B.B. Pelletier

This is going to be a long report. How long, I can’t say at this time because I’m sure I don’t know everything we’re going to do. Many airgunners have wondered openly how the twist rate of the rifling affects how their guns shoot. But wonder is as far as it’s gone because I’m not aware of any test report that’s ever been written on this subject. Indeed, whenever we get on the subject of twist rates, the equations start flying and we all lean back in our easy chairs while we ponder the implications. But nobody ever seems to do anything concrete to answer the question. That ends today.

What is twist rate and what does it do?

First, let’s all understand what we’re talking about. As a pellet travels down the barrel of an airgun, it’s held by ridges called lands that run along the inside of the barrel. These lands stick up in the barrel and twist in a spiral, engraving the sides of the soft lead pellet and making it spiral as it moves forward. The twist rate is how far the pellet must travel in the bore to make one revolution. A 1-in-10-inch twist rate means that the pellet is turning one complete revolution for each 10 inches of barrel it traverses. That twist rate is written as a ratio — 1:10 inches.

Spinning helps stabilize a pellet in flight. Just as a bullet is made stable by spinning on its axis like a top, a pellet is also stabilized the same way. But pellets of the diabolo design (hollow tail and wasp waist) are also stabilized by the high drag of their tails and the forward weight bias of their design (i.e., more weight in the head than the tail). So, spin is just one of the things that helps stabilize a diabolo pellet in flight, and exactly how much spin it takes is the question we’re discussing. We also want to know what the other effects of the spin rate might be. For instance, does a faster spin slow down the pellet because of greater friction while it’s inside the barrel?

The most common twist rate

When pellet guns were first rifled, they were given the twist rate that was common for the .22 long rifle cartridge at that time, which is one complete turn in 16 inches of travel in the barrel (written as 1:16″). If there was any experimentation with other rates, nothing’s been written about it; so, the pellet gun twist rate has been 1:16″ since the beginning — about 1905. That holds true for all four smallbore calibers (.177, .20, .22 and .25).

I can’t say for certain if other twist rates have ever been used. I hear reports of other rates, such as 1:14 inches, but no proof is ever offered. My thought is that perhaps these other rates are obtained from people incorrectly measuring the twist rate. The simplest way of measuring the twist rate in any rifled gun is to make a mark on a cleaning rod, then pass a wire brush down the bore of the gun on the end of that rod and note how far it goes before the rod makes one complete turn. This method is makeshift, to be sure, but it’s accurate enough for a rough estimate.

I don’t doubt that other twist rates have been used at times, but the makers of those barrels have not made a point of mentioning it in their promotional literature. Twist rate is something airgun writers have elected to ignore over the years, perhaps not finding the subject worth discussion since all airguns seem to have the same rate.

A few of us, though, have wondered what might happen if the twist rate was changed. Since the only way to tell is to test barrels with different twist rates in the same gun, and since nobody makes barrels of different twist rate for airguns, the question has remained unexplored until now. Some time ago, airgun maker Dennis Quackenbush approached me and asked if I would be interested in conducting such a test. I said yes, and we both settled on the Talon SS from AirForce Airguns as the ideal testbed because the barrels can be exchanged so easily.

The experiment

Dennis made two barrels for my Talon SS. Both are .22 caliber, which is also the caliber of the factory Lothar Walther barrel in my gun. He made these barrels from scratch. They’re cut-rifled, which means that each groove is individually cut. Doing it that way, he was able to use a sine bar (a tool used to measure angles) to control the rifling pitch that results in the twist rate.

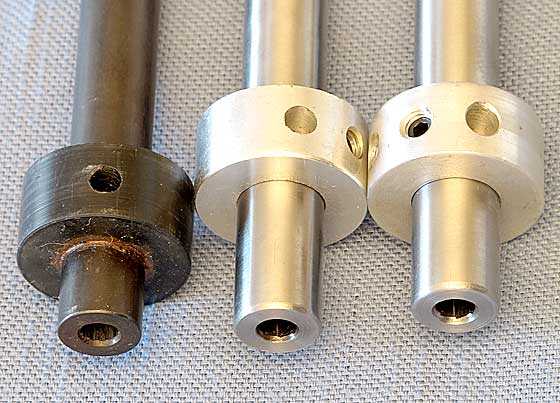

Talon SS factory barrel (center) is flanked by the two barrels made by Dennis Quackenbush for this test.

Dennis marked each barrel with the twist rate. The top is 1:12 inches and the bottom is 1:22 inches.

Dennis crowned his barrels the same way Lothar Walther crowned theirs.

One barrel he made had a 1:22″ twist rate. That happens to be the twist rate of the .22 short cartridge when a rifle is chambered for that cartridge, alone. The .22 short bullet weighs 29 grains, nominally. If the rifle is chambered for long rifle cartridges, as well, then the 1:16″ twist is used because the longer, heavier 40-grain bullet requires a faster spin.

In the other barrel, he put a 1:12″ twist. That was for no reason other than it’s far enough from 1:16″ and 1:22″ twist rates that there ought to be some differences that can be observed. One curious sidenote to this test is the fact that Aguila makes a special subsonic .22 long rifle cartridge that has a 60-grain bullet. To stabilize that bullet that leaves the muzzle at around 900 f.p.s., a rifle has to have a 1:10″ twist rate. There are special barrels made for the Ruger 10/22 rifle for just that round. Like the Talon SS, the 10/22 has a barrel that’s quick and easy to change.

The most common method of rifling barrels these days is button rifling, in which a hardened “button” is either pushed or pulled through the bore, cutting all the grooves at the same time (actually, it doesn’t cut the metal so much as it “irons” the steel into the desired shape). The button must be made for a single twist rate, taking into account the thickness of the barrel walls and the type of steel in the barrel because the steel springs back a little after the button has passed through. So, the spring rate of the barrel steel must be controlled by the size and shape of the button, as well as the type and thickness of barrel steel, itself. Using a button is a very fast way to rifle many barrels, but it limits you to just one twist rate per button.

Cut rifling is therefore a slower process but does give the barrel maker more flexibility over the type of barrel he makes. Dennis didn’t put a choke into his barrels because we aren’t interested in their ultimate accuracy. But the factory Lothar Walther barrel is choked. So, this will not be a test that pits the accuracy of the Quackenbush barrels against the Lothar Walther barrel. We’ll be examining accuracy potential, but only so far as one twist rate seems to have an advantage over the other with a given pellet at the same power setting. If something interesting pops up, we may wish to explore it further with other barrels in the future.

AirForce helped, too

Dennis contacted John McCaslin of AirForce Airguns for some of the critical dimensions of the barrels. John shared these with him and also provided the bushings for the barrels he made. Even though they were made 12 years after my SS was made, these bushings fit my rifle perfectly.

Test objective 1

The first test objective is to determine the effect of a different rifling twist rate on the accuracy of various pellets at various velocities with barrels of different twist rates. All three barrels will be considered, but we’re really interested in the results of the two barrels supplied by Quackenbush. I can’t say that the factory barrel will be used as a control because it’s made differently than the two barrels Dennis has made (different rifling method and it’s choked). But the data will be included in the test report simply because it exists and may be of interest at some point. Any poential accuracy differences will be noted.

I’ll conduct this test at 25 yards and again at 50 yards. That will tell us how the different twist rates perform at different distances.

Test objective 2

Another factor that airgunners have talked about for a long time is the effect of twist rate on velocity. This discussion has been limited to big bore airguns because, as I’ve noted, all smallbores have the same twist rate. The popular theory is that a faster twist rate will result in a slower bullet velocity when everything else is the same. I’ll test the barrels at different power settings for each pellet I test.

What we’ll get from this test is a broad look at how the twist rate of a rifled barrel impacts (or doesn’t impact) the overall performance of pellets in a gun whose baseline performance we already know very well. I’ve thought long and hard about what would be the best way to conduct the test. Do I test the velocity first and then the accuracy? Or do I turn it around and test accuracy before velocity? I have a plan in mind, but I’d like your input before I start the testing. Remember that I already have a lot of good data on this rifle using the factory barrel.

Summary

As far as I know, an experiment like this has never been published before. Perhaps it’s been done, or perhaps parts of it have been done. If so, they didn’t put it in print. Neither Dennis nor I know how this will turn out. As he says, we’re pushing back the boundaries of ignorance in airguns.

I’d like to thank Dennis Quackenbush in advance for the work he’s done to make this test possible. I also want to thank AirForce Airguns for their part in what we’re about to do.

Do the velocity testing before the accuracy test, IMO. This sounds like a great subject to tackle, and I can’t wait to see what the results are!

Hi B.B.

What a nice technical subject! There is another number that I have seen on the CZ 200 S rifles a twist rate of 17.7 is mentioned. I also can not wait to see the results, especially the effects if any for different pellet weights.

Best regards,

Carel

Interesting I heard rumours of a progressive twist rate a while ago… no idea how truthful that was… It supposedly speeds up the twist nearer the end of the barrel.

Shakes, Yes, there is such a thing as progressive rifling. The M-1 Garand has progressive. The progressive is supposed to be a big factor in the very good accuracy of the rifle.

I was just thinking about twist rates yesterday.

Why not conduct velocity and accuracy tests at the same time, I do?

RR,

I don’t do that for two reasons. First, I’m not set up to do it, and setting it up would entail more works and rearranging than I care to do. But second, I feel I can’t give my full attention to the accuracy test if I’m concerned about hitting a window of space for the skyscreens. Too much distraction.

B.B.

Yep, trying to do just that was the reason I destroyed my first Chrony and accidentally nailed the farthest electric eye in the second. Fortunately, I only hit the plastic casing and the Chrony is still functioning just fine.

I’m also wondering how the different twist rates will affect the precession of the pellet. A faster spin should cause the pellet to drift more (90 deg from the axis of spin) or even tilt the pellet sideways. I suspect that gun and barrel makers have done just this type of experimentation and consider their results proprietary. Perhaps that’s why nothing has ever appeared in writing on spin rates. I’ll have to ask my brother at Picatinny Arsenal if he knows anyone in their ballistics sections that has knowledge of this. Could be interesting addition to what you are about to do, BB.

Fred DPRoNJ

Fred,

Yes, if I live that long. It will take some time just to test these two barrels in as many ways as seems reasonable.

B.B.

BB,

Might as well follow your usual pattern of velocity first, them accuracy. That way you’re not upsetting your routine and throwing yourself off…

/Dave

All right! This is gonna be interesting!

I’ll echo RidgeRunner: is it feasible to measure velocities as you shoot groups? Too distracting?

-Jan

B.B.,

Can the 1:12 & the 1:22 barrels be choked after the test is done?? but then again the rifling is different. I really think you will be opening a can of worms if these two barrels turn out to be not as accurate as the original. To do a fair comparison(compiling unbiased data) i think that all three barrels should have been made the same way.

Pete

Pete,

Yes, it might be possible to choke the two barrels after the fact.

But to answer your second question, this test is not supposed to pit Dennis’ barrels against a Lothar Walther barrel for accuracy. It is simple to see which of the two groups better and is the difference that noticeable? However, Dennis has rifled smallbore barrels in the past (with buttons) that have grouped as well as LW barrels, so who is to say that he hasn’t done it again? I guess we’ll just have to wait and see.

B.B.

I’m chuckling as I read this post. BB, you dive into so many diverse topics, each with about 4 parts or more….Are you the kind of guy who starts multiple home improvement projects, but none of them ever seem to get fully done before you take on the next one? I’m teasing here, not criticizing. Love the blog!! On a serious note from someone who doesn’t understand this stuff…due to the slower velocity of a .22 pellet versus a .22 rimfire, shouldn’t the rifling be tightened more? Meaning 1:10 vs 1:16?

se mn airgunner,

I’d like to answer that: Yes 🙂

Edith

Greenhill’s formula would lead you to believe that, since velocity does play a part in stabilization. I’m not sure how valid the numbers would be concerning the Diabolo pellet shape/composition. This will be a fascinating test, I’m looking forward to seeing how it develops. If the results are definitive enough, this could lead to an abrupt change in the design and manufacture of airguns, although they seem to work pretty well at present. Great stuff!

se mn,

I frankly don’t know. Nor does anyone else who is willing to talk. That’s why the test.

B.B.

The diabolo shaped pellet is self stabilising. Why not try a smooth bore barrel?

Markus2240,

Dennis actually suggested that, but in other tests I have found that a smoothbore pellet rifle cannot keep up with a rifled bore for accuracy. So we decided not to test one at this time, since we doubted people would ever choose a smoothbore.

Good thinking, though!

B.B.

My Slavia 618 has a smooth bore and while it’s a great plinker and I have yet to miss a soda can with it, it doesn’t have the accuracy of a rifled barrel and I think (someone please correct me if I’m wrong) but the longer the distance gets the bigger the advantage of the rifle barrel is going to get.

J-F

J-F,

That’s always been my experience. Out to 30 feet a smoothbore is okay, but never great. Past that, though, the accuracy falls off fast.

B.B.

BB,

I love the test, but there may be something to consider in the “very slow” twist rate category. Tests that were done to find the effective twist rate of the new FX Smooth Twist barrels have shown an effective rate of about 1:13.5 feet, even though the rate as measured on the last few inches of the barrel is about 1:16” – the pellet clearly “blows through” the rifling, only picking up about a tenth of the actual spin rate.

So this is a lot more twist than a plain smooth bore, but an order of magnitude less than typical. And we do know that the ST barrels are proving to be very accurate, so maybe here is something to learn at the VERY slow end of twist rates.

Here is one of the tests on the Smooth Twist effective rate: http://www.network54.com/Forum/79537/message/1277076002/Smooth+twist+rate+confirmed

Alan,

I have read that the Smooth Twist barrels are very picky about the pellets they like. Maybe that has something to do with what works?

B.B.

That could be part of it. I also find the pictures of pellets that have been shot interesting – no ridges, just a mild deformation, kind of like a polygonal barrel only milder.

There is definately a lot going on with those, that is for sure.

A 618 with a smoothbore? That’s a new one on me….

I don’t maybe we only got them in Canada? My bore couldn’t be smoother, it’s like looking down a mirror tube and I’ve seen people advertising them as smooth bores and as rifled one. I have also seen people asking if it was a smooth bore or a rifled one. Could it have been shot enough to take all traces of rifling off?

I’d love to get rifled one. I missed one that seemed to be in excellent condition by a few hours a couple weeks ago.

Slavias were very popular here and so were Relums. You guys seem to have had a lot of Chinese and Spanish rifles, we got the Hungarian, Tchec and Turkish ones (we have lots of Hatsans).

I only have one Chinese brand and no Gamo rifles but 2 Slavias, one Relum and 2 Hatsans.

J-F

Want a rifled barrel in .22? I’ve got one here, and I’ll gladly send it to you if you wish.

Funny you should mention the Relum. I’m preparing a guest blog on the Relum Telly I just bought. Never even heard of one before.

Just the barrel or the complete rifle? Do you have an idea of how much the shipping could be to Canada?

What Relum are you working on? Looking at mine and talking to other owners, what comes out is they seem to be built like tanks. No one said tanks couldn’t be accurate LOL.

Why don’t you write to me : docgadget “at” gmail.com

My 618 even with it’s smooth bore and missing the rear sights, they broke during shipping but the shipper paid the fully insured price of 100$, I had paid 50$ for it so we splitted the money half and half. So he got 100$ for his rifle and I got the rifle for free.

J-F

Relum Telly in .177 – shoots, but it feels like I’m shaving 5 thou off of something every time I cock the gun.

If it’s one of the models with two springs inside I’ve heard the inside spring often breaks.

Can’t wait to see your guest blog on it!

J-F

“we’re pushing back the boundaries of ignorance”

What a great way to say it. Ask him if you can borrow it and put it as a header for the blog.

Instead of “focusing on new and old airguns…” Pushing back the boundaries of airgun ignorance one blog at a time” sounds great and it’s exactly what happens here everyday in your blog and because of the gigantic amount of information given in the comment section.

We have all the advantages of a forum without the disadvantages of ego wars and pissing contests.

I can’t wait to see the result of these tests. I’m wondering if we’ll see result across all the range (all pellets being more accurate at all velocities for ONE twist rate) or if pellet one will be better at velocity X with the 1:12 barrel but pellet two will be better at velocity Y with the 1:16 barrel.

Given the large amount of variables I think we’ll be good for a while with this test.

J-F

I forgot about the distance in the variables!

Could a certain twist rate be superior at shorter distances and another be better at longer distances?

J-F

J-F,

Lots of good questions, We’ll all find out together.

B.B.

Though experiment time…

The gyroscopic spin stabilization is going to try to keep the pellet pointing in the orientation it had on exiting the barrel. This means it points generally in the direction of flight during the first phases — but would be pointing transverse during the latter part of the flight (when the pellet is “falling” below line of sight it would still be pointing upwards).

OTOH: the “badminton birdie” design of the pellets is going to try to rotate the pellet to point into the descending trajectory (well, actually, it is continuously trying to point the pellet into the tangent line of the trajectory).

Together, the two effects should be similar to trying to tip-over a toy gyroscope. The top (where you push) will try to move 90deg to the side of the push.

Hypothesis:

1) a faster spin may be desirable during the “ascending” phase (where the pellet is “rising” to the line of sight/first zero) as the spin stabilization and drag stabilization are mostly in agreement.

2) long range (second zero) shooting may be favored with a slower spin rate, minimizing the precession resulting from drag stabilization fighting spin stabilization.

Even if the “accuracy” in case 1 at long range is acceptable, the pellet may be punching the paper sideways.

Of course, we then have to consider how well the pellets were made. Fast spins will likely compound problems from an unbalanced (say a skirt that is thinner on one side than the other) pellet.

Wulfraed,

well written and well thought out. I can see who was getting the “A’s” in your physics classes! Obviously you were screwing up the “Bell” curve for the rest of us :).

Now all we need is Pete Z to weigh in with his thoughts and of course, Rocket Jane.

Fred DPRoNJ

Fabulous idea. You have teased my brain to overload. Bring on the rest of the test!

Wow, this is very persuasive as a neglected but worthy question with all of the resources to answer it. This would make for a great grant application. I think I asked at some point what the twist rate was for airguns, so it’s interesting to see that it’s 1:16. My current understanding of twist rate is that it’s correlated to the weight of bullet that you might want for any number of purposes and that, for firearms, there is a rough correlation between higher twist rates and accuracy although other factors are involved. With that in mind, bring on the test.

I sent my Enfield No. 4 MkI* off to the gunsmith and heard, as I expected, that it looks like it has hardly been fired and is in perfect shape. But after that, the good news ends. I received the rifle back and looked at the chamber cast. I asked the gunsmith to take the exact dimensions of the chamber so I would know the precise overall length (OAL) of the cartridge for handloading. What I can make out from the squiggly handwriting is 2.223 inches, but the Lyman reloading manual says 2.9—. Isn’t that a little weird to have a chamber .7 inches shorter than the regulation length? I don’t believe I will be using that number.

It gets far worse. The action which was the slickest I owned and a joy to use is now extremely stiff as if it is all gummed up. Not only does the bolt not slide easily but it’s difficult to lift the bolt. This is particularly odd since as a cock on closing action, there should be almost no resistance as was the case before I sent the rifle. My first thought was that the guy had put the action in a degreaser as part of cleaning and forgot to lubricate it. I dumped in a lot of ballistol and some white lithium grease in the breech, along the bolt raceway, and all over the bolt, but it hasn’t improved things. Cut now to a scene from the film A History of Violence where a red-faced enraged mafia don is screaming at his subordinate: “How did you screw that up?!” . . . That feels better.

The question is do you guys have any idea what in the world is the problem and, secondly, do you know of any reliable gunsmith in this whole great nation who can fix the gun and bring it back to working condition? I can’t believe it. The two airgunsmiths that have done work for me, Mike Melick and Rich Imhoff, have been outstanding. But with the exception of Clint Fowler, I’ve had nothing but grief from gunsmiths and gun store owners in the way of rudeness, misinformation, borderline criminality and flat incompetence. I don’t get it.

Matt61

matt,

I started to use a fellow in the Pistol league I belonged to this year. He seems pretty capable. You’re not in Jersey, are you? If you want, I’ll send you his name and number and you can talk to him.

Fred DPRoNJ

One gun store owner told me he doesn’t carry air guns or air gun supplies because they “attract kids”.

Les

And how does he expect to grow if he treats potential customers like that?

J-F

Matt,

The bolt of your SMLE is a two-piece affair. The front of the bolt comes in 3 or 4 different lengths, so you can adjust the headspace easily in the field. There is a number stamped into this nose-piece. The higher the number, the longer the piece. Take the bolt out of your rifle and look at the number. I’m betting it is a 3. You probably need a 2.

I said 3 or 4 different lengths because I am not sure that there isn’t a piece with a 0 on it. I don’t think so, but I’m not certain.

Do a Google search on headspacing the SMLE and you will find out about this.

B.B.

There is a “Zero”. Here are the specs. Tradition has it that the bolt head “numbers” fall within the following dimensions :

0 – .620 to .625 in.

1 – .625 to .630 in.

2 – .630 to .635 in.

3 – .635 to .640 in.

Mike

Mike,

Thanks for that information. Now we all know.

B.B.

In addition to what BB said . If you have managed to unscrew the bolt head a turn ,the bolt on your SMLE #4 will bind and be hard to close, as now it is to long. Remove the bolt from your rifle. Check to see if it is screwed in as far as it will go, which will be just before it is tightened down fully.

BTW Matt 61: The .303 British cartiridge headspaces on its rim not it’s shoulder. The main issue with re-loading for them is a generous chamber , that is the chamber is a bit oversize. The rifle was meant to fire with even dirty ammo. So you don’t get many reloads out of a case. They stretch and seperate. If you have a tight chamber count yourself lucky. Measure the head of that chamber cast and see how much over it is compared to the Lyman manual you have. I have had experience with SMLE Mk #3’s, 4’s ,and a Mk #5 jungle carbine. The mk #5 carbine was the worst of the lot.

Tom,

How many different pellets are you planning to use in this test?

David H

David H.,

I haven’t decided that yet. I will probably begin testing with three different pellets, but once I learn more about the barrels the test could go anywhere.

B.B.

B.B.

Experiments! That’s what I like most. I cannot wait for speed/accuracy/stability tests as some time ago I was a witness to a very heated discussion on that. I did not say a word, as I had my own opinion then and now is a great chance to see the results from a competent, meticulous and higly skilled man.

Considering my project – polishing is complete. Next will come mounting the rifle and then applying coat, but first I must wait for bushings. And then – installing gas springs, scope – and here we go with testing a newly made rifle.

duskwight

duskwight,

You will soon be shooting the world’s first dual-opposed piston rifle with gas springs! You must feel wonderful!

We all cannot wait to hear how it performs.

B.B.

Congratulations duskwight. You and your project are one of the many reasons I read this blog religiously each day it is written. Todays blog is another excellent reason why. To use are horse race axiom, you’re coming down the straight and headed for the wire. We will be anxiously awaiting the first shooting test of the Duskcomb 1(I believe that is the working name you use). Will you be campaigning this rifle in any field target competitions, or will it be solely for your own amusement? Whatever your plans be, it must be a gratifying experience to see your dream become almost reality. I know I’m excited. All the best.

Caio Titus

Titus,

First of all, thanks for your faith in me.

It’s just DWR Mk.0 or DWR-TD (TD for technology demonstrator). In blueprints it’s marked as Object 4.4.02 (Type four, composition four, revision zero-two) with (I can only guess – too much rework and I may have missed count) some elements of revision zero-five, namely receiver and bypass body.

If I’m successful with it, I’ll keep this very rifle for my own I guess. I’m not a big shot to ravage FT fields, and the rifle in current configuration has one major flaw – its weight. If I’ll be stubborn enough to make another one – it will be much lighter and much more refined version, based on Type 5 Improved engine. We’ll see about some havoc in FT then 🙂

However, real monsters still lurk somewhere in depths of my brain – I just can’t get out of my head those wonderful linear actuators – 6 inch pull distance, 400 lbs of force and 3 seconds to work its full cycle. Call it e-OPR (electric opposing pistons rifle) and imagine that baby becoming a true death incarnate for PCPs.

duskwight

duskwight,

Be advised, you have, for sometime now, been affected by the “Dreaded Resolve”. You will not stop until you have achieved and defeated those monsters in your brain. We are waiting to bask in the glory of your success!

-Chuckj

Duskwright,

Please, I beg of you. Try to remember the five most important words in promoting International understanding: 1.) Pictures, 2.)Pictures, 3.)Pictures, 4.)Pictures and 5.) as if you didn’t already know, … MORE PICTURES!

We don’t want to read about your progress … we want to SEE IT!

So, pictures, pictures, pictures pictures and more pictures, please.

J

Tom,

I must add, you are AGGRESSIVELY attacking air gun ignorance. It appears that you have almost enough chapters, so far, to begin developing that book: “The Air Gun Owner’s Definitive Reference for Pushing Back the Boundaries of Ignorance”.

You have us on the edge of out seats once more.

-Chuckj

duskwight,

You be the man! Yes we all are waiting for your report. Is it possible to ask for a video showing your rifle coming together, etc?

B.B.,

How about including some “heavy for caliber pellets” in your test. I would think they would do better with a faster twist, but who knows for sure?

Bruce

Bruce,

I will do it just because you asked.

B.B.

Mr. B.,

By video you mean disassembling the rifle and then assembling it again in front of the camera in real time? Oh, that would be too long a movie with lots of metal sounds and bad words in 4 languages.

I promised B.B. a long review article on my rifle and I’ll make enough photos to illustrate this, so I hope readers will be satiated. First part will be dedicated to sketches – in pencil and in CorelDraw, a real freak show, trust me. Eer… well she’s not much of a beauty even now 🙂

duskwight

Yeah, the heavy-for-caliber pellets might also be long-for-caliber. Long pellets could give interesting data points, as I think B.B. mentioned that bullet length is a factor in the ideal twist rate, at least in firearms.

I wonder if the .20 pellets like different twist rates. They’re pretty long, right?

-Jan

I was thinking the exact same thing, and a long-for-caliber pellet that was also especially front heavy might have different results than one more traditionally weight balanced front-to-back.

David H

duskwight,

No, to the disassembling and assembling in front of camera. But it would be nice to see the gun being shot by its builder and any peeks at its innards that might be possible. I don’t know how far along its assembly is at this point in time.

Bruce

This proposed test is very exciting to me. I’ve read a lot about airguns and this is certainly uncharted territory in my experience.

When you consider all the variables, i.e., 3 different barrels with different twist rates, the enormous range of velocity adjustment that the Talon SS can provide, the variety of pellets that could be used, etc. this test could go on for years. Add choking the barrels and you could re-run the test!

Even after all these years Dennis Quackenbush still has a desire to know more about airguns and plays a role in experiments to learn more about airguns. What a great quality that is. Most that would have achieved his success with airguns would be comfortable stuck in their ways since airgunners line up at his door for the chance to hear what he already knows and for the chance to obtain what he builds.

My respect for John McCaslin and AirForce Airguns has been elevated for their contributions to this unprecedented test.

Since B.B. asked, “Do I test the velocity first and then the accuracy?” I’ll give my two cents.

IMHO this test requires that both velocity and accuracy be tested concurrently IF you want the test to be as credible as possible. Eliminating variables is the key to any test for it to have veracity.

Yes, I know that your not set up to do it, and setting it up would entail more works and rearranging than you care to do. But once you’re set up properly you don’t have to be concerned about hitting a window of space for the skyscreens. You won’t be distracted.

More importantly, you’re proposing to spend an enormous amount of time conducting and then writing about this experiment. The FACT is that all your conclusions could be called into question since the accuracy and velocity WERE NOT done concurrently.

Sorry. I know it’s not what you wanted to hear but I can already hear the detractors running their mouths.

kevin

Kevin,

I understand what you mean. My plan is to test each pellet at specific power settings, then repeat those settings during the accuracy test. I will get each pellet to within 10 f.p.s. of its chronographed bspeed for each accuracy test at each distance.

B.B.

Tom,

Apologies. I’m not sure I’m following your proposed control(s) for this massive, time consuming experiment.

Are you saying that you’ll test for velocity (chronograph) with specific power settings and then replicate the power settings and assume during accuracy testing that the velocities remain the same shot to shot?

If so, I don’t understand how you will know that you “will get each pellet to within 10 f.p.s. of its chronographed speed for each accuracy test at each distance.”

Tom, I’m your number one fan.

I think this test is groundbreaking for airguns and will be referred to for years IF as many as possible can be taken out of this huge equation.

Since you asked for input you’ve gotten mine and now probably regret asking. Sorry.

kevin

meant to say, IF as many variables as possible can be taken out of this huge equation.

Kevin,

Yes, that was what I was saying. The Talon SS has incredible repeatability, so I know I can hit the same velocity by returning to the same power setting again and again.

Now, each barrel will probably have its own set of velocities for each pellet at each setting, but they will all get tested at the same settings for every pellet I test.

I couldn’t do the test this way with many guns other than the Talon SS, but as I know its repeatability is near-perfect, I know it works.

B.B.

Tom,

OK. I get it.

Your years of working at AirForce give you irreproachable credibility when you say the “repeatibility is near perfect.”

I’m looking forward to your reports on this massive undertaking.

If todays responses are any indication I’ll speculate that you’ll not only continue to receive worldwide attention but it will grow.

kevin

Though, if the intent is to test twist rates, it would seem that the gun should be adjusted so that each pellet (type) has the same muzzle velocity regardless of which barrel is in use.

I have always been curious about this topic. It seems to me that the twist rates are way too fast. I keep going back to my black powder guns that have twists ranging from 1:48 to 1:72. My .58 Zouave shoots a slug that looks a lot like a straight sided pellet with the hollow base (Lee REAL) in a 1:66 very accurately. I wonder if the reason for the fast rate is that when the twist was determined the velocity of pellet guns were in the 500 fps range or slower and as we have crept up no one ever bothered to slow the twist.

Just wondering, would the softness of the lead have any affect? I have seen a big difference in the pellets. Thank you for another great job(lesson).

Steve B,

I don’t know that we’ll find that out. It will probably be buried in the bowels of the data.

B.B.

Who’s handing out the sterile gloves?

BB,

Young people seem to like the word “epic” a lot these days. In this case, for this big of a test, I think it’ll fit here… This will be an EPIC test! ( in my day it would have been BAD! guess my age is showing…)

/Dave

Tom:

Several years ago LD (Larry Durham) had a long discussion on this topic on his airgun builder forum on Delphi. I don’t want to speak for Larry, but this is how I remember it. He was worried that getting one great barrel in a unique twist could skew the results over a bad barrel with another twist that was actually better. Discussions ranged from doing a group of barrels (say 10 of each twist) and throwing out the best and worst from each group and then comparing the averages. LD also wondered about modding the twist of a known good barrel somehow. He believed that only the last inch (or so) could be twisted externally to change the spin of the pellet. There was discussion of welding large nuts to the barrel and heating and twisting the barrel between tests (with maybe a large sleeve to keep things straight). I don’t know if he ever followed through on it. He tweaked the way the forum worked and I lost interest. It would be fun to see his comments on this. His design on 2 & 3 groove Benchmark barrels are pretty good I hear…

I am really looking forward to these tests. The many combinations and variables make my head spin – but I’m glad you’re actually doing it rather than just talking about it. Lots of talk on Internet forums without actual action. On reflection I don’t want anybody to think I’m slamming LD. That guy gets stuff done. Thanks again Tom!

Chris B.

Chris,

I have a lot of respect for Larry and also for his buddy, Tim. They both know their stuff and are both good shooters who can prove what they say. The USFT rifle and its associated airguns is a tribute to the things these men can do.

As for this test, I have seen this subject debated for so many years that I am glad to be able to begin trying to answer it. I agree with Larry that there are more variables than just the twist rate. But if there are gross changes in performance that pop out in this test, they will tell us where more research and experimentation needs to be done. And, as Dennis put it so well, we will have rolled back the boundaries of ignorance by that much.

B.B.

BB

Seams like the it would be best to ask Dennis to make another barrel with1:16 rate so that all three barrels are the same and not introducing the variable of the AirForce barrel.

Flyboy

FlyBoy,

Well, that’s asking a lot, since we already have a barrel with that twist. Bear in mind that this isn’t a test of barrels, as much as it is a test of the effects of various twist rates on things like accuracy and velocity. I can see your logic, but since we know next to nothing at present, perhaps we should just test what we have before going into other hardware?

B.B.

BB

Really looking forward to this test. But if the 1:16 turns out to be the most accurate will it be the twist rate or the chock or the rifling method that are different on the AirForce barrel. I realize Dennis has contributed a lot to this project and respect both of you very much for what you do. It is because of you and this blog that I have just purchased my first PCP. A Tallon SS .22 with additional 24″ barrel. I will be retiring in March and moving to an area where I will be able to shoot a lot. Can’t wait!

As a side note I was able to correct a barrel offset in my Tallon SS by taking careful measurements and then rotating the the collars on the barrel. In effect rotating the barrel. I was able to get the POI much closer to center of scope adjustment.

Thanks for all you do

Lou

Everyone points to gyroscopic stability when explaining improved accuracy with a spinning projectile. But there is another simple consequence of spin that must be acknowledged. By rotating during flight, the projectile averages out any asymmetric aerodynamic forces perpendicular to the airflow (aka lift) that may result from an imperfect shape as it travels toward the target. We’ve all seen deformed pellets, well with no spin they will tend to drift away from the Point of Aim the further they fly. With spin, the projectile will trace a spiral around the point of aim, remaining nearer the POI at the target. A consequence of this is that faster spin results in a tighter spiral, and keeps the pellet nearer the POI. Looking forward to the results…

RE: “By rotating during flight, the projectile averages out any asymmetric aerodynamic forces perpendicular to the airflow (aka lift) that may result from an imperfect shape as it travels toward the target. ”

Not really!!

The rub here is that the pellet is slowing down as it travels through the air. So if there is an aerodynamic perpendicular force It doesn’t “average out.” As the velocity slows the aerodynamic force would get smaller.

I would point out that it doesn’t matter that the deflecting side forces get smaller as long as the projectile makes a number of revolutions before reaching the target. This is because each revolution of the projectile averages out the forces over that 360 degrees of rotation. For a typical barrel pitch of 16 inches, each 16 inches of forward motion will result in one revolution. There will be many revolutions before the projectile reaches its target, and each revolution constitutes one cycle of averaging.

Also, as the projectile slows, more time passes as it covers a unit of distance to the target. This will give the smaller force more time to act on the projectile, which will somewhat offset the change in speed.

RE: “each revolution of the projectile averages out the forces over that 360 degrees of rotation. ”

That this assumption is wrong is the point. The forces over one revolution would average out IF the projectile had an absolutely constant velocity. The fact that the pellet slows down continuously through each revolution means that the forces don’t average out.

Look at it this way. Let’s assume that because of some malformation in the pellet that the pellet wants to drift left. There is an angle at which the pellet has the most force to the left. Let’s label that 90 degrees. Now the vector forces are such that from 0 to 180 degrees that the pellet wants to go left. Between 180 and 360 degrees the pellet wants to go right. But you can pair each point between 0 to 180 with a point between 180 to 360. If we left t=0 at 0 degrees, then for each pair of points results there is a net left drift.

That side forces mostly cancel due to spin is more of an observation given the physics rather than an assumption. No, the cancellation isn’t going to be exact, but since a projectile will slow less than 1% per revolution, it’s a very significant effect. Under certain values of spin and forward velocity, it will be the only significant effect that spin gives. However, the fact that the projectile is slowing (and its angular velocity is slowing too, don’t forget) leads to an interesting observation. Consider the unbalanced forces you mention over the course of a revolution… In the event they are significant, and that spin is slowing as well, the net force will seem to rotate around the axis of flight over successive revolutions, creating a spiral flight path. We would expect such a looping spiral to get larger and longer as the projectile moves downrange. Add in an apparent yaw at long range due to gravity, some gyroscopic precession, and things get quite interesting! This topic would make for an fascinating numerical simulation that could help explore how velocity, projectile shape and barrel pitch all interact to result in stable flight, and hence better accuracy (or don’t, and result in flyers and keyholing caused by tumbling). Thanks for your thoughts.

After some discussions on yellow, we seem to figured out more than you have proposed.

I’d agree that spin mostly cancels out an imbalance. It the bit left over that matters.

The pellet gets spin due to the rifling. So the spin rate and the velocity are initially a fixed ration. For instance 1 spin per 16 inches of forward travel. But the forward velocity slows faster than the spin, so the “spin distance” (forward distance traveled in one spin) keeps getting smaller.

Since pellets are drag stabilized they don’t “tumble” like a bullet.

Pellets have a small yaw out of the barrel. As the pellet slows the yaw angle increases. As the yaw angle increases the air resistance increases too. So the ballistic coefficient for a pellet isn’t really a constant. It depends on yaw angle.

At some point the pellet reaches some “magic” balancing point where the precession turns into a “spiral”. A spiral being defined as a helical path of increasing radius. At this point group size starts to increase dramatically, not in a geometric ratio.

Herb,

All of this will be tested at practical distances in my test, which starts tomorrow. What the pellet does at 100 yards is meaningless if you never shoot it that far, so I will constrain the distance testing to 50 yards.

B.B.

To boldly go where noone has gone has before! With regards to crowning I cant help but wonder. Would differing rpm of a projected pellet at the muzzle alter the effectiveness of choking? It seems like the slower the spin of a pellet the more difficult it would be to precisly release the projectile on exit. Like a thrown football (American pigskin type) that sticks or slips out of the hand throwing it. Anyways assumptions like this should be ignored in uncharted ground. btw I like where this is going……………..

Very late comment, don’t know if it will be seen, but I read this some time ago and wanted to round up some documentation before responding. I remembered reading in a Cabela’s catalog (a long time ago) that the Sheridan Blue Streak had a twist rate of 1:12 and the 397/392 had a twist rate of 1:14. Among the factors that led me to purchase the Blue Streak over the 397 was the faster twist rate, which I assumed increased accuracy at the expense of a few fps; I have always preferred accuracy to velocity. Of course the 10 year old me had no science to cite for this decision. The 30 year old my loves this blog, and this entry. I did notice you said “I can’t say for certain if other twist rates have ever been used. I hear reports of other rates, such as 1:14 inches, but no proof is ever offered.” My proof is in the manual, and on Pyramyd AIR. I assume this page was put up after your article. The 397 does in fact have a 1:14 and the Blue Streak 1:12.

John,

Far more likely is that both those numbers are in err. Cabelas just prints whatever they are given.

B.B.

I verified both of those at Pyramyd.

John,

You are right! I’ll be darned!

Thank you.

B.B.

Thank you for such an interesting and informative blog; I read it everyday!