Rifling revolutionized!

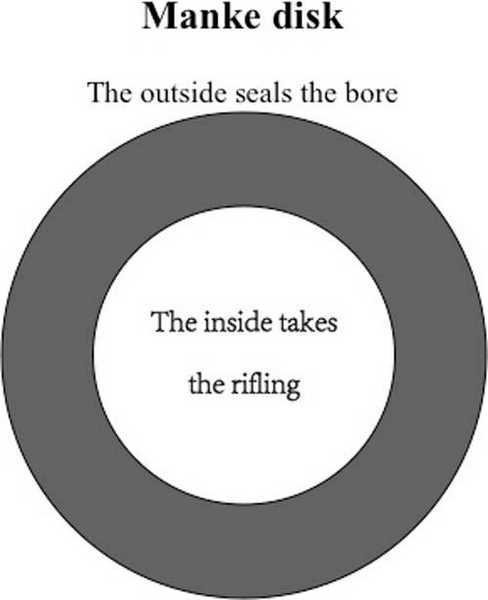

by Tom GaylordWriting as B.B. Pelletier This report covers: Outside the box Rosenthal award Rifling How it works Outside rifling? Accuracy Range increased by orders of magnitude! Trouble brews What is to come? Rumors are flying! Summary Outside the box I’m sure you have heard the phrase, “Think outside the box.” Many organizations don’t really … Read more