by Tom Gaylord, a.k.a. B.B. Pelletier

Today, I’m starting a long series on lubricating airguns. Blog reader Joe asked for this; but as I was researching the subject, I stumbled across another request that came in through the customer reviews on the Pyramyd AIR website:

“I wish that RWS or Pyramydair would explain the process and frequency of oiling these RWS rifles in particular the RWS mod 48. Everyone I talk with says the RWS owners manual is outdated and that with the new seals they use does not need to be lubed maybe for years….I purchase the RWS chamber and cylinder oil at a cost of almost $30.00 and now am told I probably will never need it? This topic should be cleared up once and for all by the manufacturer.”

Perhaps this customer is referring to RWS Chamber Lube and RWS Spring Cylinder Oil as the two products he purchased. And they do add up to $28 before shipping. Are they necessary? Should he have bought them? That’s the question I’ll start answering today.

This subject is so vast and complex that I cannot address it in a single report. In today’s report, I’m only going to look at lubricating the piston seal. That constitutes about half of the lubrication requirements for many airguns, in my opinion. In the next installment, I’ll address all other spring gun lubrication, including the mainspring and piston.

Leather piston seals

In a spring gun, the piston seal is what compresses the air when the gun fires. As the piston goes forward, the seal keeps the air in front of the piston, where it gets compressed because the only escape is blocked by the pellet sitting in the breech. If the gun’s working properly, all other avenues for the compressed air to escape have been blocked.

In the past, pistons were sealed with a leather pad or cup. Leather is an ideal material for this job. It’s rugged, lasts a long time and will conform to the shape of the compression chamber after a few shots — much like a leather shoe that eventually fits your foot perfectly.

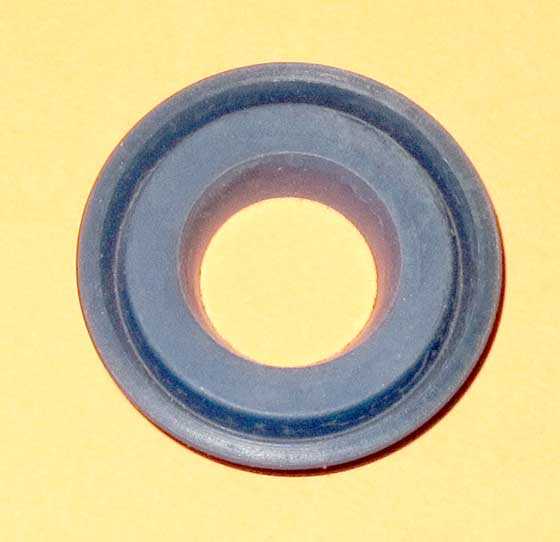

This cup-shaped leather piston seal is for a Chinese spring rifle.

To do its job, a leather seal has to stay soft and pliable, and oil is the best thing for this. As the spring gun operates, a little of the oil is consumed with each shot, so a leather seal needs to be oiled frequently to stay soft. How frequently? In some older guns, I’ve found that oiling every few weeks is necessary if they’re shot a lot. Certainly, all guns with leather seals need a couple drops of oil at least once each month if they’re to be shot. You can leave a gun with leather seals unoiled for years if you don’t shoot it; but before you start shooting it again, that seal needs to be oiled. When I start shooting an older gun that I know has leather seals (I use references for finding out things like this), I put about 10 drops of oil through the air transfer port and let it soak into the seal for at least an hour, although a half day is even better.

What oil to use?

The type of oil you use depends on the velocity of the gun. Guns that shoot less than 600 f.p.s. in both .177 and .22 caliber will be oiled with regular household oil. Any petroleum-based lubrication oil will do. Yes, gun oil will also work. For guns that shoot faster than 600 f.p.s., I use silicone chamber oil, like the product listed above. The spring cylinder oil is not for chambers and should not be used on the piston seals of these guns.

Synthetic seals

Starting in the 1950s, manufacturers began experimenting with piston seals made from synthetics. Some of them, like the ones used by Anschütz and Falke, worked well and lasted for many decades. But others, such as the seals used by Walther on all their airguns and the seals that Feinwerkbau used on the 121 and 124/127 sporting rifles, were made from a material that dry-rotted within about 20 years. If they were oiled by anything, they failed even faster. These seals started out as a light beige color, but as they absorbed oxygen and oil, it turned them dark yellow and brown until they began to break apart in waxy chunks.

Diana was one of the last companies to switch from leather to synthetic, and they had the benefit of watching the others. They were still using leather seals in their powerful model 45 rifle in the late 1970s, at a time when that airgun had broken the 800 f.p.s. “barrier.” When they started making synthetic piston seals, they used a blue-colored material that was tough and long-lasting. It’s interesting to note that the others adopted similar piston seal material when they finally realized their seals were perishing in use.

The blue Diana parachute seal is so rugged that hobbyists use it for many other airguns. It needs very little oil!

These 2 FWB 124 seals are made from modern synthetic material, yet they look like the original ones. The one on the right has been inside a rifle for a few thousand shots. It looks bad but is still in great shape and will last for many decades.

Don’t fixate on the color blue for piston seals! These synthetics can be colored any way and still be fine. I have modern FWB 124 seals that look similar to the old seals in color, yet they’ll last indefinitely. It’s the material, not the color.

Which oil to use?

With synthetic seals, I always use silicone chamber oil. That’s SILICONE CHAMBER OIL — not brake fluid, silicone spray lubricant or any other concoction. Chamber oil is for piston seals. It does not lubricate metal parts because the viscosity is too low. It’ll ruin metal parts if you use it that way. On the other hand, nobody knows what will happen to a gun that’s lubed with anything other than SILICONE CHAMBER OIL.

Diana recommends using two drops of chamber oil on the piston seal every 1,000 shots, and one drop on the breech seal at the same time. That’s it. To answer the person who asked if he needs the chamber oil, the answer is yes. But one small bottle will last a long time. I’ve observed that most Diana airguns can get by with even less oiling than what’s recommended. One diagnostic for when a gun need its seal oiled is when the seal honks like a goose as the gun is cocked.

Silicone chamber oil has a high flashpoint. Since the air in a spring-piston gun reaches about 2,000˚F with every shot, this is important. This heat is adiabatic — it doesn’t heat the gun because the interval is too brief.

Overlubing vs. underlubing

It’s almost impossible to overlube a leather piston seal. And it does not harm the seal if you do.

On the other hand, overlubing a synthetic seal can start the gun detonating. Not dieseling — most spring guns diesel. When you smell burning oil, your gun’s dieseling. Dieseling is just a few oil droplets vaporizing with each shot. It’s perfectly normal in a spring gun.

Detonation is when a lot of droplets vaporize and cause an explosion. That will damage your piston seal if it’s allowed to continue for a long time. It can also break your mainspring.

So, dieseling is okay, but detonations are bad. And overoiling synthetic seals causes detonations.

Do you see why I had to cover just the piston seals today?

Lubricating(line 1), Just tryin’ to help there, Old Timer!

B.B., Thank You for creating an online, encyclopedia of Airgun Knowledge!

As stated previously,I’m Stuck! and swear to always, make sure I can’t answer my own question, before I ask it,(Good luckw/that!)

Gotcha B.B!, I’m, actually takin’ it slow on this one. I’m just uneducated and seeking proper guidance from wide open minds mad in Spain Beeman RX2-$80?

You’re right! I need to slow down.

Reb, it sounds like someone’s got a little ADD….. lol, right there with you buddy! Is that beeman the dual caliber model? I bought one that was so filthy it was ridiculous, the chamber had chunks off something and within a few shots ground to a halt. This was before I did any mechanical work on them or I would have opened it up and cleaned it all out, it was a solid gun that looked nice but if the internals are shot that’s no good. Returned that one. Heavy as an old TV too. Overall evaluation from me is it would sit or sell, probably wouldn’t take it for free besides to sell, at least not if they’re all even close to as dirty as the one I got. Id love too see other guns with the quick change caliber option. – Long day today, early day tomorrow, Goodnight evrybody

No, This is another animal!

Your issues?, or the beeman? Herro! Jk, ttygl

What does BB have? ADD.

I would of never known. I had that before so I know there is a cure. First you have to find out what started the problem. Then you start putting on the medicine to reduce the problem to see if the medicine works.

All I know is ole Gunfun1 was sad at that time. But it was all better after he got it all balanced out again after the medicine worked.

Oh I forgot the most important thing about ADD. Usally its not the person that you think that has something wrong. Its somebody else!

And all that time they thought back when I had that it was me.

So you will find out about this type of ADD that that BB is really ok. Same as they found out about me.

GF1

You confused me.

twotalon

TT

This is the first time ever that I heard of you being confused.

And Im a bit confused also now after reading what I wrote.

What and the heck am I talking about. Yep to much wild turky. I need to go to sleep.

Ignore what I said. See I got to sleep. Really

We really need a edit button you know.

I should shut up now!

GF1

Wild turkey ? Yup….that will do it.

Go to bed.

twotalon

Careful with that Kickin’ Chicken! I remember giving myself 4 stitches after a knife sharpening debacle, while rather well lubribricated with it!

Phew. And they say that stuff is suppose to be good for a tooth ache.

Wrong! I still got the tooth ache and now a head ache! I should of known better. But it was ok at first. 🙂

And now I got to go out and move that wood and stack it from that tree that fell the other day. Hopefully I can get done and get some shooting in. Its nice out.

Is that Latin?

If it is a Beeman RX-2, it is made in Germany by Weirauch. If it is a RS-2, it is made by Wang Po Industries in Chea Po, China. If it is made in Spain, it is not a RX-2.

If someone is selling one for that price, they either really like you, have no idea what they have or it is a scam.

Exactly what I was thinking! I lost a lotta Nice guns thru a pawn shop back around ’05. Time to get even?

MADE IN SPAIN was stamped on the left side of the breechblock. There was also a Chinese Beeman beside it and a “pump air rifle” that felt like a fully loaded AR15 for $150, wasn’t interested in much else once It clicked.

Possible barrel swap?

Thanks for the info, buddy. Looks like someone swapped barrels on it. I guess whatever it is it’s more than likely worth $80, And I can put it on layaway for $14. I’ll be lookin’ at it again today while I’ve got the money in my pocket. Imagine a .20cal 30fpe $1000 gun on MY wall! The laminated stock makes absolutely no sense to me. I can only hope it’s for structural integrity because it’s uggly!

Reb

Laminated stocks may be something like plywood in a couple respects.

You have different runs of grain with glue holding them together. It becomes more stable and less prone to warping . The grains tend to reinforce each other and will have less tendency to split. Then there is less tendency to have a resonance .

twotalon

When I held this gun i got dizzy. No, I’ts not the one at Wally’s.I got one of those back when I first saw them but had to take it back for the $.This thing is the biggest, most heavy duty air rifle I’ve ever held! I needa headsup on what to look for on it, didn’t even find the caliber stamp.

It’s been a while since I made $1000 in one day.

~Daddy needs a new pair o’ shoes~

Reb

Reb,

The “MADE IN SPAIN” stamp on the breechblock leads me to believe the gun you found is a Beeman RS2. Some of the RS2 had laminated stocks.

The Beeman RX2 was made by Theoben of England for Beeman. You would find the name “Theoben” on the breechblock and on the side of the tube. All of the RX2’s came in a laminated stock.

kevin

If I recall correctly, it said Beeman RX2 on the spring tube. I’ll be taking a second look in a couple of hours,We”ll know for sure then! Stuff like this drives me nuts!

You were right and I’m Definitely not interested in it but it did have a nice trigger. They go down by the week at this pawn shop. hmm buying a gun for a trigger?

I left the .22 barel on mine to keep it sub-sonic.

BB

I guess Im going to be asking for it after I ask this guestion. And remember most of my guns have been pump, pcp and Co2 and I forgot nitro piston guns.

I have 2 spring guns to my name. One is the 54 Air King and the other is the Stoeger X20.

Im just going to talk about the 54 because its the oldest. Im going to say its about 11 yrs old. It came with the little bottles of lube that you talked about above.

There was a schedule for maintenance that came with that gun. Here is the problem. I never followed the schedule. The gun has been lubed maybe a dozen times over the years.

And here is the other thing about it. I got the chrony almost a year after I got the 54 and this is the thing It still chronys the same.

So am I lucky with my results or what? And remember BB I asked about those flat Torrington roller bearings in the 54. Well I still want to do that also.

Hey I thought that was my stoeger x20!? Hehe, I do need to buy something with some really quality in it, I might have to ….make you an offer….you can’t refuse….. lol. I have yet to own any airgun I really just LOVED and feel like Id have in 5 years still.

RDNA

I have really been wanting a TX 200 Mark lll for some time. But I keep buying other guns knowing deep down inside I should be putting money towards the good one if you know what I mean.

When you get a good spring gun in your hand you will not want to get rid of it.

I shot some pretty heavy hitting firearms in my younger days. And I will say I dont enjoy that kick any more. Thats why I shoot the buttery smooth pcp’s these days.

The 54 falls pretty darn close tp that buttery smoothness. And from the way every body talks the TX mark 3 is like that also.

Beazer where are you.. You got a TX. You know how they are better than me. (sorry to call you out again buddy but they made me do it)

I dont know about you all. But airguns can be very addicting.

You are buying some pretty cheap stuff if you think the X20 is quality. Don’t get me wrong, I am sure Stoeger has it all over Wang Po Industries, but they ain’t Air Arms or Weirrauch or Feinwerkbau, etc. If you hunt around, you can get some real sweet deals on quality.

I just picked up two FWB 300S’s at an unreal price. They need new seals, but that is no biggie. My 1906 BSA needed rebuilding, but because the quality was there, it could be done and without that much effort. That tiger striped walnut stock looks real nice also.

RR

Oh I knew the Stoeger wasnt quality. i was hoping that maybe they would introduce a smoother spring gun with the technology thats available today.

And I said I didnt want to talk about the Stoeger. They have thier place in time.

But come on Crosman with the NP2. And you know whats bad about it all. I will buy one for myself to try. No matter what anybody else says about it. Sorry stuborn ole Gunfun1 again. 🙂

Stoeger is probably better quality then I’ve been able to buy, the NP is the first gun I’ve bought over one hundred bucks, that had been my limit for a long time. If I put all the hundred dollar guns I’ve bought together Id have an evanix 3D rainstorm by now! I’ve never been with much money, and when I did make 800 a week I wasn’t airgunning at the time, too busy with bills girls and being a bad boy! Now I survive well enough but there is no extra money for toys… 🙁 I have to sneak them in, what I need to do is sneak my next three toys together,( about 6 months+) and get something nice.

Heh… For many years $100-150 was my price range for fountain pens… In that range they used to come with at least a 14K gold nib. One had to check the specifications closer for those in the $75-100 range. Below $75 tended to be highly polished, maybe plated, steel.

Now? Steel nibs are common in pens selling for $200. Bexley, I believe will allow one to order a gold nib… for $200 extra 14K, and more like $300 more for 18K.

What do you do with expensive fountain pens? Draw or calligraphy?

RDNA,

Fountain pens are highly collectible! In fact, there was a time when B.B. was interested in collecting vintage fountain pens. It never took off, however, because they’re not as much fun as vintage guns 🙂

Edith

Scrawl… (my hand-writing is that bad…)

I’ve been using fountain pens since the end of the 60s — 6th grade.

A good one (which, strangely, more and more seems to be the cheap steel nib models — Lamy AlStar, for example) have good ink flow, and need NO pressure on the paper. Makes for fast writing without much strain on the hand.

RDNA

Some of them hundred dollar guns can be winners. I just got one of the Daisy 953 target pros with out the sights.

I left a comment about it farther down where RR but up the link about the Walther LGV and the Torrington bearings.

But you got to get your hands on one PCP gun for a day of shooting. You will be hooked. Now what needs to happen I believe more than ever is if Crosman is going to take on the $100 PCP they need to get on the ball with it. Even though I have some high end guns and qiute a few of the lower end guns. I will buy a hundred dollar PCP if Crosman makes it. Even if it is loud.

I too thought of getting a X20, but I knew that before I even shot it the first time, I was going to have to put a new trigger in it. Then I was going to have to drop a few hundred bucks on a stock. It would be cheaper for me to buy a TX200 M3 with a walnut stock or a HW 35.

I am not going to have a room full of these things so why not just have a few really nice ones?

RR

And thats what Im talking about. You know what kind of PCP guns I have.

And look at my 54. Sooner or later the quality top end performance bug will get you.

I got a Daisy single stroke on the way right now. I bet you know whats going to happen to that gun RR. I will put it this way. I will not be able to keep my hands ofg of it if you know what I mean.

By the way how is your AirForce project going?

It is temporarily on hold right now. I spent all my money on the two FWB 300S’s. LOL!

There are some things I can do with it that will not cost anything and with the warmer weather I will be able to get to it out in the shop now.

A question about those Torrington bearings. Are they made in such a manner that you would place them under the end of the spring and they would allow the spring to freely rotate as it twists?

RR

Yep thats exactly what the Torington bearings do.

On both ends?

I was thinking of such for my 1906 BSA. It has a washer at the trigger end. I may put in another and a little moly between to see if that would have an effect.

RR

I think that would be a good idea.

I had a coworker buddy that slipped some of these in his transmission. a ’67 Mustang capable of 10.30@ 126mph!

GF1,

If that turns out to be a good experiment, may be you could share it with the rest of us in a guest blog?

B.B.

BB

Just aint going to happen no matter what you say.

Sorry.

BB

It sounds like I hollered at you with that comment about the guest blog. Sorry about that. My brain was not in full function this morning.

And I would rather leave the blog writing to the expert. You BB. But thanks and sorry again.

sir

not a great blogger but sorry this is off topic. Person in very humid country was wondering how to protect his pellets can not find the blog or who it was. Anyway if you clean lube and vacuum pack they will will be good till you need them.

Snakewolf,

Welcome to the blog. You don’y have to stay on topic here.

Thanks for that tip, which works for a lot of things, doesn’t it?

B.B.

Torrington bearings!? Awesome!

Reb

At the machine shop I work at we made stuff forTorrinton in the earlier days. That was at the begining of my career in the machine shop world.

I thought you meant in the cocking linkage, not on the spring. That’s gotta really tame one down!

Hi B.B.

I’m sure you can read minds Sir. I was just hoping for this & your timing is spot on. You see my best friend is going overseas for a couple of years & gave me his Norica Titan Basic with brand new mainspring & piston seal (synthetic) for tuning & safe keeping. I have no experience with synthetic seals so this is so timely. Its rated 623fps so do you think Singer Multipurpose Oil would do? Just a few drops or would it damage the new seal? Please keep up the Great Work & God Bless You.(the gun is 2 years old and is in super condition but the mainspring is weak cos he used to keep it cocked for long spells)

Errol

Errol,

No, on the Singer oil. It’s used for lubrication, not for sealing. You really do need silicone chamber oil for the piston seal of that rifle.

I have never seen a synthetic seal fail in normal use, with the exception of the ones made in the 1970s and -80s from improper material. I doubt you need to do anything but shoot your rifle. Maybe ONE drop of oil (silicone) through the transfer port each year, unless the gun starts honking like a goose when cocked. Then the seal does need some oil.

B.B.

B.B.

Thanks for the advice Sir. Will do. By the way its honkin like a whole flock.

Errol

If I got this right, a couple of drops and no more of that silicone chamber oil should be safe on any spring air gun, regardless of what the seal is made of? But how can you tell if you’re shooting an under oiled leather seal? So that you could give it more of the oil it needs.

JPM

You will notice a marked drop in power & there would be no dieseling.

Errol

JPM,

Welcome to the blog.

Errol is right — a loss of velocity is the best diagnostic for leather seals that need oil. That’s why a chronograph is such an important tool.

When I lubricate a gun that has leather seals during a teardown, I use a petroleum-based grease on the piston seal and also on the rear of the piston. I have a Diana 27 with leather seals I lubed 15 years ago and it still functions fine. Of course I don’t shoot this rifle that often. If I did perhaps it would have needed more oil or grease by now.

I have many airguns, plus I’m always testing new ones, so I don’t get to shoot even my favorite guns as often as I would like. But I know guys with one or two guns they are constantly shooting. These are the fellows who need to worry about more frequent oiling.

B.B.

B.B.

Didn’t know about greasing the seal. Thanks again. Will try it next time I have to strip my old air pistol.

Errol

Hey if you ever need to lighten the load, you know I could use an airgun that’s actually worth holding on to. You know a super powerful .22 springer is my cup of tea and your least favorite, so….. 😉

The owner’s manual for my 1906 BSA says to put a couple of drops of oil in the chamber after every 50 shots or if it has not been shot for some time.

Is there a lubricating oil that works better on rubber piston O rings?, or should i invest in some silicone chamber oil. At the moment i’m using Abbey SM 50, which i’m lead to believe is silicone based.

Sir Nigel,

I’m not familiar with that product, but if it seems to work I would go right on using it. I recommend silicone for rubber piston o-rings, just to err on the safe side.

Having said that, I lubed my battered old Meteor Mark IV seal with moly grease. So I guess I’m a bit of a two-face.

B.B.

I picked up a RWS Diana 45. The manufacture date is June 1987. Is the piston seal leather or synthetic? It currently shoots 7.9 Boxed Premiers at 690 to 695 FPS over the chrony.

Heat,

This is a real tough call, but your 45 is definitely dry. I’d try 10 drops of silicone oil through the port and let it soak into the seal for a couple hours — just in case it is still leather. After that you can work the barrel up and down through couple inches of arc — not cocking it, just moving the piston a few inches. If you hear a squishing sound, the seal is leather.

The date on your rifle seems to indicate that it was made in the synthetic seal era, but the 45 was the last rifle Diana converted from leather, so your seal may be leather.

After the oiling job, if the velocity settles down around 850-900 f.p.s with those Premier lites, the seal is leather. If it settles at 930-980, it’s synthetic and you may have some smoke for a while.

B.B.

Kansas Heat,

Scroll down to see another reply. It’s from Gene Salvino, who’s a tech at Pyramyd AIR.

Thanks,

Edith

B.B.,

Thanks again for another great report. The basics are most important, and often most interesting.

I enjoyed your writings this week. Have a good weekend, and don’t forget to tell us about the airgun show.

RB

B.B.

Looks like a nice weekend coming up for the show at Findlay. Have fun.

twotalon

If you’re interested in vintage guns, you may want to read this news story about a British firm that’s making a replica of a BSA rifle:

http://www.birminghampost.co.uk/business/manufacturing/bsas-bell-target-gun-reborn-6948521

Edith

Awesome! I wonder how true it will be to the original that I have. there is some major machine work in one of these. I am not so sure they can sell it at that price. We’ll see.

Shucks, I got all excited for nothing. They are not going to build the “Lincoln Jefferies” again. They are going to build a low powered PCP that will be inexpensive by Europe’s standards.

Kansas heat ,

Your RWS 45 has a leather seal for sure, the cutoff was 1988. If Your rifle has the cross pin holding in the trigger through the stock it is a leather seal gun. Beeman Precision sold these as the 250. Air tool oil is great on these seals and also helps lube the piston and compression tube. I have brought quite a few of these back to life with oiling.

Thank you Edith, BB, and Gene Salvino! I will oil this old dog as you have suggested. Unfortunately today at Noon this project moved to my ‘back burner’ list. I was informed today that my services are needed in Tulsa, OK and will be traveling that way Sunday night for up to 4 weeks. It sucks to work for a big company and not to be in full control of your destiny. I’m putting all my gun toys away and will unpack them when I get home.

Now for some wishful thinking….are there any BB Blog Contributors that are located in the Tulsa area that I could touch base with? I’m fairly green on this whole subject and would certainly appreciate meeting more experienced shooters to absorb some knowledge.

I’ll buy dinner and beer,

Randy

In addition to the older Walthers and the Feinwerkbau 121/124/127 series the Air Arms Pro-Elite used the synthetic seals that deteriorated quickly. Turned waxy and disintegrated.

If you acquire any of these guns it’s a good idea to open them up and check on the piston seal. Doesn’t take long to ruin the piston and/or end of the compression tube by shooting these guns with a disintegrated seal.

kevin

OK the possible substitute that I’m considering for velocity tar is…CYCLE CHAIN LUBE-Ideal chain& cable lubricant-anti sling formula-inhibits corrosion-designed for all O-ring chains. This stuff is really sticky! kinda reminds me of what’s left inside a tire that Fix a Flat was used in. Gunk liquid wrench ML2S.

ANY thoughts?

Thanks

Reb

Reb,

You asked for my thoughts.

Quit trying to find substitutes. Use what has been tried, proven and has withstood the test of time.

Buy the package of lubes from ARH.

kevin

I do apologize for appearing to not take good advice and in no way mean any offense. I will be buying the kit eventually but really dislike having to wait for parts or materials, always have.

Thank you Kevin, for the advice.

Reb

Personally, I would not apply the tar unless I had a vibration issue. I just coated the spring on my BSA with some lithium grease so it would not rust and went on.

Vibration is a major source of this gun’s problem, alongside a bore that looks like It’s just been slathered with roofing tar.

All the lithium greases I found were too thin for my taste. The moly we packed in the CV joints was almost like a tar but after about 10,000 miles would be about the consistency of the lithium based stuff.

Reb,

Highly unlikely that you can offend me. Don’t worry about that.

With all due respect, if you would of ordered the package of lubes from JM @ ARH last Saturday when we discussed this you would likely have them in your hands now. I’ve learned that patience, especially with the hobby of airguns, is necessary. Good luck.

kevin

I had just gone “all in” on the Chrony, which will be here today so I’ll be velocity testing this weekend. I’m probably buying the RX2 by 5:00 so my money is gone for a little while. But a RX2 for $80 would be idiotic to pass up!

Reb,

if you want to try a substitute for Jim Maccari’s “black tar”, see if open gear tractor grease does the trick. When you put it on, just a light coating on coils should be enough to dampen any vibration. However, I have Maccari’s product and can attest to it’s effectiveness.

Fred DPRoNJ

Well the RX2 deal went south so I’ve still got that money but The spanish one had 0035 on the tube, feels like a 600fps .177 gun. It looks a lot like B.B.’s Gt600 but i’m looking for more power than that. Time to place another order.

Reb

I have a Marksman 0035 . Might be the same thing. Not very fast, but would be fun for a kid.

twotalon

It was a nice looking and handling gun, I felt quality, the RS2 had a nasty cocking linkage rattle but it was in .22

That rx-2 wouldn’t be worth fixing at that price?

I was also studying the open gear greases.

Reb,

You might try silicone brake grease if you need to do something now… Those little packets for a buck at any auto parts store. You might need 2 of them for one gun. That stuff is so sticky and viscous that it slows down low powered guns like it did to my LG55.

/Dave

That stuff is awesome when the surfaces are polished or plated and sometimes over paint. But like B.B. said, If you miss a burr, this offers no protection and almost acts like cutting oil. Did that.

For havin’ my back,Thank You, Fred!

Reb,

Cycle chain lube is too thin. Open gear lubricant is also too thin.

What really works well is Velocity Tar sold by Air Rifle Headquarters.

I called it black tar when I first encountered it in an Ivan Hancock tune and Jim Maccari liked the name. So he called what he sells Velocity Tar. Try it. It works.

B.B.

BB,

See you tomorrow at the Findlay show.

Derrick,

See you there.

B.B.

I’ll be getting some on order when I finish the rack & pinion job that i’m working on nowThanks

Reb

Well I have to say I was Wrong. I was no RX2. There, now I feel better!

Just saw the Fed Ex truck parked across the street while making a shammich, as I walked out the door he cranked up and went the wrong way! Tried to chase him down on my bike AARGH!

Well, It’s here! Everything appears to be in top shape, even the box! Is it just me or did this stuff shrink? Now, for my lesson in Greek about this Chrony!

BB

I visited ARH from my mobile phone could not find velocity tar, under lubricants, only found listing as large heavy tar & large clear tar is this the same stuff?

H.E.,

That would be a question for ARH.

I don’t know.

B.B.

The way I understood it, when I read it, the clear is for sliding breech guns.

Pardon, but shouldn’t that first sentence be “… lubricating airguns…”?

A “lubrication airgun” would be a pneumatic powered greasegun at an auto shop…

Yeah I tried to get him on that right off the bat. Caught ‘im slippin’!

Wulfraed,

Changed. Thanks.

B.B.

Help: I dropped a pellet into my cocked RWS 48 and it went inside the piston tube. I cant shake it out and because the spring is compressed I’m afraid to disassemble or fire it…any suggestions?

Mark,

It’s been done before. No harm will come from firing the gun once, to uncock it. After that you can disassemble it to remove the pellet.

I have removed as many as half a dozen lead pellets from the piston seal;s of some guns I’ve worked on.

B.B.

Thanks for your quick reply. Do you have a pic post of directions to get at the seal?

Thanks again!

Mark,

Oh, no. I thought, from the way you spoke about it, that you knew how to disassemble a 48. If this is your first teardown, the 48 isn’t the gun I would recommend doing it with. There are some complexities.

You might want to send this gun to Pyramyd AIR for a rebuild, after you have fired it.

B.B.

Hey Tom, I have a Benjamin Titan NP and I love it, very smooth shooting and fairly accurate once you find out how it liked to be held. (not every single spring gun likes or needs the artillery hold) but even after 500 or so shots it’s still dieseling. Not much, but smoke comes out of the breach after the shot.

Should I just let it go away, or take the time to rebuild it? I’ve rebuilt my Crosman Quest 1000 and it was fairly simple.

Thanks!

Andre,

Dieseling is the normal state for a gun like yours. They always diesel. What you don’t want is a detonation, but a little smoke is no cause for concern.

B.B.

Well that wasn’t so bad, helps if you read the instructions. Big surprise! Rem. Airmaster 771 with Crosman Destroyer7.9=10.42fpe!

I had an incident similar to Mark’s today also, as I was closing the breech on my QB-36 I felt slight resistance so I opened it for inspection, The pellet is nowhere to be found, worked it back & forth all in vain. Finally I closed the breech and felt a lil squish and pulled the trigger. A Crosman wadcutter flattened to about the size of a quarter greeted me on reopening for the next round. I figured I couldn’t be the only one.

Go Figure!

Reb

Wow, no wonder the .22 Crosman pointed were dropping them so hard through the 392, 14.3grain @686fps=14.94 fpe!

Reb

Sounds like your happy with your new toy.

I guess so did you see what the AM is doin’-over 10 flbs, the 880 is over 8 and the QB-36 is a little over 7 alongside my 760. Then I ran outta daylight for the Red Ryder. Just took a break from the 3120. The intake seal must be mushroomed or sumpin’, The pump won’t push it out. Grrr!

Hope to see some of you all at the airgun show in Findlay Ohio this morning!

Mitchell,

It was nice to meet you at the show today, And I’m glad you got what you came for.

B.B.

Likewise Tom. This was the best day I’ve had in a long time. And the rifle I picked up is a serious shooter as well. Looking forward to Monday’s blog as always… Thanks again!

Help! Anybody have experience with rivets? The one for the pivot link on my 3120 was loose when I got it.A couple whacks with a pall peen got it down enough to pump it, for a lil while. I feel if it’s not attended to it will be a skeleton in my closet. This rivet takes the brunt of the force involved in pumping, It’s also countersunk and flush mount so I believe heat will be necessary but how will this affect strength? and will the heat hurt the bronze bushing/bearing?. I’m thinking, heat it away from the gun till glowing then install and whack. Sound right?

Any input will be up for consideration and will be greatly appreciated!

Thanks

Reb

Those rivets are soft steel, Reb. You can drill it out and replace it if the hole isn’t wallowed out. If it is you can put in an oversize rivet by just peening it in with a hammer on one side and a flat bucking bar on the other. Pretty easy if you’re at all accurate with a hammer…

/Dave

Dave, I can get it out but I would like to have one that’ll last, when I get done. From what I understand this is one of the few weak links on this gun. Can I replace it with something harder? I have a fastener fabricator 1 mile away. Everybody keep this in mind if you need something because these guys make ANYTHING including taps and dies! And dirt cheap!

I’d replace it with like material. Rivets are cheaper and easier to obtain and replace than the arm parts. Think of it as a consumable… It is the weak link for a reason. If you strengthen the rivet then the something else wears out first. Which piece would you rather replace?

OK, will justa nail work? If cut to the proper length? or where do I get an original? I’ve already talked to Tim at Mac1, No gottee.

McMaster Carr or Aircraft Spruce should have what you need. A nail will work if you anneal it (soften) first. Heat it cherry rd and slowly take it out of the flame until it no longer glows red. Then set it aside to cool slowly. You can then cut it to size (grip length plus 1-1/2 x diameter) and install it. If the head is supposed to be countersunk, you’ll need to make a form to do that.

Good info Dave! Just so happens, I found a magnet that fits it perfectly when I whacked it before. most magnets shatter when impacted however, this one’s already survived quite a few.

The one thing that really hit me when it failed, was how much damage was averted. Yeah I grabbed the whole thing! I also recall sharing an incident here(just came to mind) where the pump handle almost slipped. It felt like the valve had just dumped 6 pumps through the intake! ever heard of that?

Well, it acted like it went through that time but it’s nowhere to be found(sassafrasin’ dagnabbit cow patty!)

Guess I’ll have to type it all again,Grr!

Help! Anybody have any experience with rivets? One of the ones for the pivot link on my Benjamin 3120 was loose when I got it. I gave it a couple whacks to get it down so it would clear the slot but it’s not gonna last once I get pressure on it. This rivet is countersunk and flush mount so I don’t see doing it without heat. what effect will this have on strength? There is also a bronze bushing/bearing that goes between the rivet and link. I’m thinking heat the rivet while uninstalled, insert while glowing, whack and grind if necessary. Sound right?

Any input will be up for consideration and will be greatly appreciated!

Thank You

Reb

See above…

I guess that’s why nobody’s talkin’ today!

Reb,

You ended up in spam. That’s why your comments weren’t posted. All are approved now. I’ll now go thru them and see which ones are duplicates.

Edith

Thank you Edith! Please pick one of the ones from before I got so frustrated. Sorry ’bout the mess.

Reb

I think someone else was logged into another site on this computer,(probably a game)when it happened. Again my apologies and Thank You

Reb

I think i have been marked as spam because now I have to do the math again, even after I logged back in. Is there something wrong on my end?

Thanks

Reb

Reb

When you logged in, did you tell it to remember you ??

twotalon

Yes, Guess I’ll try to remember what I was saying because I’ve lost so much information today.

Reb,

I think your internet service provider (ISP) doesn’t give you a permanent IP number for connecting to the internet. There are a LOT of IP numbers that are known sources of most spam, and I’ve added those to the spam filter over the years. So, if your ISP changes your IP number from time to time, then that explains why you can post freely and frequently most of the time but occasionally get caught by the spam filter.

FWIW, my ISP gives us the same IP number all the time. However, if our internet service goes down and then comes back up, chances are good that there’s some repair going on & our IP number changes.

You can check this yourself to see if that’s the issue. Go here: http://www.whatismyip.com

Mark down the number. Whenever you write a comment that doesn’t get posted, go back there and check your IP number. Is it the same one you had when you were able to freely post a comment? If not, then that’s the problem.

If your IP number is the same, then there’s a word in your comments that’s causing you to get kicked into the spam folder.

Edith

OK, I’ve got it written down, If I have anymore problems I’ll check this first.

Thank You, Edith!

Just in case anyone else ever has this problem,by following the steps, outlined after clicking this link,it gives you the option to change your IP address, (right?might work?). Good luck!

Hello Edith

Thanks so much for this website. As it happens, I have been having problems with what I thought was my brand new iMac. Running the speed test the offer, tells me my computer is tickety boo. I have owned these ‘time saving machines’ in one form or another for over 25 years now, and it seems I’m still learning the basics today. Much gratitude.

Ciao

Titus

Edith

Thanks for the computer teach’n again. 🙂

B.B., So when I get into this QB-36 if it has a leather seal and it looks alright,Which would be better, the leather one or replace with a synthetic? And why? The bore on this gun is very nasty right now and I’m kinda thinking the leather seals and having to oil may be part of the reason for this. The gun clocked at about 600fps yesterday with just about anything I ran through it.

Thank You

Reb

Based on my QB36-2 (longer stroke, but very similar), you’ll likely find the leather has been torn by the cocking lever shoe slot on installation; this causes excessive dieseling and possible detonation with oiling, possibly even breaking a spring eventually. If this is the case and you clean up the cylinder, you can use whichever type of NEW seal you want, leather or synthetic. I went with synthetic (JM Apex), for the challenge (had to rig up mounting) and I’m glad I did, as it requires a lot less attention. If you don’t do much to the cylinder, install another leather seal as it is more forgiving, but do at least smooth the burr that cuts seals on installation.

I can only imagine how much deburring a Chinese gun would need! I feel this is one of the top most important parts of prep work. once it’s done things are easier to handle, go together easier, with less damage, it’s easy and once it’s done, it’s forever.(or until you drop it!)

My gun’s running about 600fps,this may mean I’ll have no choice because the original is toast. I was hoping for 800, I assume this is doable and would like to start building from the ground up. Where would you start, and will a leather seal support this much power? If it’s gonna have recoil behind it, I want power in front of it!

Reading this all again makes me glad I used a synthetic lubricant for soaking. I figured, if it was leather and I let it soak overnight, that it should raise velocity by 10-30 percent. Today’s conditions were unacceptable for the Chrony, here, so, nothing concrete, But, no real increase after 10 drops soaking for 2 hours

At least it’s not blowin’ up, on me!

Reb,

If the leather seal is okay I would keep it in the gun. If it has to be replaced I would try to get another leather one. Leather takes care of a host of weaknesses in spring guns, including rough machining. And the Chinese synthetic seals aren’t the best.

B.B.

Thanks for your explanation(these really help me)of their benefits.One more question I would like to know the answer to would be, how much power can a leather seal support? Although it feels like draggin’ around a boat anchor, I’d like to turn this one into a 40 yard hunter.

Thanks again

Reb

Reb,

Leather seals will top 900 f.p.s. without a problem. And they will still work 50 years later.

B.B.

thank You for your answer,Sir!Last night I had visions of a leather seal slowly smoldering away, while locked in a gun safe, after a long day of shooting.?

So no threads on np muzzle, guy wouldn’t do it if he couldn’t put it on a lathe, I didn’t think it would be much more difficult either way but he’s so anal its obnoxious, urrrggh.

So what’s the problem? He has a lathe, Right?

Yes he has a lathe but can’t put it in with the breech block and link arm attached and I don’t know how to get the barrel out and don’t want to mess it up. Its all set, I wrote part two and you’ll see how I bypassed the threads.

sounds like a job for my buddy “heat!”

RifleDNA, I had to break out the MAPP gas twice today. I don’t know exactly what you have going on but would like to help. Please explain or show me what you’ve got.

You still have a supply of MAPP?

The only manufacturer quite production some years ago. The stuff I can find is just a propylene compound that isn’t quite as high in heat output (which leads to the propylene/O2 torch that I haven’t used yet — considering the O2 tanks have about as much air as a birthday balloon — good for maybe 20minutes run time per cylinder).

https://en.wikipedia.org/wiki/MAPP_gas

RDNA

A hole with a roll pin through it?

Or drill and tap it for a set screw. You could but the hole thing in a Bridgeport that way.

Suppose to be you could (put) the whole thing on the Bridgeport.

Wouldn’t it be a press fit?

And I really don’t know what end he originally cut off.

Does anyone know of an air rifle scope that focuses closer than 10 yards (like the UTG Bug Buster which can focus at 3 yds.) AND has a SWAT focusing knob? I already have a Bug Buster, but it doesn’t have SWAT.

Thanks,

Jerry

B.B.

Back on the road ? Going to lay up in a motel for the night before the long cruise south ?

Pleasure meeting you .

twotalon

TT,

I’m laying low in the motel this evening, writing Monday’s blog, which is about the show. As you know, I really enjoyed meeting you!

I got so much out of this show I will have material to write about for months!

B.B.

B.B.

Well, I know you got at least one new gun. I won’t squeal on what kind.

You need to hire a dozen more writers and testers.

Be careful heading south.

twotalon

tt

Did you pick up anything for yourself?

SL

No…I was not shopping. Went to meet B.B. in person.

I am quite happy with where I am right now …..at least for a while.

twotalon

Nice meeting you earlier today sir. Had a really good time chatting with you and Tom. Always nice to be able to put faces to the names you see here in the comment section. Take care…

Mitch

Nice meeting you too. Hope you enjoyed looking at all that stuff.

twotalon

Theres a little bit for just about anyone’s airgun fancy there, but if you were someone who was into early American made airguns you would be in hog heaven. I’ve never seen so many Daisy model 25s in one place in all my life. I’m just not into shooting steel BBs, with the whole “you’re gonna shoot your eye out” and what not.

Mitch..

I started out on a 25 when I was young enough that I had trouble cocking it for a while. Not long until I wanted more power and accuracy. Then I had trouble finding anything that filled the bill. We did not have internet back then . Just what the local stores had was all that I knew about. Things have changed a lot.

twotalon

twotalon,

Why did you said “Be careful heading south”?

B.B. has to go that way to go home. I can’t feature him wanting to go to lake Erie.

twotalon

Joe,

Tom has some business to take care of on the East Coast and is going there before coming home.

Edith

Edith..

I hope he stays away from N Jersey….the brain damage might rub off on him.

Then there is W. Virginia…..mutant, inbred, cannibalistic hillbillies !!!!!

twotalon

He wouldn’t be stopping by to see me would he? With a nice quality AG? Lol….. ahh dreams….

Goodness ya’ll, where do I start? Anyhow, I attended the airgun show in Findlay earlier today, and for some reason my wallet is considerably lighter. Meeting Tom after reading his blog after all these years was quite the treat as well. Tom autographed my Blue Book of Airguns for me like the true gentleman he is. Also got to meet Mr. Twotalon as well which was a surprise. I went to the show with the image of a Feinwerkbau 300S burnt in my mind after lusting after one for somewhere near a decade now, and I failed at that mission, but all was certainly not lost. Another fine 10M match rifle lay on the table before me, and upon picking it up and examining it I discovered I was holding none other than a well preserved Anschutz LG-380. You see, I have a serious weakness for anything that possesses surgical accuracy and precision but always assumed a 380 would be out of my league pricewise, but this one wasn’t!. After some slight negotiation, the rifle was mine! Interestingly, someone in the past added a little artwork to the stock in the form of a rather beautifully carved and painted Ram’s head almost like a little medallion to adorn the stock, but other than that the rifle appears to be well maintained and cared for. I hope Tom shows that picture he took of it to you all because it really is rather unique and well done. After bringing it home and running some various pellets through it rather informally, I realized what a jewel I now own. I managed my first honest one hole group totally off-hand and unsupported earlier today so needless to say I’m just over the moon. Thanks again to Tom for the autograph, and I’ll be looking forward to the next installment of this blog as I always do! Take care everyone…..

Mitchell,

They will get to see that ram’s head carving in Monday’s blog!

B.B.

Sounds good. I wish I would have taken more pictures of the show but I was too busy socializing and shopping.

Mitchell, Congratulations on a wonderful sounding day! Hard to beat a rifle that hits where you’re aiming!

Thanks Reb. Its really hard to beat the feeling of achieving a nearly 10 year old dream, ie: owning a top of the line match rifle.

Mitchell and TT,

The Daisy 25 was my first love. And I saw more of them at this show than I’ve seen at the last 3 shows I’ve been to.

B.B.

Somehow I had a sneaking suspicion that bringing up model 25’s would elicit a reply or two… =) I have one too, but it wasn’t my first. My very first airgun for me was a god forsaken Marksman Model 1010 pistol. Cocking that pistol all day long would literally make my hands nearly bleed, but boy did I have a blast with it. And as soon as the pellets ran out, I always had my wrist rocket slingshot as a sidearm.

One last thing for tonight, my buddy stopped by to see the Anschutz and try it out, and we were shooting playing cards in half on edge in no time. I don’t want to admit it, but he was actually out-shooting me on my own rifle! :::gasp:::

Mitch

That kind of thing happens to a lot of people. Most often, the owner does not have a clue as to how to shoot their own gun. Now if you take two guys who both know what they’re doing, somebody is usually going to do a little better anyway.

You do have an edge…it’s yours and you will get to shoot it more than your friend does. You should be able to wax him in no time. Enjoy !!!!

twotalon

Mitchell,

I used to think when friends outshoot you it’s time for new friends, but I ran through so many of them I decided to keep the ones I have and learn how to use Photoshop. 😉

B.B.

I feel that the one’s who shoot better, are the one’s to learn from. But my pride still chokes me going down!

Cool joke, Combustible targets, for your “Better” Friends! 😀 “Oh yeah! Prove it!” … R&D’s gonna be a Blast!

Ironically enough I almost bought a pack of Tannerite the other day. Since it doesn’t work with airguns and I don’t get out to shoot my powder-burners all that often I decided against it. Other competing companies make these little round reactive targets with a special blend that work with rimfires, and I know I’ve seen videos of people setting them off with PCPs, but I wonder just what kind of velocity or kinetic energy those thing truly require.

I found “rimfire sensitive Tannerite available last week at a local dealer, I would imagine it would take 850 or better to set it off. seems like it was $5/ lb

Wonder what the neighbors will think?

I just noticed a Crosman 140 laying on my couch! I can hear air coming through the transfer port as I pump. Where should I start?

Again?

Reb

While remembering that I swore not to do this; Sounds ,like there’s something caught up in the seal or maybe the sear/ trigger/hammer is jammed

As a matter of fact, the safety feels weird, on this gun?!

Reb,

For your Crosman 140 that has a/several problem(s) here’s a good place to start:

http://anotherairgunblog.blogspot.com/search/label/crosman%20140

kevin

Thank you, Kevin, for the link! this was the first good info I found on this gun. As soon as it stops raining and dries up, I’m goin’ in!

Reb,

Glad you found it.

kevin

GF1,

The discussion of the Torrington springs got me to thinking that the new Walther LGV had something similar, so I went the their site and what they have done is the piston is free to rotate in the compression chamber. I also noticed in their video that the spring is not under any compression when it is at rest.

http://walther-lgv.com

A pox on them! I am going to have to end up with one of these.

RR

I just watched the video. Always have liked when they show the views of the guns mechanisms.

I just wonder how much of a difference it does make in the way the gun feels when you shoot it if a person would go to the Torrington bearings. Is that what they did?

And I had to make a order to PA the other day for some pellets and a longer air hose for my Shoe box compressor to fill the guns instead of using my little Benjamin carbon fiber bottle. I had some Bullseye bucks saved up. And PA had that 10%+free shipping. So I got me one of the Daisy 953 target pro without the sights also. And also put a little fixed parallax, fixed power 4×32 UTG scope on it. (killer little scope, very clear)

Cool little can killer is all I got to say too. I think its what I have been looking for. Only got to pump it once and nice and smooth when it shoots; like a PCP gun. Alot better than the Stoger x20’s vibrating kick. Been looking for something like that so I can shoot while I’m refilling the PCP guns and the Benji bottle. Of course its not got as much power. But its going to come apart today to give it a little more power I hope and the 6 pound trigger has definitely got to be worked on.

Will see how all that goes. And time to go out and shoot for now though.

I don’t think they went with a T bearing. The piston is free to rotate in the compression chamber. If I am not mistaken, so does the TX 200 M3 and possibly the RWS 48/52/54’s. By doing such you eliminate the need for a T bearing as the spring will rotate the piston as it uncoils. Would it help? Maybe.

SSPs and MSPs are in effect PCPs with an onboard pump. That is why they are so smooth when you shoot them.

The Independence by FX is a hybrid that you can pump up or charge. I wish Crosman would make a version of the Marauder like that.

Me too! put it around $300 with 20fpe and I’ll bite!

RR

You know I got the Monsoon. If FX makes the Independence semi auto like the Monsoon I will be all over it.

Problem is I wont have enough money to buy it without selling a gun or two. Hmm, which one would I sell. That would be a hard decision with the guns I got now.

But wait what am I thinking. If its semi auto like the Monsoon and you can pump it and top it off like a PCP then you know what I would probably do. Or not I like my Monsoon too.

But here’s another thing. The cost verses value of the Benjamin Marauder. Its probably one of the better PCP guns out there for what you have to pay for it. So if Crosman made a PCP with a independent pump and offered it at half the cost of the FX Independence I think they would have a winner.

Come on Crosman you can do it.

You’re really gonna love your 953 with a scope on it! The headspace mod is very easy and takes about an hour plus set time, and increases effective range substantially! The single stage part ain’t so bad but the trigger is heavy and rough, so a little trigger work would definitely be in order. Good Luck!

Reb

Reb

You just don’t me yet do you.

I just put a little heavier spring in front of the knock valve. I took the pin out that seals the transfer port from where they cross drill it from the factory. I opened the transfer port up to about .085″ And put a bigger pin in to seal it.

Then came the trigger and also smoothing the gun out a bit. I cut some coils off the striker spring so when the bolt and trigger was at rest like after you fired the gun. The striker spring sat in it place freely. Then the spring under the sear got a coil cut off of it. Same for the spring that controls the magazine advance.(all those springs work at making the trigger heavy) And I put just a bit of radius on the sear where it latches the striker and a bit of polishing at that point.

I know got about a 2 pound trigger(6 pounds when it started). And the gun is more tame when it fires and the point of impact is higher now. So to me that means its making more power since the point of aim was higher than the point of impact frrom before the mods. Didn’t get a chance to chrony it before or after the mod for that fact but its hitting higher for some reason.

How did they do that in the old days with cars before the dyno’s came out. Didn’t they call it seat of the pants tuning. Punch it and see how the car pulls. 🙂

Supposed to be since the point of impact was higher than the point of aim.

I need to proof read before I post.

Pictures from the Findlay, Ohio airgun show are up on http://www.anotherairgunblog.blogspot.com

Derrick,

Thanks for the pictures. Wish I could have made it.

My favorite caption of yours that is under one of your pictures is…”… I think the show was about 65% pellet guns and 45% BB.” Seems the show was a 110% success 😉

kevin

Maybe the extra 10% were the dual-fuel models?

Good catch! I rewrote part of that sentence and didn’t fix the numbers. There were more HW guns as well as vintage match guns this year than ever before. And many, many good deals. You could’ve bought at least a two or three R1’s for less than $350 each. I was really close to pulling the trigger (no pun intended) on a Diana Model 10 pistol but I’m really not in acquisition mode anymore.

There’s an amazingly informative pictorial/tutorial after the pictures posted here, anyone about to go into a spring gun should definitely give it a glance!

Thanks for sharing, Derrick!

Reb,

Thank you for the kind words. My co-blogger Nick and I have almost 700 posts there related to airgun repair and tuning. The index down the right side will link you to all the various models we’re covered over the years. The “older posts” button at the bottom of each page takes you back to earlier posts.

And please tell Nick I said Thank You!

Just took a peek at the 2015 Z06 ragtop. This thing is gonna be a Monster! With a 6.2L Supercharged V8 AND choice of 7 speed manual or 8 speed paddleshift, it’s gonna be major competition for the overseas Supercars, Especially once a few good tuners get busy with their projects!

Be sure to check it out Gunfun1!

Reb

Reb

I will have to check it out. But now only if I could drive it. 😉

Here’s a Walkaround!

Reb did you forget the link?

Got way jammed up yesterday and then had to go to work. My computer ‘s actin’ up and crashin’ left & right. AARGh!!! Really bad today!

https://www.google.com/search?q=2015+corvette+z06+specs&oq=2015&aqs=chrome.1.69i59l2j69i57j0l2j69i59.10053j0j1&sourceid=chrome&es_sm=93&ie=UTF-8#q=2015+corvette+z06+specs&tbm=vid

Finally!

Reb

Thank you. 🙂

Oh and yes the Corvette has always been amazing from the beginning to look at it now. 😉

This is off topic but I watched a documentary I guess that is what it was. It was about Fred Bear. The owner and maker of Bear Bows.

It was pretty neat to watch how they made the bows. Plus he was a hunter and a amazing shot with a bow and arrow. What I also thought was cool was he knew what it took to market a product. He made amazing films about hunting with the bow and arrows.

Me and my daughters watched it. They thought it was good since they are both into bow and arrows also.

Just wonder if the other people here that are into archery ever saw it.

I never saw that but I know Bears are really good bows. I mentioned before that I got some lessons with an archery/bow hunting pro! This guy was amazing, he could hit bulls from just miles away, his trophy room was filled with EVERY type of big game from across the globe. His pointers changed my bow shooting fast, I am a pretty good shot now, always a pretty naturally good shooter, but there’s no denying the difference. I had a question about opening up transfer ports for .22 spring/gas spring guns…. Any blogs that have any experiments with changing the size?

RDNA

My daughters are both actually pretty good with the bow and arrow. I stink. I will just stick to my rifles.

And I’m sure BB has wrote about that but I don’t know for sure off the top of my head. And I haven’t done anything on spring or nitro piston guns but I have on pcp’s, pumps and C02 guns.

I would have to say on a spring/nitro gun its probably more critical than with the guns that I mentioned I worked on.

RDNA

BB did something like that.

/blog/2010/02/changeable-air-transfer-ports/

Thanks guys I read both that and the older one and ended up opening up the NP to just under an 8th of an inch, about .15, where it was maybe .10 or .11, probably didn’t change much but since no chrony, its all guessing anyway, but it feels good. The numbers from B.B.s tests say it should have given me about 20 fps. I wrote the part two for it but I just did the transfer port so that’s not on there but its not much to talk about without a chrony, anybody got an extra one for like 20$ or 40$?

Time to bite the bullet and spend the money! I’m glad I did and I’m glad I got the Alpha Master, at first I was a little disappointed because the Chrony itself didn’t have a readout but after using it I believe I prefer my electronics off to the side, out of harm’s way, and the jumper’s gotta be 10 yards long.

$119, cheaper than a gun and a very valuable tool. I now know, with confidence what my guns are capable of, and I gotta couple that need work. Consider it an investment in knowledge!

Reb

My transfer port experiences have all been fixing ports that are too large. If you don’t have enough restriction, you won’t see a peak in pressure that prevents the piston from slamming into the front of the compression tube. I’ve had two previous and now working on a third gun that need a reduction in port size. So, go easy if you do enlarge that port–it’s a lot easier to open it up than to reduce it. I’d recommend an all around size of 0.125″ (1/8″) for a .177, .20 or .22 cal. How the pellet fits the bore (for resistance) will also come into play at some point for any given caliber. A loose pellet fit in the barrel means it’ll be halfway down the barrel (or gone) before the piston can build that cushion of air –and then it slams into the front of the compression tube. You’ll hear this as a “ping” at the end of the shot cycle. Piston weight is also a factor. And I think a heavier piston needs a bigger cushion of air. But I’m not saying that all heavy pistons need a small port. And I’m not sure that very low powered guns need small ports. But I do think there several factors that interplay and it’s not a one size fits all answer.

Sorry, my measurements were way off, it is now opened up to exactly an 8th of an inch, so its .125, and it was just under that to start, probably 3/32 Id say. The pointed Benjamin’s fit blatantly loose and those get the ping, the domed fit tightest and shoot smoothest so It definitely wants fat pellets.

Bear bows are great. I’m looking at a Montana longbow if my current longbow gives out.

Matt61

Matt61

I don’t know how some people are so good at the bow and arrow. It looks so simple but all the things there are to learn. (kind of like how airguns are I guess)

I don’t know if I should relate the two together here but what is funny is I could shoot the heck out of a wrist rocket in the day. But not the bow and arrow. So I’m wondering where the heck my daughters got it from.

They both hold the bow straight up and down. And they have both arms positioned right.

I just hope they continue the interest of guns and bows. I remember what happened to me when I was a teenager.

Piston seals are on my mind after the one on my IZH 61 gave out after 100,000 shots. But I don’t think it was from lubrication but from the very dumb thing that I did.

Matt61

I think your piston seal was simply worn out from all the shooting that you do. It’s really hard to kill a seal with a few dry fires in such a low powered gun.

B.B.,

Thank You.

B.B., I’ve been trying to find a rebuild kit for this Crosman 140, sliding breech cover gun. Does PA not carry this kit?

Contact Rick Wilnecker at Precision Pellet.

I tried E-mail. If that don’t work we’ll goto planB!

Thanks Kevin!

Reb

I was looking at that 48 and would love that in .22, something to work for!

B.B.

Great blog today! This report is a gem that I needed to read–and reread often! I admittedly overuse silicone chamber oil on my spring and gas piston air guns.

In addition, I do have one question: How does silicone chamber lube ruin metal parts? I, incorrectly, have been using a few drops of silicone oil on the cocking linkages and occasionally on the gas pistons and springs. Well, we live and learn. But, surprisingly, they have suffered no ill effects regarding their performance–yet.

Thanks again for the much-needed report.

Mike

Mike,

It doesn’t lubricate them, so they rub together and gall.

B.B.

Hi PyramiydAir,

Please be kind enough to demonstrate the installation of a piston seal ( FWB 124 seal types).

Regards.

Zuwain,

The installation is obvious, once you have the piston and seal in hand. You simply button it onto the piston.

Have you read the 15-part report about the 124 in which we show that?

/blog/2011/02/a-shrine-built-for-a-feinwerkbau-124-part-15/

Look at parts 12, 13 and 14.

B.B.

I’m still completely confused as to how often I should use chamber lube in my Crosman TR77 with a metal spring. The owners manual say one drop every 250 shots. One drop affects my accuracy for so many shots if I used it every 250 shots I would only have about 100 accurate shots before I needed to apply another drop of oil. I should note that I am using 100% silicone chamber lube by Alchemy Gun Werks Which has a slightly higher viscosity than RMCoil. I’m wondering if RMCoil burns off faster and needs to be applied more often. I’ve read I should lube the chamber 3,000 to 5,000 shots, not every 250 as stated in the owners manual.

Mitchell,

You have discovered that a drop every 250 shots is way too much. One drop per 3,000 is better. But I don’t lube until I hear the piston seal honk like a goose.

In this instance, less is best.

B.B.

I have an RWS 52 Deluxe that I bought years ago but haven’t shot much until recently.

Finally got a scope (Nikon Pro staff target EFR) that has parallax done to 10 meters.

Any way the accuracy (consistency) seems to have really dropped off. I thought maybe the seals had dried out.

I too bought both oils a long time ago but had forget the procedure so I broke down & read the instructions.

1. Does long term storage change the rules for lubrication?

2. Could I have damaged something by firing cleaning pellets?

3. Too much recoil for this scope?

Any suggestions would be appreciated.

Thanks for the timely article,

Brian Ward

Brian,

Welcome to the blog,

1. Long term may affect lubrication, depending on the lube and how long. My guns have been lubed past 15 years and are still fresh. Today’s post talks about this subject. Read it here:

/blog/2015/03/rws-diana-45-part-7/

2. Cleaning pellets are not meant to be shot. They are to be pushed through the barrel with a cleaning rod.

3. A 52 can damage a scope, but if the scope’s elevation is set too high because you have a drooping barrel, then the scope may be fine, but unable to hold zero. That is the cause of 99 percent of accuracy problems.

B.B.

The 52 is a side lever so I’m not sure if the reference to the 45 applies.

The instructions for the RWS cleaning pellets say to “fire the cleaning pellets as you would a regular pellet”.

Again, the 52 is a side lever rifle, so I’m confused by the reference of a “drooping barrel”.

Brian,

The fact that the 52 is a sidelever has nothing to do with how the gun operates. It is still a spring piston powerplant. The cocking method is divorced from the rest of the powerplant.

Now, the 52 does have a sliding compression chamber, and that does make a difference in some ways — though not in the one we are discussing. And the 52 does have a synthetic piston seal that makes all the difference in the world. My answer was suited to guns with leather seals — not synthetic seals, so you were right to question what I said.

As for RWS telling you to fire the cleaning pellets, you have to remember that these companies are staffed with people for whom the job is just 9 to 5. They are not airgunners, and many times what they write in the instructions for their products is something they have read in other instructions for things the company sold many years before. In other words — they simply do not know and are not interested in finding out.

“Cleaning pellets” are simply pieces of felt that a marketeer sold in the 1970s to airgunners for cleaning guns that are far less powerful than they are today. They are a poor joke and a travesty, foisted on an unsuspecting public by marketeers who have no idea whether they work or not.

Dr. Robert Beeman, whose company sold these cleaning pellets, revised his instructions for using them several times, when he discovered they do not cushion the blow of the piston like lead pellets do. His final instructions were to load as many as 6 cleaning pellets in-line in the barrel, in hopes of cushioning the piston blow. Airgunners soon discovered that was impossible to do, and in the late 1990s there were lots of discussions of the “right” way to use felt cleaning pellets.’

Today the accepted method is to push them through the bore one at a time with a cleaning rod, which is the same as pushing a patch through. So, why waste your money of a product that doesn’t work?

But the fantasy of cleaning pellets will continue, because the retailers haven’t got a clue about how they really work or how to use them. And their title — “cleaning pellets” — sounds so right to people new to the hobby.

Now, to the barrel droop situation. Droop isn’t the right word. Downward slant is more correct, and, yes, fixed-barrel airguns can have it. In fact, the Diana (not RWS) 48/52 is notorious for being a drooper. That’s why I developed an anti-drooper base for the rifle with Leapers several years ago. Tens of thousands of fixed-barrel sidelever Diana 48 and 52 rifles were finally able to hold a zero, because their scopes are no longer adjusted too high. Read the 3 articles I wrote about mounting scopes and sighting them in on the articles page.

/articles

/article/All_about_scopes_Part_1_January_2005/19

/article/All_about_scopes_Part_2_February_2005/21

/article/All_about_scopes_Part_3_April_2005/22

When a scope is adjusted too high, the erector tube that contains the reticle starts to “float” or to bounce around with the vibration of each shot. This is the number one cause of a scope that won’t hold zero and is responsible to a high percentage of scope problems. Get that scope closer to the center of its adjustment range and it suddenly starts to work as advertised.

B.B.

I have a Model 48 Diana RWS side cocker and would like to know what type of piston I have and where to oil the air rifle. I have bought many years ago Pyramid and would like to know what of oil to use, I have a plastic bottle of Beeman oil, I would like to know if I can use this oil on my RWS. The air rifle was bought about 10 years ago from Pyramid air what is recommended for this air rifle. Plus I have a Benjamin Nitrogen piston air rifle and can I use the same oil or what type of oil.

Robert,

Welcome to the blog.

Your Diana 48 sidelever can accept one drop of silicone chamber oil through the air transfer port every 3,000 to 10,000 shots. The air transfer port is the hole in the center of the sliding compression chamber. I don’t know what kind of oil you have, but it must be silicone chamber oil with a high flashpoint so it doesn’t detonate when the gun fires. If you read on the Beeman bottle the words silicone chamber oil, you can use it.

A Diana spring gun doesn’t need much oil. I never oil mine at all. The piston seal is self-lubrication to a large extent.

The Benjamin Nitro Piston II is a gas spring powerplant that also doesn’t need much oil.

Basically these guns only need to be oiled when they start squeaking when they are cocked.

B.B.