by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Two centuries?

- Reverend Alexander Forsyth

- Maintainence

- Danger

- Percussion cap

- Flobert

- Gallery guns

- Galleries again

- Recap

Today we begin a subject that lies at the heart of the airgun. Rather than try to defend that statement at this time, I will present evidence as we go, because the body of evidence is both large and spans much of the over two centuries of the rimfire cartridge history.

Two centuries?

Wait a minute, BB. I just read on Wiki that the .22 Short — the first .22 rimfire cartridge — was patented by Smith and Wesson in 1854 and launched to the public in their new revolver in 1857. Today is 2018. That’s only 161 years. How can you say the rimfire cartridge has been in development for over 2 centuries?

I will address that now!

Reverend Alexander Forsyth

Reverend Forsyth was a Scottsman, born in Belhelvie, Scotland on December 28, 1769, and died in the same town on June 11, 1843. He was a Presbyterian minister who experimented between 1805 and 1807 with a fulminate of mercury compound that exploded when hit with a sharp blow. He did not invent the compound, but rather worked with it to invent a way to use it. He knew immediately that his invention could replace the troublesome flintlock that often misfired, was subject to rain and water and had to be scrupulously maintained in order to work.

His first successful attempt at replacing the flintlock came in 1805. It was a small steel container, called a “scent bottle” for its resemblance to that now-obscure item. [At this time smells in public were overpowering and there weren’t many ways of masking them. Some women carried a small bottle of scent, or perfume, to block or mediate the foul smells.]

This is a double barreled pistol that has a scent bottle for each barrel.

The scent bottle fed a small amount of loose fulminate of mercury priming powder into a place where the hammer smashed it against an anvil. The explosion was contained within the bottle and was directed into the barrel by a channel, in the same way that a flintlock directs its explosion into the main powder charge. There were a couple of problems with this.

Maintainence

First — remember that maintenance I talked about with the flintlock? The scent bottle has the same requirements, but now they are not as accessible to the shooter because of the bottle. You may get a couple shots without cleaning, but when you need to clean the lock it needs to be opened for access. A flintlock is exposed in this area and much easier to clean. Forsyth made his locks easy to dismantle for this reason, and at the time (before 1820) repeating arms were almost unheard of. So the slow speed of gun management did not deter people from the novel new system of percussion.

Danger

The bigger problem, though, is having a container of explosive powder next to your face when part of it explodes! History doesn’t report many cases of explosions with Forsyth locks, but his scent bottles were very closely-fitted and therefore expensive. Not that many were produced. I have read that Forsyth used a tapered plug that was covered with platinum to separate the reservoir of priming powder from the charge being detonated, but other less exacting makers that followed him made scent bottles that were cruder in construction. I have to think those might have had problems.

There is a lot more to Forsyth’s story, but I’m now going to skip ahead to the next significant step — the invention of the percussion cap.

Percussion cap

The percussion cap is a copper cap that contains a small disk of percussion compound at the bottom. When they first came out, around 1820, the compound was still fulminate of mercury, which is very corrosive. Less corrosive compounds were found over time, and today’s percussion caps are non-corrosive. Today’s percussion caps are quite similar in construction to the first ones in all other ways.

These modern percussion caps aren’t much different from those made 150 years ago.

The cap is placed over a hollow tube called a nipple, where it can be struck by a hammer to initiate the explosion. The hammer keeps the explosion contained (the copper cap is often blown apart by the force) so all the force of the explosion is directed down the hollow nipple and into the main powder charge in the barrel.

The nipple on this French model 1822 pistol was added during a conversion from flint to percussion in 1826 (the date of the conversion is stamped on the gun). Notice that the end of the hammer is cupped to prevent the exploding percussion cap from sending flying copper pieces out to injure the shooter.

Where the scent bottle was almost unknown in its day, the percussion cap gained immediate attention among shooters — most of whom were either hunters or soldiers. By 1825 the firearms world was embracing percussion ignition. Champions of the new system touted its reliability, speed of reloading, speed of ignition (so-called lock time that the flintlock was responsible for) and most importantly, resistance to weather. Are you aware that battles in those days were often cancelled because of rain that made bowstrings slack and flintlocks unreliable?

The naysayers asked what happens when they ran out of percussion caps? Any self-reliant man of the day could find flint and knap it into shape for his gun. But when your percussion caps ran out, all you had was a long club!

By the middle 1830s the flintlock system was fading away. But then something very strange and exciting happened. Nobody knows who came up with the idea, and it probably sprang up in several different places in Europe around the same time. I’m talking about the idea of using the power of just the percussion cap to launch a small lead ball!

This is the birth of airguns, but not for several more years. First, people learned that a percussion cap would launch a small lead ball very fast. The smaller the ball, the lighter it was, and, with experimentation, 4mm was found to be a good size. They didn’t know it then, but they were topping 1,000 f.p.s.! Then somebody wondered if rifling the barrel would improve accuracy, which of course it did. Thus the Zimmerstutzen was born! It would then evolve on a path of its own and is still alive in Europe today.

Flobert

However, at close to this same time (1845) a Frenchman — Louis Nicolas Flobert — modified a percussion cap by putting a rim on its closed end. That allowed the loading of the cap into a chamber that was bored straight through from one end to the other.

The priming compound went into this rimmed cap wet and was spun into the rim by centrifugal force. Because it was concentrated in the rim, a firing pin or the narrow end of a hammer would strike the rim and crush it, causing it to explode. This invention did away with the need for a nipple, and the bore could be open on both ends of the barrel. The rim sealed the breech. This is the beginning of both the rimfire cartridge and also of the breechloading cartridge!

There were flintlock breechloaders before this time (Collier and Hall), but they had problems sealing the breech against gas loss and were ultimately unsuccessful. With a copper cap-turned-cartridge in the breech to expand with the pressure, the gasses could be sealed.

Flobert made his cartridges and guns in both 6mm and 8mm, with the 6mm being the most popular. The earliest guns did not have a breechblock. They used just the weight of the hammer plus the strength of the hammer spring to keep the hammer down on the cartridge when it exploded. But breechblocks followed soon after.

In the U.S. companies loaded Flobert-like cartridges, but they made them in inch patters and soon settled on .22 caliber, which is very close to 6mm (.243). The first cartridges were called BB caps, however the exact meaning of that acronym is no longer known. Early 20th century catalogs refer to them as Bulleted Breech caps, so that name has trickled down to today. I have also seen references to ball breech caps, but they are not as common as Bulleted Breech caps.

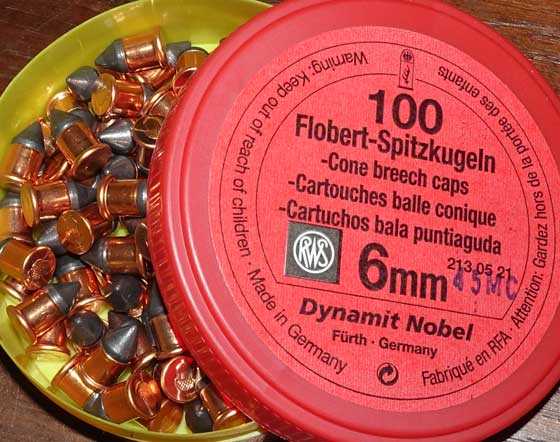

The next development, though, is well known. Manufacturers started putting conical bullets into these rimfire cases, calling them Conical Breech caps, or just CB caps.

This box of RWS cartridges ties everything together. They are called Flobert pointed bullets, but also Conical Breech Caps. They are labeled as 6mm but the bullets measure .222-inches in diameter, which is 5.64mm, and they are shot in .22 rimfire guns!

Gallery guns

Flobert guns abounded! This was an idea whose time was overdue. It brought shooting indoors — safely and quietly. One place it was soon seen was in shooting galleries. No longer did a shooting gallery have to be outdoors. Flobert cartridges made it possible to set galleries up inside buildings, out of the weather. Flobert cartridges were also quieter — a major benefit for indoor shooting. Because of the shorter distances on indoor ranges, the cartridges didn’t need to be as powerful, which played into the CB cap design.

In the early 1850s Horace Smith and Daniel Wesson acquired a patent for the bored-through cylinder. A revolver cylinder was bored straight through from front to rear and could be loaded in the rear and fired out the front. Until this time, all revolvers were loaded from the front and fired their bullets back out the same way. The back of the cylinder was closed except for a percussion cap nipple. Loading from the rear sped up the process of loading many times!

To go with their first revolver — the First Model S&W — Smith & Wesson took a CB cap and filled it with three grains of black powder (which was just called gunpowder in those days). The bullet was a 29-grain lead conical with a heeled design. The heel of the bullet inside the case is smaller than the bore but the part of the bullets that’s outside the case fits the bore perfectly. The heel is designed to expand when the cartridge fires. That seals the bore.

This nice S&W first model revolver was the first firearm chambered for the .22 Short cartridge.

During the Civil War men on both sides bought and carried this small S&W revolver for use in tight situations. Given that the cartridge was loaded with three grains of black powder and the bullet was fired from a short revolver barrel, it was probably lucky to develop 15-20 foot-pounds of energy at the muzzle. A standard speed Short bullet today develops around 56-58 foot-pounds.

This cartridge was just called a .22 rimfire until 1871, when the introduction of the .22 Long cartridge caused this one to gain the name Short.

Galleries again

The new .22 Short was also great for indoor galleries except for the smoke it produced! By the time it came to market, some shooting galleries were using hand-built airguns that saved them a lot in ammunition costs. These airguns were expensive — ranging from $10 to over $35 at a time when a Flobert-type rifle might cost $5 or less, but the savings in ammo costs paid for the airguns in a short time, if the gallery had a lot of traffic.

Recap

So, .22 Shorts owe their existence to CB caps, that owe their existence to Flobert caps, that owe their existence to percussion caps, that owe their existence to the developments of Reverend Forsyth and his scent bottle lock.

The .22 caliber was probably based on the 6mm Flobert that is so close in size that even today many people shoot 6mm BB caps and CB caps in .22 firearms. I have done so many times.

I didn’t make the connection in the report, but the Zimmerstutzen I mentioned earlier is where the modern 10 meter target rifle came from. All of the rules of that sport of target shooting and the targets came with it. So, we are already deep into the history of the airgun, and there is a lot more to come!

BB

Nice report today. I thoroughly enjoyed reading it.

And at the beginning of the last weekend blog I wasn’t sure if you was connecting rimfire with air guns when I made the comment about the higher powered CCI low velocity rounds shooting similar to my .25 Marauder. But now it’s more obvious. 🙂

B.B.,

That first sentence of the last section brought a flashback of the old series “Connections” by James Burke. I hope this link can be helpful: https://www.youtube.com/watch?v=_rCZHG_eEak

Will Friday reveal the next part of this historical series while you gather more samples of ammunition for the new Remington model 33 to try?

Siraniko

Siraniko,

Well, I was hoping to do the accuracy test for the Crosman 102 for Friday and the next installment of this report on Monday. We’ll see.

B.B.

B.B.,

I hope you are feeling better. I was thinking you would be taking it easy this week and use mainly historical articles like this one. That should give you rest and less stress from the weather.

Siraniko

Siraniko,

I am feeling better, but not yet entirely back. This article was so relaxing to write that I think it was a big part of the cure!

B.B.

Dear BB

I enjoy your stuff. I am a 60 + year old new shooter and I’m lovin it. Especially airguns and rim-fire I am Working on a Crosman 180 (I read your articles) and I want your opinion and the forum do I blue or cericote what d’yall think?

Scottnpatty

SnP,

You have to be approved before your first comment will post. You are now approved and your comments will post after you submit them.

B.B.

SnP,

Welcome to the blog. My vote is for bluing for that gun, I am old fashioned and like the classic looks of the 180.

Of coarse beauty is in the eye of the geezer. If you go with the Cerakote and do it yourself you will have to tell us how you did it and how it turns out.

Don

B.B.,

Most folks are aware of the recent scarcity of .22 ammunition. I wonder to what degree that has helped the air gun industry do so well recently? After all, there are many air rifles these days that are capable of doing much of what .22s are used for (pesting, plinking, small game). On the other side, I wonder if air guns will eventually overtake the simple .22 rifle, perhaps the most common cartridge firearm.

Michael

Michael,

I don’t think that will happen in the next 20 years or so. After that, you guys are on your own! 😉

B.B.

B.B.,

Well, if I’m still around in 20 years, I might be reduced to shooting at flies with a spud gun from a wheelchair in the courtyard of a nursing home! =8^O

For what it’s worth, .22LR cannot be scarce anymore as I regularly see it and 12 gauge (always) and 20 gauge (usually) shells on the shelves of my local big box store. They also have Pyrodex (always). Occasionally, they will have 9mm, and I once saw of all things one lonely box of .44 Magnum.

Michael

Michael

I see various brands and type of regular .22 rimfire in stores now. Always some on the shelf.

But I don’t see much of the lower velocity .22 rimfire on the shelf. Well other than the ones that people have learned don’t work.

It’s hard to find those CCI 40 grain 710 fps long rifles. That makes me wonder why. Don’t know if it’s because CCI don’t produce them as much as the other bullets or if people like the lower velocity and less noise they make. My way of thinking is that if I wasn’t a air gunner and I had a .22 rimfire. Those lower velocity CCI’s would be my choice for pesting. There really isn’t anything else other than a shot gun. And even if only a .410 shot gun you have to be careful if you shoot in or around a barn. Plus just to noisy. Especially if you have neighbors or even farm animals.

And also on your comment of scarcity. You did not mention .410 shot gun shells. And don’t know about you. But I hardly see .410 shells anymore. I wonder if that is from the rise of more .410 self defense pistols. Seems like whatever has become popular. The harder it is to get. It goes in waves it seems.

Gunfun1,

Might subsonic .22 LR ammo not produce enough pressure to operate some blowback-based semi-autos? If so, that might explain their lack of support by some shooters.

Michael

Michael

These are what I’m talking about. And they work in my semi-auto rimfire.

http://www.cci-ammunition.com/products/detail.aspx?use=3&loadNo=960

If anything that’s why they are hard to find because they work.

B.B.,

This report is the Rosetta stone for me and makes it clear how we went from the first gun to the modern. I have wondered about this for a long time. Now it all makes sense.

Thanks

Don

Don,

Your comment means a lot to me. That was exactly what I was trying to do. And there is a lot more to come.

B.B.

B.B.,

Fascinating stuff. I would imagine that you did quite a lot of research to put this report together. Nicely done.

That first picture of the double barrel pistol is a treat all by itself. That workmanship is pure art.

Good Day to you and to all,… Chris

Chris

Heck BB’s got this stuff memorized in the back of his head.

BB,

Thanks for this trip into the past. I am a bit of a history buff and this helped to fill in a couple of blank spots for me.

BB

This is one of your finest. You amaze me with your historical knowledge of all kinds of guns. Lots to learn from this report today about evolvement of firearms. You have often mentioned shooting galleries but until today I did not realize they put both .22’s and airguns in fast forward.

There is a collection of converted firearms on display nearby. Some date back to 1600’s. I’m thinking they have more collector value than I had thought before reading today’s report.

Hoping you are recovering.

Decksniper

Decksniper,

The shooting gallery concept dates back to at least the 1300s, when towns had archery rages set up permanently or on special occasion for festivals. When firearms got sophisticated enough to be used by most people, the gallery idea was already there from the archery ranges, so it took hold. But today’s report documents the real beginning of the small or indoor gallery.

B.B.

History buffs

Look for search and type history. A large index of historical topics are there for your enjoyment. I just discovered it.

Decksniper

Decksniper,

Or, you could just click on the link I provide in every historical article at the top of the page.

B.B.

Thanks B.B.!

Really enjoying these blogs!

Hank

B.B.

Great article, didn’t some of the Flobert rifles come with very fancy schuetzen style stocks? I’m assuming those stocks would be custom fit to the shooter much like a tyrolean stock.

Codeuce,

Actually, there are Zimmerstutzens that use a Flobert action, but shoot Zimmer (4.0mm to 5.45mm) ammo. Read the Zimmerstutzen article.

B.B.

BB,

Glad you’re feeling better. It’s a real testament to your skills that you could put an excellent report like this together while convalescing.

On the subject of shooting galleries, I’d like to know what volume of people a successful one would service in a day and at what cost to the customers. If anyone could shoot in them were there big safety issues since, and I’m only guessing here that they were mostly in large cities, country folks probably got all the shooting they cared for outside their doorstep and the city folk might not know as much about gun handling as they should.

Halfstep,

At Frontier Village where I worked in college, our outdoor gallery (used tethered airguns) had 6 positions (I think) and could handle about 250-300 people each day. One turn was 12 shots, as I recall.

The galleries were in cities and larger towns for two important reasons. The first was the population you mentioned. The second was out in the country, people were still shooting muzzleloaders that were cheap and available.And country folk were more acquainted with firearms. In fact, the galleries sprang up after theCcivil War because so many city men had been introduced to guns during the war.

B.B.

BB

Thanks for a great article. I always enjoy these histoical segments.

Gerald

BB

Maybe a evolution of targets they shot at could be thrown in the report too.

GF1,

I don’t know enough to write about the evolution of gallery targets, but I have seen my share of really cool older ones.

B.B.

BB

That would be great if you can throw in that information. I always wondered what they shot at.

You know how targets make a difference in the type of shooting you do.

My mind keeps having flashbacks of shooting out the red star when the carnivals came to town in the summer time. And I’m sure that is nothing like what they shot at.

But then again. That’s why I mentioned it. Would love to see any of the targets they used.

GF1 and ChrisUSA,

If you guys will remind me after SHOT next week I will try to work in a historical look at targets. I have them going back to the early 1400s.

B.B.

BB

Will do. 🙂

B.B.,

Will do,…. my best. 😉 Yes, that would be interesting. Automated ones would be of high interest. How was something automated back in the old, olden days? A person on a crank wheel? Then of course, any of the more common ones. I am sure that there is someone, somewhere, that collects old targets. Maybe even a Blue Book of sorts?

Chris

Chris

Maybe they were wind up metal stamped steel targets that moved around.

I remember something like this. And I’m sure it was in the 60’s and probably earlier.

I think BB posted some in the past. As well as me.

But the spring powered stuff was common back then.

GF1,

I do remember all of the wind up stuff. Not so much targets, but lots of other toy things.

Great article BB. I like how you tied together different developments into a continuous line, really well done. I found particularly interesting the role of the shooting galleries, of which I had no idea. One request, would be possible in a future blog to comment on pin guns (Lefaucheaux)? I have seen some in museums but I don’t know much about them. Henry.

Henry,

Nor do I. They always seemed so strange to me.

B.B.

BB

I agree this is was very enjoyable episode. The history is fascinating and enhances the enjoyment of all shooting.

I’m wondering if you have any information about how the “cap” guns we played with when we were kids came about. The ones I recall had a paper roll of caps. I see they are still available:

https://www.amazon.com/Parris-Stagecoach-Single-Holster-Shots/dp/B06Y3PH3D8/ref=pd_sim_21_6?_encoding=UTF8&pd_rd_i=B06Y3PH3D8&pd_rd_r=1HAM590Q9XRYNRX84EEB&pd_rd_w=VsSFd&pd_rd_wg=g70KY&psc=1&refRID=1HAM590Q9XRYNRX84EEB

Really impressive at 7:00 minutes remaining in the CCI tour to see how much lead is consumed in a day!!

For those wanting more gun history this is a great source:

http://firearmshistory.blogspot.com/2010/05/rifling-manufacturing-hammer-forged.html

Looking forward to the next installment.

Idaho,

Are you reading my private files? 😉

Cap guns, indeed. How about a cap gun that was used un the Civil War?

B.B.

B.B.,

That might work for a shot or two,.. until the person that it is being fired at realizes that they are not actually being fired at. Or were they? A black powder replica revolver with (just) percussion caps would essentially be a cap gun,.. wouldn’t it. I used to have a Navy model many years ago.

Chris

BB

My computer skills are light years from any hacking of private files 🙂

Somehow I’m not surprised though that you would have the scoop.

Can’t wait to find out about how they might have been used in the civil war. Some kind of training, or signaling I’m guessing.

Idaho,

I think perhaps this kinda cap gun from the civil war; https://www.youtube.com/watch?v=1iDS9w-i9yU

Mike

Mike

You are likely right. I enjoy reviews by Hickok45.

The Enfield being from England gives reference to their long history of gun making, now carried over in their fine airgun production.

I can get stuck watching hickok45 for too long, entertaining indeed. That was an older video using a replica, I saw one from 2017 and he has acquired one actually used in the civil war.

And yes again on the quality of English air guns.

Idaho,

A “softer” report from a random fire might lead the enemy to think that the shot was from a further (and hence safer) distance and might prompt them to flush into the open,.. at which time the opposing side would bring out the real stuff? Diabolical? Perhaps. I am sure far worse diversion tactics have been employed in warfare.

Chris

Sound deterring was something that some learned.

And some wished they learned.

All is fair in love and war:)

Idaho

What happens when you tape a strand of some of those paper caps on a steel spinner and shoot at them with a air gun? Even blanks taped to a spinner.

I know reactive targets. 🙂

GF1,

Yea, the rings and the paper rolls just made it to the Fri. shopping list! 😉 I did take a quick cruise down the toy aisle (yea,.. I will admit it!) and saw nothing but Nerf and Nerf-ish stuff. Might have to go on-line for the good stuff that goes “pop!”. Even percussion caps for black powder. At a 1/4″ or less on all,.. that would be some mighty fine accurate (or lucky) shooting for sure.

Chris

We still got a bunch of paper caps that come in rolls of 5 if I remember right without looking the kids had for their cap guns. Haven’t tryed them for about a year or so now. Kept them in a cool dry place tough. So they should be good still.

And you know PA does sell blanks for firearms. But nothing in .22 caliber. And I’m pretty sure I know why that is.

But here’s a link if you want to check it out.

/product/umarex-8mm-k-blanks-50ct?p=1042

/product/umarex-9mm-blanks-for-revolvers-50ct?p=671

/product/walther-9mm-blanks-for-full-semi-auto-pistols-50ct?p=672

And you know what else makes a nice pop when you show at it and hit. The nail gun cartridges. The gray and brown color code are the weakest.

And no the .22 rimfire nail gun cartridge’s will not fit in a .22 caliber Air gun. They are a bigger diameter. And I’m sure because of that purpose.

And another thing. If you ever try the low velocity tannerite. Beware. They go boom good. 🙂

GF1,

Long story,.. short. Idiots. Tannerite. Loaded in a broken microwave. Phone video. Open fire. Previously said broken microwave door comes flying back 40 yards at the shooters,.. but about 20′ to the left. Microwave door goes out of view. Until,.. they look at the buddy’s truck that was parked to left. HUGE dent in the driver’s door. End of story. Me thinks?,… no thanks.

Chris

Dumb is as dumb does.

There will always and I’m stressing always will be those type of people like that.

Probably those are the ones that should leave the trying to others in more way than one.

You know what would be fun. A shooting party.

Or should I say get together for those that think a party has to be with those other things.

But seriously good times can be had if you think it through and include other people in the thought process.

Safety and common sense is more important than one can imagine.

Chris

I just realized your talking about those little plastic caps that were held together with a plastic ring connecting them all.

Me and Idaho are talking about the paper cap rolls.

GF1,

BOTH would be fun to have a go at!

Chris

🙂

GF

I have not tried that.

Suddenly sales of cap rolls on Amazon are spiking…

Idaho

Yep. All of a sudden there will be a shortage of paper caps.

Guess I better stock up on them now. 😉

Idaho

Thanks for your history site. There is a good piece on the Whitworth rifle and eye catching accuracy comparisons vs the Enfield 1953.

Decksniper

Correct the date to 1853.

Decksniper

Deck sniper

You’re welcome.

So much good reading there.

Good evening all,

Could someone please direct me to the article that mentions some sort of lubrication mix that utilizes automatic transmission sealer?

Larry in Algona

Larry,

/blog/2016/01/a-proven-co2-fix-for-leaving-guns/

B.B.

Thank you, Sir!

B.B.

Should there should be a warning on the blog you linked to about using transmission sealer on PCP’s? Clearly the article is about CO2 guns but just saying.

I would think it could become explosive under high pressure, but not really sure.

Not a lawyer and don’t play one on TV.

Mike

BB and Fellow Airgunners

This has to be another of your many excellent blogs that tie in .22 rimfire ammunition, and the humble beginnings of the sport of airgun shooting we all know, and love today. You seem to be a bottomless pit of information when it concerns the shooting sports.

When I first purchased my single shot .22cal Cooey, I always purchase .22 long rifle ammunition exclusively, as I believed the speed would offer me the best accuracy, as well as knock down power. I knew nothing about, nor was I concerned with CB shorts, or other .22 ammo that advertised a slower fps. I was about 15 years old, and a victim of advertising that touted speed over all else. Information to the contrary was more then likely out there, but without the benefit of a computer, I would have spent hours in a public library pouring over tombs of information that probably would have seemed meaningless to me at that age.

Thanks to you, your blog, and the usual knowledgeable comments, I’ve lived up to the adage that you can still learn something new every day.

Ciao

Titus

B.B.

Just finished reading today’s blog. I thoroughly enjoyed the report. I learned some things that I have always wondered about in regards to BB caps and CB caps. I’ve seen them but never knew anything about them. When I was a youngster I believed what may have been an old wives tale, that .22 shorts were not accurate and would lead the barrel. So I always shot .22 longs or .22 LRs. I know that .22 shorts were not accurate in my Winchester .22 semi-automatic.

I have an old Remington single shot .22 that was passed down to my dad and then to me. My dad told me that his dad only used it to butcher hogs. He said that grandpa could hit a postage stamp at a good distance. I have it in my gun cabinet but one of these days I will get it out and check the model number. It looks a lot like your model 33 and has the bolt that you have to pull back to cock it. That’s the gun my dad used when I first learned how to handle and shoot a firearm. He told me “Don’t let that bolt slip out of your fingers when you cock it.” It does have some history.

Geo

Thanks, BB; I almost skipped this one thinking, “Ah, I already know all about this.”

Nope; I was wrong; you brought in and tied together some facts I did not know.

As usual, great job on your part, and a wonderful history lesson…also, a great read; thank you!

Fascinating! Thank you, Tom, your historic spins are the best.

B.B.,

The history of firearms and air guns is truly interesting. I just watch the linked video. It is not about the .22 but it is about the development of rifles used for sniping, from the beginning to present day. The history of the .22 is no less interesting.

https://www.youtube.com/watch?v=RN72np_cE2k

Your report does remind me of many years ago. It was fair time in Jennings Louisiana. Fair there was somewhat different than the fair in Beaumont. Their carnival had the bb machine guns and the infamous diamond I couldn’t shoot out. They also had .22 pump rifles neatly chained to avoid turning the muzzle away from the little shooting gallery. Both were fun. I would like to have another go at it.

Glad to hear you are on the mend.

~ken