by Tom Gaylord

Writing as B.B. Pelletier

Diana 27S.

This report covers:

- Trepidation

- Disassembly

- Anti-beartrap mechanism

- Pictures!

- Secret washer

- Remove the trigger?

- The rest of the disassembly

- Cleaning

- Lubrication and assembly

- Hit the wall

- Frustration

- The solution

- The final solution

- Denny was a pattern maker

- The irony!

- One more thing

- Summary

Today I do something different. I show you a tuneup that is not complete. I do that because the monster has been vanquished and I will be able to get the Diana 27S back together to report on the performance after a cleaning and a lube tune. Here we go.

Trepidation

When I began this job a week ago I had trepidation because of the anti-beartrap mechanism Diana put in this model. I have stripped other springers with anti-beartraps before and I’ve always been successful, but their presence complicates the rest of the powerplant quite a bit — especially the trigger.

I also knew that the 27S probably had the trigger from the Diana 35 instead of the trigger that’s found in the 27. They are similar, except the 35 trigger has a more powerful spring pushing the inner ball bearing cage. And that particular spring also has a guide rod that the 27 spring does not have.

So, I took a lot of pictures as I worked. It turned out those pictures saved the day, though not in the way you might think. Explanations are coming.

Disassembly

First the stock is removed to get to the barreled action. Since the 27S has an articulated cocking link it has an additional stock screw on the bottom of the forearm. I was prepared to see that screwed into a steel bridge that the link passes through — to keep it from buckling. But there was no bridge. The screw just has a rounded end for the link to slide on and the absence of a mark on the link told me it had never touched that screw. The stock keeps the link from buckling!

That screw under the forearm was supposed to screw into a steel bridge that the cocking link passed through. But it didn’t.

The forearm stock screw attaches to this threaded bushing inside the wooden forearm. The tip is rounded to allow the cocking link to slide over it, but the link never touched it! The wood of the stock keeps the link aligned.

The end of the forearm stock screw is rounded to allow the cocking link to slide over it freely, but the link has not touched it yet.

Anti-beartrap mechanism

Setting the stock aside, I now examined the anti-beartrap mechanism.

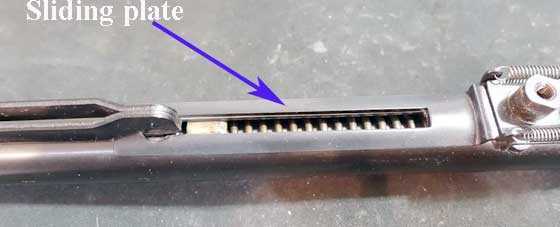

This picture shows the long sliding plate of the anti-beartrap mechanism. Two springs pull it into the trigger when the cocking link moves far enough to permit it.

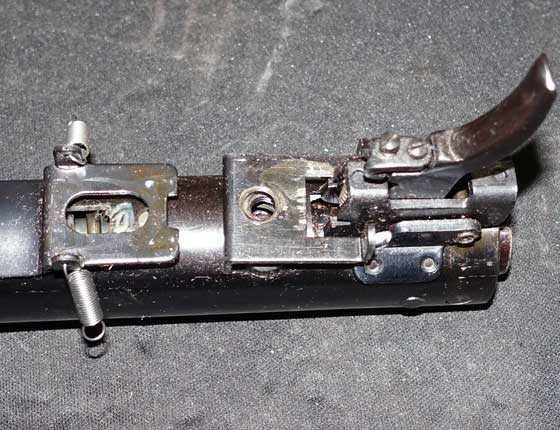

This is the anti-beartrap mechanism interfacing with the trigger assembly. The two springs pull the sliding plate into the trigger when a notch in the trigger blade permits it to enter.

At this point I thought I was home free. This mechanism is simple and looks straightforward. But I was about to encounter a problem!

Pictures!

Because this is the first time I have seen this mechanism, I took a great many pictures of it. And they saved the day several times. The large bolt in the center of things is where the forward triggerguard screw attaches. It also limits the movement of all the anti-beartrap parts to a short range of movement that you will see in a moment. But that wasn’t the most important thing. I will get to that in a bit.

The bolt in the center of the anti-beartrap (arrow) limits the movement of the rest of the parts.

Secret washer

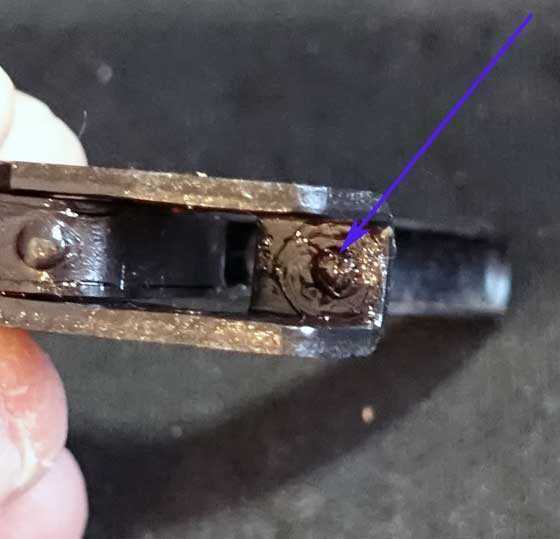

Here is the first surprise this mechanism gave me. After I disassembled it completely a small thin washer remained on the spring tube. Where it came from I had no idea, but when I reviewed all my pictures of the mechanism, taken while disassembling it, I found it! It took me quite a while (45 minutes of trying the parts various ways and then searching through the photos) to determine where this small washer belongs.

The arrow points to the small thin washer in the anti-beartrap mechanism that I found after disassembly. Only a portion shows, but it’s enough to determine which layer the washer sits in.

There is the tiny thin washer, hiding under the trigger blade. Apparently it is shy. Next to the trigger are the crosspin and the stout trigger spring that gave me so much trouble!

Remove the trigger?

At this point in the disassembly I decided to disassemble the trigger assembly from the spring tube. I believed that was necessary, though I now know different. It meant I also had to remove the anti-beartrap mechanism — also unnecessary. But I did it. At least you get to see the parts that are in the mechanism.

The trigger mechanism with the anti-beartrap still connected. This picture was very helpful later, as well.

The bolt has been removed, giving access to all the parts. I have also disconnected both anti-beartrap springs.

I don’t show all the beartrap parts apart, but they are basically several sliding plates of steel that can be seen stacked in the picture of the assembled trigger above that was taken before disassembly.

The rest of the disassembly

Now the barreled action went into the mainspring compressor for complete disassembly. With the beartrap apart and the trigger out of the rifle the two side pins that restrain the internal trigger parts (the black and silver cages and the ball bearings that are in the black cage) can be removed. Just press in on the black trigger cage with the compressor to take tension off the two pins and they fall right out. Then back off the compressor and the mainspring relaxes. You can then remove the spring guide and the mainspring.

At this point all other spring rifles require removal of the barrel to disconnect the cocking link from the piston. Then the piston can be removed. I did remove the barrel, and only later discovered that the two-piece articulated cocking link would allow me to remove the piston without first removing the barrel. However, taking the barrel off allowed me to lubricate the pivot bolt and the to pivot washers with moly grease, so the effort was not wasted. But this was another difference the Diana 27S showed me.

Cleaning

I cleaned all the parts with denatured alcohol. To get inside the spring tube I used a long dowel with paper towel wrapped around the end. The inside of the spring tube was surprisingly clean and did not appear to have ever been taken apart. I will let reader Carel address that, since the gun was his before I received it.

The other parts were also very clean for the 40 or so years this airgun has been around. The mainspring is not perfectly straight, but it’s close enough that I don’t think a replacement is needed.

Lubrication and assembly

I lubed the leather piston seal and the front and rear of the piston body, as well as the central piston rod, with moly paste grease. Then I lubed the mainspring with a light coating of Tune In A Tube grease. I also used TIAT to stick the three ball bearings inside the black cage for assembly. Even when the cage fell to the concrete floor the balls remained tightly inside. Now for assembly.

Hit the wall

And assembly was where I hit the wall. To this point in the report I had spent perhaps 90 minutes on a job that usually takes me 30. I was taking my time to understand the anti-beartrap mechanism completely. And I missed the biggest challenge of all — the trigger spring!

Frustration

I took the remainder of that day and two hours into the next day trying to put the crosspin and the trigger spring back in the rifle! I could get it partway, but never all the way in. I started with brute force and when I didn’t have enough of that I used wood clamps. Let me show you what challenged me so much.

This is where the trigger assembly goes. That small bump (arrow) holds one end of the trigger spring in place. As you can see, it is coated with TIAT to hold the spring.

The trigger spring is standing up on the small bump. It’s held by TIAT. The trigger assembly has to come down and connect to the other end of the spring.

The underside of the trigger assembly has another bump (arrow) that has to fit inside the trigger spring on its other side.

You might think that keeping the powerful trigger spring in place was a problem. But it wasn’t! Tune In A Tube is so tacky that it held the spring through all I did. The problem was pressing the trigger assembly down far enough so the crosspin could pass through both side and hold it. That was what I struggled with for the rest of the time.

The solution

The solution was in two parts. First I had to find a way to use the small wood clamps to press the trigger assembly down against the force of the spring and still not slip off the greasy spring tube and trigger assembly. I am now estimating that spring has 60-80 pounds of force. It’s way out of proportion with its size!

I played with clamping positions for hours, almost getting it before the clamp shot off and I had to start over. Then the lightbulb went off and I put the clamp where it could not slip, no matter what. It still slipped but now it was slipping because the force of the spring was bending and twisting its jaws. That made it easier for me to control.

It was now Day Three of my saga, but I knew I was going to succeed this time. It only took me 10 minutes and a few tries before I succeeded in getting the crosspin 3/4 on the way through.

The crosspin (arrow) is almost through the trigger assembly and the two anchor points on the spring tube.

The final solution

The second part of the solution was to ask my neighbor, Denny to tap the crosspin through the trigger assembly while I held it in place with a more powerful wood clamp. I had read somewhere that many hands make light work or men should learn to ask for help or something like that!

Anyway, I showed Denny what I was trying to do and then he tapped the pin though as I held the trigger assembly down and in line with the wood clamp. It worked the first time in less than ten seconds.

Denny was a pattern maker

Then Denny looked at the job and told me I probably needed to get a Kant Twist clamp for tight work like this. You see — Denny was a pattern maker. That’s a guy who makes jigs, fixtures and patterns for production work. He worked last in the aviation industry, making patterns for the B2 bomber.

I looked Kant Twist clamps up at Granger and saw a wide variety of cantilever clamps. They are indeed the tools needed for a job like this. Better still — DON’T TAKE THE TRIGGER OUT IN THE FIRST PLACE!

So why did I take the trigger out? Because I thought I had to! The 27S trigger is very similar to the trigger that’s in the Diana 35 — with one important difference. The Diana 35 trigger pin passes through the spring tube of the rifle, where the 27S trigger pin is below the tube. Let’s see.

The crosspin that holds the Diana 35 trigger assembly passes through the spring tube (yellow arrow) as well and has to be removed to get the piston out. The blue arrow points to another powerful trigger spring in the 35 trigger that was somehow easier to work with last year than this 27S spring has been.

As you can see, the Diana 27S trigger crosspin (arrows) hangs below the spring tube. That allows the piston to come out without the trigger being removed. And, unless my eyes deceive me, the wire in this spring is thicker than the wire in the 35 trigger spring.

The irony!

The irony of this misadventure is this — Diana designed the 27S to be easily maintained. The trigger doesn’t have to come out to remove the piston, nor does the anti-beartrap need to be removed. Even the barrel can be left on the gun! I didn’t know any of that up front so I did all of it and increased my work a lot. Of course I did get to examine, clean and lube all the parts, which is what you want to do in a tune, so I would have done most of it anyway. But I wouldn’t have removed the trigger!

This report is now a detailed set of instructions for the next brave soul to follow. That’s why I have taken the time to spell out all the details.

One more thing

When I disassembled the rifle I noticed that the trigger in the 27S resembles the Diana 35 trigger in many respects. The spring that pushes the black cage holding the three ball bearings is very strong, just like the one in the 35 trigger. It’s not like the regular Diana 27 trigger that’s weaker. The 35 cage spring has a short steel spring guide, while the 27 trigger does not. This 27S did not seem to have that guide when I disassembled the rifle, or if it was there I never saw it and it has now gone to the same place as all my missing socks.

The truth is, I found a photo that shows conclusively that there was no spring guide in that spring to begin with. I tried to assemble the action without that guide, but that powerful cage spring just bunched up. When I removed it, it was kinked. I don’t want to assemble the rifle wrong, so I ordered a new spring and guide from T.W. Chambers and will wait for them to arrive to complete this job. I don’t want to do this job again, so it’s worth doing it right this time!

There is no steel spring guide in the black cage spring in the Diana 27. It’s end would be in front of the end of the spring. Look at the same part in the Diana 35 above. Photo was taken before disassembly.

Summary

This has been a bit of a horror story of what can happen when you disassemble a spring-piston air rifle. This is perhaps the second time in the last 25 years that I have been so challenged — which is my way of telling you it usually isn’t like this. Please don’t be put off by this tale, but glean what you can from what I did and how it turned out.

Oh, and guys — please be open to asking someone to help you when you need a third hand. I mean — honestly! Pride goeth before a fall!

And this is why I like working on pumpers, gas and pre-charged guns.

Some o-rings, a few LITTLE springs. easy peasy…

(and by little, I don’t mean 1/2 inch long spring thats strong enough to be a front strut on my SUV.)

Those big springy things are mysterious.

Just kidding, glad you got it back together, and I will always remember to look at the spring path before removing things off the main tube.

I hope everyone has a great weekend.

Ian

B.B.,

I’m very glad that the 27s didn’t turn into a basket case. So no Moly grease above the screw with the rounded end? Doesn’t this mean the entire forearm is free floating?

Siraniko

Siraniko,

I didn’t put any moly there because the bolt isn’t touching the cocking link. There are two screws from the sides that hold the forearm, so no, it doesn’t float. This bolt is an extra.

B.B.

B.B.

You just made the perfect advertisement for all the airgun tuners out there!

I had to look up the “kant-twist” clamps, great stuff. All tool boxes should have a set.

-Y

PS why is the trigger spring so strong? Could you have replaced it with one that is less stout?

Thank heaven for Chambers and all the other vendors that make replacing 40year old+ parts possible.

-Y

Yogi,

I don’t know why that spring is so strong. Right now I suspect it has to do with the anti-beartrap mechanism. To keep it functioning reliably, that spring was made extra strong. But that’s just a guess.

I did try a lighter spring, but the rifle wouldn’t cock.

B.B.

Would it have been possible to completely disassemble the anti-bear trap system and still have the gun still shoot? I know B.B. would never let a gun leave his tuning hands that is unsafe.

-Y

Yogi,

The short answer is yes. It will not necessarily make the air rifle unsafe, at least no more than most sproingers. This bear trap keeps the barrel from flying up before you intend it to. No chopped off or mashed finger ends or bent barrels.

With most airguns there is some tuning and tinkering that can be done, but there are some things that should just be left well enough alone.

B.B.

Proper break barrel SOP is to hold the barrel with one hand while loading it with the other. I think you taught me that!

-Y

Yogi,

If you do not, you are a fool. Even with the bear trap. Murphy’s Law.

Yogi,

There was a time when someone else taught me! What goes around…

B.B.

Yogi,

I tried that and the rifle didn’t work. However, it also had the weaker spring in the trigger, so…?

B.B.

BB,

Glad you got it back together. I have been in more than a few of those tight spots with various mechanical things myself. You of course have a camera and a smart phone. I just recently got a smart phone,… so at least I can take descent pictures easily now. Before, it was the ol’ pen and paper,… making worded notes and hand drawn pictures.

Good Day to you and to all,……. Chris

BB,

Once again I offer my gratitude to the Wizard of Oz for allowing us to have another peek behind the curtain. I for one particularly enjoy these episodes as I enjoy taking things apart to see how they work. What is really nice is when you put these old gals back together they will likely work better than before.

RR,

I know what you mean. I just got an email from Chambers that my parts are on the way!

B.B.

BB,

Awesome! Maybe we will have a follow up next Friday.

RidgeRunner,

Friday? I think that the Godfather puts up the follow up by Monday. I want to see if the tune did anything to improve it.

Siraniko

Siraniko,

Me, too! Now that we have a good baseline of velocity I want to see what TIAT does to it.

B.B.

Wow! I just had the wildest experience. I tried to update my post and it told me I did not have permission to do such. It said I was logged in, but I logged in again and it took me to the WordPress site. I clicked on the blog name at the top of the page and it brought me back here.

I’ve been to Kansas and back and I did not even click my heels together.

RR,

There’s no place like home. 🙂

B.B.

B.B.,

“I also knew that the 27S probably had the trigger from the Diana 35 instead of the trigger that’s found in the 27.”

I have a 27D of roughly the same vintage. The broker who sold it to me even told me the original owner bought it new with a 27S. Is it safe to conclude it has that same 35-like trigger? (Mine is light and crisp, by the way..)

Michael

Michael,

Golly! I don’t know but I doubt it. I think it has the regular 27 trigger, which is the same one that’s in your Winchester 427.

B.B.

B.B.,

I just now picked up and handled my 27D, and in so doing, I rediscovered a second air rifle I bought from that broker. If I recall correctly, the orginal owner bought all three at the same time. The other one I have is a Diana 28! Both it and the 27D have the two-screw adjustment for the trigger.

Needless to say, I am perhaps the last person on earth who should mess with the internals of any air gun trigger, much less a three-ball sear model, hence your tuning (to perfection) my Winchester 427 / Diana 27.

Diana sure did issue a model for every number, didn’t they?

Michael

Michael;,

Don’t you love it when that happens? 🙂

Yeah, Diana not only used a lot of model numbers — they reused many of them to keep us all confused. For example I know of two completely different Diana model 30s.

B.B.

Michael,

It is beginning to sound like you have waaay to many Dianas. I am certain we could find room at RRHFWA should they decide they would like a little vacation.

RidgeRunner,

My wife would agree I have too many Dianas, and not a one of them is a person! If/when I decide to thin the herd, I promise to let you know. I already have, from way back, a standing “1st shot” promise to Gunfun1 for two of my collection (neither Dianas nor springers). Perhaps this summer for a few of them.

Michael

We can hope.

RR,

Hah! ;^) You flatter me, Sir.

Michael

Michael

Thanks for remembering me.

If ever you decide to do something let me know.

B.B.,

Ah! The 7/8 sized military trainer! I have come within a second of purchasing one or another of those many times, but the price is always pretty high, higher than my desire to have one, anyway. Besides, nowadays if I wanted somehting like that, I would probably purchase either a Mauser springer by Diana or a CO2 replica by Gletcher.

Or, I would continue to wait for the military rifle Holy Grail to appear on the market — a Garand!

Michael

I just read where FX is now producing a line of scopes. They are priced like their airguns.

Hi BB,

I’m still stuck on this idea that might help install the tough little spring. The picture of the pen spring engaged on the edge of the coke can should say it all. Maybe play around with this concept as applied to the trigger unit? … Assemble the unit first with the crosspins in place, but without the spring. Then laterally slide the edge of the housing between two of the spring coils. Then turn the spring on its axis so that it is screwed along the housing edge. Notch one end of spring onto the bump in the housing, then continue to screw the spring deeper until the second end is flush and can be pushed onto it’s locating bump. Can you see what I’m suggesting? I don’t know if it will fully work, but seems worthy of examination.

-Andy

Andy,

It might work, but I don’t know. Now that I have it together I’m not willfully taking it apart again! 🙂

B.B.

BB,

Did you try a flat head screwdriver? Insert driver head,.. insert spring,.. apply downwards pressure on spring (compressing said spring),.. push spring in,.. pull driver out (while holding spring in)?

Chris

Chris,

Many times. I bent a screwdriver shank!

B.B.

Andy,

That is a brilliant idea/concept. Turning the spring past the “jump in” point (or at all) would be tough as it is “boxed” in, limiting access. Nice thinking “outside the box” though!

I still like the idea that someone offered of putting a loop of wire in the spring coils,.. compress the spring in a vice,… twist tie the wire tight,.. drop in,… cut wire,.. pull wire out.

Maybe the more important question is to figure out how they mass produced these rifles and did this task (probably?) in a matter of seconds. That be the million dollar answer right there!

Chris

ChrisUSA,

I think Andy has a great concept too! I think B.B. has pointed out the limits of the concept…would you think it would work for you when installing a coil spring in an automobile suspension? I think the bent screwdriver shank is that tough spring showing who’s the goes!

The hammer spring on a DAQ Big Bore has surprised quite a few folks when they unscrew the end cap the first time or when they bugger up the threads on trying to screw it back on. I use a Nylon U jawed Kant Twist to do that task!

shootski

Well darn it.

I forgot to feed the squirrels tonight. One showed up just minutes ago and had nothing to eat but peanut butter.

Got them fed with peanuts, and just had one come down and grab one.

It’s eating right now. I need to be careful. They have short tempers and get irate very quickly. They could start tearing limbs off the tree and start throwing them at me.

tt

TT

I thought only woodchucks do that.

Gunfun1,

TT has some Branch Manager Squirrels living in his yard!

shootski

Shootski

Ferocious little critters they are.

I hear they will suck the blood right out of your neck if you get them rilled up on a full moon night. Bam and another flying vampire squirrel strikes again. 2″ long fangs and all. They say their fangs are almost longer than their body. Scarry.

GF1,

Really??? You did say that one leapt from a tree at you. There is some videos of “pet” squirrels going after a home burglar. In one, the police responded, entered the home,… and the squirrel leapt from the dinning table,.. right at the officers head.

2″ fangs,… eh? Working that second shift and watching them B-rated horror flicks late at night after getting home have taken a toll on your mind. 😉

Chris

Chris

Just regular squirrel attacks. Not even flying squirrels.

And no not 2nd shift 3rd. So see I’m really messed up. 😉

ChrisUSA,

Ever hear of Squirrel Girl?

A Marvel Comic Super Hero with 2-3″ extendable knuckle Spikes; much like the Adamantium ones that Wolverine has.

FEAR THE SQUIRREL!

shootski

Shootski,

I missed that character. We had fair bit of comics as kids. Many came from another family that also had 5 kids, but a bit better off. When I had money, I went for this one:

https://en.wikipedia.org/wiki/CARtoons_Magazine

After many years gone, it is now back in publication as a bi-monthly. I in fact saw a copy at Walmart about a year ago,.. and should have picked it up just to have a look see. They have a web site. This type of reading/entertainment material appealed more to me as I was always working on models, bikes, mowers and cars as a kid. If it could be torn apart,.. it was coming apart! 😉

Chris

ChrisUSA,

I remember CARtoons! I built model airplanes, ships, rockets, trucks, and cars when I was a kid. Then I got into the real full size things.

shootski

Just wanted to mention I’m getting my FWB 300 back tomorrow. Again. I can’t remember how many times I have owned this gun and I got a pretty good rememberer.

It keeps coming home. Maybe it’s trying to tell me something. Maybe I should start listening.

Gunfun1,

Is that the FWB 300 you hot-rodded?

Michael

Michael

Yes sir it is.

It’s got the Daisy style rear peep sight on it now and the factory globe front sight. Going to put a fixed 4 magnification UTG Golden image scope on it. They are a bit shorter scope and give more room to load the pellets. Well I think I am. I believe I still got one somewhere. I hope so because they don’t make them anymore and they are nice little scopes. We’ll see.

Michael

Changed my mind after shooting her again with the peep sights. She’s staying that way for a while.

Gunfun1

Carel likely has a FWB300 aperture if you plan to keep her.

Deck

Deck

A original rear peep would be nice. Did FWB make their own? The one that is on it does fine though.

Gunfun1

Think so but have been wrong before. FWB made more of these wonderful rifles than sights at the time when single stroke target rifles gained favor. This is one reason many are scoped. I got my FWB300S “for scope” from Carel. Works great with scopes that are not too heavy to mess with the anti recoil sledge. Later I decided I wanted the globe and aperture sights. Carel had them so I got them.

Your Avanti aperture may be just as accurate as the original. I expect your rifle can compete with any you own out to 40 yards.

Deck

Deck

I had a couple different scopes on this 300 throughout time.

Now remember this. This 300 is modified. By me. 🙂

It has shot out to 100 yards on a calm day with respectable results with JSB 10.34’s. So yep it works well with a scope too.

Gunfun1

I remember it is a “Gunfun Custom”. All the more reason to keep her in your family.

Deck

Deck

I agree. 🙂

GF1,

Nice pic.. I thought that you were looking into some of those high end ones,.. a year or so ago? I think they had lenses to magnify, lenses to change color, adjustable aperture, etc., etc..

Maybe you were just (thinking) about it?

Chris

Chris

I had the rear peeps with adjustable iris on one of my HW30s. But didn’t get into the magnifying front sights.

I do still want to try that some day.

Gunfun1,

Used FWB peeps are all over auction sights for about $100.

Your 300 has two springs end-to-end, right? So about how fast does it shoot?

Michael

Michael

No this 300 has one spring. The Macorni spring I believe it was if I’m saying the name right.

And I dont have the cast iron ring in it either. It has a o-ring instead of the cast iron ring. It took me about 3 times of taking the gun apart and putting back together to get the right fit o-ring I wanted for drag of the piston and velocity I wanted of the pellet.

It shoots the JSB 10.34 pellets at a bit over 700 fps. A real flat shooter with those pellets and bucks the wind pretty good out to 50 yards.

Gunfun1,

Wow! Wanna trade? Well, how hard is the cocking compared to stock?

Michael

Michael

Some years back I got 2 FWB 300’s from RidgeRunner. He even through in a extra stock and the sights. Even a flexible gun carry case. He made me a really good deal.

One of the guns was real nice and I did some body work to the stock and did s oil stained stock. It had the 2 factory counter wound springs. The guns went to Buldawg. Then I got the modified one back from him. He ended up selling the nice factory one. Don’t no where it lives now. But the other one came back to me which is the one I have now again that I would I have to say I owned at least 5 times now. It needs the stock done up and reblued. But it’s a shooter the way I have it set up.

So really you will be probably down grading rather than staying the same or upgrading. So probably won’t work really trading. Just saying. The way the gun sets it’s been trading hands for a $150. When I get the stock and action done it will probably sell for $250 or more. That is if I sell it again. Who knows right now what could happen with it.

Oh and cocking is still 2 fingers. Maybe a little harder than the factory springs. I think the right fit o-ring instead of the cast iron ring made the difference. Probably a combination of both the spring and the o-ring.

Gunfun1,

Does it still ride on rails in the stock as it is?

Michael

GF1

Yep still got the two 300s here shooting just as good as ever. i have my beater mini that has the maccari single artic spring in it with the steel ring shooting jsb 8.44s at 650 fps. i have used it in FT matches hitting targets out to 55 yards quite easy and it has enough power to drop them at that range.

Then i have the near mint condition 300 match L that we experimented with the o rings in place of the steel ring on the pistons years ago and it to has the artic spring in it but mine never shot quite as fast as yours does. its more of a safe queen now and only get shot occasionally to keep it operational.

I still have the two stocks that i got from you in the deal but have not fixed the broken wrists yet. I did swap out my match L action onto the walnut stock so its a real looker for sure.

Still out here and kickin ok but have had some more health challenges to deal with that I have finally got ahead of for now anyway.

Chris reached out to me and thought I would pop in to let you all know I am still shooting and tinkering with my ever growing collection of orphaned airguns.

I hang out on the GTA mostly now so if you get a chance pop in and join the fun. I still read the blog every night but just lurk for the most part.

BD

GF1,

Doesn’t a stock and action re-do actually subtract from the value? Or,… is that an mid-level upgrade? In general,…. I thought that it was better to leave things as is,…. and if “as is” is awesome 100%,.. then all the better. But in general,… leave as is.

Chris

Buldawg76

Good to hear from you.

ChrisUSA,

When reselling it’s always best to stick with the original. Any modifications will be to the desire of the owner but not necessarily to the buyer usually leading to lower price. That’s why Gunfun1 (if I recall correctly) always mentions that his modifications are reversible.

Siraniko

Michael

Yep still rides on the factory rails.

Still shoots pcp smooth.

GF1,

It is trying to tell you something. It wants to move back to RidgeRunner’s Home For Wayward Airguns.

RR

I’ll tell you the truth. I dont know why I keep letting her go.

I sold her to Dave/RAI this last time that made the AR butt stock adapters and stocks for the Crosman/Benjamin guns. She is still setup the way I sold her to him. Soon as I got her I loaded a JSB 10.34 pellet and hit a 1″ spinner at 35 yards standing unsupported. And to note again. That was with a peep sight.

She just hits always. All I can say is I’m glad RR home let this girl run free. She may of been around the block a time or two. But she knows what she’s doing. She’s a good one.

Gunfun1,

Nothing squirrelly about: “Soon as I got her I loaded a JSB 10.34 pellet and hit a 1″ spinner at 35 yards standing unsupported. And to note again. That was with a peep sight.” Even after working Graves! Or what Sailors call the Dawg Watch!

shootski

Shootski

Yep.

GF1,

No, no, no! You are misunderstanding her! She wants to join the other ladies at RRHFWA! She longs for the sunny afternoons hanging out on the veranda with the other girls and punching holes in paper or lazily flipping spinners. Her heart’s desire is to feel my hands upon her stock and become my mini-sniper.

RR

Sorry for now. All the girls at Gunfun1’s house was so happy to see her they all got out and shot together yesterday. It was a nice warm 55° winter day yesterday. They even took a break together while they watched us 4 wheel and caught up on whats been going on.

I think she’ll be happy here. But if she decides she wants to do some running around again I will let you know.

GF1,

I understand. You be sure to do that.

I had the Webley/Hatsan Tomahawk out some yesterday myself. The more I mess with her, the more I like her.

I am hoping by spring to have my range and shooting bench ready to go. Then I will really be able to stretch the legs on that HM1000X.

RR

I will let you know.

And it sounds like a nice plan you got there.

And suppose to be in the low 60’s today. Already 50° right now. Getting ready to go out and shoot and enjoy the day.

GF1,

I am certain one or more of the ladies will get out for a little sunshine and fresh air today.

RR

Enjoy it when you can.

RR,

What power level do you have the Tomahawk at? My 11.8 fpe R1 just gets sweeter ever time I shoot her. I can shoot the R1 better off sticks than my .177 Euro Maximus (probably because the R1 weighs about 2 lbs. more than the Maximus-both with scopes).

P.S. Your .357 RAW is now street legal for deer hunting in Tennessee.

Brent

Brent,

I cannot recall what the Tomahawk is doing right now. I need to pull out all my toys and play with it some. I do believe it is over 12 FPE as it has a good little jolt to it. There is the strong likelihood I will be tuning it down some in the future. It is right hefty. It is a good size sproinger sitting in a nice looking chunk of walnut. It may not be a very good shooting sproinger, but it looks good.

My RAW is legal here also. Gonna hafta try some of them thar slugs init.

Did some shooting down in my basement range this afternoon. I started out with my old Crosman 147 multi-pump. I shot 30 shots at a 1″ bull at 5 yards and 10 more shots at 10 yards. The best I was able to shoot were groups of 1″ at 5 yrds and 1.5″ at 10 yrds. That was best I could do with opens. Then I got my Diana RWS 34P out and shot at 17 yrds. I forgot how much kick that rifle has. I was able to keep most of my 30 shots inside of 1″ groups. Then to finish up, I got the Urban out and shot two 10 shot groups. What a difference. By shooting all three rifles, I could really feel the difference in their shot cycles. The Urban is so smooth, and the trigger so nice, it was very easy to shoot one holes groups with it at those 17 yrds. I think I am ready for spring pesting season. 🙂

Geo

Geo

That’s why I usually have 3-4 or more guns out shooting.

That helps you get good at shooting too just for the reasons you mentioned about your guns.

Buldawg

Hope you see this down here. Nowhere to reply above.

Good to hear from you on the blog again. And I thought at one time you sold the nice 300. Or maybe you was talking about it. And I think we came to the conclusion that both our chronys wasn’t reading the same. We tryed comparing several air guns and even some of those 710 fps rimfire cartridges in our .22’s. My chrony always seem to get higher readings.

But glad yo hear from you again. Oh and I got that 95 Mustang GTS. It’s a runner.

GF1

I may have thought of selling the nice 300 but only for a fleeting moment of insanity. Its just to nice of a looker and shooter to ever let go. Plus I am a hoarder by nature so its very hard to let my toys go unless its to someone I know will cherish them as i do.

Yea I remember our testing between our chronies and the higher reading yours always recorded. I do now have a Caldwell pro chrony as well as the old F1 alpha chrony and they both are within 5 to 8 fps of each other so pretty sure mine are accurate for my location at least.

I have been tuning most of my gun for the 12fpe level since our FT club has switched to shooting the UKHFT game which is set at 12fpe with any gun/scope setup with target from 8 to 45 yards and shot in prone, kneeling and standing positions with supported and unsupported lanes. The challenge is that once you address the first target you cannot adjust the scope at all for the rest of the match. So you can be competitive with a 200 dollar gun/scope just as well as you can with a 4000 dollar gun and scope setup. You have to set the scope so you have the best picture from 8 to 45 yards and use only holdovers for pellet placements and use bracketing to determine yardage to targets. I enjoy it better and actually have better scores than in the AAFTA game we shot before.

I have tuned my TX and B40 with the Tony leach 22mm skirtless piston kits he sells that shot right at 11.7fpe and cock with one finger and have virtually no recoil like a pcp that you can watch the pellet all the way to the targets. Its all completely reversible as well so no permanent changes to the guns.

Hope all is well with you and your family.

BD

Buldawg

I like the UKHFT rules better too. More like how you shoot when your hunting or pesting.

And I remember a little while back we was talking and you mentioned that about the kit you installed in your TX. Sounds like its working out nice. (Is that the one you got from me?) You did get a TX from me didn’t you?

And we have had some things go on at home but all good for now. You know how that goes.

GF1

I do like the UKHFT rules better as well as it is more like actual hunting and that’s what it is designed to be simulating. We are the first US sanctioned club here in the US and hope to hold a world match some time this year. We are also joining the US air rifle benchrest club as well to hold sanctioned matches for that as well. Some fun thing starting to happen in 2020 here.

Yep its still the TX I got from you that I put the kit in and I also put one in my B40 so as far as I know its the only B40 with a 22mm kit in it in the US. They shoot 7.9 grain pellets at 815fps and are capable of one hole groups at 30 yards if i do my part. A pellet on top of the scope turret does not move at all during a shot cycle. Its the difference of a 500 gram piston versus a 150 gram piston of inertia causing the recoil during the shot and the piston has a HW style piston seal as well as an o ring seal on the piston. It uses a TX355 12fpe spring with up to 2 coils removed to reduce the power to under 12fpe.

Glad to hear things are good at home, i know your wife had a real scare awhile back so glad that’s improved. i have finally gotten my severe sleep apnea under control with a new device called the Inspire that is an implant that senses when you inhale and sends an electrical impulse to your tongues nerve causing it to move forward in your throat opening the airway. I have had it about three weeks now and am finally getting some good sleep after over 2 years of little to no sleep and starving my mind and organs of oxygen at night ..

Still day by day here doing the best I can with each day i am given.

BD

Buldawg

Sounds cool what you all got going on at your range.

And man that’s some smooth shooting to not move the pellet on a turret. And I was going to ask if you went to a lighter pellet. Wasn’t you shooting the JSB and AirArms 10.34’s in it or was that your Marauder when you was shooting the other class? And I did a experiment one time some years back with a lighter piston I did up at work. I new that was the ticket for a smoother shot cycle. Problem is now I don’t remember what gun. Thinking more I just did a bench set up with a air and floating ball gauge. But sounds like a nice kit to me.

And yep wife had a heart attack a while back and a stent put in. Then I was in the hospital for food poisoning or something about a week after she got out of the hospital. We are doing good after that but wife was out of work last week or so with a rotator cuff sprain in her left shoulder but she went back to work at the end of last week and has been doing good. And you told me a while back you was going to try that for your sleep problem. Sounded scary to me but glad it’s working for you. The things they do now days. How has your wife been with her knee problem? I hope ok.

And we we got to keep chugging along. One way or another.

GF1

We are trying to change some thing up to get more particpation from younger shooter and parents with the new games. Make it easier and less costly to have as good a chance of scoring well if you know your gun and its shooting capabilities.

I was shooting the 8.44s in the TX but the 22mm kits prefer the AA 7.87s best in all the ones that have been fitted here in the US and UK so far. My B40 likes the CPL 7.9s but only because it has a looser bore and they tend to run in the 4.53/4.54 sizes so are a better fit to its barrel. The 22mm kits also speed up the lock time so the pellet is out of the barrel almost before the gun reacts which helps the hold sensitivity and accuracy. It was my mrod I shot the 10.34s in for AAFTA. I finally put that lightened and polished piston you did for me in my firepower crosman clone tuned to 12fpe and its a close rival to the 22mm kitted guns as well. Its not bad for a 40 dollar chinese break barrel.

I knew the wife had some heart issue but did not know it was a heart attack but glad a stent got here fixed up now. Hate you had some food poisoning as that’s no fun for sure. I got a bad left shoulder also but with everything else wrong with me it’s real low on the list of priorties, I can still cock my springers so can live with it for now. I had another stent put in in may of last year so 4 total now for me but no heart attack yet. I truly believe the stent and most other issues i have developed since 2016 are a direct result of my sleep apnea causing my brain and organs to be starved of oxygen when I do sleep since my blood oxygen saturation levels drop to 75% and below for quite a long time. Normal is 85 to 90% during sleep and 96 plus when awake..

The wifes knee is still causing her pain and issues and will never be 100% due to her bodies allergy to the metal used in implants even though its supposed to be hypoallergenic. She is also now allergic to the codeine in the pain meds the doc gives her so can no longer take them to help with the pain. So now talking about having to go to a pain gestapo nazi and be treated like a criminal going to a parole officer every month just to live somewhat of a pain free life.

Ok end of my rant for now, our golden years are more dark and dreary than bright and sunny these days.

BD

Buldawg

Ok so that is what gun the piston was for. Done so much stuff back then can’t remember what I done.

And yep the faster the pellet can get out of the barrel tends to help. Another thing where timing is important. I bet the TX is a lot like the modded 300 I have. Get the right combination makes all the difference.

And ok I thought it was the Mrod with the heavier pellets. How did the Maximus end up doing. I still got my modded .22 Maximus with the regulated HPA bottle. Its another good shooter.

Man really. 4 stints now. So lack of sleep hurts more than we think. And bummer with what is going on with your wife. If I remember right you went through a bunch of bull with the doctors over medicine at a point in time.

And yep I know. Seems to get more challenging than easy now days.

GF1

Yea I finally got around to installing that lightened and polished piston in the firepower about 3 months ago when tuning my spriongers to 12fpe for the UK matches. It cocks super easy and is a real nice shooter for what it is being a B19 crosman platform gun.

The main difference between the stock TX/B40 and the 22mm kit other than piston weight is the chamber pressures developed during the shot cycle. A stock TX makes around 1200 psi pressure during the shot duration behind the pellet and the 22mm kit makes 1800 psi behind the pellet so due to adiabatic heating of the air in the chamber during the shot cycle being higher in the 22mm kit it makes it more efficient with the energy released from the compressed air. A 22mm kit in a 22 cal TX is actually even more efficient than in a 177 cal.

Don’t shoot the mrod much anymore since its still at 18.5 fpe but going to detune it to 12fpe one day to us in the UK matches. Just got to many others at 12 fpe to play with now. Got a crosman challenger, 1720T, CZ200, bottled QB78 to name a few. The maximus is Donovan’s gun and hes not into shooting much anymore so it is not used much but its a good shooter as well.

Yea I have had three stents since 2013 and was doing good till June of 2016 when our govt decided i can no longer manage my pain meds and have to see the pain gestapo and jump thru hoops just to get a pill. Never going to happen by me. So I have lived in a 5/6 level of pain since then and my ability to stay active and exercise is greatly diminished so much that from June of 2016 to April of 2019 I gained 85 pounds, from 200 to 285 and developed the apnea in 2017 as well as type 2 diabetes. Yes not breathing when asleep is very hard on the body since you are basically starving your whole body of oxygen slowly suffocating yourself. In April of 2019 I took the bull by the horns and started a drastic diet losing 45 pounds in 3 months down to 240 where i am stuck in a plateau at now. Then had another stent in may from my heart being starved of oxygen I am starving all the time and live on salad and oil and vinegar dressing since the vinegar unbinds the sugar from the red blood cells keeping my diabetes under control and the salad has pretty much zero calories.. Also now have L1 to L5 vertebrae and discs in lower back all out of place with spinal stenosis. Getting old aint for sissies. Still ornery and irritable as ever so just another day in the neighborhood.

I thought you were still on third shift. I don’t know how you manage it for so long. The 2 1/2 years i was on it at Harley nearly killed me since i could not sleep at all during the day so was always worn out. Hmm kind of like the last thee years with my sleep apnea. Stay healthy my friend.

BD

Buldawg

I had a Challenger. I liked it. But I let it go as part of a trade for some tuning and dyno work on the Mustang.

And how do you like that 1720T. I would like to get another one. They are pretty accurate guns.

GF1

Yea I got the challenger off ebay for a steal at 300 bucks with sights included. It had a slow leak that turned out being a loose foster fill fitting that some new Teflon tape sealed right up good as new.

I went to the Hickory North Carolina airgun show this past November and got a deal on the 1720T and live it. got a regulator in it set at 100 bar shooting AA 10.34s at 715fps for 35 shots. Its a one hole 30 yard gun if i do my part with the LW barrel. Got it in a tom west stock with a rocker 1 shroud. Nice little carbine for sure.

BD

Buldawg

That’s a good looking 1720T.

And funny you say that about your Challenger. I got mine to for a good price. It was $350 and came with the sights. It was like brand new. Got crazy shot count for a unregulated 2000 psi gun.

GF1

Yea the challenger is a 10 meter gun by design so it has a very small .047″ transfer port and shoots in the 500 fps range in factory tune with an easy 200 shots per fill. I have drilled out my TP to .089″ and adjusted the hammer spring and stroke adjustment to give me 715 fps with 10.34s for about 40 shots. Its also has a LW barrel and is a one hole 30 yards gun if i do my part as well.

Have you seen where JSB is releasing a new Hades style pellet in the 10.34 dumbell design for hunting purposes to go along with their 22 cal 15,89s that have proven to be very accurate and deadly on game.

That and all the new slugs coming out is really shaking up the long range air gun accuracy capabilities. Interesting times ahead for sure for air guns.

BD

Buldawg

Him that’s funny. We didn’t know each other had a Challenger and that’s pretty much what I did too. Only I went with a .062″ hole for the transfer port and about the same fps with the 10.34’s.

And no didn’t know about the .177 caliber Hades pellets. But have been using the .22 caliber Hades in my modded Maximus. Very effective on squirrels and pest birds. They have the Hades in .25 caliber now too. I want to try some of them in my .25 Condor SS. Its shooting the JSB 34.95’s at around 980 fps. Them Hades in my Condor SS should be pretty effective too I’m betting.

And I don’t think I’m going to try the slugs just yet anyway. I want a pellet air gun not a bullet air gun. Just a me thing.

GF1

I may have went to .067″ instead of .089″ as its been a while since I re tuned it and mt short term memory aint what it used to be with my lack of sleep issue. But yes basically just below,the 12 fpe limit for our UK matches.

I just read a thread in the GTA today about the 10.34 Hades being out this April or so time frame so just need to keep ans eye out for them. i have not tried any as of yet but have read they are as accurate as the regular JSBs.

I have played with a few slugs out of my mutant so far to try to get some sub MOA groups at 100 yards but have not founds ones it likes very well yet. My only reason for interest in slugs if for the better BC and therefore flatter trajectories and downrange energy levels. My mutant is a laser with 18.13s at 880 fps shooting 2 MOA groups at 100 yards with ease. Its actually the only gun I have that is still completely stock from the factory and i have had it two years now. They are just that good and by far the best trigger of any gun i have ever owned, It has 7 adjustments that can be tailored to suit anyone tastes.

I think I am going to try to sleep now. I was in bed three hours trying to sleep but wide awake so got back up for a few hours. Going to try again.

Talk later

BD

Buldawg

Give the .22 Hades a try in one of your guns. I think you will like them.

And what is the Mutant? I don’t think I know what that is.

And good luck with your sleeping. Hope you get some rest.

GF1

Yea i need to get some Hades pellets to try and will probably wait till the 177 are available so i can get all in one order.

Its a Tiapan Mutant bullpup made in the Ukraine with a CZ barrel in 22 cal that’s regulated and shrouded and fills to 250 bar. Since all the upheaval in the Ukraine in recent years the factory has closed down and moved to Czechoslovakia and are now called the Veterans. They also come in 177 and 25 cal now as well but use LW barrels instead of CZ barrels now as well. They are super quiet and highly accurate with exceptional build quality. The Mutants are highly sought after now due to the switch from the Ukraine to Czechoslovakia although the veteran as just as good and basically the same guns less the CZ barrels. Its a 1350 dollar gun as a mutant and up to 1500 dollar gun as a veteran depending on caliber and length. The Mutants came in shorty and standard lengths, mine is a standard, about 4 inches difference in overall lengths and barrels length. The veterans are shorty, standard and long with shorty and standard the same as the mutants and the long is about 4 inches longer still.

Here’s a pic of my standard mutant.

Buldawg

On 3rd shift still so getting ready for sleep. Won’t be able to answer back till late at night. Really busy at work anymore so can’t get no time till later on in the night.

GF1

Here’s another pic

Buldawg

The Mutant is a nice looking bull pup.

And yep the Hades work nice. Well with my .22 Maximus anyway. They do mushroom apart (the pieces stay connected but open up) depending what you hit and what distance you shoot at.

What I have noticed is the parts of the pellet that open up are twisted a little instead of opening straight up like hollow points do.

I think the rotating pellet is making that happen. So the pellet is acting like a drill bit when its hitting. To me they are the pellet I have been waiting for when I’m pesting.

GF1

Yea I got the mutant used in as new condition for 945 bucks with vert few shots thru it. It took a little getting used the the short bull pup style setup but once i get the trigger set to my liking it made a huge difference and i can hit a 1/2 spinner at 50 yards all day long repeatedly with out trying. Like i say its the only gun I have not had to tinker with other than trigger adjustments in the two years I have had it, never even cleaned the barrel. its a perfect as they come with never a glitch in its operation ever. Its one of those gun you will never sell for any price.

BD

Yea i have seen some shots on game from the Hades pellets and they do some real devastation on the unlucky recipients. i agree the act like a drill bit rotating and sawing into the flesh of the prey they impact.

Just waiting for, another sale from PA to get some more pellets stocked up.

Buldawg

Same on a PA sale. And I’m going to get a couple tins of the .177 and .25 caliber Hades pellets to try when they get them in stock

And maybe one day I’ll get me one of those Mutant bull pups. Especially with them being reliable and accurate.

GF1

Same here on the Hades pellets at a RA sale.

On the mutant you will have to find one used off one of the airgun classified sites as they are no longer made, but the veterans are still in production and as I stated the only difference is the LW barrel versus the CZ barrel and a mutant is only 22 cal. Veteran can be bought in 22 and 25 readily with a few 177s here and there. Also the veterans have a 20 MOA weaver rail built in where as the mutant rail is not 20 MOA. this is to aid in long range shooting by not having to use adjustable scope rings or shim rear mounts.

https://utahairguns.com/airguns/taipan

http://taipan-airguns.com/

https://talontunes.com/product-category/airguns/rifles/taipanmutant-rifles/

https://talontunes.com/shop/taipan-veteran-standard-25/

BD

Buldawg

They are some nice guns but a little expensive for now. Especially since the money is going towards the Mustang. Getting ready to buy some steel wheels and slicks right now. Going to start running it at the dragstrip when it opens next month. And I’m saving up for a turbo kit for it. Then to top it off I think it’s getting time to buy a new washing machine. The gearbox or something is starting to make noise. But guess it’s about time. It’s got a few number of years on it.

So probably don’t see me getting one in the near future.

GF1

Question regarding turbos…do you think that engine longevity is shortened on the modern turbo charged engines, such as my wife’s Buick Encore 1.4L? I’m wondering if the turbo puts increased stress on an engine’s internals, thus shortening it’s life.

Geo

GF1

Yea the only reason I had the funds to get my mutant was I had just did as bunch of work on my good paying buddies harley dresser so had cash burning a hole in my pocket and the deal came up at the right time.

Glad you are getting back into some drag racing since i know you have missed it alot.

I have had to buy a new fridge in the last year and now a new stove a month ago and a dryer awhile before that but they all were 19 to 20 years old so I believe I got my moneys worth out of them. The washer and dishwasher are still going after 20 plus years. Knock on wood. LOL

I have been strongly considering selling off my bikes and some other toys I don’t use much if at all anymore to build me a little street hot rod to play with. Got lots of old skool chevy hot rod parts tucked away that all I really need is a rolling chassis to get started. To many toys and to little time.

BD

Buldawg

I replied at the bottom. Running out of room up here.

Siraniko and Chris.

As far as keeping them original as in finish. As it has been said I think that’s owners preference. But here’s the catch. If a person does a nice job redoing the stock and bluing the action how do you know if it’s been redone or original. That’s the question.

Gunfun1,

As long as it looks original it doesn’t detract much from the desirability of a shooter. From a collector’s standpoint that’s going to be another thing that lowers the value though. Determining if the finish is original or if it has been redone is something I would leave to an expert though. Having bought a few modified air rifles I now appreciate the value of an untinkered unit.

Siraniko

Siraniko

Yep that can be a tricky subject. It probably boils down to what the buyer of the gun wants.

Siraniko

February 23, 2020 at 7:16 pm

Buldawg76

Good to hear from you

Siraniko

Good to talk to you also and hope all is well with you. I still read the blog most every night but don’t post. I hang out on the GTA mostly now.

BD

Buldawg76,

Good to hear you have found something to help with your sleep. Enjoying the modded trigger of my Webley following your instructions. From your conversation with Gunfun1 it is only now I realized how small PCP transfer ports need to be for efficiency. Considering I’m restricted to under 25 yards range it doesn’t make sense to have a powerful air rifle. Will start thinking how to go about modifying my Discovery in .22 to bring down the output. Maybe start with an O-ring buffer for the striker?

Siraniko

Siraniko

My sleep is getting better slowly but still have some nights that I have trouble falling asleep. It did not occur overnight so will take time to get my biological clock to reset fully.

Glad I was able to help get your Webley trigger much more to your liking. A good trigger does help be a more accurate shooter.

The smaller the TP is the less air can pass thru it per shot but there is also a point where it can be to small as well making the need for a heavier hammer or hammer spring tension to achieve the desired fps. It is a balancing act between TP size, hammer weight, spring energy, plenum volume and barrel length just to name a few.

If your discovery has a stock hammer it has no striker adjustment to help fine tune using a o ring buffer setup. In that case i would use the appropriate amount of o rings that will give you between .060 to .080″ of valve stem travel before the hammer hits the o rings. To do this the easiest you need to remove the breech/barrel assy and degas the gun so you can be able to measure the valve stem travel allowed before the hammer hits the o rings by depressing the hammer against valve spring pressure and measure hammer travel. You will have to try different thickness’s of o ring to get the desired .060 to .080″ stem travel limit and then just play with hammer spring tension to get the flattest longest shot count.

If you use a Prod style hammer you will have a striker adjustment that you can use to fine tune the valve stem travel but the hammer must have a notch cut into the top front of it to clear the forward breech mounting screw where it protrudes into the tube. The disco hammer has that half moon cutout on the top front of it to clear that screw. With the prod hammer you stack enough o rings so that with the striker adjustment all the way CCW the hammer cannot open the valve before it hits the o rings and slowly adjust the striker CW to get the desired fps, hammer spring is not near as critical so just needs to have enough energy to open the valve at highest fill pressure.

Good luck on your modding.

BD

BD76,

I’m going to study things a lot before taking a screwdriver near it. Replacement parts are not ready to get.

Thanks for the pointers

Siraniko

Siraniko

i understand fully about your parts availability and in that respect your best bet would be to just use o rings to limit valve stem travel to the .060 to .080″ limit from hammer impact and use hammer spring tension to tune as best as possible and all that is completely reversible.

It can actually be done by just degassing the gun and removing the trigger assy and rear hammer spring end cap, the o ring can be slipped into the tube in front of hammer thru the slot for the trigger sear and with the end cap out you can use a screwdriver to compress the hammer against the valve stem to measure total travel before contact with o rings occurs and get as close to the above travel as possible. Keep in mind the o rings will compress some so going on the low side of .060″ will likely give best results .

BD

BD76,

Do I base O-ring size based on the outside diameter of the valve stem or the inside diameter of the tube the hammer goes through?

Thanks again for the pointers.

Siraniko

Siraniko

You would use the o rings based on the tube ID size. The o rings that are used on the valve, gauge block and fill fitting are 016 size o rings. You can also use 116 or 216 size o rings in either 70 durometer or 90 durometer also ( durometer is the hardness or a measure of compressibility with 70 being softer than 90 ). The 016 o ring is 1/16″ thick, 116 is 3/32″ thick and 216 is 1/8″ thick. All are 3/4″ od which will fit the tube ID properly and stay in place where installed between valve and hammer. They can be used in different stack ups of thickness’s to give the desired amount of valve stem travel and compression during shot cycle.

Its a trail and error type of tuning but once you have it how you desire its good to go.

BD

Yes, it looks as if Diana decided to make successive evolutions of 3 ball sear trigger guns easier to maintain. The later 34 series is easier again. Thankfully.

As an aside, I picked up a model 25 (non ball sear) the other day. What a superb little gun. I have a few small Dianas and this is the nicest shooter so far. The wee gun will be 49 years old this summer.

Regards to all.

Buldawg

I was lucky with the 95 Mustang GTS. It’s got a lot of good parts in the engine and drive train. Plus got it for under $2000.00 and its emissions exempt. So basically can do what I want to it and still drive it on the street. Its been in the mid to upper 12’s on street tires when the other guy had it. It’s now got a different computer and O2 and air temp sensor that is able to be piggy backed and tuned with a laptop. We dynoed and tuned it 2 different times and now it’s making 430 hp and 465 foot pounds of torque at the rear wheels. So not sure what it looses through the drive train but has to be making close to 500 hp and over 500 fpt at the engine. It red lines at 7500 rpm and we took the mph top end limiter off of it too. I’m thinking now with the tune and slicks it should be in the high 11’s which is pretty good for all motor and no power adders. Going to see soon. The track opens the middle of March.

And you should throw you a car together. You know it will be fun. 🙂

GF1

That’s is real good with a non power added motor and I remember when I first starting working on cars at an independent shop in the late 70s that my boss would tell us youngsters that he could take a 289 ford motor and build it and outrun any big block we cared to build with ease. Its not always cubic inches if the parts used do not compliment each other properly.

I remember a buddy had a 64 nova wagon with a 283 and 4 speed corvette close ratio trans with a 4.11 rear, The motor was built to turn 10,000 rpm at peak power and the number of big blocks we out ran stop light to stop light was amazing. It would leave at 8000 rpm on the rear wheels and shift at 10,000, drop to 8 and back to 10 thru all 4 gears. If a couple of us bigger kids would sit back against the tailgate when launching it would drag the bumper all the way thru first gear and just touch it hitting second. Fun little car for sure.

I need to pull my 78 datsun 620 pickup apart and fix all the rust in the body and put my 400 4 bolt small block in it with the BW super T10 4 speed and a 9 inch rear end and really have some fun. That would be a 24/2500 pound 500 hp street screamer that would be a handful of fun. Problem is I would likely either end up dead or in jail for the rest of my life. Got a real problem with lead foot syndrome in those types of toys.

BD

Buldawg

Yep the Ford 289’s were screamers. They had a short 2-3/4 inch stroke.And yep had a early 70’s Nova with a .080 over 283 in it. The 283 had a 3 inch stroke that made them rpm nice too.

What surprises me with this Mustang is the torque its making. Its still a 3″ stroke .060 over with 10 to 1 forged pistons 5.0 roller e303 cam engine with ported and milled heads and ported intake. Basically the roller lifter pushrod 5.0 that was used in earlier Fox body Mustsngs. And the the engine is turning 7500 rpm. It’s got the electronic AOD auto tranny with a shift kit and a 2800 stall converter. And its got a Ford 9″ in it with a 4.11 posi. Also has headers and 3″pipes and 2 chamber Flowmasters. So when they biult it they got the combination right.

And my left foot never wants to listen to me.

Buldawg

How about let me try this again.

My left foot and right foot doesn’t want to listen. 🙂

GF1

Yea I was always a fan of small blocks over big block for the most part. Just something about the high pitched scream of a small displacement high revving motor makes my blood get flowing more than a low growl of a big block. i guess its why I liked my KZ1000 so much since they have an exhaust note unlike any other inline 4 street bike with a nice open header on them, music to my ears.

That 283 was balanced and blueprinted with forged pistons and power pack heads and a corvette cam and tranny all matched to work in perfect unison just right. It surprised a lot of hot rods but ran out of gearing by 120 mph.

My oldest son got to buy a friends 79 cobra, (the first fox body stang) that only had the 2 barrel carb on it. We pulled the motor and bored it 30 over and put a 3/4 cam kit in it with a 4 barrel off a 66 396 chevelle a buddy gave me and it had a 4 speed with 4 being an overdrive. That car would turn low 13s in a 1/4 yet get 22 mph on the highway at 80 mph in 4 turning only 1800 rpm. He fell asleep at the wheel one night on the way home and ran head on into an oak tree and totalled it out. He was ok and walked away but really like that little car.

I really need to get out of this slump I have been in from lack of sleep and get myself back into enjoying life like I used to, not sleeping 100% yet but its getting better every day so got to get the butt in gear. The weathers is starting to get back warmer so the body will cooperate easier and I really need to do some spring cleaning of over 10 years of hoarding stuff i never use any more.

I have not rode my bikes in over a year due to aches and pains they create so I guess its time to move back to 4 wheels.

Don’t let your two left feet get you in to much trouble now. LOL.

BD

Buldawg

Same with that 283 I had. Balanced and blue printed. It had the big valve 461 heads and the spring rev kit that kept the lifters on the cam. It had the Duntov 2nd design road race cam. It didn’t smooth out till close to 4000 rpm and was nothing for it to hit 10,000 rpm in a blink of a eye when you got on it. My Nova had a 13″ dumptruck bellhouseing and flywheel and had a 3 finger Borg and Beck 3500 lbs pressure plate with a close ratio Muncie 4 speed. I miss that car.

And I think you would have fun if you built another car.

And yep all my left and right feet. 🙂

GF1

That nova my buddy had was built by a local chevy hot rodder that would build and sell the cars. My buddy had just turned 18 and I was 17 so this was his first car and my first glimpse of the hot rod world. We were told it was a complete corvette drivetrain with some added goodies and tuning done. So not really sure about all the internals but it did also idle very rough and liked over 4000 rpm best as well. He let a friend borrow it one night and he was racing it and on launching it shifted from first to fourth instead of second at 10,000 rpm and did the AAmco tranny commercial by splitting the tranny case in half with all the guts rolling out from under it on the ground. Never could find the right tranny to go back in it to be a matched setup like it was.

Those were fun days for sure..

BD

Buldawg

Sounds like the same setup that we both had.

If I remember right the 461 heads were the power pack heads. Some people called them the double hump heads too. They had two bumps in the casting at the bottom of the front of the heads. And if I remember right the later heads had the accessory holes in the front and back of the head so either head could be used on the left or right bank of the engine. The earlier heads didn’t have the holes drilled and tapped. Then there was the 461 heads. And those numbers didn’t have anything to do with engine size. They was casting numbers. And I still got a paper here somewhere that gives the top 10 factory small block heads up to the mid 70’s. It gave runner and port and valve sizes as well as chamber cc’s. Also said what years the heads were made and where they was made.

I got alot of different formulas for tire and gear and rpm to use for different 1/4 mile times. Kinda like a automobile Chairgun in a sense. Also some to get cubic inches figured out for different bore and strokes.

And back all the way up to 2000 I had a garage full of old muscle car trannys and engines and heads and intakes and rear ends as well as cams and carbs and headers and so on. And all different makes. Even AMC. Sold it all for good money to someone in Detroit.

And it was one thing to know how to work on a car but the real trick was learning how to put the right combination together then knowing how to tune it after that. No pushing buttons on a lap top back then. That’s when you learned how to read a plug. And you don’t know how many people I talk to about reading plugs on their computer cars now days when they tune and they have no clue about what I mean. Then ask them if they know what plug indexing is. And that’s not even a start of what we did back then.

And yep I use to hord too. 🙂

GF1

Yep of memory serves me which I may have backwards the 461 head were the early double hump heads without bolt holes since they hung the alternators down low off the blocks instead of up high on the heads. The 462 had the bolt holes to mount the alternator and ac stuff off the heads, may be exact opposite casting number wise but both had the double hump marking on the ends of the heads. The 461/462 were the last three numbers of the casting numbers located in the rocker valley of the heads. Then you had the later 041 heads that were also the same as 462 with bolt holes but had a triangle symbol on the end of the heads that came on the 350 Z28s and chevelles. They all could be either 150/194 or 160/202 valve sizes and 64 or 72 cc chambers. Lots of combos to choose from and yep you had to know what worked with what to build an effective performer.

Yea reading plugs is a lost art that we had to learn if we wanted to go fast and not blow up motors all the time, I also had charts with the gear combo, tire size, bore and stroke and all that important tuning info we used to reference when tuning and building cars.

I still have all my hot rod stuff from an 010 350 high nickel alloy 4 bolt block out of a 69 Z28 and a 71 400 4 bolt block, set of 461 150/194 64cc heads, cams and roller rockers, couple carbs, borg warner super T10 4 speed and lots more goodies.

I have not heard plug indexing in a very long time and believe it or not I used all those old tricks when I built my Harley shovelhead to get the best out of it that could be had and it paid off big time. Even got double plugs in the heads, one on either side of the hemi combustion chambers for more complete fuel burn. It makes 95 hp and 104 ft/lb torque on a dyno which is more than a Harley CVO 103ci does from the factory and will out run them all day long and its only a 88ci motor. What I really like is when we race and I play with them by letting them stay with me till they run out of gearing at about 110 to 115 mph and I just look over at them and smile while I roll the rest of the way into the throttle and just pull away like they are standing still. On my speedo at 120 mph I am turning 5200 rpm and my redline is 6000 so really don,t know just how fast it goes but it does bury the tach at 6 grand with ease. The KZ is a whole nuther animal all together with 11,000 rpm redline and will bounce the 160 mph speedo off the pin way to easy. Got to be careful on the street with it as you can get into trouble way to quick from other vehicles getting in your way due to its rapid acceleration rates that other do not expect from it.

That’s why I need a cage around me now since I don’t bounce like I used to and sure don’t heal near as quick either. Plus way to many distracted drivers on the roads today to keep up with on two wheels.

BD

Buldawg

Yep I use to know all those head numbers and stuff right of the top of my head. Been awhile and need to joggle the old brain to get it going sometimes anymore.

And heck you sound like you got a good start there to build another car. I imagine you could get pretty good money for both your bikes now days too.

Buldawg

Well what did you think about the video of the Mustang burn out.

I know we talked a bit off the blog. But figured I would ask since we was talking here.

GF1

I liked it and its got my interest peaked on getting a 4 wheeled toy project back going. Could not get the videos to send to my PC with audio so no better audio than what phone allows. I just don’t do email from phone at all so have issues trying to transfer from phone to PC.

Spring is getting here and hopefully the rain will stop soon here so can get outside to sort thru all the stuff in the shed.

BD

Buldawg

Yep I can’t get to send to a email either.

But definitely fun to drive. Haven’t had any kind of muscle car for some years now.

Hope you get something.

GF1

Its going to be awhile as I have to sell some toys and parts to get the funds up for starting the project but its time to retire the two wheels for 4 except i will likely keep my KZ since its part of my soul at this point.

Even thought about selling everything and going to a Barrett Jackson auction to see what can be had cheap on the Thursday and Friday sales. See some real gems go across the block on those early days real cheap..

BD

Buldawg

One of these days I would like to get another 72 Z/28 like a had when I got my license. It got crashed sitting in my driveway and was totalled. What’s funny is I’ll occasionally have a dream that I found it and it was restored. I’ll be driving it then wake up and bum out that it was a dream. I do miss that car.

And know what you mean about your KZ.

GF1

I wish i could find another 64 goat like I had back in the late 70s. It was the one that Fred Wagners and John Delorean snuck out under the corporate big wigs noses back then as a 64 tempest with the GTO option. It was a 389 tri power, 4 speed and posi rear with delete A/C, PS, PB, sound deadening and mastic, 4 wheel drum brakes, no seat belts and a AM radio. There were only 650 of that exact model made out of the 6500 total for 64. It ran a 12.70 off the showroom floor and beat the 64 327 fuelie corvette for showroom stock 1/4 mile performance that year and was the fastest production car of the day.

I have also dreamed about it as well and wake up right as I wrapped it around a 72 caddy sedan deville in front of weekie wachee spring attraction on highway 19 in Homosassa spring Florida in august of 79.

My true dream car would be a 66 shelby AC cobra GT500 but at 5 million starting prices its just a dream.

Lots of blood, sweat and tears in my KZ for sure.

BD

Buldawg

You know what always gets me when we start reminiscing about old times is we both lived very similar times through life. I love all the old muscle car memories. I know I said this before that the muscle car era should be a part of history class in school. Just like here where we are commenting on this gun in BB’s history series of reports. It shouldn’t be forgotten.

Both of my daughters are speed demons. They will sit and listen and ask questions for hours when we start talking race cars and dirt bikes.

My youngest daughter that still lives at home took the video of the Mustang burnout. She goes dad. That smelt so good. I remember the smell from the burnouts at the dragstrip. Once you smell it again I bet you will be getting another race car before you know. I really should be warning you to stay away. But once it is there. It will always be there. For me anyway there is no denying that.

GF1