by Tom Gaylord

Writing as B.B. Pelletier

Webley Hurricane

This report covers:

- Qualifier

- Lotsa pix!

- Begin

- Remove the stocksides

- STOP!

- Roll pin 3

- Roll pins 4 and 5

- Safety

- Remove plastic forend

- Remove the barrel pivot pin

- Remove the barrel and cocking link from the gun

- BB’s first tip

- Not a lot of spring tension

- Remove the mainspring and guide

- Problem identified!

- What to do?

- Three lubricants

- BB’s next tip

- Test the pistol

- BB’s final tip

- Summary

Better put on a whole pot of coffee. This is the longest blog I have ever written.

Here we go — diving into the Webley Hurricane — an air pistol I have never wanted to see the insides of! I was warned about little springs that might fly everywhere. There aren’t any. But there is a sear spring that is attached to absolutely NOTHING, and yet does its job well — IF PUT BACK IN THE GUN THE WAY IT WAS BEFORE IT CAME OUT!

There are several things like that — things the blog that reader Derrick directed us to never mentioned or showed. Things that the Webley manual got wrong!!! My aim is to set the record straight and then to advise most of you to never go inside this pistol or a Tempest. I will show how it comes apart and describe how it goes back goes together, but before you undertake such a task take a look at my qualifier, below.

Qualifier

Rate yourself as a careful worker. Are you someone who has difficulty replacing batteries in things? Or are you the type of guy who can take an old lawnmower engine and use it to power a go-cart you built? The first guy scores a one on the careful-worker scale. The second guy scores a 10. You need to be honest with yourself and rate yourself on that scale. I’m a 2 to 3 who sometimes rises above a 3. Today is one such time.

An HW 80 is a 2 in its level of difficulty to assemble. An FWB 124 is a 3. A BSA Meteor Mark IV is a 6 and a Haenel 311 is a 10. This Webley Hurricane is a 5-6. That’s mostly because of all the roll pins holding it together. I complain about them, but, given the pistol’s aluminum frame, they really are the best way to secure crosspins without wearing their holes.

If you are a 2 on the handyman scale, you have no business tackling a 5-6! Send it away! Gene Salvino at Pyramyd AIR loves helping folks like you.

Lotsa pix!

I took 32 photos of this disassembly and I used 24 of them. That is as many as I take on the second day of the SHOT Show! I took that many because there was that much to see and to understand! I won’t get to the velocity test today because there is too much to plow through with just the fixit job.

I have my magnetic dish, my new roll pin punches and my new hammer, ready to go!

Begin

Make sure the pistol is uncocked. Well — DUH!

However, I have seen and heard of people disassembling spring guns that were cocked. I had to do it myself once when there was no other way to uncock the gun.

When I was in the Army and taught soldiers how to prime and detonate high explosives, things mostly went well. HOWEVER — on one occasion the 4 blocks of C4 in one demolition pit didn’t detonate. That’s 5 pounds of explosive that is more powerful, weight for weight, than TNT, and far more powerful than dynamite!

Besides being the officer in charge of the range and the instructor, I was also the safety officer this time, because my lieutenants were in the class with the other soldiers in my company. Guess what the safety officer has to do when a charge fails to detonate? After waiting a length of time for a possible hangfire, he has to go into the pit, collect all the charges, put them together again and prime them a second time. The problem is — three of the blasting caps had detonated without exploding their block of C4, but the fourth one had not detonated. That was highly suspicious and that block was now considered very sensitive. The explosion of the other three blasting caps had ripped open their blocks of C4 and scattered them around the pit.

Old BB had to gather all the explosives together, taking care to not move or even touch the one block whose cap hadn’t gone off. Then, after molding each of them back together again where the caps had ripped them apart, he stuck new blasting caps into the three C4 blocks, and attached igniters to each of their fuses. At the time I remember thinking that if that block whose cap hadn’t detonated blew up now, I would be the last person to know it.

In the Army we called a situation like this a pucker-factor exercise, and if you get through it unharmed it usually advances you by at least a point on the careful-worker scale.

Make sure the pistol is uncocked!

Remove the stocksides

Ha, ha, Webley. On Earth we call them the grip panels! And here is the first oddity. You would think the grips attach to the frame of the gun, but they don’t They attach to each other with the frame sandwiched in-between. The right panel screw is screwed into a long tubular threaded bushing that Webley calls a nut. Remove the left panel and screw first and then the right panel will also be free of the frame, though still attached to the threaded bushing.

The right grip screw threads into a threaded bushing that also accepts the left grip screw.

Removing the grips exposes all five roll pins that have to be removed next. In Another Airgun Blog all five pins were not visible.

Remove these five roll pins in order of the numbers next to them. See the text below.

Pin 1 removes the back of the triggerguard. Pin 2 removes the front, freeing the triggerguard to be removed. The sear spring will probably fall out with it.

With the two triggerguard roll pins out the guard can be removed and the sear spring will also probably drop out.

STOP!

I didn’t see the orientation of the sear spring inside the pistol before it fell out, so I spent some time puzzling out how it had to fit when the gun is assembled. This spring is held inside the gun by nothing other than the triggerguard being in the way. No roll pin passes through the central circular hole or even the smaller hole on one end of the spring. The roll pins are too large to fit through that hole.

That rolled end of the spring is simply formed as a foot to rest against the sear when the triggerguard is in place. The long straight end of the spring sticks down in front of the sear. Let’s look.

There is the sear spring with the short end resting on the sear and the long end sticking down (up in this upside-down view). When the front end of the triggerguard is installed it pushes the spring down to where it makes the sear function.

Roll pin 3

Remove roll pin 3. This is the axel that holds the trigger, trigger spring and trigger adjustment screw. A circular coiled trigger return spring is inside the trigger blade. The adjustment screw is a wee-teeny Allen screw that, on my gun, is deep inside the blade. They come out together.

There is the trigger with its return spring. The adjustment screw on my pistol is deep inside the blade because I never adjusted it. Roll pin 3 lies next to the trigger.

Roll pins 4 and 5

Pins 4 and 5 are for the sear. Tap out pin 4 first. That’s the sear stop pin. Now, LOOK AT THE SEAR BEFORE YOU TAKE IT OUT.

That is the sear, still on its pin inside the frame. Note that the long flat end goes toward the rear of the pistol, which is to the right in this photo.

Now remove pin 5, knowing that the sear will go back in exactly the way it was when it came out.

There is the sear and the two roll pins that hold it in the gun.

Safety

Now we can remove the safety. Unscrew the single screw and as you do, pull up on the safety lever to loosen it. It should come off the square safety shaft easily.

With the safety lever off, the wire spring can be removed from the square safety shaft that will then drop out of the frame. Pay attention to which leg of the spring is on top of the square shaft.

Here are the parts of the safety.

Remove plastic forend

Punch out the roll pin and remove the plastic forend. The manual says it’s a spring fit, but mine just slid right off.

Remove the roll pin and slide the forend off.

Remove the barrel pivot pin

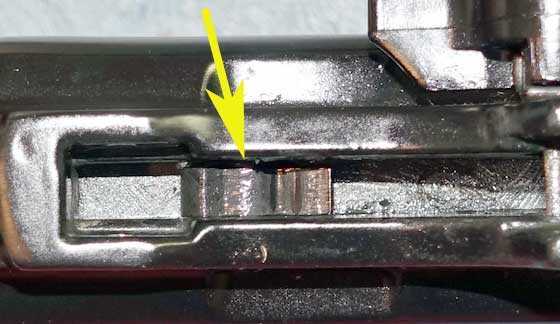

With the forend off we can see the pin — not a roll pin — that holds the barrel to the frame of the gun. This pin is also the axel the barrel pivots on when the gun is cocked. When this pin is removed, the force of the mainspring pushes the base of the spring guide out of the gun. However, we don’t do that yet. First we drive the pin out just far enough that the barrel pivot is freed and can be removed from the end cap/spring guide base. The pin still holds the end cap/spring guide base in the gun against the force of the mainspring.

The barrel pivot pin (arrow) is removed and the base of the spring guide that holds the mainspring in the gun is pushed out. First we tap the pin in just far enough to remove the barrel pivot.

Remove the barrel and cocking link from the gun

Older Webley pistols had a threaded end cap that has to be unscrewed, but this spring guide base is only held in place by that pin. Now that the barrel pivot is free from the gun, the cocking link can be slid back toward the rear of the pistol to a large disassembly hole at the end of the cocking slot. Once there, the cocking link can be lifted out of the pistol and the barrel and cocking link are now free of the gun.

The barrel and cocking link are free of the gun.

That end cap pin is still in the end of the pistol, holding the end cap against the mainspring pressure. I have a tip for you on removing it.

BB’s first tip

Drive the end cap pin all the way out with the pin punch. The pin punch will now hold the end cap from coming out.

The pin punch has driven the end cap pin completely out. The punch now holds the cap against the mainspring.

Hold the pistol in your hand like you would to fire it and set the end cap on top of the bench. I padded my dining room table with a folded towel. Now, lean on the pistol with your chest. The end cap will be pushed back in and the spring compressed enough that you can easily remove the pin punch with your other hand. Now slowly lift the pistol up off the table.

Not a lot of spring tension

The end cap will now come out of the pistol about 1 to 1.5 inches. The pistol’s spring is not strong. I estimate there is about 30 to 40 pounds of energy pushing on the end cap.

Remove the mainspring and guide

You can now remove the end cap/spring guide and the mainspring.

The end cap/spring guide and mainspring are now out of the pistol.

Problem identified!

Now that I could see the spring guide I learned why the pistol had grown so difficult to cock. Webley had lubricated the mainspring and the spring guide generously when they built the pistol, but they used the wrong type of grease. They used either a thin machine grease or more likely a lithium-based grease that does not have adequate surface tension to lubricate parts that are under as much pressure as this pistol imposes.

The grease could have initially been light in color but it was now black with metal particles and dirt, collected over the years. I now went on the search for shiny places on all the pistol’s parts. I found them on one part right away — the spring guide. All over the body of the spring guide were shiny places where the mainspring had rubbed under pressure and worn away the surface. The guide was initially very smooth and the worn spots were thankfully not grooves. They were just shiny surface patches.

The largest shiny spot on the guide was wrapped in a spiral — just like the coiled steel spring would do when compressed during cocking.

This is a different place on the spring guide and you can see another shiny spiral spot. Look at the shiny spot on the tip of the guide. Look where the tip enlarges into the body of the guide and you can see that the guide has retained its original shape and just the surface has been rubbed shiny.

At the base of the spring guide you can see two more shiny spots where the mainspring has rubbed hard when the gun fires.

An insert in the spring guide base bears against the cocking link when the pistol is cocked. The end of the insert is shiny but the place on the cocking link where it rubs is only mildly affected. That means the pressure against the link is not that great, but the small spot on the insert contacts it throughout the cocking cycle.

That constitutes most of the shiny spots where the Webley grease failed. They are all on the mainspring guide. I still examined every square inch of the pistol looking for more shiny spots. I found a small area of the mainspring that was a little shiny, but that is common in a spring gun. When the gun is cocked the mainspring kinks up and twists as it is compressed, and if any place on the spring bears against other metal there will be shiny places. What I saw on the Webley mainspring gave me no cause for concern.

This small shiny area on the mainspring is nothing! The spring is still in good condition.

What to do?

Let me review where this article has gone. First I described in detail how to disassemble the Webley Hurricane and showed you the details you need to know as we went. Those pictures will help you assemble the gun again, though I also have a couple more things to tell you about that. None of this “assemble in reverse order of disassembly” garbage!

Next I showed you what was wrong with the pistol. In the last report I stopped using the pistol because I felt its parts galling, which is parts that are rubbing against each other with too much pressure. In this report I showed you the proof of that — the shiny paces on the spring guide — ALONE. No other part in the gun had shiny places, other than the small place on the mainspring that is normal.

Now I’m going to tell you how to fix the pistol. Since the problem was with the lubrication, that’s what we will fix.

Three lubricants

I selected three types of lubrication for this pistol. For the spring guide I normally would have chosen Moly grease, but I decided to do something different this time. I have an injector tube of a grease called Extreme Weapons Grease. Of course the manufacturer says wonderful things about it, but I thought why not give it a try? So, on every place where there are parts that rub under high pressure, I used EWG. If it doesn’t hold up I can always redo the pistol — now that I have this report to follow.

I used Extreme Weapons Grease on every part that was under high pressure. That’s mostly the spring guide, but I used it on a couple more spots that I will tell you about.

The pistol had a small bit of vibration when it fired before the galling started. It was so small I decided to live with it, but now that everything was apart I cleaned off all the old grease from every part in the gun and used Tune in a Tube on the mainspring. The spring was heavily lubricated before, so I figured a light coat of TIAT would probably preserve the velocity. Naturally I will check that when I test the velocity again.

I also used EWG on the cocking link shoe that retains the link inside the pistol. It wasn’t shiny, but as long as it is exposed, why not do it right?

There is the “shoe” (arrow) that connects the cocking link from the barrel to the pistol. I also used EWG on every surface of this part.

I mentioned there is an insert in the end cap that bears against the cocking link. I also coated the shiny spot on this part with EWG.

I also put EWG on the part that rubs against the cocking link (arrow).

Besides those parts I put EWG inside and on the sides of the pivot point of the barrel and also on the pin that holds the base block/end cap in the pistol.

I lubed the ends of the piston with moly that then transfers to the inside of the now-clean compression tube. The Teflon piston seal (the Brits call it PTFE, for Polytetrafluoroethylene) was in perfect condition and needed no lubrication.

Lube the parts of the piston that come in contact with the inside of the compression tube and also with the sear. They are the circular places that stick out.

BB’s next tip

Yes, the pistol is assembled in reverse order and I have given you all the details you need to do that. But getting the end cap/spring guide into the pistol so the pin can be driven in isn’t easy. Remember, the pin has to be driven in partway to hold the end cap, and then the barrel pivot hole needs to be aligned with the pin before it’s driven all the way home. Webley has you pushing the pistol against a table, but I find doing it that way takes three hands. A much better way is to use a 12-inch wood clamp to slowly bring the spring guide into the pistol. Sure, the clamp slipped off a couple times, but it took me only a few tries to get it right.

Then I assembled the remainder of the pistol. I used Moly grease on the sear parts, though the way this pistol is designed that will not lighten the trigger pull a bit.

Test the pistol

The gun is together again. The job took me three hours because I was going very slowly and carefully. I was also taking pictures.

To test the pistol I tried to cock it and it would not cock. However, this was not my first rodeo

BB’s final tip

After assembling a spring airgun always squeeze the trigger several times to sort out the parts. When I did I heard a couple clicks and the second time I was able to cock and fire the pistol. Job done. And, by the way, there is now NO VIBRATION when the pistol fires!

Summary

Now the velocity of the Webley Hurricane can be safely tested. And, if the Extreme Weapons Grease works as advertised, the pistol may now function correctly for many years.

B.B.,

Thank you for going where not many have gone before. I tried looking at the composition of EWG but the MSDS looked dodgy in that it is described having three different proprietary synthetic hydrocarbons of varying proportions. Doesn’t contain PTFE though. If there was still vibration present after your lubrication job I would be in a quandary. That thing was assembled with tight internal tolerances with regards to the spring and spring guide.

Will have to wait for the next installment of this pistol. Friday?

Siraniko

PS Problem Identified 1st picture caption: “The largest shiny spot on the guide was wrapped in a spiral — lust (just) like the coiled steel spring would do when compressed during cocking.”

Siraniko,

Fixed it. Thanks.

I am torn between shooting the Haenel 311 for accuracy and testing this pistol’s velocity on Friday. I really want to know how this one did, given that I used TIAT.

B.B.

B.B.,

You really outdid your self this time. I will have to read it again carefully after a couple of cups of coffee in the morning.

Don

Don,

Yeah. Me too! 🙂

B.B.

B.B.

I think you passed your mechanical aptitude test! You are now a certified 4 on the scale to 10.

Are all over-barrel cockers so difficult to disassemble?

The Hurricane is such an ugly duckling, I’m not sure that it deserved all the love that you bestowed on it!

-Y

Yogi,

I think all over-barrel cockers ARE difficult to disassembly. The Beeman P1 comes to mind.

But the older Webleys were much easier because they had steel frames and no roll pins.

B.B.

I’m sure those roll pin punches you purchased made the disassembly much easier. I’ve never seen roll pin punches before but I can see them having great advantage.

George,

I will try to remember to show a pic next time and tell you what is different about them.

B.B.

BB,

I did a quick search and the roll pin punches seem to have a rounded “nib”. There is different lengths and even a holder,… (so 3 tools). I am familiar with centering/transfer punches, which have a pointed “nib” and may work just as well. At any rate,…. looking forwards to your explanation as I was going to ask to see them as well.

Chris

BB,

Great job! I thought that you would surely show some of the cribbing/propping/supporting of the gun while driving out the pins. Since you did not even mention it, it must not have been much of an issue?

Chris

Chris,

I laid the gun on a wadded shop towel, so I guess it wasn’t much of a deal. Wad it thick enough and you can drive the pins out safely.

B.B.

BB,

The pin size and hole ID must have been very well matched for a lighter press fit then. Most roll pins I have encountered (not air guns) required a very solid backing of the object and substantial pin driving. Glad it worked well for you.

Chris

BB,

GLAW! Gotta Love A Webley!

From it’s inception way back when to the day it died, Webley and Scott went their own way when designing airguns. When others would do it with one part, Webley would do it with three. The Service MK II is right out of a Steampunk movie. Their crowning achievement, the Paradigm has the most complicated firing mechanism I have ever seen in my life.

Though they are really not that accurate, they are so cool to shoot.

B.B.,

(Feel free to delete this edit suggestion after you correct the text.)

“Roll pin 3

. . . the axel that holds the trigger,” should be axle, and same correction for the below.

“Remove the barrel pivot pin

. . .This pin is also the axel ”

Back to reading! :^)

Michael

B.B.,

This particular Webley Hurricane is fortunate you happened to come into possession of it. Most owners would have continued shooting it and worn out the spring guide. By the way, when blog that contains a phrase like, “lean on the pistol with your chest,” one just knows the ride was a bumpy one.

Michael

BB, I have a Tempest that needs to be cleaned, smoothed out, lubed, and a lightened trigger. So, I am trying to take this all in. I have never dealt with roll pins. I know they are spring steel tubes. I didn’t know there were special punches for roll pins. Looking on line, it looks like the only difference is that roll pin punches have a little nub in the center. Is the correct? I have not looked on you tube yet but I think I may need a roll tube tutorial.

Thanks,

David Enoch

BB ,

Good for everyone to see how critical lubrication is , I get razzed by the other guys in tech because the way I tout Ballistol and Tune In A Tube all the time . They think I have Ballistol stock options or get a commission on it . I have seen the EWG before it is a excellent product and it will not thicken in the cold weather . Some Police Departments around here use it in the AR15 Patrol rifles because it wont seize the bolt in our cold winters ( occasionally below zero ) . The SLIP 2000 products are probably the best synthetic lubricants for the AR series rifles. I use good old LSA since I have a quart can of it from SARCO many years ago and I am cheap at heart !. Great article and pictures .

Gene Salvino

David ,

Go to Brownells and You will have them forever . Brownells or Midway USA will have nice sets . Do Not attempt it without these punches , You will damage the pins and possibly the aluminum receiver if they mushroom out . I have a set I got at Brownells over 20 years ago , I did manage to bend the 1.5mm on a Beretta safety ! But it did not break so the heat treat is good , on cheap punches they will be very brittle and break easily , a harsh look will break them . Don’t be intimidated by the pistol , take some pictures with your phone as you go along and The BB sear picture is the most critical on this model . Good luck

Gene Salvino

David,

Genes advice is spot on.

Quality is absolutely needed in a Roll Pin Punch.

That little “nub” is crucial to its function!

shootski

B.B.,

Great job on the report and great pictures! But to me, the most interesting part was the part about the C4 episode!

Getting back to the pistol, you now have me hoping my Dad’s Tempest stays good for years. However, there was one part that broke on my old Tempest; after over 10,000 rounds (mostly fired with Beeman Silver Jets), the trigger guard broke; it snapped in half as I was firing the gun (needless to say, the pellet went way off target!). Back then, it was no problem to get another trigger guard (they seem to be scarce as hens’ teeth these days). At the time, I think I sent the gun back to Beeman to be repaired; but now, armed with this report, I can change the trigger guard out myself…if it ever breaks (I’m way careful not to put any stress on it…I stressed the old one a lot).

I need to order some roll pin punches from Brownells (thank you, Gene =>)…just in case.

Thanking you for a super-informative report,

dave

Once again, the Wizard has allowed us to have a peek behind the curtain. You have no idea how much I appreciate these little peeks. They are invaluable to me in keeping these old gals going at Ridge Runner’s Home For Wayward Airguns.

BB ,

I can’t believe I didn’t notice this earlier . That is a Santa Rosa gun . This goes way back .

Gene,

Maybe it goes way back, but Edith bought it for me in the 1990s. I suspect Beeman didn’t move them too fast.

B.B.

Gene,

Now I’m wondering if I need to worry that my gun may develop the same lubrication issues as B.B.’s.

Here’s a pic of it; I BELIEVE I bought it for my Dad back in 1982…but my memory could be wrong. =>

Thank you,

dave

TheDavemyster ,

You are correct parts are very scarce . Webley stopped all production in the UK in 2007. You will have to get that part from Airgunspares.com or Gunspares.co.uk to find a New Old stock one . Possibly David Slade at the Airgunwerks would have a parts gun ? That’s the problem servicing these old guns , if something is broken It could become a paperweight . There have been no new parts produced for 14 years ! I do know that the Turkish mainspring and piston seals will fit the UK guns. Hope this helps out .

Gene Salvino

Gene,

That is helpful; thank you. As posted to you in the pic up above, it is a “San Rafael” Beeman, and is marked “WEBLEY & SCOTT LTD” and “MADE IN ENGLAND” on the two lines on the bottom of the plastic shroud. The serial number is in 4 or 5-point type; I has to use a 12X glass to read it, but it’s: 038856

I don’t know if that is before or after B.B.’s gun; but, so far, thank God, it is shooting very well. And since it’s an heirloom from my Dad, even if it becomes a paperweight some day, I still won’t part with it; I’ll just hang it on the wall. Thanks again for your help! =>

Take care,

dave

Dave,

Santa Rosa is where Beeman started it all. The collectors wet themselves when they see Santa Rosa.

That’s good to know for future reference; thanks! =>

RR

My FWB127 is stamped San Anselmo. I believe that predates Santa Rosa.

Larry from Algona

Larry,

Yes, it does. San Anselmo was the address Beeman used when they worked out of their home.

B.B.

Off topic,

I just saw a letter from the owner of Shoebox (on the GTA site) saying that they are throwing in the towel for good. I do not think it is Covid related, but rather just getting beat up by all the new/cheaper stuff coming out. Just some FYI for anyone interested.

Chris

Chris,

That I do not doubt. His compressors have never been cheap and you need a shop compressor to feed his. That alone would hurt sales.

Also, the Shoebox was good for filling an airgun, but it was never suited to the task of filling a tank. It was just too brutal a job for it.

RR

The Shoebox compressor does fill a 90 cubic inch bottle very well. That bottle will fill a Marauder rifle about 8 or 9 times. My Shoebox would fill that bottle in about 40 minutes.

Now a big 90 cubic foot bottle would be another story. But not many compressors will fill a 90 cubic foot bottle at a reasonable time. Let alone even be able to fill it.

So no the Shoebox was not just for filling guns. Hmm makes me wonder now if that is what people think the Shoebox compressor was for. If so they are mistaken.

GF1,

Mine does great. I do not fill to gun. I fill to a small CF tank. 3500 to 4500 in 30 minutes. I have the “10” pulley/belt kit and several rebuild kits that came with it. Unless I start shooting a HECK of a lot more, I will probably never have to buy another one. At any rate,… the company is history. 🙁

Chris

Chris

That’s a bummer about the company. So now does that mean no replacement parts for it after supplies run out.

And mine was one of the first ones that went to belt drive instead of the chain drive. It also was when they changed over to hardened piston rods.

I had mine for about 5 or more years before I got the China compressor. I had no problems with the Shoebox. Matter of fact my buddy has my old Shoebox and it’s still going strong.

And the Shoebox originally got made for paint ball guns and filling buddy bottles so they had air supply at the shooting fields.

It’s a shame they will be gone. I imagine they wont be the only ones either. Probably even some of the bigger quality (supposedly quality) compressors will go by the way side too I’m thinking. We’ll see one way or another that’s for sure.

GF1,

As I recall, the post said that he sold off everything? (finished units, parts, etc.) to the military. Apparently he was in with them as well as the civilian market. Given that they buy $1000 toilet seats,….. a Shoebox was probably good for an easy 5? 😉

Hey,… gotta fund that UFO/Alien covert stuff (off the record) somehow,… eh? 🙂

Chris

Chris

Smart move for him I suppose. If it’s all true. Either way. Hate to see the Shoebox go.

GF1,

It was a post on GTA (today) directly from the owner thanking GTA for all their support. I tried to search it again and was unable to pull it back up again. That GTA site navigation takes a bit of getting used to.

Chris

Chris

I wonder if we’ll hear more or if it will go under the radar and be done.

GF1,

Go to GTA and sign in and look for (new posts),… (since you last visited). I read that one,.. so I guess it would not show for me again. Even a search showed up nothing current. ? Figure it (Shoebox) gone and done. Run it till you can’t no more and get a new one.

Chris

GF1,

Found it. (Regarding Shoebox company shutting down.)

“READ THIS ! email to me from Tom

Dan,

We completely agree with you, china can make all the compressors now. We are no longer going to compete with the Chinese compressors and have thrown in the towel. We are effectively out of production and will continue to sell them at the 1300 dollar price for specific people like NASA that have a particular need. Parts will continue to be available but at a higher price. Please tell the folks at GTA we appreciated their business over the years and they have been great customers.

Thanks,

Tom Kaye”

Tom is the owner. This was the first post in a thread of about 5 pages from 4-4-2020 from a reader, Dan.

Chris

Chris

It sounds like parts will still be available possibly to the general public at a higher price. Hard to tell by the wording.

Usually it’s just o-ring replacement and cleaning to rebuild them. So one could probably keep one going until a hard part breaks. Then at the point it would be good to know a good machinist if the parts aren’t available. If I had one still I’m sure I would figure something out to keep it going.

Chris

Read my response to RidgeRunner. What do you know from the experience you have with your Shoebox compressor.

BB ,

You’re correct on that , they were expensive back then with the Pound to Dollar exchange . Same thing now I bet we sell 20 to 30 guns under $100.00 for every over $500.00 gun we sell , my guesstimate . No evidence to back it up ,just seems like the price-point stuff is taking over the world .

Gene,

I was laid off in 2006. I have been in my present job since. After all of these years I am finally making what I did then. Most of us cannot afford those things, most especially those overpriced FX airguns.

RR

Most are overpriced in my opinion.

TheDavemyster ,

If You hear rubbing sounds . Lube the piston bearings with some gear oil from the top cocking slot I believe You should be able to drip some on the mainspring guide also . Only do this if The gun is tight or has rubbing . I have told numerous customers to do this and this beats a disassembly .

Gene Salvino

“I have told numerous customers to do this and this beats a disassembly.”

Excellent! Thank you. =>

Well, I never tried to disassemble my Tempest so I can’t relate.

However I fully understand and appreciate the pucker factor of unexploded C4. I was the commanding officer of the 59th Engr Land Cleaning Company in Vietnam. We were finding unexploded land mines and 250 pound bombs on a regular basis. As the CO, I always set the explosive and capped the C4. Crimping the fuse in the caps without the proper crimping pliers was a problem and one day a Spec 5 said I can crimp it. Before I could stop him, he crimped the cap with his teeth. Guess what, the charge didn’t go off, in his mouth or in the C4. I waited a full hour before I went back to reset the charge. That was the highest my pucker factor ever reached including when we were under attack. After 50 years, I can still see that unexploded C4 on that bomb just like it was yesterday.

Jonah, wow, what a story; thanks for sharing it!

B.B.

Nice job! Now you are more than ready for a P1.

I have set up some steel plates in the porch area (no right angles, towel at the bases)

because of the shelter in place. ( I watch this Miculek guy on you tube.) Then I practice with my Gamo revolver.

I’ve had to reinforce the frame in some key areas. Cheap roll pins are the reason. How come

when its time to reload a revolver, the wheel doesn’t spring open and eject the emptys when I thumb the release?

Is it because there is a thing called a semi auto matic pistol?

Best,

Rob

Rob,

Making a working cylinder crane (the thing that flips open) is expensive. That’s mostly why.

B.B.

BB,

If you had un-exploded C4 charge like has been described,…. why would you not just set a new charge (to explode the stuff that did not) as opposed to messing with/fixing the original charge?

Chris

Chris,

What I failed to tell you was this was the final round of shots. We had no more explosives to do what you suggest. It certainly would have worked, if we had. But even it we had, all the blocks in the pit would still have had to be gathered together so they would all detonate

B.B.

Ridgerunner ,

I agree , I was in the same boat for awhile in 2007 . It is sad to see all the emptied out factories around here. My Father retired from Timken Roller Bearing in 2000 and it closed the Canton, OH plant in 2012 . Moved production to Romania , China , India and a plant in SC . Unfortunately this is the new normal ! The sad thing is there are allot of tool and die makers , millwrights and electricians who will never get to where they were . Scary thing is there will be a much less skilled pool of labor to recruit from , they don’t even have shop classes in HS anymore .

Gene Salvino

Gene,

It is a shame. The only way this country is going to make it is if we make it, not import it.

An example is airguns. I have fought myself long and hard about a Chinese airgun. They have really improved over the years and the price is reasonable. The problem is it is made in China. I would really like to get one of those Air Venturi Avengers, but… I will probably end up with a Maximus.

RR,

I missed the Avenger. Wow. That has a lot going for it. Like,… everything. Still, Gene has a good point. I got a hunch that buying USA is going to be taking on a whole new meaning.

Chris

Chris USA,

“I got a hunch that buying USA is going to be taking on a whole new meaning.” I pray that you are correct in your hunch Chris! Some how I doubt, that even with this lesson we are all experiencing, that the Pricepoint mentality will not go right back to buying Junk NOW rather than delaying gratification by saving up for a QUALITY product a bit down the road.

Example: There is but one Made In The USA Flatware company remaining: http://www.libertytabletop.com

shootski

Shootski,

Perhaps. Perhaps not. The fact that this could have been stopped (at the source), and wasn’t,.. is going to leave a very bad taste not just here, but worldwide. Second,.. this involves families/friends and if that is not personal,… then nothing is. That said,… the China ties will not be broken over night.

Chris

Ridgerunner ,

You cannot go wrong with the Maximus . Benjamin isn’t going anywhere and parts will never be a concern . I pretty much tell customers only buy stuff from western powers . UK , USA , Germany , Spain , etc.. Third world stuff is shoddy and You never know if they fold if You can get parts. Who wants to pay a machinist $100.00 to make parts for a $200.00 gun . I have always been a fan of AirForce Guns , simpler is better.

Gene Salvino

Gene

Well maybe for a while with Crosman and the COVID-19 shut down you mentioned the other day.

I’m a fan of the Crosman pcp guns. Their China break barrelguns not at all.

Is Crosman open now in the parts department while this is going on. Or did they shut down completely?

Dynamite is actually stronger than TNT. C4 is not much more powerful, but it’s physical properties make it detonate without confinement, and that is a huge advantage to, say, TNT flakes when you want to blow up something in the field.

Hats off to BB for disassembling this pistol!

Mel,

Okay, that is something I did not know. Aren’t there grades of dynamite, from the percentage of nitroglycern in the sticks?

I have worked some with TNT. We got it in one-pound can-like containers. But it wasn’t moldable like C4, which was much easier to use.

I have worked with C4 a lot more. It burns at over 26,000 f.p.s., which makes it a high explosive. It’s base component is RDX, which is, I believe, one of the military’s most powerful non-nuclear explosives.

I have also worked with detonating cord, also called primer cord. Wrap enough of it around something and cut it in two!

B.B.

B.B.,

We used det cord on the ranch for removing trees/stumps. Even used it to remove beaver dams quickly since it works under water. As you said, give me enough det cord and I’ll remove your house from its foundation.

Detcord is basically a plastic explosive (such as C4) in a flexible tube.

Indeed Dynamite is a trade name and there is a number of different Dynamite product grades.

One really cool application of plastic explosive is hardening of metal. Pack it around a metal part, detonate, and if fine right, the metal object is “hammer forged” from the shock wave

B.B.,

Terrific job on this pistol’s disassembly. Very nice photos too. I’m not a pistol guy but this was very interesting to see.

Hope to see a disassembly of a Benjamin Model 137 pistol some day. It appears to be a tough one to take apart.

Geo

Geo,

Glad to see ya’ post’n. 🙂 Which version do you have? Plastic grip seems std.. Wood grips, add 10%. Black nickel finish, add 30%. Plastic grips, box and instructions, add 15%. Wood grips, box and instructions, add 35%.

95% condition is $100 in the 11th edition Blue Book. Last manufacturer suggested retail was $85. 1946-1985.

Chris

Chris,

It very old and in pieces except for the valve assembly which is still in the gun because it takes some specialty tools to remove it. It has wooden grips and the barrel appears to be brass. I posted a picture a while back but I didn’t get many responses to at that time. Here is another photo: the bottom photo is a 130 BB version and the top photo is the 137 which is .177 rifled barrel.

Geo

Geo,

Thanks. I do remember now.

Chris

Geo,

anotherairgunblog has the take down repair of the 132 version that’ll help you.

Jonah

Jonah,

Thank you for the suggestion. I have bookmarked both parts for reference. The problem is I do not have access to the needed tools. It would be nice to have a shop with a lathe, mill, and drill press. It appears that would be needed in order to fabricate new parts and tools to remove the valve assembly. Appreciate your response.

Geo

Pyramid Air has the valve tool. It is the same as for the Sheridan and Benjamin guns. It is not too expensive.

Haven’t heard from Vanna2 / Hank in a while. Hope he’s doing ok.

GunFun1 ,

I was told about a week ago that they might have to shut down . I was told by purchasing that they are operating as essential. I am sure they have done what we did and everyone that can works from home , they are shipping .

Gene Salvino

Gene

Thanks for the info.

Off subject , thanks for a great blog . Pic uploaded, if it appears are my Webley Stingray, Airsporter and UK made ‘Diana 27’

Cheers , I these difficult times, from Hayling island, UK.

Mike 58,

Welcome to the blog. Those are nice.

Siraniko

Thanks , and stay safe everyone.