Webley Mark II Service air rifle.

Part 1

Part 2

Part 3

Part 4

Part 5

A history of airguns

Today’s report is a follow-on to the 5-part series I republished a few months ago on the Webley Mark II Service rifle. The original posting for that series was in 2016. And two years later, reader RidgeRunner posted two guest blogs of his own on the rifle. Today we read the first of those.

This year (2023) I reposted that series to cover me while I traveled to, covered and traveled back from the 2023 Pyramyd Air Cup. Today’s post was the first of the two guest blogs written by RidgeRunner, who now owns the rifle. He tells us about the maintenance he did.

RidgeRunner, once again, take it away.

This report covers:

- A little history

- Something funny going on

- We’re going in

- Doodad

- Onward through the fog

- Back together

- What’s next?

A little history

Those of you who have been hanging around for a while may vaguely recall BB doing a blog about one of these air rifles. What some may not know is my loving wife contacted BB and conspired with him to have that very air rifle be my Christmas present last year. Needless to say I was quite surprised — shocked is more like it. This lovely old lady is now a permanent resident at RidgeRunner’s Home For Wayward Airguns.

Something funny going on

With the Webley BB had sent me a new piston ring. I have wanted to replace the old one but have hesitated to go in as she has been shooting fine. Then the other day at a spinner flipping session on the back porch, I noticed she had developed a twangy vibration and a sharp jolt at the end of the firing cycle. As I was oiling and wiping her down to hang her back up a piece fell off. The barrel pivot pin had broken in half. I promptly ordered a new pin and retaining screw from John Knibbs.

John Knibbs comes through.

We’re going in

With having to replace the pin and the piston ring I decided it was time to go in. Of course BB asked me to take lots of pictures to share with you guys. I apologize for the quality of the photos as I am not as talented as BB and lack any type of Photoshop to fix them.

Doodad

Before I start spreading parts all over the table though, I wanted to show you folks a little doodad that BB somehow overlooked in his review, the anti-beartrap mechanism. It is a small lever under the barrel that prevents the piston from slamming home after the air rifle has been cocked, even if the trigger is pulled. When the barrel is locked in the firing position, it depresses the end of the lever, unlocking the piston.

Barrel unlocked. The anti-beartrap device is grabbing the piston.

Barrel locked. The anti-beartrap is free from the piston and it can now fire.

My first step in the disassembly was to remove the barrel by pushing in the barrel retention button and slide the barrel out of its cradle.

Barrel retention button.

In the picture above you can see the barrel retention button, barrel cradle, barrel pivot pin and retaining screw. I next removed the retaining screw which allowed me to push out the broken pivot pin and then, by lifting up the cradle, I could slide it back until it disengaged from the piston slot.

Cradle removed.

You can see in this picture the broken pin and the new one. I too noticed the new screw (below) seemed a bit long. It later turned out that the new screw would not work and I used the old one which works fine.

The next step I took, which really should have been before the previous one, was removing the stock from the action. Two wood screws held the butt plate and a long through bolt held the stock in place.

Stock removal.

I noticed the stock had a pin which fit in a hole in the action which kept it from rotating. A very nice touch indeed.

Stock end showing pin

Action, showing pin hole.

With the stock removed I could now begin disassembly of the action. Because this air rifle has been so well cared for over the years, this was a simple task. Taking a box wrench, whose end nicely fit in the slot of the compression tube plug, I began to unscrew the plug. I did not have to use any force as it turned with ease.

Removing the plug. The wrench acts like a big screwdriver.

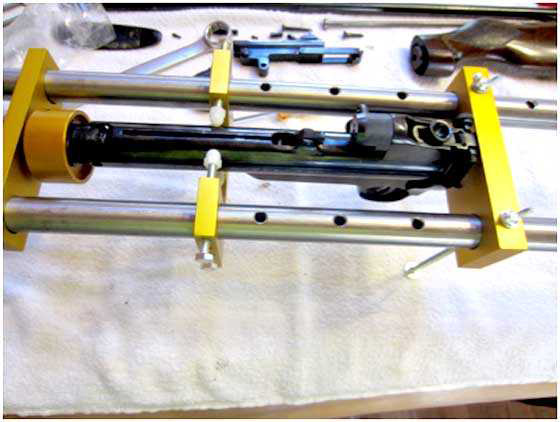

Once I had it unscrewed most of the way I mounted the action in my spring compressor to finish removing it. I did not have the desire for the plug to go sailing about the room.

Action in spring compressor.

It was then a simple and safe task to back off on the spring compressor and finish unscrewing the plug.

Amount of preload.

In the picture above you can see the amount of preload that was on the spring. I was then able to remove the plug with spring guide and spring from the action.

Plug, spring guide and spring.

As you can see from the above picture the spring is in great shape and well lubricated.

The next step was to remove the piston from the action. This was accomplished by pulling on the trigger, lifting the end of the bear trap lever and sliding the piston out the end of the compression tube with a small screwdriver.

Piston.

Notice the bronze piston ring on the end of the piston. Feinwerkbau used a similar arrangement on their older 10-meter air rifles.

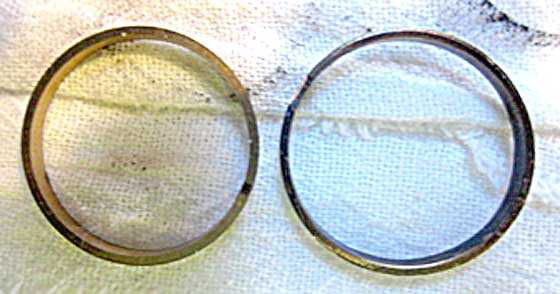

Ring comparison. New one on the left.

Here is a picture of the two rings. Can you spot the old one? It was a simple matter to remove the old ring that was worn and install the new one.

New ring installed.

Here you can see the new ring installed on the piston. Notice the notch just below the ring where the anti-bear trap mechanism engages the piston.

Back together

With this done it was now time for reassembly. This was accomplished in the reverse order with one exception. I found that when I was reinserting the piston that I could not get the sear to clear, requiring me to remove the trigger assembly. I did not take any pictures of this, but it was a simple matter of removing three screws. The trigger is a single stage direct sear type. It would be difficult for it to be much simpler.

What’s next?

Now that she is all back together and working properly, I will have to do a velocity and accuracy test so as to compare to BB’s previous tests. Hang on; I will get a round tuit.

RidgeRunner,

Great report! Very informative; and I think you did a really nice job on the pics.

I’m looking forward to the velocity and accuracy report! 😉

Blessings to you,

dave

Dave,

Believe it or not, they are coming.

Cool! 🙂

RR

I have been known to glance over some reports on springers, not having any thoughts of changing or working on mine, but the pictures of this unusual one drew me in. Nice report.

I am somewhat of a perfectionist, well was anyway, and hate to tell you how many times I reread and change the wording to make sure I make my point clear when I comment. An entire blog would take me forever to finish with corrections to the corrections to get the words just right and making sure each photo is exactly as I want it to be. Then there has to be an intro, a body and conclusion to avoid confusion and make it interesting.

I’m sure BB has it down pat by now and the right words just flow out.

After taking an instructor course and having to write a lesson, provide training aids, monitor and maintain class participation (and) changed to > as well as, understanding, I am very critical of myself.

One day, we shall see. Thanks for your time.

Bob M,

I do understand. I also have a very similar “problem”. That is why I do not write more blog reports, though sometimes I do have rather lengthy comments where the words seem to just roll out.

Excellent report, Ridgerunner. Thanks for taking the time to show us so much detail on the inner workings of this unique airgun.

I am really looking forward to your upcoming report on your Diana 34.

RG,

I have yet to shoot this old gal since I sent it to BB. I did find my round tuit and hope to do such this week while I am on “staycation”. Of course this is on the assumption that I can finish all of the “honey-doos”. 😉

Roger that. Around here, after two weekends, “it’s beginning to look a lot like Christmas.”

You could say working on and shooting the Webley is part of your “honeydoos” because, after all, your Mrs. gifted it to you and no doubt she wants you to respect and take care of it. Note FM is not legally qualified to practice Family Law or any other kind. 😉

LOL! Maybe you are not qualified to “practice” Family Law, but I do like your perspective of such.

RR,

Great report! I wish my guest blogs were as well thought out as your is.

-Yogi

Yogi,

That is one reason you do not see more guest blogs of mine. I only have rare moments of clarity and thought. I need to learn to use those moments to write with.

Thanks guys for your kind words.

Sooner or later BB will find a round tuit and put out my report on the velocities. I lost my round tuit shortly after that and never did write an accuracy report for this old gal. I did find my round tuit the other day and hopefully I will use it and give you an accuracy update, a blog series on my Diana 34 that BB “fixed” and a couple of other gems that have moved into RidgeRunner’s Home For Wayward Airguns.

By the way, when I do the blog on this old gals accuracy, do not expect much. She is fun to shoot, but not really that accurate. If you dig back through BB’s blogs on this air rifle you will know what to expect.

Well done, a very interesting post. If I understand the introduction correctly, it was written in 2018. How’s the gun doing these days? Here’s some more recent news (next best thing to wabbit):

:o)

LOL! My first turkey was not near as spectacular! I am glad you finally was able to get one of those birds!

The old gal is doing just fine! She is not the most accurate of the airguns around here, but she is quite a joy to pull out and shoot every once in a while. A good bit of the time she is hanging out with a very old Webley Senior. 😉

RR

Goodun!

Many of us look forward to your future reports, especially the 34 shakedown. Hope the staycation is going well and is a permanent arrangement.

Deck

The staycation is going quite well and it will be permanent soon!

RidgeRunner,

Thanks for the fine report! Your beautiful sproinger is so clean and the pieces came apart without fuss. You are smart to wear nitrile gloves while working on a greasy project, I have a box of ’em and I always forget they’re there. The pics were excellent and the content was very readable and clear to understand. I’m also looking forward to learning more and we’ll see if there is a velocity increase with the new piston ring. This Webley Mark II Service is a beautiful machine, made almost 90 years ago and is in great shape. I can see why you love the way these older gals look and work.

Regards,

Will

Will S,

I can help you most always remember to put on your gloves in only one word.

CORROSION

Wearing a Latex or Nitrile glove doesn’t just work for Surgeons/First Responders/Mechanics/Machinists/and others who worry about contaminating their work!

They do work to keep dirt off the hands and under fingernails when working on greasy projects or cleaning out the stables but that is what soap and hand cleaner is for!

Keep your airgun parts CLEAN of salts and other contamination even if your project isn’t greasy!

One word reminder again say it three times:

CORROSION CORROSION CORROSION

shootski

shootski,

Of course you’re right about our salty skin sewing the seeds of corrosion among concealed steel parts. I guess I don’t mind the grease on my own hands, but I admire the attention to detail when others wear them. Point taken on the real reason for wearing them, thanks bud!

Regards,

Will

Thanks Will! As you note, she is very well made. She is all machined steel and walnut. So many of these old gals are made the same way. This is why I was able to rebuild the 1906 BSA that I have. There is something there to work with.

Good article and good read, RR. Thanks. If you are interested in photo retouching software, the one included with Microsoft 11 is very basic but can do wonders. Something more powerful and what I use is called paint.net. Finally, if you are a serious photographer and don’t want to spend the money on Photoshop, do a search for Gimp. All are free – my favorite word ahead of cheap.

Fred formerly of the Demokratik Peeples Republik of NJ now Happily in GA awaiting Turkey Day!

Hey RidgeRunner, Guest Bloggers, and B.B.,

Do you use an outline or checklist to start/do your blogs?

Mightcould help others write blogs to share how you get off TDC (Top Dead Center) on writing a blog.

shootski

PS: grateful for your work on the Guest Blog!

BZ!

shootski,

https://www.pyramydair.com/blog/2015/07/how-to-write-a-guest-blog/

BB

B.B.,

Thank you!

Anyone with an interest in doing a Guest Blog should read your linked blog and the comments as well.

shootski ;^)

RidgeRunner,

Interesting ring wear pattern on the old ring!

From the photograph it looks like the ring keps the split in the same position and greatest wear is/was opposite the split? Or is that an artifact of the lighting?

shootski

That was some time back. If my rememberer is working correctly, the seal is worn thin there. I had not thought of such, but it is somewhat interesting the way it is worn. The bronze ring does not just seal the piston, but also acts as a bearing to keep steel from marring steel.

RidgeRunner,

Thanks for answering.

I have wondered why more use of soft(er) metal compression rings wasn’t more common; especially since tuners go to the trouble to fit buttons to pistons when compression rings do the centering/friction reducing job as well as seal the compression tube and likely better at both tasks.

But i’m obviously not much of a Springer guy.

shootski

shootski,

The compression rings and the piston seals are at the front of the piston. The buttons are at the back to keep them from rubbing and/or gouging into the compression chamber/tube. If kept properly greased, this is not an issue.

I had to repair the inside of the compression chamber/tube of my 1906 BSA as it had been shot several times when totally dry and the leather piston seal had dried and disintegrated. The rear of the piston had badly gouged the tube. Fortunately, it was at the rear and did not affect compression. In the front of the tube there is still the impression of the screw head used to hold the piston seal on.

RidgeRunner,

Thank you for taking the time to explain those vital considerations in springer design to the ignorant Dark Sider. LOL!

shootski

Great report RR!

I am also somewhat of a perfectionist when writing, perhaps aware of my limitations, so I admire when someone does it effortlessly as you have done – or so it seems from this side of the screen. Very clear photographs too. I am looking forward to the next section.

Technical question: it seems like soft metal compression rings would be preferable to any of the other systems considering pressure, friction, temperature, speed, etc. However they are not common. Would you say it is cost or performance?

Henry

Henry,

A wild guess would be both. The metal compression ring does not seal as well as a more supple polymer seal, but it does have a longer life. The cost of a bronze compression ring such as this is far more expensive than an o-ring or two would be.

The FWB300 also uses a compression ring, but some have used o-rings instead and greatly improved the seal and compression, giving the FWB300 more power. I have considered this and may yet experiment with such, but I will most definitely hang onto and reinstall the bronze ring, just because.

Sorry for the late reply RR. Although I am not mechanically trained, I worked with enough good MEs and MTs that something must have stayed with me. Then again, you know what they say about a little knowledge.

Anyway, I thought that the friction of an elastomer O-ring would be detrimental to the piston speed. Obviously I was wrong. I wonder how much if any compression is designed between the O-ring and the cylinder wall. Also, what composition and durometer, I guess 90.

Digging a bit deeper, a quick search revealed that graphite, bronze and molly filled PTFE rings are now available. These are capable of taking high pressures and temperatures, while having low friction coefficients. These open the door to a whole lot of possibilities worth of experimentation.

In this hobby a curious person can dive as deep as he dares.

Thanks again,

Henry

Henry,

I regret not being able to answer your question concerning the amount of compression between the o-ring and cylinder wall. That requires way too much thought and effort on my part than I am willing to devote to such. I am inherently lazy. Doing actual scientific research into such things requires more energy on my part than I am willing to devote to such.

Now, for the short version.

I know of no airgun manufacturer that uses o-rings on their sproinger pistons.

Fair enough RR. I was just thinking out loud while typing, not proposing any research on my part, or much less on yours for sure. I find many aspects of the ‘simple’ springer action fascinating. In a way I find PCPs simpler, perhaps not mechanically but in the physics department.

Best,

Henry

I have never considered the sproinger as “simple”. You are quite correct in saying the PCP is easier to design than to properly design the sproinger. It seems that so few truly understand how these work properly.

This is a personal opinion, but it is my belief that a sproinger works best at around 11-12 FPE. A prime example is my Diana 34 that BB was so kind to rebuild for me. It went from a hard to cock, hard to handle, heavy recoiling behemoth to a docile, very accurate shooter. Now I wish I still had my Gamo CFX.

Most of my sproinger rifles are around 6 FPE. This Diana 34 is almost twice that. I have a full power Webley/Hatsan Tomahawk that will see some experimentation with, but if I need more power, I have a few PCPs.

I do like to piddle around with stuff. If I did a better job of documentation I might be mistaken for a scientist, or at least an engineer.

The writing and pics are so clear that perhaps even an FM could work on this type of rifle. On second thought, NO. Too much perfectionism and “intestinal retentiveness” in the way, which is another reason he quit blogging about 15 years ago. A recent message from

The writing and pics are so clear that perhaps even an FM could work on this type of rifle. On second thought, NO. Too much perfectionism and “intestinal retentiveness” in the way, which is another reason he quit blogging about 15 years ago. A recent message from Google brought the cheery news all that labor of love is about to be “dissapeared” into the ether unless the blog can be migrated to a designated “legacy” site.

I do not do Google. This is a good reason not to.

P.S. If I can do it, so can you. Of course, I have the attitude that if someone else can do it, so can I. If Jethro Bodine can be a brain surgeon, so can I. I know all my naughts.