by B.B. Pelletier

Fresh from the closet, another fine Crosman 160 emerges into daylight. We’ll watch this one blossom.

Today, I’ll report on the cleaning of Jose’s Crosman 160 and the adjustment of the trigger. This rifle was quite rusty when I got it, so today it came out of the stock for a thorough cleaning. The barreled action comes out of the stock by removing one nut on the bottom of the forearm and by removing the safety switch. To remove the switch, it must be turned toward SAFE while you push it out of the triggerguard. It will pop right out when you get it in the right position.

The broken safety has been pushed out, and the nut removed from the stock. That’s a new safety to the left of the broken one. The barreled action is now ready to come out of the stock.

Once the action was out of the stock, I could see that it was far rustier than I originally thought. The rust that could be seen when the rifle was intact was just surface rust, but the stock was hiding deep active rust that had to be removed.

This was under the stock — heavy, active rust that must be dealt with!

I used Ballistol and a special scrubbing pad I bought at a recent gun show. A friend of mine says this pad looks like a stainless steel pot scrubber. All I know is that it removes all the rust and doesn’t harm the blue.

I used Balistol in a spray bottle and a special metal scrubber to remove the rust.

I was surprised at how fast the rust was removed. In all, it probably took no longer than 15 minutes to completely clean all the metal parts.

The trigger

With the gun finally clean, it was time to address the trigger. I mentioned in Part 1 that this trigger is one of the finest ever put on an inexpensive air rifle, and it can be adjusted to a very light, crisp pull. When I got the gun, the single-stage trigger had lots of creep and was breaking at 5 lbs., even. Something had to be done about that.

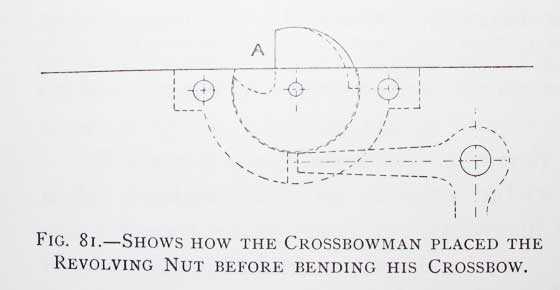

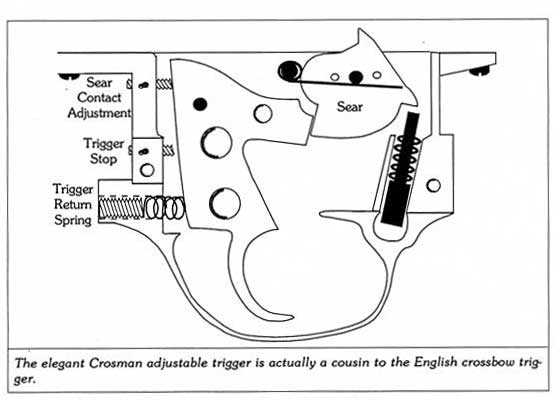

The Crosman 160 trigger is an adaptation of a 15th century crossbow trigger, where a rotating piece called a nut forms the sear that releases the hammer — in the case of the pellet rifle. The nut is a lever that’s shaped like a circle. It allows a small force (the sear) to overcome a greater force (the hammer spring) through leverage. No filing or stoning of the trigger contact surfaces is necessary, because the trigger doesn’t work like a conventional one.

From Sir Ralph Payne-Gallwey’s book, “The Crossbow,” (published in 1903) this illustration of a 15th century crossbow nut shows how a great force can be overcome by a smaller one.

But the Crosman 160 trigger is more sophisticated than the crossbow trigger. It allows the adjustment of the sear contact area and also the point at which the trigger stops. This gives the shooter a safe trigger that breaks cleanly, yet feels like an expensive precision target trigger.

The trigger in the subject rifle was about as filthy as I’ve ever seen. This trigger has a sideplate that allows the user to watch the adjustments of the parts and even to cock and fire the trigger with the parts exposed. Normally, this sideplate keeps the parts inside pretty clean, but you can see from the photo what I saw inside this one.

I’ve removed the trigger unit from the action here. It isn’t necessary to do this, and in fact you must be able to cock the rifle when you adjust the trigger, so leave it connected. I did this for cleaning purposes.

Compare this photo to the previous graphic, and you’ll see all the important trigger parts. This is before cleaning. The rusty red part at the upper right is the nut that’s the sear.

I removed the trigger blade from the trigger assembly and cleaned it outside the trigger box, but all other parts were cleaned where they were situated. Ballistol on cotton swabs worked wonders at removing the rust, dust and dirt. And it left all the parts with a lubricated surface.

The two trigger adjustment screws were stuck in place by dried grease, so Ballistol had to dissolve that before I could clean the threads. The final touch was to apply moly grease to the mating surfaces of the trigger blade and the rotating nut that serves as the sear. Then it was time to adjust the trigger.

Trigger adjustment

The first step was to back off the trigger return spring, which is located at the bottom rear of the trigger box. With this spring relaxed, you can feel the engagement of the sear much better.

Next, I adjusted the top screw, which adjusts the trigger/sear contact area. I set it very quickly because I’ve adjusted dozens of these triggers over the years and I know what they need. You may have to adjust the screw then cock the rifle and fire it several times to get the engagement you want. The engagement needed is very narrow, and it looks like the trigger is about to slip off the sear; so I always give the cocked rifle a bump test after adjusting the trigger, just to be safe. If I can’t jar the trigger off the sear, it’s safe.

The final screw to adjust is the trigger stop or overtravel screw. It stops the trigger blade after the sear has released, and the closer this is to the release point without impeding the trigger-pull, the better the trigger feels. Once the engagement area is okay, it’s easy to set this screw to stop the trigger immediately following trigger release.

With that done, I put the cover plate back on the trigger and shifted my attention to the S331 sight. By the way, Robert of Arcade explained in a comment that the S331 sight was actually made by Mossberg and not by Williams, as I originally said in Part 1. I changed the maker to Mossberg in Part 1, and now I’m telling you.

The rear sight on this rifle was loose when I examined it, so I removed it from the rifle and disassembled it for cleaning. Most of the parts are aluminum, but a couple are blued steel and suffered from rust to the point that there were pits left on their surfaces after the rust was removed. The detents are very crisp and easy to feel as you make the adjustments. This is a simple peep sight assembly, but it works very well and adjusts precisely, which is all you can ask of a sight.

Once the sight was clean and back on the rifle, I put the barreled action back into the stock. I had to use the old broken safety switch because the replacement I have is slightly too large to fit the hole. I’ll trim it down in a separate session so the gun has a complete safety switch. For now, I’ll just keep the rifle off safe.

How does it look?

Because the bulk of the deep rust lies below the stock line, the deep pits that appeared from cleaning do not show. What was above the stock line was mostly just surface rust that’s now completely gone. The metal on this rifle now appears to be 80 percent or better. The stock finish is still flaky and needs to be taken down all the way with sandpaper and reapplied, but it doesn’t detract from the rifle’s appearance.

And the trigger?

The trigger now breaks at one pound, even. It’s glass-crisp, and you would swear that it releases at just a couple ounces if you didn’t see the trigger-pull gauge. I think the owner will be amazed at the transformation this rifle has undergone.

Yet to come

I won’t bore you with the other mundane jobs like the safety and the stock finish, but I’ll test this rifle for accuracy. So, there’s one more report yet to come. We already know the velocity is in the right ballpark — 656 f.p.s. for a 14.2-grain Daisy pellet on a 90-degree day. But I want to show you the accuracy these old rifles can give with modern pellets.

Nice save on a classic Crosman. For deep pitting that “potscrubber” and ballistol sounds like a good one. Never tried that. Looking at the metal that was encased in the stock is a great example of why we should remove the actions from their stocks periodically and wipe them down with your favorite metal protector.

Congratulations to Pyramyd AIR for being named Airgun Retailer of the month by the yellow forum:

http://www.network54.com/Forum/79537/message/1344103211/Featuring+AG+business+of+the+Month+-+Pyramyd+Air

kevin

BB,

This was really a superb report. Thanks.

pz

BB,you really earned your supper on this Crosman! I never would have imagined the trigger coming out so nice! Why would they abandon such a great design,I wonder? You have made me want a 160 for sure.

Frank,

Well, the QB 78/TF78 & 79 also have this trigger and it is just as good. You have to get one with a good barrel, because they range from average to great.

B.B.

B.B. I hope you’re getting compensated for this super restoration job. There must be a special enjoyment in bringing back a nice piece of equipment from dereliction.

Matt61

Matt,

The owner of this 160 doesn’t like the idea that it uses two CO2 cartridges. So I may be able to buy it or trade him a springer for it.

B.B.

Does he know that it will work on only one? Just put an empty one in with a full one. You’ll get half the shots, but it will work just fine.

No wonder the QBs are so popular.That will help my search…..thanks for the reminder on the barrel “crapshoot”.I had not forgotten completely what you wrote……but lets just say the reminder kept me from feeling dumb later!

The “crap-shoot” is pretty much over. It was true when the QBs were new, but they’ve been in production for several years now, with input from some American vendors. QC is way up. The current crop of Cr160 clones is as good or better than original Crosman guns.

I traded a NIB Ruger Airhawk for a used 2078 at Findlay last spring. In .22 it was an absolute tack driver. I swapped it out to .177, with a barrel and sidelever breach that I bought from Archer. The barrel is 1st quality, requiring NO crown or leade work. I just bolted it in and the damn thing will one-hole at 7M in the basement, shooting RWS Basics. I also installed an Archer HDD, and I’m getting about 80 consistent shots off two carts. Not bad mileage. I have done nothing to the valve or springs.

I flat LOVE this gun, and frankly it gives my Diana 66 and Daisy 753 a good run for the money at short range and tiny targets.

Hi Jim…..all of that is really great to hear.I have to be more careful with my wording.I was really thinking of the older ones….but my wording omitted that.Until now I’ve concentrated on shooting & collecting other stuff…….clearly,I have turned a blind eye to some good stuff.I spent my spare time today researching the “B’s” & “QBs”…….I’m learning. 🙂

Jim,

Eighty shots? That’s pretty impressive.

B.B.

That potscrubber looks like it would take off everything down to the bare metal. I’m convinced about the need to remove rust even apart from the unsightly looks. Rich Imhoff said that my B30 was full of rust when he received it, and he certainly got it shooting well. As for trigger jobs, I’m meditating on my first ever trigger job by replacing my Mosin-Nagant factory trigger with a Huber Concepts anti-friction ball trigger. Meditating…meditating…

Mike, yes, I know that maintenance is key for the AR and that they can be made to run well. But I’m trying to think of that in terms of extended time in the field. Reading up on the duties of the infantrymen in some army handbooks (without any direct experience!), it appears that there is quite a bit to do. One must scope out lines of travel with the least exposure to enemy fire, coordinate the leapfrogging of various units, find a proper position to fortify, figure out where to place the weapons for best effect, dig in, cut firing lanes, fill out range cards, replenish supplies of food, water, ammo, eat, sleep… And that is before the -50 degree weather closes in or you get overrun and are fighting non-stop for days on end. Then I read a zealous person on the internet who says that the people who complain about the AR just don’t understand maintenance. As an example, this person detail-stripped his weapon after 200 rounds and soaked all the parts in oil. He exhaustively tested all of his magazines, stomping on those which didn’t work. And he finished by saying that when you’re not eating, you clean your weapon; when you’re on the march you clean your weapon; whenever you have a spare moment, you clean your weapon. ??? I have trouble visualizing this (granted it is extreme). And I would think that having less of a maintenance burden is all to the good.

Yes, I’ve read about the problems with the chrome plating of the bore and the ball and stick powder, but I’m more interested in the choice of bullet. Part of the rave reviews from the Special Forces who were first issued the weapon in Vietnam had to do with the extremely destructive effects of the light bullet. They weren’t always repeatable because they were based on instability but they seem to have been there. That does seem to make sense out of what seems to be an underpowered cartridge. But the word is that this bullet was not achieving acceptable accuracy in Arctic environments. So, then the push began to increase the weight of the bullet. And when the U.S. Marines got hold of it and designed the M16A2 for greater accuracy, the original design concept was changed out of all recognition. I would venture to say the .223 has had its ups and downs as a service cartridge although I have no complaints about its performance in my Savage 10FP on the range.

Matt61

All those duties needed in a combat unit are divided. You wouldn’t do them all yourself. You take care of your weapon and it will take care of you. You make time. You get it done. This is true even if you use an AK.

In early Vietnam, the AR-15 used a 1 in 14 twist with a 55 grain bullet. It was just stable but as soon as it hit it would tumble which would really dump the energy. It was found that in Arctic conditions 1 in 14 would not stabilize the round so it was changed to 1 in 12. This eliminated some of the tumble on impact. Now we have gone to heavier bullets and a 1 in 7. A quick Goggle search will bring up all the information to the present day.

If you are really interested, buy one. They are great fun to shoot. Accurate with little recoil. You will like it!

Mike

Patrick wrote to the wrong address, so I have posted it here and will answe here.

B.B.

Tom, I love your podcast. It’s just fantastic, and I hope you keep it up. I know it’s been a while, but that’s the nature of podcasts anyway. I have a question that I think would make a great topic for an episode. I’ve just started squirrel hunting with my 18″ Crosman Custom 2400KT in .22cal. The gun is dead on at thirty yards (the width of my back yard), but I have not hit a squirrel with it yet. I suspect that the pellet’s trajectory is different for a steeply elevated shot than it is while shooting more horizontally. I can’t see where the pellets are impacting out in the thick woods, so I have no idea how to adjust. It’s very frustrating. Is there any truth to my theory, or is there something else going on? If I’m right, do I need holdover, or holdunder to correct?

Patrick,

I don’t do the podcast anymore. There just wasn’t enough of a listening audience to warrant the time it took.

As for those long shots and the trajectory, here is an easy way to figure it. When you shoot up you are shooting over a certain linear distance. If the squirrel is 100 feet up in a tree and you are standing 50 feet from the base of the same tree (the spot the squirrel would hit if he suddenly fell from the t ree), your pellet will act like it has traversed 50 feet. So if the pellet drops a half inch when shooting at a target 50 feet away on the same level, it will also drop the same half-inch when shooting up into the tree, even though the target is actually farther away.

If this seems confusing, think of it this way. If the squirrel was directly over your head, how much would the pellet drop? Zero — right?

This also works the same way for targets that are lower than you.

B.B.

Swell. More confirmation that I’m a mutant in the minority. Wondered why the podcasts ended.

Such a shame. The multi-part series with Dr. Beeman was excellent. Where else can you get this kind of insight into the American launching pad for airguns that Beeman provided?

We silly airgunners seem so obsessed with what is the newest and most powerful that we ignore and loose sight of our roots/history. I’m concerned that we, as a whole, don’t understand or appreciate the history of airguns. Very important IMHO. So much of the “new and improved” introductions in airguns, tuning kits, pellet designs, etc. are NOT NEW.

Unless the majority of airgunners know history of airguns the majority of airgunners can’t/won’t call BS on these “new” developements and we can’t move forward with truly new designs and development. I’m not saying there aren’t new designs and technologies but I am saying that most of the stuff that is generating the buzz on forums has been done. Been down this path (in some cases with the same snake oil salesmen) and should know what’s at the end of this road but yet this “new airgun or airgun product” is todays best thing since sliced bread. Give me a break.

In this aspect the internet is both a blessing and a curse. Sorry for the tangent perspective that may appear as a rant. Just poured forth. Don’t blame me I think another entity took over my fingers while typing.

kevin

Kevin,

You’re gonna enjoy tomorrow’s blog!

B.B.

B.B. & Edith,

I’m fortunate that you’re so tolerant to my thinly disguised airgun rants. I’d have been banned from your former forum since nowadays the sponsers that grease the palms of the current owner are given not just great latitude but are allowed to be put on pedestals while selling snake oil. I was happier about the internet information exchange regarding airguns when I was ingnorant. You’re at least smiling about my naivity if not laughing out loud since you’ve been part of this rodeo for so long.

I’m intrigued about tomorrows blog.

kevin

Kevin,

I would never call anyone who owns more 10-meter rifles than I own airguns naive! 😉

B.B.

B.B.,

It’s a quality vs. quantity paradigm.

The guns you own and have kept are accurate or have inherent/dormant accuracy.

Therein lies the difference between us and thus the student that dutifully follows the master.

kevin

Thanks BB. I’ll be using your information on adjusting the trigger with the one I have. Folks that complain that it uses two CO2 cartridges aren’t looking at the big picture. The rifle works great. At the end of the day the cost is really small. Now, if you look at the price of gas……………!

Mike

That is a very interesting trigger design. I like that the safety locks the sear as that seems like a more certain way to prevent a misfire if the gun were dropped. However, it looks like the trigger is free to move while the safety is on. If there was enough wear on the safety pin or enough dirt in the mechanism and the trigger was pulled after the gun was cocked but the safety was on, then the trigger might not return completely to engage the sear. In that ‘perfect storm’ scenario, the gun could fire when the safety was released.

Just an arm-chair observation from looking at your pictures. I expect the design tolerances rule out that possibility.

Again, thanks for showing us a very interesting design.

Steve

Steve,

Did you have any involvement in the recent Mars landing?

kevin

That 160 is built very well.I have a crosman 147 and 1400 those were the days when Crosman used the highest quality materials.Nowadays its all about making less expensive for higher proffit.I dont think the airgun industry bubble didnt pop yet to were they have to scringe on high quality.I have been supporting Crosman /Daisy buying every Xmas.I constentaly check PA web site Crosman/Daisy line up hoping to score a 2100/2200 classic wood trim or to see if Daisy sub out to Weihrach or Diana like they did many many years ago. I bet the high quality guns would sell like hot cakes. But what do I know my wife thinks im a fool for owning 70 airguns.

Chris,

You remind me that I should do a Crosman model 70 sometime.

B.B.

I have a crosman pelgun 160! seeking parts kit! Where can I purchase and is it difficult to repair? It leaks air only, figure it needs new seal kit? thank you!

Jack,

Try this guy:

And, no, the 160 isn’t difficult to reseal.

B.B.