by Tom Gaylord

Writing as B.B. Pelletier

The Benjamin 392 pump assist modification is an interesting side street in the hobby.

This report covers:

- How is this historical?

- What is it?

- How does it work?

- The inventor

- How much?

- The butterfly hand pump

- What are they worth?

- What comes next?

This is a report I have wanted to write for a long time. I actually did a 5-part report on this unique air rifle back in 2008. But this belongs in the historical archives, plus there are tens of thousands of new readers who haven’t even heard of this novel airgun.

How is this historical?

The Benjamin 392 multi-pump pneumatic is still in production. How can this be an historical report? Well, the 392 is still being made, but the pump assist modification is not. It has lapsed into the history of airguns.

What is it?

At its foundation, this rifle is a standard Benjamin 392. Not much is changed, as far as the performance of the rifle goes. The inventor did optimize each rifle he modified for a slight velocity increase, but that wasn’t the purpose of the modification. Don’t confuse this with the Steroid Streak conversion that Mac-1 can do. That one does increase the power of the gun by a considerable amount.

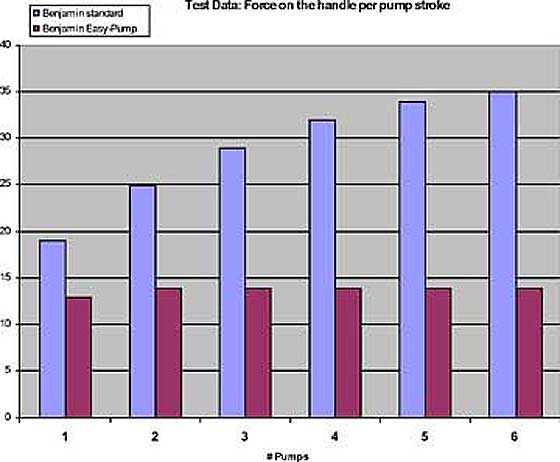

The pump assist is there to reduce the effort required to pump the rifle. For the first 3-4 strokes a 392 is fairly easy to pump, but as the number of strokes goes up, so does the effort that’s needed to complete them. Here is a comparison chart of pump effort for standard and modified guns.

Darker bars are the modified gun. Lighter bars are a standard gun. Scale on the left are the pounds of force applied to close the pump handle.

I will test the pump effort for you in Part 2, when I test velocity. In the past I have noted that the maximum pump effort remains around 14 pounds for the pump assist. I can’t remember if I actually tested it or just took the word of the inventor from the chart shown above. It’s just much easier to pump is the best I can tell you now.

How does it work?

This is the key to the pump assist. The mechanism, which you can see adds extra levers to the rifle’s pump, changes the geometry of the pump stroke as the number of strokes increases. It does this based on the resistance of the reservoir inlet valve that increases as the pressure inside the reservoir rises. The pump assist compresses the air more with each stroke, and the geometry of the pump mechanism increases in efficiency as it does.

This Sheridan Blue Streak pump mechanism is virtually the same as the standard 392. Notice there is a single pump rod that connects the pump arm to the sliding pump head.

The pump assist adds two additional rods that connect to the pump rod. Where they meet (at the lower right) is the fulcrum of the pump assist mechanism, and this is what changes (position) as the number of strokes increases.

The inventor

Robert Moss invented the pump assist and it took him a long time and many prototypes to get it right. It wasn’t just inventing something that worked the way he envisioned it. That was the easy part. The hard part was finding the right materials that would allow the pump assist to be built into a Benjamin 392 without adding a lot of extra weight and bulk. Also the materials that were needed were very exotic metals with high cost, so Moss had to find ways around that. Nobody wants to pay more to modify their 392 than the rifle costs originally!

The anchor point for the pump assist is silver soldered to the pump tube. The pin that the pump assist link pivots on (arrow) had to be made of extremely tough material to withstand the stresses of continual pumping.

In the end Moss found what he needed and learned how to make it. He was able to convert several new rifles and bring them to the Roanoke airgun show, where I bought one. But he wanted to reach more airgunners and was daunted by all the marketing that is involved.

He decided to enter into partnership with Air Venturi, to modify 392s and 397s for them. They already had the distribution network established, so it seemed to be the right thing to do. But it did add an additional layer of cost to the project, so Moss went back to the drawing board to see what could be done. The goal in the end was to get a modification that could be offered by Pyramyd AIR for $100 over the initial price of the stock 392.

How much?

When people heard the price of the modified airgun they went ballistic. They thought Crosman should find a way to do this at the factory. People shouldn’t have to pay for it! Many shooters wanted the benefits of the pump assist, once they understood what they were. But very few were willing to pay for them. Bob Moss spent many years and a lot of money perfecting his idea, only to find the market wanted him to give it away. So the customers stayed away in droves, as they say. I think no more than 20 pump assist conversion were done. If it was more than that, it wasn’t a lot more.

The butterfly hand pump

Moss also showed Pyramyd AIR owner, Joshua Ungier, a unique modification he had made to a high-pressure hand pump. I was visiting Pyramyd AIR when he was there, so I saw it, too. He added two of his pump-assist mechanisms to a hand pump and created a hand pump that pumped with a lot less effort! The two pump assist mechanisms stuck out on either side of the pump and I thought it looked like a butterfly when it was pumped, so I gave it that title.

For some reason he wasn’t able to work out a deal with Pyramyd AIR, so he took the idea to Crosman and they mocked up a non-working prototype that was shown for at least three years at the SHOT Show. I was thrilled at the thought of this new pump and really touted it in several SHOT Show reports, but so far nothing has come of it.

Crosman showed the butterfly hand pump for many years at the SHOT Show. They weren’t able to get it into production for a reasonable retail price. It has two pump assist mechanisms — one on each side.

What are Benjamins with pump assist worth?

That’s a good question. My friend Mac sold his pump assist 392 at the now-defunct Roanoke airgun show many years ago for around $200. Stock 392s were selling for about $135 then and as I recall the buyer was resistant to the higher price until Mac showed him what it was.

I wouldn’t sell mine for less than $300, and it’s not for sale. Maybe you can get a better deal at my estate sale in a few years. I like it because it’s a 392, but also because it shows the ingenuity of a man who wondered why something couldn’t be made easier. Then he made it easier and discovered that people weren’t willing to pay for it. That’s part of Marketing 101, but it’s a hard lesson to learn.

What comes next?

My plan is to test this rifle in the traditional way. Part 2 will look at the velocity, plus I’ll measure the pump effort for you and compare it to the effort of a Blue Streak. And I’ll measure the trigger pull, though that comes with the factory 392.

In Part 3 I’ll look at accuracy for you. We will see what a Benjamin 392 can do.

This should be an interesting report series.

B.B.,

I hope and pray that your estate sale is not only a few but several years (maybe a decade or two?) away to give me a chance to reach your shores and meet you.

In the What is it? section first paragraph at the second to the last sentence. “Don’t confuse this with the Steroid Steak conversion that Mac-1 can do.” Sounds tasty but tough. “Don’t confuse this with the Steroid Streak conversion that Mac-1 can do.” looks better.

Last sentence of the second paragraph, “Hewre is a comparison chart of pump effort for standard and modified guns.” probably should be “Here is a comparison chart of pump effort for standard and modified guns.” unless we are going to very Old English.

Siraniko

Siraniko,

Fixed.

Thank you,

B.B.

If someone ask how is this historical?

Given the generational lineage of the Benjamin 3xx series, I would say it’s very historical.

They have been able to keep the best attributes of the lineage, brass & steel construction, wood stocks, minimal plastics.

All the while changing with manufacturing improvements over the decades.

And selling it at a reasonable price today.

If a 20 something enthusiast buys one today there is a very good chance his grandkids will be using it one day.

It is one of the few guns that defies the term “they don’t build them like they used to.)

45Bravo,

You’re right on all accounts.

B.B.

When you do part 2, could you shoot a short video clip of you pumping it showing the arm working so the linkage makes sense?

It has always looked confusing to me, given the way a 392 conventional pump arm works.

Thanks.

45Bravo,

I’ll see what I can do.

B.B.

PCPs and scuba tanks killed this gun. The people willing to spend the money this gun costs are willing to spend a little extra so they can turn a valve and get more power, and more shots without expending any energy.

BB,

I do believe John is right. That is why people are willing to spend the extra for the Mac-1 conversion and get more power and were not willing to pay for the conversion that made it easier to pump. “I don’t care if it is the Bow of Hercules, I want more speed!”

I am really surprised that Crosman even took that pump to the prototype stage. Their attorneys would take one look at that contraption and see pinched fingers all over the place. That pump would spend more time in court than filling air rifles. I am surprised they have not killed these air rifles themselves.

B.B.,

I see how the additional levers/rods can reduce the effort to pump. What is (not) clear is how this additional linkage (responds) to the additional pressure. I would think that the chart would show the 2 sets of bars to be (parallel) to each other,… with the assist version remaining at say,….15 pounds less than the non-assist version. But,.. the chart does not show that. So as you said,… the linkage responds/reacts to the additional pressure.

So my interest is what part of the linkage,.. responds/reacts/changes,.. as the pressure increases?

Thanks,…. Chris

Chris,

Remember Archimedes said if he had a long enough lever (and a fulcrum) he could move the earth? He never mentioned the fulcrum, but it is very important to that problem. The length of the lever is important, but so is the placement of the fulcrum. The pump assist moves the fulcrum as effort increases.

B.B.

B.B.,

Your description in the article and in your comment is good. “The pump assist moves the fulcrum as effort increases”.,…… is the part(s) that I would be interested in seeing and understanding more. Maybe not so easy to show or explain? This obviously takes the use of pivots/fulcrums/lengths/levers,.. to the next level by adding in another mystery mechanism,….. one that can sense, respond and change.

Chris

B.B.,

I just read the 5 part article linked at the top. It is good and part 1 is probably the most descriptive but still does not show what part moves,.. or changes position. One suggestion would be to use a ruler to measure from a point A,.. to a point B,.. with one stroke,… and then measure the same 2 points with 8 pumps. That would show what moved and by how much. More to the point, what allowed that movement? A spring? A ratchet mechanism? A? Fixed pivot points do not just move on their own.

Yes, it is more work and just one more thing that you do not need in an otherwise busy schedule. Perhaps it is just me that wants to know this. In the end,… it really does not matter other than the simple fact that it does work and is a part of air gun history.

Chris

Chris,

Look at the linkage. As the two outer pump arms come together they push the fulcrum (the part at the lower right in the picture) back. That makes it more efficient. It’s exactly like cocking a breakbarrel rifle. Hold onto the muzzle to get the best leverage.

B.B.

B.B.,

I am assuming that something in the lower right hand corner “slides” instead of just pivoting. That said,… in looking back over the past article and this one,…. it seems that the compression stroke is achieved on the (opening) stroke on the modified one,… as opposed to the closing stroke on the stock one. This seems obvious as the unmodified one has the rod connecting to the piston at a all the way forward stroke,…. while the modified one has the rod connecting to the piston at a all the way rearward position. (The cocking arm is full open in both pictures) No mention was made of this operational reversal in any article. (perhaps because there is none?)

I am done trying to figure it out. My analytical nature curses me once again. 🙁 Maybe the short video that 45Bravo suggested would explain all. Thanks for trying to explain it though.

Chris

chris,

there’s one thing I know for sure, there’s no free energy 😉

I don’t know what’s going on there either, but if it is lowering cocking force it is doing one of three things: lengthening the stroke of the hand lever, lengthening the lever arm, reducing the length of the pump stroke resulting in less air compressed per stroke.

BB says it’s moving the fulcrum which leads to choice two and three combined, and adding in choice one would restore the pump volume.

just straight up, moving the fulcrum for less effort means the lever you push is longer and the lever pushing the pump piston is shorter. so you either move your lever over a longer distance or else you will be pumping less air per stroke.

some may say I don’t know what I’m talking about but 😉 …… there is no free energy 🙂

so if you are moving the fulcrum and lengthening your lever stroke to reduce effort while retain the same pump volume, why go to the complexity to make a changing ratio. just make a simply change so that you have the same lever stroke on every pump and make every stroke lighter. much cheaper to do it that way.

Again, I’m sure someone will say I don’t know what I’m talking about, LOL

6.5,

Very true,… no free energy,… though solar, wind and wave might be close. Jerry C’s link below is a real mind blower, very lengthy and quite complex. It is worth a look though. B.B.’s link to the past article is worth a look too,… with most of the “workings” info. in part 1 and 2. Interesting was that handle stood proud of the stock as more pumps were added.

Something senses the extra pressure on the linkage and something in that linkage responds/changes/adapts to that pressure allowing the pumping force to remain the same. Like I said,… I give up for now.

B.B.,

It’s time. For Crosman to revisit this rifle. Start by restyling- make it look more like a rifle rather than a wooden club.

They did a beautiful job on the Maximus. Keep the original version for the purists that are turned on by wood. Tinker with the valve and reservoir to give more shots.

Volume is what drives costs down and if you reduce t the price sales volumes will go up. Imho, the marketing gurus make their decisions only on the U.S. market ignoring the much larger world market( they have become lazy thinkers) for example, in the Caribbean you would be hard pressed to find North American vehicles yet every month a car boat comes all the way from Japan and offloads hundreds of cars. The Japanese are not stupid, they won’t be doing it unless they are making money.

There, you have my two cents worth, I Will get off my soap box now.

Pete

Pete,

I do not know what island you are on, but the new car sold on this C island are all Brazilian or Panamanian specification models. This means no airbags, no emissions equipment. Even with shipping, these models are $1,000-2,000 cheaper than the same cars in US spec. FWIW-All the used cars on this island come from Miami.

-Y

Yogi,

I don’t want to start a political discussion. But all of us can agree that some things are worth paying for.

When I was on Ambergris Caye two years ago, the lack of any emissions control on golf carts and scooters (almost no cars) was enough to make the air in tiny San Pedro Town filthy. You could literally see the exhaust hanging in the air, and every breath was difficult, unpleasant, and no doubt incredibly unhealthy. I remember L.A. in the 1970s, too, with daily smog measurements broadcast on radio and TV. Ugh.

Michael

Yogi,

I’m on St Vincent. Which island are you on??

Never heard of any Caribbean Island allowing cars to be imported without airbags or emissions control.

Any car more than 5 years old imported into St Vincent carries a $ 5,000 environmental tax.

Pete

B.B.

When I hear about a situation like Mr. Moss I get depressed!

Why didn’t he go to Benjamin and and have them incorporate his improvement into their design and pay him $0.25 per gun royalties? Isn’t a “better mouse trap” really better?? Maybe we should all write Benjamin and complain about their “hard cocking” gun and couldn’t they do something about it!

-Y

Yogi,

He did. I left that out of the report. Crosman (who make Benjamins) didn’t want it.

B.B.

We should all boycott Benjamin until they do incorporate it into their design. Write letters!

Shame them on “social media”. Throw rocks at the Chairman of Benjamin, who owns Benjamin ??

-Y

Yogi,

When you joke like this you should put a smilie face after your comment. 😉

B.B.

Yogi,

To add an emoticon (smilie) skip a space after the period, then type a colon followed by a right-side parenthesis. 🙂 If you want to wink, change the colon to a semicolon. 😉

B.B.

Yogi,

Benjamin has long been owned by Crosman. The first thing my professor in Intro to Marketing said in class was that dozens of better mousetraps had been invented, patented, and manufactured, and the world has not yet beaten a path to any of the doors of those involved. The same old spring trap is the go-to, even though it is difficult to set. Why? He said the saying should be, “MARKET a mouse trap very well and the world will beat a path to your door.”

The graveyard of defunct-but-excellent inventions is no doubt immense.

Michael

That may be a four bar linkage. For all you scientific types, see: http://web.mit.edu/2.75/fundamentals/FUNdaMENTALs%20Book%20pdf/FUNdaMENTALs%20Topic%204.PDF

Jerry,

Thanks for the link. That is some full blown scientific stuff for sure. From a quick scan, the 4 bar linkage looks to be the most likely example. Fascinating stuff with a whole lot more involved than what you think,… at least for us uneducated sorts.

BB

Being intrigued by multi pumps, I am trying to patiently wait for part 2 and 3. I returned a 397 a couple of years ago because it was woefully inaccurate. I liked everything else about it and have considered calling the repair folks at Pyramidair to see if they had a refurbish with proven accuracy. I look forward to your accuracy tests. Looking back at your 2008 part 5 report you had some groups at 1/2 inch at 21 yards. Not sure you were testing 5 or 10 shot groups then. Either way 1/2 inch at that distance seems okay for a 392/397.

Just a comment about pump effort. Anyone who shoots a lot with springers and multi pumps knows a trick or two about mechanical advantage (lever length and fulcrum location) without even knowing why. Example: My Webley Rebel with mounted scope can be pumped easier by placing an open hand on top of the barrel sleeve as a brace against the pumping hand. Its easier to pump a rifle or pistol while seated than when standing (at least it is for me). I am passing this along for readers who are new airgunners.

Decksniper

Decksniper,

You are going to LOVE tomorrow’s report!

B.B.

I don’t know what it is about the 392 but I find myself continually drawn to it. At first glance it seems like a lot of work but there’s just something about it perhaps it’s the wood, but it’s something more.

It has a timeless quality to it. Something that just conjures up images of a father passing it to son or daughter.

35 years ago on our first Christmas together, my new bride gave me as a present a Benjamin 347 with the OEM peep sight. That rifle was literally shot thousands of times before I rebuilt it 3 years ago and since the rebuild it has seen over 2,000 additional rounds through it. Over the years and for no explainable reason, I longed to also own a new Benjamin 342. Finally in 2015 at the Crossman Cup shoot in Rochester, NY, I purchased a 342. When first pumping and shooting it, I could not believe how crude it was compared to my older 347. So I set out to “improve” as much as reasonably possible on the rifle.

First to change was the trigger – Installing a SuperSear and reducing the trigger spring rate greatly improved the trigger pull and feel. Next was working on making both the pumping mechanism and cocking smoother. Lastly was the addition of a Williams peep sight. 1-1/2 years later and my 342 now has over 3,000 rounds through it. Every time I shoot either the older 347 or the newer 342, the first thought that comes to me is fun. FUN!

B.B.,

I keep promising myself to have a bootleg butterfly pump made by a manufacturing student at the college where I teach. Maybe this latest mention of it here will be enough of as push to get me going on it. We don’t get paid much, but every now and then the job has unexpected perks!

Michael

Michael,

Unless you have ten grand to spare, I would drop that idea. This mechanism is not easy to build affordably.

B.B.

B.B.,

You might be right — usually you are. A couple years ago I did show our machining program instructor both a photo and a drawing of the pump, and he said as a project an advanced student might be able to do it to an existing pump. It was a while ago, but I do seem to remember his commenting that the toughest part might not be any of the fabrication but getting the proportions just right, because they would have to be JUST right.

There are now light duty one-piece HPA compressors available for $1200 or so, and industrial HPA machines can be bought for less than $10K. :^) So technology and cheap foreign labor are gradually making the high-end hand pump ($300) and the Shoebox (roughly $1300, including a shop compressor) obsolete. So I guess a $500 or so Turbo Aire would now no longer be wise for Crosman as a business decision.

Michael

BB,

This blog makes me wonder how many good ideas just were not financially feasible or at least did not come to fruition. You probably know of enough of them to make a very interesting blog or two. I are privy to a lot of inside information that most of us never know about.

David Enoch

David,

That might make an interesting blog. I remember seeing a .44 Magnum pistol at the SHOT Show that had zero recoil. But the gun weighed about 8 pounds and was the size of an M3 Grease Gun. So the size and weight killed it.

B.B.

B.B., wow! What a cool piece of engineering! =)

I’ve been close to getting the 397 series, but the clackity clack multi-pump design always stopped me.

Gunfun1, regarding how the Marine Corps establishes accuracy for its best rifles, I’m not sure. However, I read a book by a Delta Force veteran who said that the Marines get the cream of the crop of shooting talent. So, I’m guessing that what’s difficult for us might seem different to them.

ChrisUSA, yes plywood is hard. I got it because it is easiest to access. But one knife that has bounced off the plywood repeatedly, has stuck repeatedly in an old log. So, you might try softer wood. I believe that cross-sections of logs are the traditional target. As for technique, the ones that are most effective for me are taught in a DVD from the teachers of the Russian martial art of Systema, but unfortunately, they no longer sell the tape. There are basically two techniques: gripping the handle or the blade. And there are a fair amount of demonstration videos online.

BG_Farmer, I believe Brother Jonathan was supposed to signify America’s relation as a junior partner to Great Britain in the early days of the Republic as well as the predominantly rural and agricultural lifestyle of the time, neither of which are really relevant today.

In other news, I have reached another level with reloading. I’m now trimming cases to within .001 inches. Ogive length is to the same tolerance. Powder charges are measured to literally the last grain. Recently, I trimmed three cases in a row to the exact trim-to length to the .001 inch, and it was as satisfying as shooting bullseyes. I now think that I will suspend shooting so that I can spend the time making ammunition. Just kidding. But it is fun. I know that the hard part of reloading is finding the right load and materials. But as far as assembling the cartridge, I wonder if there is anything else left to do. I am crimping the bullets in place which is supposed to create even starting pressures for better accuracy. All I can think of is adjusting the “run-out” of the bullet which seems to refer to the axial alignment of the bullet within the case, but that does seem a little excessive.

Otherwise, I’ve been feeling entrepreneurial and have wondered about slogans for an ammo-making business. “Old World craftsmanship and attention to detail!” “Perfect ammo down to the last grain!” 🙂

Matt61

Matt61,

🙂 Like B.B. said,…. it’s all about the marketing,….

I would shorten the tag line up a bit and make it sound a bit “cooler”. Maybe something along the lines of B.A.B. & B. (aka,…. Bad A** Bullets and Brass) 😉

Matt61

Well I think you answered the question. Maybe there is more to good shooting than equipment. Maybe talent does make the difference.

So add in good equipment, talent and practice. And one more thing. A good teacher. Maybe that’s why those snipers can do what they do.

From conversations I have had with some military people they did only have one gun they shot. Or I should say one gun they shot regularly. And yes they were snipers. And I know that they took care of that gun like it was their baby. From what I was told anyway. So maybe that one gun thing does make a difference. Then throw in all the other things discussed and that’s what makes a 1000 yard shot seem like a peice of cake.

Let’s face it, Crosman introduced a new gun and it wasn’t a multi-pump. With the success of the Maximus, that’s not about to change. I would be happy with just a wood stock for a 1300 from the Custom Shop to make my own gum from various parts. They can sell enough 392’s and 397’son nostalgia alone to keep them from retooling a new line.

Does the 392/397 still have a problem where some brazing connecting the barrel to the air reservoir cracks with rough treatment (rendering the gun unable to hold air) ?

I remember reading about that problem with a lot of old ones, where mounting a scope had caused people to hold it near the barrel joint, and crack the brazing.

John.

Yes. Mounting scopes or removing the rear sight is what commonly cracks the solder seam. The guns don’t typically leak after the seam is cracked, but the barrel can then move and accuracy is lost. And nobody can fix the seam successfully, to my knowledge.

B.B.