by Tom Gaylord

Writing as B.B. Pelletier

My new Sheridan Supergrade is in fantastic condition, despite the wood check at the butt.

The cheekpiece makes the Supergrade stand out!

This report covers:

- Chronograph

- How long can a multi-pump be left fully pressurized?

- The point

- Smith and Hatcher were right!

- Condition of the rifle

- Last comment

Before we start I would like to introduce you to Jake. He is the best Sheridan resource I know. Here is his website. Much of the information I have is either obtained from or corroborated on that site.

Siraniko, you were right. I’m doing Part 2 today!

Chronograph

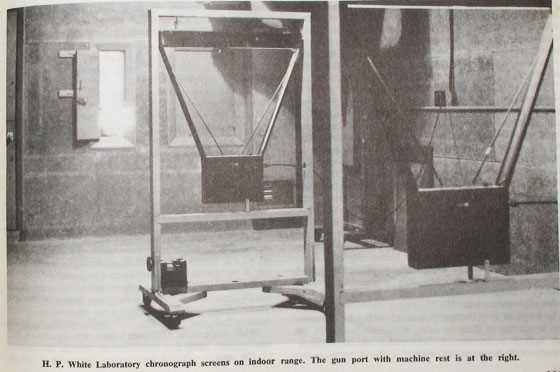

Reader GunFun1 wondered how velocity was determined back in 1947 and 1956, when General Hatcher and W.H.B. Smith wrote their reports on the Supergrade. Well, it’s found in that book nobody wants — Smith’s Standard Encyclopedia of Gas, Air and Spring Guns of the World, by W.H.B. Smith. At least the method that Smith used is found there. It was called the Potter chronograph and occupied several rooms at H.P. White Laboratories. At its heart was a quartz crystal oscillator that cycled 100,000 times a second.

This chronograph was designed by the U.S. Army Ordnance Department during WW II. As you see, it took several people to operate it. It is approximately 1/10 as accurate as the Shooting Chrony that you can buy today.

How long can a multi-pump be left fully pressurized?

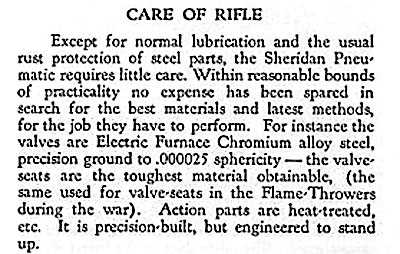

I’m finally going to address Doc Holiday’s question. Or Sheridan is. The first thing you need to know is what they say about their air valve. Let’s see.

Sheridan’s description of the valve has more detail than will be found in modern manuals.

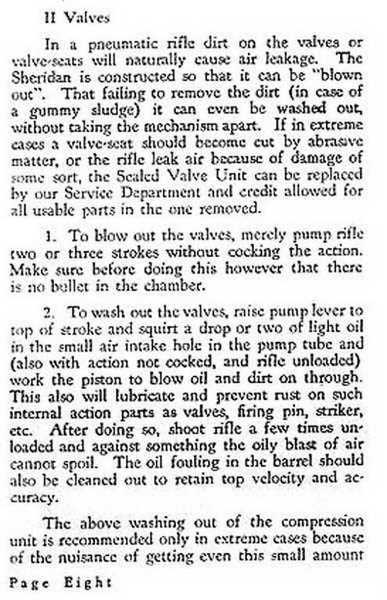

Detailed valve maintenance procedures.

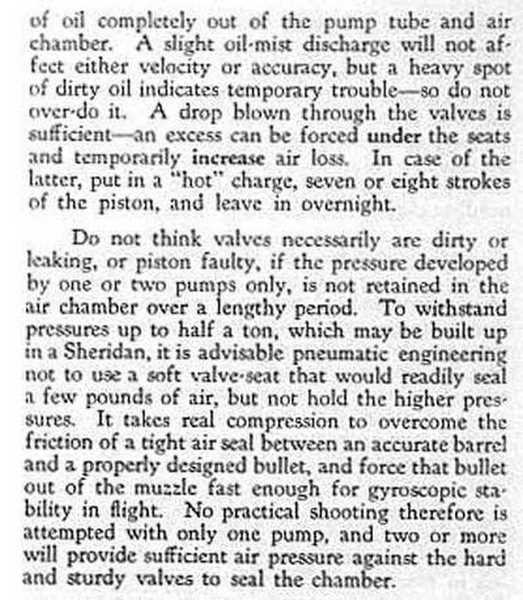

The remainder of the valve procedures.

There you have it. Sheridan says you can pressurize the Supergrade valve fully and leave it overnight. This is a serious procedure, so don’t do it often. Now, let’s talk about the differences between the Supergrade valve and valves found in today’s multi-pumps.

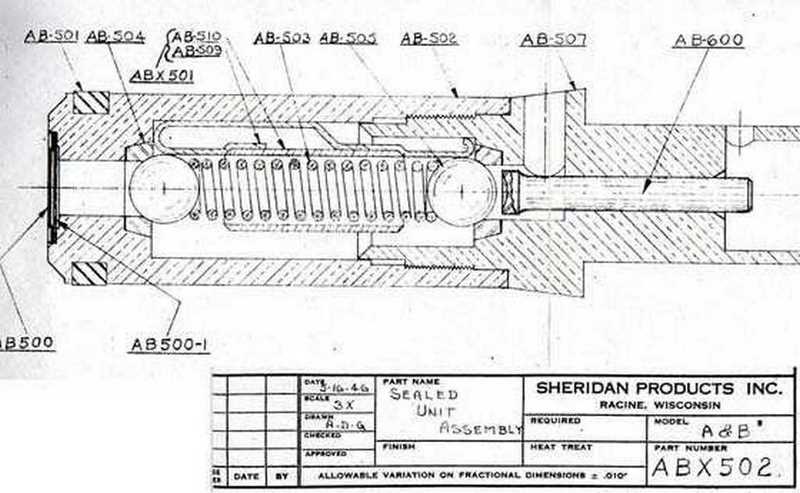

Sheridan Supergrade valves have ball bearings at each end. They are the poppets that seal against the valve seats. That’s what the mention of sphericity in the manual referred to.

This drawing of the Supergrade valve is all over the internet. It shows the two ball bearings referred to in the report.

The ball bearings are not the big deal. The big deal are the two valve seats the balls press into. They are made of hard synthetic material. I am not certain of this but I have read or heard they are made of Hycar — a tough synthetic that did not have the problems usually associated with synthetics from the 1940s. The reason is because this material is very hard. So hard that brass and steel can be used as a substitute!

I read in one of the British airgun magazines that John Bowkett had experimented with a steel poppet and valve seat. He discovered that if it was properly fitted it worked better than any other material he tried. The challenge was getting the two metals in the valve poppet and seat to mate perfectly. There are ways of doing it, but they usually involve hand-fitting, which takes a lot of time.

The point

No manufacturer that I am aware of makes a valve like this today. Most of them use some engineering plastic like Delrin for the valve poppet and brass for the seat. It works very well and is fast and easy to manufacture. BUT — and Doc, this is a big but — such a seat and valve are too soft to hold up well under continuous compression.

However, having just said that, how is it that we can leave a precharged airgun’s reservoir fully charged all the time? They don’t develop leaks from this treatment, so why am I so worried about the firing valve in a multi-pump? Aren’t both valves (intake and firing) made the same way? I have left my TalonSS reservoir fully charged for 17 years and it still holds fine. Something ain’t right! Maybe it’s because the firing valve suffers impact every time it’s fired, where the intake valve doesn’t. On the other hand, the intake valve IS the firing valve in the TalonSS (the same valve serves both functions), so… It is a puzzlement!

Smith and Hatcher were right!

Today’s report has been about the firing valve in the Supergrade. In Part 1 I mentioned that I tested the rifle and found that it shot a 15-grain Sheridan Cylindrical pellet (they range between 14.9 and 15.2 grains) at 630 f.p.s. I said that was the fastest I had seen a Supergrade shoot, in my experience with three of them. That pellet is very similar to the 15.2-grain Bantam pellet that both Hatcher and Smith used in their tests.

Then I wondered — was the synthetic valve seat fresher and more pliable in my rifle when it was new 60 years ago than it is today? Of course it was! Is there any way to rejuvenate synthetic materials?

Well, I know of one. Automatic Transmission Stop Leak will soften the surface of most synthetics, making them seal better. So I did “IT”. I lubed the new Supergrade pump piston head with ATF sealant, not once but twice, over the course of two days, to make sure the oil got to all the internal seals.

I chronographed the rifle before and after the lubrication on 8 pumps. I watched as the velocity built up past 635 f.p.s. over several shots with Sheridan pellets. It went all the way to 697 f.p.s. Here are my numbers.

Before After

oiling…………oiling

634……………652

632……………680

……………………688

……………………697

……………………694

A day later I retested the velocity with the same pellets on 8 pumps.

Shot…………Velocity

1………………675

2………………668

re-oiled with ATF sealant

3………………679

4………………696 (10 pumps and air remained)

5………………632

A week later (for this report) I retested the rifle on 8 pumps. Sheridan pellets were used again.

Shot…………Velocity

1………………648

2………………654

3………………651

4………………649

5………………650

The velocity of this rifle has increased by about 20 f.p.s. from what it was before the oiling. It is also very stable. This isn’t my velocity test. It’s just a look at something any Supergrade or Sporter owner (they have the same valve) can do. New readers need to know that I have tested ATF Sealant on various types of seals in this blog over the past five years and I have just learned that aviation airframe and powerplant mechanics (A&P) trust it for rejuvenating seals in their high pressure struts (landing gear pneumatic springs) for the same reason.

I told you last time that I would show you how to time-travel. This is it. Through nothing more than lubrication I have brought my Supergrade to within 10 f.p.s. of the velocity Hatcher got (on 8 pumps) in 1947, and it even peaked faster than Smith’s average in 1956, though its current average is somewhat less.

What I haven’t done is install a stronger striker spring or a heavier striker that I’m now convinced was in Hatcher’s Supergrade. That was what I meant in the last report when I suggested Hatcher’s rifle might have been set up for him. I doubt he was aware of it He just did what he was told by Sheridan. But I think the Sheridan folks wanted a good review from the top man in America’s best gun magazine. I can’t even fully exhaust the air from 10 pumps in this rifle, which is probably due to some amount of the striker spring weakening over time. Smith’s rifle performed very much like mine, but Hatcher’s kept on going to 12 pumps. That had to be something extra.

Condition of the rifle

I reported in Part 1 that the finish of my new rifle is around 85 percent. That’s just the metal. The wood is not as good. Though there is no serious damage, the finish seems to be gone and there is that one check (a surface crack) in the butt. But the operation of the rifle tells me it hasn’t been used much.

The bolt cocks smoothly with the resistance you might feel in a new gun. Cocking is positive and crisp. The other two Supergrades I owned had looser bolts. I just get a sense that this one has not seen much use.

Last comment

I will end the report here, but I’m not finished. There are still things to say about the Supergrade before I do the velocity test. I hope you multi-pump owners are finding this information interesting and useful.

B.B.,

A possible factor regarding the difference between the PCP and an MSP is the amount of pressure pressing on the valve. The higher pressure of the PCP probably allows the valve to seat tighter compared to that of an MSP.

I’m thinking that Part 3 will not yet deal with velocity. I have a feeling there are a lot more details to be revealed regarding this rifle. Part 4 will deal with velocity followed by a Part 5 on accuracy.

Siraniko

Siraniko,

I think you may be right about Part 3. I am learning so much about this rifle!

B.B.

Hello,

I have a Sheridan Super-Grade Model A air gun. It has a very low serial number of “228”. My questions are as follows:

On the right side of the receiver it is only stamped with “PAT APPLIED FOR”. It does NOT have the typical markings for a Sheridan Super-Grade Model A.

On the right side of the receiver it does NOT have a serial number. If you fold out the wooden forearm, you will see the end of the wood stock which

has a number 32 stamped in it and above this number 32 there is a number 228 stamped in the exposed underside part of the aluminum barrel

strap. Again, on the right side of the receiver it does NOT say:

“SHERIDAN PRODUCTS INC.” or

“RACINE, WIS.” As I said earlier, it is only stamped: “PAT APPLIED FOR”. It doesn’t appear as if the serial numbers and “SHERIDAN PRODUCTS INC.” or

“RACINE, WIS.” was sanded off. I was told that very early numbered Sheridan Super Grade Model A’s were stamped on the underside of the barrel strap

with serial numbers. It DOES say “SHERIDAN” on the left side of the receiver as it should. Other than what I have pointed out, it is all original,

untouched or not reconditioned, and is in mint condition. What are your thoughts regarding the right side only having “PAT APPLIED FOR” ?

What is your opinion about having the number 228 stamped on the underside of the barrel strap ? Lastly, what is your opinion about NOT having a

serial number stamped on the right side of the aluminum casing? Many thanks for your great help and time.

crosman55,

Welcome to the blog.

Your receiver sounds okay. Sheridan was engraved on the early rifles where yours is. They were not roll-stamped on the receivers until later. I don’t think it has been sanded.

Somewhere there is a list of rifles by serial number with photos. That’s where to verify if yours is right. I tried to locate it but couldn’t.

B.B.

Hello B.B.,

Thank you for your fast response. I messed up with the serial number…it’s 288 and NOT

228. If you can look up this serial number 288 and pass along photos or other information, I would greatly appreciate it. This air gun looks very close to mint condition to me, especially being 71 years old. Maybe too perfect? Maybe it has been refinished? Any restoration signs I can look for? So, do you really think the serial number is okay being on the underside of the barrel strap as I have described in my previous post? Did Sheridan really put the serial number on their very early Super Grade Models A’s? I couldn’t find any confirmation that Sheridan did that.

Thank you very much again,

Merry Christmas and Happy New Year to You and Your Family.

Crosman55,

I know the serial number is in the right place, for I have seen several other early Supergrades with the number in the same place.

B.B.

B.B.,

That’s totally understandable that the Sheridan folks would tweak a gun for “the man” to get a good review.

I like that the ATF gave you a nice consistent velocity boost.

And I want to thank you for attaching the link to that Sheridan page.

I was able to verify that my Blue Streak was made in 1974…she’s 44 years old…pretty cool!

My memory’s not what it used to be; I was pretty sure the gun was from 1973…or ’74…or ’75, hahaha!

It’s nice to know for sure; thanks again! And keep up the good work. =D

take care & God bless,

dave

Dave,

Isn’t that website great? Jake has done a wonderful job of recording the Sheridan history. I wish Ted Osborn (Mr. Supergrade) were alive to see this day.

B.B.

Yes it is; thanks for sharing. =>

G’day BB

My gas struts on my chairs are still going with Ballistol used months ago, may be worth a try?

Cheers Bob

Bob,

Ballistol? Really?

B.B.

Now that is how a manual should be written! 🙂 Nice insight on the how’s and why’s of the internals.

Good day all.

Chris,

There is even more in the manual!

B.B.

B.B.,

I figured there was. For them to go that depth for one aspect,.. I felt assured that the rest of the manual was as thoroughly as written. I found some of the wording to be interesting too. Not quite the wording that would be chosen today. I am sure that someone as accomplished as yourself can appreciate the old(er) style wording more than I. I just notice it,.. where as you understand/appreciate it more.

Chris

Chris,

If you have not found it yet it is over here, http://ujays.net/ahbcover.html

I really like the informative way it is written, giving a large amount of knowledge about the gun as well as how to use it to its best advantage.

Mike

Mike In Atl,

Thanks for posting that link. I plan to read that cover to cover ( I’d read it now except that I have some serious Crappie fishing to do in the very early AM and I need my beauty rest) and encourage any modern day manual writers to do the same multiple times until it sinks in. Think more along the lines of ” How can I make my customer better educated and informed about our product ?” and less about “How can I CMA?”

Half

Mike,

Thank you. I was not looking for it, but since you linked it I saved it for further reading.

Chris,

There are two reasons the wording sounds right to me. First, I’m old and that’s they way things used to be said. And second, I read lots of older references, and they are usually worded that way.

B.B.

Yes B.B.

That covers it, most older manuals just tell it like it is, as if they were talking to you.

Mike

BB,

And you have your own “folksy” writing style.

Half

I’m very pleased to read that you found an even better replacement for the Supergrade you had to sell after “The Airgun Letter” folded. Coincidentally, I just purchased my first Sheridan and it’s a “real” Sheridan too (well…at least it has a 1985-1990 serial number making it one of the last pre-Crosman Streaks from when Benjamin owned the company in Racine). It’s no Supergrade but I found it in a pawn shop for $150 and bought it. The finish is very nice (wood and metal) and it holds air and shoots well. Unfortunately there is a little barrel separation under the rear sight, which is very common in these guns, due to years of the excessive pressure at the rear sight mounting wedges, as you no doubt know. I removed the rear sight and there is no longer a visible gap, but Tim McMurray says he can re-solder it without even damaging the nickel finish so I’m sending it to him at Mac1 Airguns. As long as I’m shipping it away for awhile, I’ll have Tim “Steroid” it and install a Williams sight too. Now I have all three calibers–a 397, 392, and Silver Streak, though I have to say that I now understand why nearly everyone prefers the older ‘dans to the Crosman Benjis.

I borrowed the Williams rear sight off my 397 and shot one and only one group at 25 yards. It was a gloomy and blustery day and actually too dark for the extra small .050 aperture I had on the rear sight. My almost 60-year old eyes can only use the .050 for punching paper on bright sunny days. Nonetheless, I’m certain that the 10-shots will fit under the quarter on a good day!

Cal,

Please let us know if Tim can re-solder your gun. That is a job I had no resources for. I hope he can do it.

B.B.

I’ll certainly let everyone know how it turns out, B.B.. Tim only charges $25 for the repair and he certainly knows what he’s doing when he works on these guns. He said he’s had a lot of practice, having repaired many of them. The crack in the solder was very hard to see, even before I removed the sight. After removing it, it became impossible to see or I would’ve taken a photo for a before and after repair comparison.

I have a friend who sent his Blue Streak to Tim at Mac1 last year, as his barrel had also separated under the rear sight. Tim re-soldered it for him, and did a fantastic job. He also added a Williams peep sight and a steroid tune at the same time. One year and much use later the repair is intact and he is very pleased with it. I also own a Supergrade, purchased from the original owner here in Racine back in 2011. Looks like I may need to try the ATF sealant treatment. Mine averages about 571 fps with Sheridan 15.5 Cylindricals on 8 pumps. Mine is also in beautiful original condition, holds 2 pumps for months. I also received the original owners manual and a Sheridan pellet trap. They are really a pleasure just to hold and look at.

Kevin,

That’s a good report.

B.B.

Yes. Thanks for the favorable report, Kevin and I’m now feeling even better about sending my Silver Streak to Tim for the same fix and treatment. Also, I’ve always wanted a Steroid. This is as good an excuse as any and Tim’s not getting any younger, though on the phone and in his Internet posts he sure seems young at heart. He also has an Australian cattle dog and they are dear to my heat, having rescued one from the street once myself.

Yes Calinb, the old ones are cool; mine is a 1974 Blue Streak.

You’ve got a fine rifle there!

Just be aware that after the Steroid tune, if you pump the gun to full power (14 pumps if memory serves),

it will not exhaust all the air; so I always fired a second no-pellet shot to exhaust all the air,

for the sake of consistency, before pumping the gun for the next shot (especially when sighting in).

My Williams sight came with a .093″ aperture; I then bought .050″ and .125″ apertures;

with the .093″ it was a little hard to see the front sight in the woods; the .050″ made it really hard;

the .125″ made it easy to see in the woods, but hard to shoot as accurately.

Hence, I took the .093″ aperture and drilled it out to .107″ and that worked perfectly…for my use;

I was using it as a field gun; if I was using it primarily for targets,

I would have stuck with a stuck with a smaller aperture.

Anyway, do let us all know how the repair goes, and I surely hope you enjoy this new rifle!

take care,

dave

I mostly shoot paper with my 397. On a bright sunny day, the .050 works the best with a pumpkin on a post hold against a dark black bull on bright white paper for me. I find my best consistency with a sight picture that includes the barest sliver of white between the front sight post and the bottom of the bull. With heavy cloud cover, I think I’m better off with the .093 because I can’t see that bright sliver of light consistently with the 050.

BTW, I took the time to blast the silver front sight with a rattle can of Birchwood Casey sight black the other day when I shot my first Streak group. It’s easily removable with a little rubbing alcohol and I use it on all my front sights. Somtimes I use it on my rear sight too. Pyramyd AIR carries Birchwood Casey products and I wish they’d add it to the products they carry. It’s a bit hard to find locally!

https://www.birchwoodcasey.com/Cleaning-and-Maintenance/Sight-Black%E2%84%A2.aspx

I hear you; I periodically need to blacken the front sight on my Sheridan; my eyes aren’t what they used to be! One time, I took a bag of pistols, both airguns and firearms, to my eye doctor (I pre-warned him before opening the bag). I told him I was having trouble focusing on the front sight on some of the guns. On one pistol, I had painted the ramp on the front sight a yellowish-green color that they use on school signs. When the doctor asked why, I said, “I heard it’s a great color for your eye to detect.” He said, “Yes, it is; but it’s a hard color on which to focus…hey, I’m really enjoying this visit; we’re both learning something here!” Yes, that goes down in the record books as one of my best eye check ups; and my eye doctor earned major street cred with my for supporting my hobby. 🙂

“Me” not my…time for sleep, hahaha!

But not till I check B.B’s latest post. =>

Firearms News published an article about an optometrist in the Phoenix area who specializes in correction for shooting sports enthusiasts. Perhaps the article appear in the magazine when it was still called “Shotgun News.” I don’t recall. The eye doc’s ideas and prescriptions made a lot of sense to me. I can dig up the article, if you’re interested, and I’d like to hear how your next appointment goes too.

Yes, I would like to see that article; thank you!

Dave, I’m on the road (family move to our new homestead in North-Central Idaho) and hope that issue is not packed away in long-term storage. Regardless, I never throw out SGN/Firearms News Issues (especially the ones with B.B.’s articles in them 🙂 ). I’ll find it, scan it, and report back here with a fileshare link eventually and soon, I hope.

Thank you!!!

I forgot to add that I think the Steroid instructions say that a dry fire shot can be used to dump any remaining air. In some cases (if your unlucky), there might be so little air left that a pellet might get stuck in the barrel, I think.

Yes, I got a pellet stuck in the barrel once; the good thing is, as long as you realize it, and don’t shoot another one into it, it’s easy to clear the barrel; just pump the gun for a full-power shot, point it somewhere you’ll know for sure when it comes out, and safely fire off the shot.

Well, I’ll probably never get a Supergrade, but at a gun show last Saturday I got another Racine Blue Streak 1985 year for $70. Finish nearly all gone on wood, but metal is good, pumps up and shoots well and holds air over night. Thats makes four Racine models, two Blue Streaks and two Silver Streaks plus one Crosman “Sheridan”. Crosman should have called it a 390. The .177 is a 397 and the .22 is a 392, so why not a 390 for the .20 (5MM)?

does the madness ever stop?

Jonah, I wouldn’t even call it madness; I’d just say you have an appreciation for fine craftsmanship. =D

Jonah,

Previously Benjamin used a zero to designate a smooth bore .177 barrel. Check out the Benjamin model 310 and 340. They also had a 3100 multi-shot.

Don

Hey Reb, Happy Birthday! Surprise & Delight, Amigo! —Joe B.

Joe,

I will second that. Have you heard from Reb? I always enjoyed his comments.

Don

B.B.

Now I know the rest of the story (leaving a multi pumped “pumped up”). It does make sense now. Thanks for that info. It’s priceless.

Doc

Doc,

Isn’t that neat? They tell you what is happening right in the manual.

B.B.

I figured the measuring device was going to be a chrony. And I had in my mind it wasn’t going to be as compact and easily accessible as what we have today.

Makes me think there was probably a waiting list to get a chrony session in. And I bet it wasn’t cheap for that shooting session. That is if you could even use it.

What I wonder is that the only one that was in the USA at that time?

GF1,

Yes. You scheduled time on this equipment and paid everybody’s salaries, plus time on the device.

B.B.

BB

I figured it wouldn’t be cheap. The chrony probably cost a fortune to build back then too.

Marauder .22 caliber

I tried one of the following single shot trays in my Marauder, it fits perfect. All the other single shot trays I tried were loose.

Umarex Single-Shot Tray, Fits Umarex Gauntlet .22-Cal Air Rifles

Don

Try again;

/product/umarex-single-shot-tray-fits-umarex-gauntlet-22-cal-air-rifles?a=7752

Don,

Good catch. Though it’s been a few, my .25 fit tight and would not fully align. A fine trim job produced a precise, but non gripping fit. It is good to know that there is an alternative. It was good to see them offer it in .177, .22 and .25. $18 seems a bit steep to me though, for the .25 anyways.

As long as the pellet enters the breech with no damage,.. I fail to see the benefit. If I had wanted a single shot,.. I would have bought one. I guess that I look upon it as more insurance/reassurance/peace of mind. I should give it another go though just for the heck of it.

Chris U,

I have been using the magazine with no apparent damage to tne pellets. My single shot tray did not stay in place and the pellets were not aligned and were very fiddley to load with no damage. I perfer a single shot for bench shooting and the Umarex tray works great. At some point I mite do a test between the tray and the magzine. I would not expect a big difference the Marauder magazines work very well.

Have you been shooting your Marauder lately?

Don

Don,

I have not shot the M-rod yet this year except to cycle it for 8 live shots indoors into a trap. Too many other “chores” at the moment. Re-sighting and ranging the (new scope and new regulator) Maximus was first up. 1 session in. It is minute of squirrel out to 50 yards so far. It was a bit windy, so I want to re-confirm.

Getting the time, energy and free time to (set up) and shoot is something akin to having all the stars and planet in perfect alignment. 😉

BB,

at the Texas Airgun show last year you said I could post on the blog regarding this year’s airgun classes at Murray State College in Oklahoma. There are two airgun classes the 2nd and 3rd weeks in July. Classes must be reserved 30 days in advance. There is a minimum number of students required or the class will not make. I took a regular gunsmith class and it was very informative. I highly recommend the classes. The website is:

http://www.mscok.edu/academics/departments/gunsmithing_technology/nra_summer_program.aspx