by Tom Gaylord

Writing as B.B. Pelletier

Sig Sauer’s new ASP20 gas spring breakbarrel air rifle breaks ground in many areas!

This report covers:

- Sig thinks inside the box!

- They balanced the trigger

- Anti-beartrap

- Assembly continues

- The Keystone breech

- Piston and gas spring assembly

- One more brilliant feature

- Summary

We left off at the start of the ASP20 assembly station, looking at the Glidelite cocking mechanism. The next item I saw was shocking — an American-made air rifle trigger — the Matchlite! Is it as nice as a Rekord? That is something each shooter has to decide for themselves, but I will describe how it works when we go to the range. Right now I will just tell you what it does.

Sig thinks inside the box!

When I first saw this rifle at the SHOT Show I told Sig Air vice president Joe Huston that shooters were going to fiddle with the screws in the Matchlite trigger. Historically they do this with every new airgun trigger. When Beeman warned them not to fool with the Rekord’s screw 51b, it was like a neon sign, telling them where to start! For some odd reason, Joe just smiled back and said nothing.

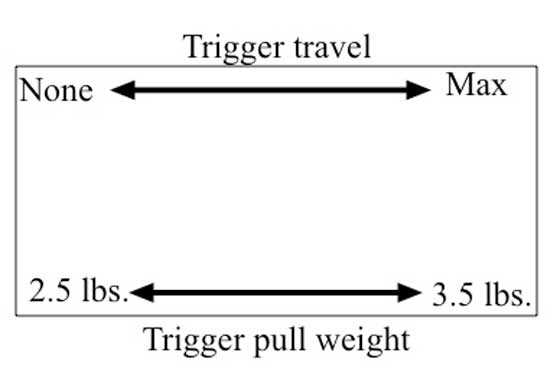

The trigger comes with two adjustments — one for pull weight and the other for the length of the first stage pull. The lowest pull weight is 2.5 lbs. and the highest is 3.5 lbs. An adjustment screw allows you to adjust between these limits in 2-ounce steps. Period! The screw bottoms out when turned to the limit in one direction and turns without effect when it reaches the other limit. Between the two limits you have full control to set the pull where it best suits you.

The other adjustment is the length of the stage one pull. If you don’t want a 2-stage trigger, stage one can be adjusted out. If you want a long first stage you can have that.

Think of a box that looks like this.

The Matchlite trigger has been designed so all the adjustments are contained inside this performance “box.”

Sig has given us a sporting trigger that’s light, crisp and can be adjusted to suit — to the limit of the adjustment parameters. If that was all there was it would be great, but now let’s look at the trigger that I watched being assembled part-by-part.

Ed Schultz (center) is about to start the tour of the ASP20 assembly line. The trigger is first.

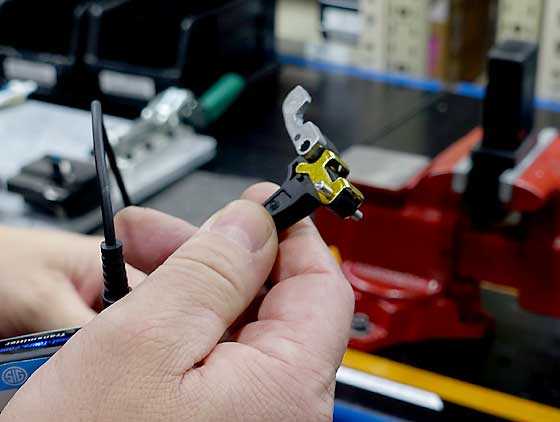

We watched the worker assembled each part of the trigger. He used a special fixture to hold the parts while the pins were pressed in.

The trigger blade is a special polymer, reinforced with fiberglass. It is relatively straight and feels quite positive when you pull it, but I will say more about that when we go to the range.

Sig has selected a two-hump sear contact design for the trigger that works in concert with their stage adjustments. They call the gold part a trigger stage bracket. It pushes up on the sear that is just above it (not seen here). When you adjust the first stage length you are moving the pivot point of this setup, if I understand it correctly. This same design approach can be seen in Mauser military triggers, but Sig has taken it to a different level to make the adjustments exact and precise.

This is the trigger, assembled. The gold part is the two-humped trigger stage bracket I mentioned. The anti-beartrap still has to be installed.

They balanced the trigger

“And then, at step two, a miracle occurs…” is the punchline to a scientific joke. Well, at Sig, it ain’t no joke! They balanced the trigger assembly!

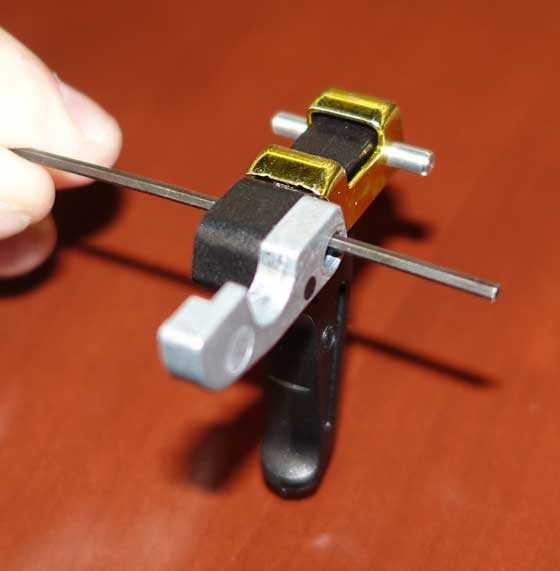

The parts that were used in the trigger were dimensioned and made from materials that allowed the finished unit to balance, fore and aft, on its pivot pin. That makes it extremely sensitive to each adjustment!

The Matchlite trigger evoked considerable discussion! Photo provided by Sig Sauer.

I photographed this back in the conference room, after the tour, The Allen wrench passes through the trigger pivot pin hole and, as you can see, the trigger is balanced. The anti-beartrap rod is not attached.

Anti-beartrap

Sig put an anti-beartrap device in the trigger to prevent accidents. As all airgunners know, you NEVER release the barrel while it’s open for loading. Anything made by man can fail and your fingers could be seriously injured if the breech closes on them. I didn’t appreciate that people were not aware of that until we were on the range and I saw several of our tour group who are not airgunners release the muzzle of the rifle to load. They were all corrected, of course.

The first stage travel screw is adjusted through a screw in the trigger.

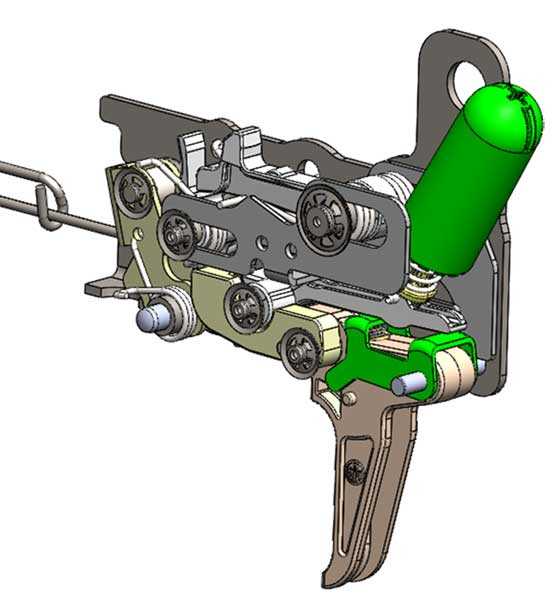

This drawing of the trigger shows the anti-beartrap rod leaving the front of the trigger assembly (on the left) to connect to the action.The green domed part on the upper right is the trigger pull weight adjustment.

Assembly continues

As assembly moved on, Ed showed us the barrel and breech. It’s held in the action forks by a large pin. And here is the important part. The number one problem with a breakbarrel rifle is barrel droop. Special scope mounts are made to counter the problem that almost every breakbarrel has. Sig decided not to have the problem, so when they bored the hole for the pivot pin, they bored the spring tube forks and the breech together! They were held in alignment as the one pivot hole was bored. And afterward that barrel remains mated to that spring tube.

Terry Doe said that other airgun companies create solutions for the barrel alignment problem. Sig designed the problem out, altogether! I wish I had been clever enough to think of that.

The pivot pin fits into the hole drilled through the action forks and base block. The parts remain together from this point on. The pin is held in by a single Allen screw, because no sideways force is needed.

This way the barrel never gets out of alignment with the spring tube. They cannot get out of alignment, because of the second brilliant thing they did. Sig invented the Keystone breech!

The Keystone breech

The number two problem with breakbarrels is a breech that wobbles from side to side in the action forks when the breech is closed. Not all guns have the problem, but far too many do and there is little or nothing that can be done to fix them when they do. Sig decided up front not to have this problem or the barrel alignment problem. They invented a breech that locks the barrel tight without requiring spring-loaded locks. It has no name yet, but unofficially everyone is calling it the Keystone breech. When you see the shape you will understand why.

The Keystone breech works by those flanges (arrows) bearing against the sides of the action forks as the barrel is closed. The detent slips under its catch in the action forks, drawing the breech tight into the spring tube.

Piston and gas spring assembly

The ASP20 is powered by a gas spring. The piston has a seal up front and some sort of synthetic piston ring at the back to cancel vibration. The piston seal was lubed with what appeared to be a moly paste.

We were shown the installation and lubrication of the piston seal, followed by its installation into the spring tube. Like spring gun tuners everywhere, Sig has to take this step carefully, or risk cutting the seal on sharp edges in the tube. For day 2 of production they did a good job, but I expect one more special tool will be created for this procedure — a blunt screwdriver to ease the seal past the sharp edges. I know I need one.

Sig installs the piston just like the rest of us. Care is taken to avoid nicking the piston seal.

One more brilliant feature

If you have ever disassembled a precision breakbarrel spring gun, you have probably encountered the thin shim washers that help the breech pivot without friction. In some rifles those thin washers can be a pain to install — especially when the rifle is new and the action fork is tight. Sig did something very clever here. They machined flats on the base block that take the place of those washers, and can never slip during installation! Just lubricate them and slide the base block into the action forks.

Other breakbarrel guns like this Diana 45 have thin washers that are often hard to install when assembling the rifle.

Sig did away with the washers and just machined washer-shaped flats (arrow) on both sides of the baseblock. Nothing to slip out of alignment during installation.

Summary

Whew! I will finish final assembly tomorrow and take you to the range, where many of your questions will be addressed. If writing was aerobic, today would have been a hard cardio. There is so much to tell about this new rifle! Yes — AND the new scope that comes with it!

So if they were going for ultimate accuracy…why not a sidelever or underlever?

Edw,

Probably would have raised the cost and weight. This is their first foray into spring piston rifle manufacture.

Siraniko

Edw

If the barrel on this does actually lock in place. It just made side and under levers extinct.

Bob,

There have been several break barrels over the years that lock in place, but the others never became extinct and I do not see it happening now. Pardon the pun, but “different strokes for different folks”.

HW35 has been around for a long time & Walther did the same sort of lockup and even Hatsan however not for our market and plenty of the Weihrauch/Beemans & Diana/RWS may have droop but lock consistently now take into consideration the new T06 triggers and mine breaks under1.5lb from the factory and the rekord trigger is like the benchmark.

Wait and see & the scope!

Mike

The Diana triggers are nice.

That trigger name tho, Match light. Its neither. 2.5lbs = 1.1kg? Real match triggers from german 10 meter rifles go down to 100 grams? My anschutz is set at 250g,

Guess the old rekord trigger is still king. Sure if you compere it to any other american made springer then yes its most likely dreamy but lets not do that.

Yep they throw around the term match trigger pretty loosely. I have no idea if a true match trigger could be made for higher power springers, but the old 10m springers like FWB 300s in early models went down to 3oz i believe that’s right @ 100g , but later models for US market given stiffer trigger & stiffer option. Personally i would love a true match trigger on a springer like my Diana 56th i like the T06 but the surfaces could stand a polish that i can feel. Thing is other rifles i have used with 2.5lb triggers so smooth and predictable no problem. Triggers are kind an obsession with me.

Deacz,

The Crosman engineer that went over to Sig may have brought the “lawyer trigger” philosophy over with him lol. 2.5 lbs is fine for a sporter though especially if it breaks cleanly

Agreed, 2.5 if crisp is most likely totally ok and fully usable, even good? But the name just irritated me a bit 😉

2.5 .lb is certainly not a “Match” trigger

what does it matter if the barrels wobbles around has a bad crown different bore dimensions and rough rifling? a 4 ounce trigger will take care of all those problems. to much money wasted on the trigger where it could be put into the barrel

Bob M,

Not extant, just irrelevant.

-Y

Yogi

Good point. I feel safe in saying the Airgun God will not lift all levered airguns up to heaven, and it takes a while for a patent to expire.

Edw,

Breakbarrels can be just as accurate as the others with less weight. Also lower cost to make.

B.B.

B.B.,

Gah! I need to read other comments more carefully before I post mine. I just used many more words to repeat what you succinctly wrote here. :^)

Michael

Edw,

I love my FWB 150 and 300s, but more powerful sidelevers can be a pain to cock compared to breakbarrels and underlevers. Also, sidelevers can have torque problems. (I think I am using that term correctly.)

Underlevers are heavier than comparable breakbarrels, and they also usually end up costing more to the end-user.

If the breakbarrel is a sweet, smooth shooter, then it certainly can be as good as a good underlever. That said, except for my FWB 124 I have never shot a medium-powered breakbarrel air rifle as smooth as my TX200. Then again, I have never shot another medium-powered underlever that was as smooth as my TX200 either! :^)

Michael

Michael,

Breakbarrels without a doubt just typify airguns. I wish that manufactures would continue to improve the state of the art. I love my FWB 300 S as well but nothing beats the zen of cocking and shooting a breakbarrel

Ton,

I agree completely. I have a recent HW30s and a vintage FWB 124, and they are superb shooters.

And I also agree that the shooting experience should be deliberate and practiced into second nature, but also with more than a little of Zen mind-emptying. Overthink, and you should just stop, lean back, breathe, and start the shot over with a clear mind.

Michael

I am impressed with Sig`s engineering design approach and construction so far.

Waiting to be told why they used a gas ram

Mercury,

The gas spring solves many spring-piston problems, like cold sensitivity and leaving the gun cocked a long time.

B.B.

B.B.,

The Matchlite trigger design seems to be the bees knees. Is the light grey arm in the front of the trigger the part holding onto the gas ram? I hope not, since it looks like an MIM part. The Keystone breech assembly seems to rule out simple swapping of calibers outside of the factory since the two pieces (what do you call the area where the spring tube forks are located?) are mated during manufacture. Those action forks look beefy to allow the insertion of Allen grub screws on either side to secure the pivot pin. Doubt if those will allow a sloppy fit in the long run unless abused.

Siraniko

Siraniko,

No. The part you are asking about was not shown. It’s in the rifle but not a part of the trigger — I think.

B.B.

B.B.

I was able to find a picture of the assembled trigger group at the Hard Air Magazine article: https://hardairmagazine.com/news/sig-air-asp20-air-rifle-technology-overview-part-two/ I am not sure if I am stepping on anyone’s toes by sharing the picture. If you decide to delete this I understand.

This is not a trigger that could be meddled with outside of its design parameters! That light grey arm in the front of the trigger seems to be the counter for the trigger return spring.

Siraniko

Siraniko,

I didn’t want to post that drawing because it raises more questions than it answers. Look at the photo where the trigger is balanced. I don’t explain it, but that is what that part does.

B.B.

BB

Looking forward to finding out why this rifle is less sensitive to hold. Is it the same back piston ring that reduces vibration or an internal shock absorber of sorts ?

BB

Went to the Sig website and low and behold highlighted in green behind the spring tube is something that looks like a CO2 cartridge in shape perhaps smaller. A gas shock absorber or weight ?

Very interesting.

Bob M,

I’ve been staring at it and it appears as part of the trigger assembly. I think it is a spring guide. See picture I attached above.

Siraniko

Bob

I bet I know exactly what that green Co2 shaped cartridge is.

It’s a extension for that screw so the stock don’t have to come off to adjust that part of the trigger.

But most importantly I believe that’s a sound and vibration dampener.

Also these drawings are available by Sig. That’s what I was talking about in Part 1.

GF1,

Bingo on the screw extension. Sound deadening, perhaps a trifle but not that much.

B.B.

BB

As the saying goes.

Every little bit helps.

B.B.,

Very nice again. Thank you for all of the technical details and photos.

Q: Is the rifle ambi at the pistol grip area?

I like the more vertical grip.

Chris

Chris,

Totally ambi.

B.B.

“Totally ambi” — YES!

I also like that long, (mostly) straight trigger blade. To reference Col. Kilgore, I love the feel of a straight trigger on an air gun. It feels like . . . leverage.

Michael

Some other thoughts,….

Looks. I am admittedly a looks guy. Usually, I have to like the looks of something. This looks fine enough until getting to the rear stock. Interesting design. It looks to be made to facilitate a sand bag and a front/rear flat slide. Functional maybe, but not very pleasing to the eye.

Cheek/comb. I am surprised that an adjustable cheek rest was not incorporated. To me, that is paramount in shooting comfort and acquiring a fast cheek weld/sight picture. YES,… I know it would add some cost.

Butt pad. A simple up and down would further add to comfort and fit. Yes on the added cost.

All in all,… I like the innovative aspects. Well thought out and well executed. American made.

Good day to one and all,….. Chris

Chris USA,

With regards to the DIY honeycomb filter don’t overthink about the small gaps between the straws. The point of the honeycomb is to help cut down the glare especially when it is reflected off the background of what you are aiming at. So a small gap should not matter. No I don’t have much use for scopes being in a restricted range of my backyard but I have some photography experience from which I derived this.

Siraniko

Siraniko,

Me?,… Over think things??? Wherever did you come up with that idea? 😉

Chris

Chris,

I have more to say. Hang in there.

B.B.

Chris,

Do we know for a fact the cheekrest is not height-adjustable? I see a line there. I do like the straight-back high profile of the comb. Isn’t that a rubber rest on the end?

The big cut-out along the bottom of the buttstock is a tactical look I do not especially like. I’ve seen it on a lot of military rifles, but it does not appeal to me. (See an airsoft example below.)

Michael

Michael and notice the stock drops down pretty good. That is a bench resting stock feature. It helps support the gun.

I do like that in a stock.

Gunfun1,

Ah! Well, if the cut-out has a practical purpose, then my opinion has changed. Does it act as a hook behind the rest platform?

Michael

Michael

I guess I shouldn’t of said bench rest. I just knew people would relate to bench resting.

That drop down adds to the bottom of the stock. So basically it let’s the stock rest on a surface without adding something under it. Like a folded towel or a palm of a hand or finger if you see what I mean.

It makes for easier support of the gun to keep it more stable.

Plus that’s more weight below the center of gravity of the gun. That will help in numerous ways. It helps with cant and recoil. It will usually transfer the recoil more down than back and into the shoulder.

You just got to try it to see what I mean. Remember back when we talked on the blog about weighting the bottom of the stock to add stability. It was some time back. But was definitely discussed in the comments on a blog

Gunfun1,

It makes sense. I should look for photos online of shooters who are fully rested.

I usually support the buttstock manually and rest just the forearm on my open palm and that off-hand resting on a bag.

Michael

Michael

I have used that technique also.

But I went away from it.

I find myself resting the guns fore stock on the bag. Then my normal trigger hand grip.

But now what I do is take my off hand and stabilize the bottom of the buttock some way. Sometimes under the trigger hand like a pistol grip. Sometimes at the rear of the stock on the butt of the stock or anywhere inbetween.

The main objective is lock up the butt of the gun. And the front of the gun is basically free to move how the gun naturally shoots. Yes in otherwards a modified artillery hold.

It’s been working really well. I just figured I wouldn’t post no targets figuring everyone would think I’m braging. 😉

And yes with my pcp guns as well.

Gunfun1

I have successfully used your hold types after you posted sometime ago. But have you tried it with a hold sensitive rifle? The Benjamin Titan was my first pellet gun since many years ago. I still shoot it and can just get under an inch with a 10 shot group at 25 yards with Field Target Trophy pellets in 5.55 mm head size. But the only way for me to do it is with open palm between barrel hinge and sandbag. Minimum contact with shoulder is attainable due to trigger pull easing after thousands of shots.

PS: My unorthodox hold with my M8 no longer works. The M8 is a wandering variable.

BB, I’m hoping your Sig arrives soon for accuracy testing. Lots of readers are impatiently waiting.

Decksniper

Decksniper

I don’t really have any hold sensitive guns anymore.

The club aest I have is the HW30s. And I can say it does improve with that hold.

Same with the other rifles I have. That hold works the best.

So that hold didn’t work with your Titan.? It didn’t help with the groups?

Yep my phone this time.

The club aest I have is the HW30s.

Should say. The (closest) I have is the HW30s.

Gunfun1

My HW30s is almost neutral to hold. It does fine with your type hold. The Titan does not.

Thanks

Decksniper

Decksniper

Some guns are tuff. What can I say.

For sure…I never did find a hold that would work with my Diana 34P. The Urban is not sensitive to any hold which works best for me because I am not always in a position to be able to hold the rifle to be accurate…even if it was accurate.

Michael,

That is a fact. They have made provisions for the adjustment which I will address tomorrow.

B.B.

BB

Ok got to say this. And I know your a busy man.

But while this is all fresh in everyone’s mind. I think you should continue the different parts of the blog report on the Sig.

And the sooner you get the blogs out in public. The sooner our fabulous Pyramyd AIR Bb Pelletier blog will be in the headline. 🙂

GF1,

No need to tell me! I’m doing it this way because, like I told you guys, my rememberer ain’t what it used to be. In fact, it never was! 😉

B.B.

BB

Just keep the train roll’n.

We’re all ready for the ride. 🙂

Yes, yes…agree with GF1. Please post the Sig parts as contiguous so we can keep it fresh.

Geo

A big yes.

Chris,

I had the same sort of reaction when I saw the ASP20 for the first time this morning – sort of eeewww… ok I’d make a new stock for that one. But then I am very (old school) conventional in my tastes, not too keen on a vertical pistol grip – find it to be inconvenient for fast shooting.

The “S” in ASP means “sport” guess I was expecting something more like the FWB 124 in style.

BTW, I am putting together some notes on stock making so time permitting, I might be blogging that in the not too distant future.

Cheers!

Hank

Yes Hank please do. I, for one, would be very interested. I did some work along those lines many years ago but I barely scratched the surface. (No pun intended . . . I think.)

Henry

Hank

Definitely want to hear your stock making story.

I seen you work. I can’t find the right words to express it.

It will be a welcomed blog.

Hank,

Your work is awesome. I do not think that too many people here have ever seen much of it. Not to mention other things. Like the canoe,… if I recall correctly.

I would find your article very interesting.

Chris

Hank,

On looks and function,…. and on the newly acquired Red Wolf,… the Red Wolf is pure drool in my book in the looks department. Adj. cheek riser and adj. butt pad aside, the fit is awesome,… those just make it more awesome. The way the forend sweeps down to the trigger guard is an awesome offhand feature. Beaver? tailed forend too.

To me,… it is best to combine looks with features/function. Looks does sell,.. to a point. On the other hand,.. my M-rod with RAI stock is pure function. It looks good too,.. without being curvy and sexy at all. This does not have anything in the way of curves,… more traditional if anything,…. but then went tactical/function on the butt stock. I just found it to be an odd mix for a first offering.

To me,… go full tactical/function,… or go full on good looks, comfort. Either way works,…. but a mix?

The Maximus is a nice mix of curves and function. Looks good too, in my book.

I am not sure,… but there was something called the Fortitude that was supposed to come out. It looked good too. Repeater as well. Then again,…. that could have just been some pipe dream?

At any rate,… I like innovation and new ideas. I like quality too. This will be an interesting one to watch.

Chris

So far I like pretty much everything I see. The gas piston I’m not so sure about yet. And a spring piston option would be nice.

It’s nice seeing about the thought that went into the gun. But still waiting for range day results. That’s the big picture. How well can it shoot.

Oh and interested in seeing how the scope does. Don’t see too many guns that come with scopes that are worth a darn. Hopefully they got that right too. Are they offering the gun without the scope also? You know that scopes tend to be a personal thing. What one person likes, another person might not.

GF1,

Yes, they are offering the rifle without the scope. If you buy the scope separate, it is north of $350. If you buy the package you save around $150.

BB,

I find it unusual that you should sing the praises of a sproinger that uses a pivot pin instead of a bolt. I myself have passed on such as there is no way to tighten the joint without some type of machine compression. Do you feel that the locking screws entering the grooves on the pin provide enough tension to prevent that from ever being an issue?

RR,

No issue. The Keystone breech puts tension on the pin. They eliminated the problem that other breakbarrels have.

B.B.

BB,

OK, I understand. the set screws will keep the fingers from spreading and the wedges will squeeze the breech into a set point, putting tension on the pin and the lock will hold it all together nice and tight. Pretty cool.

RR,

That’s it.

B.B.

I am all ears BB. Reads like you’re having fun.

I am looking for a lighter HFT piston rifle to replace my Diana 54, maybe this rifle is the answer?

2.5# minimum trigger pull concerns me tho.

Cant wait for range day!!

Erockrocket

I had a couple 54 Air King’s in both calibers. Great shooting guns. And don’t know about yours. But my 54’s were pretty darn accurate.

If the Sig break barrel is accurate. I’m all for it.

Wonder what kind of warrenty Sig will have on it. That will make difference too.

B.B.

Very informative report! For the trigger, could you not just use a longer screw to get under the 2.5 lbs pull weight?

Since the barrel and action forks are drilled as one piece, I assume that you can not change barrels afterwards(assuming you want to change calibers)? Do they make all these parts in house? Seems you have just seen the assembly station. Do they make their own gas rams? Did you see how they make their barrels?

Did they say anything about how the steel tariffs might effect their operations?

Sounds GREAT so far……

-Yogi

Yogi,

The way this rifle is designed, you can’t modify the trigger without major engineering. Longer screws are out.

No barrel change option for the ASP20.

I have yet to discuss making the barrel, but it’s coming.

B.B.

Yogi

We are dealing with that at work right now. We get or metal from Italy.

I know what they are trying to do by enforcing the 25% overseas tax. They are trying to get the factories to buy American steel. Which is a good thought. It makes jobs in the USA.

But the problem is. Who we make the parts for wants us to only use the specified by them Italian steel. They won’t help on the difference that the tax adds.

So now what does our company do. We have to put money into the part to keep producing it. In otherwards we are now loosing money making the part. That can’t go on forever.

Don’t know if people realize this but another problem with machining parts for a customer.

Our company contacted our state senator. She is suppose to visit next week and has written a letter on the companies behalf to be excluded from the tax. Can that really be done? Hopefully I can get early retirement before the company runs out of money.

What a wonderful world we live in.

Any idea if they are planning to offer a model without the moderator? (I’m assuming that’s a moderator and not a muzzle weight at the end of the barrel)

Got to say that I’m not yet sold on the lack of a pivot screw but I guess time will tell if their idea pans out. Wondering if the install the breech seal before the breech block and forks are mated and drilled or if they insert some sort of spacer between the transfer port and breech to maintain a consistent gap for the seal to be installed later…. assuming its the later.

Chachoze,

That’s one they didn’t cover. I assume the latter, as well.

B.B.

BB

Does the moderator work? Spring and most nitro guns really aren’t that loud if the right weight pellet is used.

I mean it’s a nice feature that I like. But as long as it don’t affect accuracy as we know some other manufacturers have had happen.

That would be a real bummer I’d that causes a problem.

And who said making air guns was easy.

Chachoze

True about the pivot screw.

It’s true there is no side force from the components in the cocking linkage.

But there is side force when a person cocks a gun. No one cocks a spring or air gun true. Depending on what hand they use to cock the gun and how they use the other hand will surely make side force on the cocking components.

It has to eventually spread the forks. Maybe not today. But one day. And you stole my favorite saying. Time will tell.

Chachoze,

Sig read your comment and here is what they said.

Chacoze had a question about inserting the breech seal during the match drilling process. The breech block and the forks are mated face to face, no seal and no gap. The depth of the breech seal groove controls the amount of “crush” the seal will have when the breech is closed.

B.B.

BB ,

I am glad to see so much thought has been put into the droop issue and the lockup surfaces . This is revolutionary, no else has ever done this. The trigger is well executed , no one can take the gun out of operation by adjusting the screws , this alone prevents allot of phone calls and service issues. Allot of TX and HW guns have been serviced by us for this alone . Looks like with the engineering and the attention to detail this should last a lifetime. Refreshing to see a product like this .

Gene,

You got it! That is exactly what they were going for.

B.B.

B.B.,

As Mercury, Gunfun 1, and Gene Salvino have already noted, the engineering that Sig put into this gun is way cool!

But good engineering also requires good craftsmanship, and it looks like they have that covered as well.

It’s so refreshing to see this on a gun made in the USA!!! =D

Looking forward to the rest of the report,

dave

Dave

Good point. Craftsmanship.

The breech block is definitely a work of machining art.

And I like the machined boss that simulates a washer.

I’m thinking the barrel has to lock up hard and true. Has to help accuracy.

So do we finally have a good quality American made break barrel on our hands. It looks that way. But time will tell.

Yes; I (as do all of us) look forward to B.B’s report on the accuracy of this gun! =>

Dave

Yes accuracy.

Gunfunn1,

I am neither an engineer nor machinist, but I hold a different opinion on the machined boss that simulates a washer. There is friction there during cocking and over time there should be wear. A sacrificial washer can be replaced when wear occurs. In this set up, when wear does occur, the breech bolt is not designed to be tightened! I hope I have all this wrong

Ton

That is a good point. We’ll have to see how it holds up

Hi BB,

It is interesting that gun development seems to be so slow compared to the rest of the world we live in. The 1911 design is still a standard design. The Mauser action is still a standard bolt action design. Revolvers, and even shotguns are pretty much the same as 50 to 100 years ago. In light of this, taking 50 years to significantly upgrade the FWB 124 may not be so unusual.

I wish my brother, Bryan, could see the plant. I am sure he would love all the CNC mills and lathes and robotics in the place.

Thanks for taking us along on the tour. I look forward to your testing of the new rifle.

David Enoch

David,

Gun development is probably reaching maturity. It follows the pattern of most technical things in human histoty. Some have matured and morphed like the film camera into the digital but as a camera its still around. I can only guess what the gun will morph into in the next hundred years but I bet it will still be around in the modern version of the 1911 and the revolver. How about an AI gun that shoots with no direct human intervention!? The anti gun crown would love that! Lol.

BB

Here’s a question from the folks who don’t know that much about airguns. What is a bear trap and why is being anti bear trap good? What has the rod from the trigger got to do with the anti mechanism?

Bob,

If the barrel closes under spring power while you are loading it, it amputates the ends of fingers. This has happened so many times that a beartrap device is put into most spring guns today. It does exactly what the name implies — stops the trap (barrel or breech) from closing on your hand!

B.B.

B-I-l

It really should be called a bear trap stopper.

Like BB said.

The breech will cut your finger off like a guillotine. All that spring pressure or gas ram pressure would go directly to chopping off those body parts If you so happens to let go of the barrel or cocking arm and the bear trap mechanism wasn’t there.

Bob,

That why the word anti is in the name.

B.B.

So if the shooter holds the barrel once pulled down and cocked with one hand and loads a pellet with the other, this could be called a “manual anti- bear trap hold”?

B-I-L

One time I pulled out all my break barrels to see if they could be loaded without cocking them by just breaking the action open .

About half of them could be loaded this way without cocking them .

tt

TT

Yep but still. Not a good thing if the anti-bear trap wasn’t there.

Cock fully and accidentally slip off the barrel and your day could be ruined in multiple ways.

GF

Am I missing something here ?

tt

TT

Yes you are.

Yes on some you loaded the pellet so now your loading hand is safe.

But here’s what imtey to say.

If the beartrap wasn’t there. Even if you load the pellet like you said. If you slip of the barrel or cocking arm it’s going to slam shut.

Maybe you don’t waxk off a finger. But your gun ain’t going to be the same no more.

The beartrap is a good thing.

GF

If the barrel gets away from you, or there is a failure (beartrap or not) it is going to wreck the rifle . I see no difference, other than not getting your fingers bit off.

tt

TT

Yep that’s definitely it. The thing is when the beartrap engages.

Look at the Tx and LGU. The bear trap engages at multiple spots during the cocking stroke before you go to full stroke

The thing I would say is always hold onto the cocking lever or barrel if it’s a break barrel and don’t let go till you let the barrel or arm back to closed position.

Don’t know any other way to say it.

You are correct! I installed a GRT-III trigger in my Crosman Nitro Venom and for some reason it was not compatible. The first time I took the rifle out to try it, the rifle fired before I even touched the trigger. On my second attempt, while I was returning the barrel to the closed position, it snapped shut on me. I adjusted the GRT-III trigger as much as possible but it was still a “hair” trigger. My next shoots were 6″ high at 10 yards. Yup, it bent the barrel.

I bought that first Crosman Nitro Venom on Amazon so it was an easy return. The triggers on those rifles are horrible. When the replacement came, it’s trigger was just as bad as the first one. So I tried installing the GRT-III trigger in this one, being extra careful that the trigger was holding. This time it was perfect and the GRT-III trigger was very smooth and pull weight was nice at about 2#.

So you are correct. If the barrel gets away from you and slams shut, it’s toast. This was my first experience with a break barrel airgun so I was lucky that I didn’t lose a finger. I now know better and always hold the barrel securely when loading a pellet. This is really relevant to new airguners using a break barrel.

B-I-L

Yep that would work.

But it’s a disaster waiting to happen.

I wouldn’t teach my kids that. Or anyone else.

And I know your bringing up a answer to the question.

But I’m afraid there would be other answers to that question at some point in time that could not be good.

And trying to remember. But there was airguns made that way in the past. BB I’m sure knows some.

The anti-bear trap is our friend is all I can say.

I don’t think my Diana RWS 34P has an anti-beartrap because I can de-cock the rifle by pulling the barrel down to almost the end of the stroke and then pulling the trigger. I had to de-cock the Diana a bunch because I would cock it and load a pellet and then go out to shoot a sparrow or starling and by the time I got set they were gone. I didn’t want to waste a pellet so I always de-cocked the rifle. My Crosman Nitro Venom on the other hand can not be de-cocked, so I am assuming that rifle has an anti-beartrap. But because it’s a gas piston I could leave it cocked for a period of time. I still didn’t like the idea of it being cocked and loaded in the house though. I may not have this right so maybe you can set me straight.

I find it much easier to de-cock the bolt on my Urban PCP and that works a lot better for my normal usage, as I often have to de-cock it for the same reasons as above.

I also have a Diana 34 and Crosman Nitro Venom. The Diana has an automatic safety so no anti-beartrap needed. I removed the anti-beartrap from the Venom for the very reason you stated of not being able to decock the gun. The anti-beartrap in the Venom does not prevent the barrel from closing. All it does is prevent the trigger from being pulled. If the trigger sear fails, it’s going to close regardless of the anti-beartrap. If your really concerned about accidentally pulling the trigger while loading the gun, just engage the manual safety. I suspect that the anti-beartrap in the ASP-20 works the same way, just preventing pulling of the trigger vice actually preventing the barrel from closing.

outdoorman,

Welcome to the blog.

B.B.

Thank you sir. I read the blog but seldom read the comments however I’m very interested in this gun so the comments are helpful. I’m still a rookie with just over 2 years of air gunning but sure happy that I got into this hobby/sport. Something else to keep me busy in my retirement.

Outdoorman,

This blog helps everyone who reads it — even me.

I hope to receive an ASP20 to test soon.

B.B.

Thank you for replying. Appreciate the information.

Outdoorman,

Just curious, what size groups are you able to shoot with your Diana 34 and Crosman Nitro Venom? The best I could do with my Diana 34P is about 1 1/2″ to 2″. It was about the same with my Crosman Nitro Venom and that was the reason for purchasing the Diana 34P. I just didn’t know how difficult a breakbarrel springer is to shoot at that time. I thought it was the rifle, when all along it was me. I tried for over four years to shrink my groups with the Diana. It just never happened for me. This spring I sprung for a Gamo Urban and now groups are no longer an issue. I can get 5-shot 1/2″ groups all day at 25 to 30 yards. Still have not moved out to 50 to see when I can do but I have confidence that I can achieve very good groups at that range too. The learning curve with airguns has been huge.

BB,

I’m eager to hear about what make this gun insensitive to hold as that is where I, and I assume many others, struggle with spring piston guns.

In the fork pin hole boring process is there some precaution taken to ensure that the BORE of the barrel is aligned with the spring tube or do they simply align the outer part of the barrel? If it’s the latter, do they have some way of insuring that the bore is dead center and parallel with the OD of the barrel when they manufacture the barrel? You and others have commented that part of barrel droop and other misalignment issues are sometimes a result of the bore not being perfectly straight in the barrel.

Half

Half,

I talked with Ed about the barrel/bore alignment problem. Everyone in the industry acknowledges it.

You minimize it by inspection, and by how you rifle the barrel.

The ONLY way to make it perfect is to rifle the barrel and then turn the outside true with the bore. When you spend a pile of money with a custom barrel maker they can offer that service.

As for aligning the bore with the spring tube, Sig does it as well as they can by using precision fixtures and jigs during manufacture — the same as everyone. But boring the pivot pin hole in both parts is a major leap forward in this area, and, coupled with the Keystone breech, it does advance the precision of the build.

B.B.

BB,

That Keystone arrangement looks like it will definitely do the job as long as the care has been put into the barrel. I like it. I think they should just call it “The Keystone Breech”. It has a nice ring.

Half

Half,

Lincoln Jeffries solved that problem over 104 years ago. His solution was to make the barrel and breech block of one piece of steel.

RR

Maybe so.

But that still doesn’t fix the problem if the breech isn’t machined to line up where the scope will get mounted.

That’s the problem.

RR,

I don’t want to pay for that “technology”. LOL

Half

Halfstep

I know you worked maintenance in your job.

But I have to say if you ever worked in machining and know how many variables apply.

It would be way easier in relationship to get a air gun to shoot as accurate as you want then try to reproduce the part on a production line.

Yes engineering is involved. But the big picture is what’s important. It all has to come together and be repeatable for it to work.

Machining is alot like air gun shooting. You got to get your technique and components and procedures right to produce consistent parts. Or accuracy in making that part.

And then comes assembly. If the machining isn’t right. Then everything goes down hill after that. It all has to call me together. The big picture.

GF1,

I did do some machining in my job, but it was one off stuff like boring a hole and broaching a keyway in a sprocket. Never did any batch work or CNC stuff. As an apprentice I did make a bunch of copper chill bars for a resistance seam welding operation for one of our production buildings. I used a “state-of-the-art tape” mill to do it, if you have been in the field long enough to know what that was. LOL I also understand what you mean about variables. We called it compounding errors. Something gets off and they just start stacking up the farther you go along.

Half

Halfstep

Yep I have made repair parts for the machines. In other words no mistakes. Make that particular part to fit and replace the broken part. Only one try. Or cost the company money. And believe me when your a machinist you don’t want the reputation of not getting it done right the first time. Kind of a bragging rights thing. Ya know what I mean.

And then also production. And making machines to check the parts being machined. Too much to even list here of things done

And yep we called it tolerance stacking too.

In the quality field the compound errors are called “adverse tolerance stackup”. Meaning that parts are machined using all the tolerances allowed, but in the worst possible direction relative to each other. Engineers design part tolerances knowing that a very small percentage of them will not assemble. Statistical process control can reduce the possibility of this occurring to almost zero.

George,

That was what caused Irwin Pederson, a firearm maker, to never pass the M1 Carbine through government inspection. They were the only prime contractor who failed to deliver one gun. Their contract was can=celled and General Motors took over their parts to finish them correctly.

B.B.

B.B.

Thanks for today’s report. I like all the details and photos of the workings. Very nice report and looking forward to even more 🙂

BB,

I have only two possible issues with this air rifle, both of which are related to the gas spring.

The first one is the jolt that is typical of gas spring airguns. I myself have been slapped side the head by these. I am certain it was likely because the piston was more powerful than it needed to be, but when you are pushing 20 FPE it needs to have some power behind it.

The other is longevity. I am certain that gas spring technology has improved over the years and I am also aware that some manufacturers have much better quality control than others, but just how long can I expect that thing to last? I look around my place and I see some pretty old sproingers hanging around. It may not really matter to me, but what about my grandson’s grandchildren? Some of these old gals should still be shooting, assuming they have not been outlawed by then.

Neither will stop me for getting one of these, but I do think of such things when I start to look for a new boarder.

RR,

I ain’t a gonna spill the beans, but trust me. I used your exact words about the fining behavior in tomorrow’s post.

You will love this air rifle.

B.B.

RR

I know what you mean. And the other that gets me with nitro guns is tuning brings more difficulty.

My way of looking at things is always. Simple but effective. That be said the spring gun. Not the gas ram.

But BB keeps assuring us there’s more to come. If this Sig break barrel is the stuff. Just think how many will be sold.

Accuracy and dependability . That’s the hard ones. If Sig done it. Watch out world!

GF1,

I have seen some of the targets from that little show and tell. It has the accuracy.

RR

That’s what I’m waiting for.

GF1,

Check out Hard Air Magazine.

RR

Will do.

Gunfun1,

“Accuracy and dependability.” Amen!

So this will surprise you…I think! This break barrel rifle may actually be the first I buy for myself!!!!!

Why you might wonder Gunfun1; since I seem to be Big Bore crazed and certainly PCP nuts!

Because I think this is only the first iteration of the ASP20. IF SIG AIR finds that something in the first iteration is not up to spec in mod 0 they will make a mod 1 since the rifle s obviously a marvel of sub assembly design. I suspect that a full target stock for various discipline could be a Mod N and a full up light trigger might be a swappable trigger pack at some future date; or heaven forbid, a heavier trigger for a full hunting rig might also be Mod Ns.

I have not gone for break barrel airrifles in the past because I viewed them as finiky and or custom built and way to spendy for my taste; think Wiscomb. So IF SIG AIR is like SIG firearm then I believe they are JUST at the opening chapter of a phenomenal run at the airgun world. I look forward to owning one or perhaps even two; one in each of the current calibers. I also believe this is going to be like the Never Ending Story! Sig builds shooting systems and NOT one offs all that often.

shootski

shootski,

Well said! That is exactly what I have been trying to report. If a 50-year company had done this, the news would be fantastic. The fact that a firearm company has done it first crack out of the barrel is unbeliveable!

B.B.

Shootski

Don’t be surprised when you find your statement wrong.

If Sig is indeed on top of this ball game they are in. There won’t be a second chance.

They got to get it right this time. I seen this before in different things.

It’s always good to improve. But right now isn’t the time. Too many have tryed. And also failed.

If you want to be a world beater you better be on the game the first time around. It’s a hard game to play. But once you step in. You can’t turn back. You got to make it good first. Then make it even better the next time.

Gunfun1,

Remember the FWB Sport? I don’t hear anything of it. They got something wrong or maybe I am just not about their success

Ton

Yep I do remember it. Supposedly it didn’t turn out as good as people thought. I remember people complaining about it. But can’t remember exactly what. Other than it was way over priced for the way it was performing.

That’s why I do hope this new Sig break barrel is good. I’m definitely interested in hearing more about it.

B.B.,

Thank you!

I look forward to your complete reporting on the SIG visit.

I also look look forward to your testing of the .22 cal. ASP20 as soon as you get one in hand.

And, I look forward to what else you got/ordered (think X) while at SIG! Some time.

shootski

Ski,

I know — I know! It’s sitting next to me on the desk. I ALMOST went a bought the firearm after my Sig visit.

Next week for sure!

B.B.

While this is interesting , there should be more of interest than a break barrel rifle . What about the updated 320 with integral co/, pelketmah? Maybe the rumored365 blowback bb Pistol?

ichaelr,

I’m writin’ this stuff as fast as my fat little finger can fly. It’s all coming.

B.B.

I’ve not bought a spring gun in three years, and hadn’t been looking to get one again. But this gun is truly making me think about getting another spring gun…

Sounds like an interesting new air rifle. Lack of barrel droop is a nice feature. Next up should be a repeating version. Speaking of which here’s a picture of actarget shot with Diana Chaser 22 at 10 yds, from Weaver stance with the 7 Shot mag in place

Better view

Michaelr,

Very good shooting!

B.B.

Can probably do better as I get used to th pistol and experiment with pellets , this target shot with H&N. For the price pretty good. Not a Crosman 600 but not bad

I thought I wrote it on the target but that is 14 rounds, two magazines

Michaelr

It’s always good to see other people’s group’s they shoot.

When your good, your good. 🙂

Do you shoot alot?

And is the gun good?

Sorry for the questions. But the Diana Chaser and kit has been one that I have been watching. It is a interesting gun.

Thanks to airguns I shoot a lot more than I did with just firearms. I am a pretty good gun hand. I was pleasantly surprised by the Chaser. Good trigger, and accurate out of the box . Hidden under the foam insert was a case , that guess what the insert fit right into !

Michaelr

Nice package. 🙂

Definitely like the idea of the interchangeability of components too.

How many shots you getting out of a 12 gram cartridge?

Can you shoot out at farther distances where your at? I would like to know what it shoots at 25 yards. Or even 35 yards.

Will try the pistol out further , would think the pistol will go out to 15 yards, with the rifle barrel barrel throwing the 22 at close to 575 should get out to 25 yards at least.

Michaelr

Bet it will go out farther.

Sometimes one will be surprised.

I will take it out farther if I had one.

Mchaelr,

I was not familiar with the Diana Chaser 22, so I had to look it up on the PyramydAir site.

That’s a nice group, especially shooting offhand with a gun that weighs less than 2 pounds. =>

Happy shooting,

dave

GEO 791

No room for an answer above…..

You have to watch triggers. If you set them too light, it usually involves getting the sear set on a razor edge . You can expect it to fail at any time.

I like a light trigger, but I want to see some trigger movement in the second stage before it lets go. As long as you have a smooth trigger, you won’t even feel the movement . It feels like the trigger stops at the second stage and only requires pressure to cause it to release. In fact the trigger does travel a short distance, but you don’t feel the movement.

tt

TT,

The GRT-III trigger upgrade in that 1st Crosman Nitro Venom was scary. I don’t know why it didn’t work on the first rifle but then worked great on the 2nd one.

My Gamo Urban had way too much creep in the 2nd stage to suit me. I replaced the 8mm adjusting screw with a 10mm screw. Now it is just as you described. I can’t even feel it move in the 2nd stage. I actually shorted the screw to 9mm because initially it felt too light. Now it’s perfect now and feels just as good as the T06 on my Diana 34, or the GRT-III on the Crosman.

I must say it certainly refreshing to see Sig keeping an eye on this discussion and taking the time to answer a question about the breech matting process! Wasn’t expecting that.

In the Keystone Breech photo it looks like this rifle uses two wedge locks instead of the usual single wedge and cross pin? Does that bottom wedge retract as well when the upper passes by or is it more of a static mounted wedge? I don’t recall seeing that arrangement in other break barrels although that isn’t saying much since I haven’t seen that many but those that I have seem to use either a wedge or ball and cross pin setup…..perhaps I’m getting a little ahead of the Part 3 blog. lol

Chachoze,

I don’t know for sure, but all the other ones I have seen have been static. That’s why the detent is spring-loaded.

B.B.

Hi, B.B.

I really enjoy the sub-strings of thought that appear here thru-out the blog. I reread the string started by Bob-in-law and almost posted after Geo791 almost wrapped it up, but then it occurred to me that I’m starting to sound like: “Back in my day, we didn’t have any anti-beartrap devices. We weren’t pansies about losing a finger, unless it was the trigger finger. We kept shooting our springers, and WE LIKED IT.”

Sometimes I think you and I are the only ones that remember the early ’70s and I wonder how to get in sync with these other bloggers.

Anyway, I do have a question – Do you have anything that documents or tells when the anti-beartrap devices were beginning to be used in springers? I remember the side-lever FWB 65 I had in the mid ’80s had some sort of ratcheting set up but I don’t remember a reference to anti-beartrap.

I find I’m like Geo791 in appreciating the ability to uncock a springer when you feel it’s been cocked too long.

Larry from Algona

Larry

Man and how much different it was back then

A pansie. Do you know how long it’s been since I heard that.

Back then we wasn’t scared of anything. A anti-bear trap. What the heck is that I could hear me and my buddies saying. Why do we ever need that. Whatever it is.

Little did we know that someone was actually watching over us and helping make air guns safe and continue on. My FWB 300 has a anti-bear trap. And that was at least 40 years ago when it was made

GF1

Maybe I’m getting confused – not unheard of.

I was thinking that if you could uncock a springer, it had no anti-beartrap. All of my “keepers” except one can be uncocked. The exception being the Hatsan 95. I have a newer FWB Sport and you can uncock it just like the 43 yo FWB 124. I didn’t even bother checking my “these have to go” guns.

Am I correct here or is there another way to tell if there is an anti-beartrap?

LMo

LMo,

If the trigger doesn’t fire the gun until, the breech is closed there is an anti-beartrap. Some folks are getting a ratcheting hold-open device like the Diana 48 has confused with an anti-beartrap that works with the trigger.

B.B.

BB

And so what.

The object is to keep from loosing digits.

Whatever way the mechanism works.

Larry,

As best I recall, it was the problems with the Chinese guns in the early ’70s that brought about the anti-beartraps. I can’t remember seeing them, before that and I did manually uncock springers all the time.

B.B.

B.B.

Ahh, just as I thought. Thanks for the reply.

Well, I never thought it was a bad thing to use the “manual anti-beartrap” as B.I.L. says, and still feel this should be part of every safety lesson.

LMo

I’ve owned and tuned for myself and others more B-3’s than I care to remember. Along with proper cocking/loading methodology the anti bear trap is a wonderful device.

Larry,

Confused,… not unheard of,….. I can relate. 😉

To me,… once closed,… if you can fully re-cock, hold lever, pull the trigger,… while at the same time returning the cocking arm,… then the gun can be un-cocked. As for bear traps,… to me,.. they are for when you are ON your way to the sear latching.

Once the sear is latched,.. no issue. Still,… hold on to the lever and return it to the rest position. Heck,… hold onto it no matter what you are doing.

That is my take on the topic at any rate,…. Chris

Same here, Chris.

Still, is being able to uncock a springer an indication that there is NO anti-beartrap? As I just mentioned, out of 8 springers in my gun cabinet, only one cannot be uncocked. (the Hatsan)

LMo

Sorry, B.B. I believe you answered this already. LMo

Larry,

I do not know. I will defer to B.B. on an official answer. To me, they are (separate). While vague,… I think that removing the safety has some play into the matter as well. Some guns apply the safety automatically. Some do not. Even if uncocking,… I would think that the safety would need to be taken off in order to pull the trigger to un-cock the gun. To me,… the bear trap is (for) the ON THE WAY to the sear latching. The in-between stage of cocking,… if you will.

Chris

Larry

How are you uncockiing your gun?

Bring the gun to cocked position and hold the barrel then pull the trigger then bring the barrel to latched position.

The under levers are a bit different. As well as pcp guns and multi-pump guns. And certian Co2 guns. And I’m talking decoking.

Starting with a cocked gun.

Bring the barrel all the way down to the cocking position. Holding the barrel, release the safety. Pull the barrel all the way down and squeeze the trigger. There should be a click as the barrel, sear, and piston release. Ease up on the barrel .

The Hatsan won’t work like this since moving the barrel resets the safety so you can never pull the trigger.

I only have two under levers, a B3 and a Browning Leverage – both Chinese.

I have a 1377 and a P17 which is no problem firing with blanks. The Benjamin Trail NP cannot be uncocked. The Webley Premier has no safety and can be uncocked easily.

LMo

Larry

You can decock a 1377 too. Pull the bolt back and hold it. Then pull the trigger and let the bolt close while your holding it. Don’t just let go of the bolt because the bolt will fly forward.

The 2240’s and other pcp’s will do the same. But remember you will still have a pellet loaded. Also if you have a Marauder or gun that uses a magazine. Remember to take the mag out before you close the bolt like I mentioned above. And remember you will still have the previous pellet loaded from the magazine. Make that shot before you load the magazine again.

Gunfun1

Interesting! I never thought to try anything like this due to the nature of the 1377. Since I have only been shooting it at my indoor target, it was always easy enough to just let it “blow” after poking out any loaded pellet with a short section of cleaning rod.

But, since I’m starting to find mice in my yard it my be a perfect gun for pesting, so I’ll give your method a try. Still a pump could be left cocked longer than a springer, right?

LMo

Larry

I believe so with leaving the gun pumped. I always have if I was walking the property pesting mice. I have not had any problems.

Let me know how the 1377 does for you pesting. I have always liked mine for it.

GF1 & LarryMO,

I de-cock my Diana RWS 34P using this procedure: First, the rifle is cocked and loaded and ready to shoot. Then to de-cock it, I break the barrel open and move it all the way to the end of it’s travel at a point where just a little spring pressure is felt. Then while holding the barrel securely, I press the safety to the off position and pull the trigger. If I do it just right it doesn’t even make a noise. Sometimes it will click when I pull the trigger. Then I just return the barrel to the closed position. The pellet is still loaded, so I just re-cock the rifle and it’s ready to shoot.

I read B.B.’s comments but I still don’t know if the Diana 34 has an anti-bear trap or not. I’m thinking not.

But when I am pesting this procedure is needed most of the time…unless the pest waits on me.

Geo

That’s pretty much what I do.

Same here.

Works on ALL my German guns and the Xisico X25 Diana 34 clone. I farmed my only Gamo out to my nephew so I can’t test it but the Hatsan 95 must have an anti-beartrap.

Anyone able to decock one of these or any other Hatsan?

LMo

Larry

I don’t own any Hatsan’s anymore and can’t remember. Can’t help on that one.

This is a seductive breakbarrel…for many reasons. But it brings up the following thoughts. Lemme know what you think.

First, regarding droop and its dubious, to me, relationship to lock up integrity. Think of the breakbarrels out there with well-deserved reputations for droop. I’ll wager they have tight lockup when new. Yet they also have droop when new. That droop has nothing to do with lockup tightness and may or may not be due in part to lockup geometry. So the Keystone design, while it may insure initial (i.e. as new) side-to-side integrity, would have nothing to do with droop, if exist.

Second, regarding lockup integrity, the Keystone design, while helpful in minimizing side-to-side play, could actually prevent lockup by preventing the barrel/block from rising rise high enough.

Third, regarding the unthreaded pivot pin, the machined-in bushings eventually wear. Ok, say they last longer than brass. We’ll see after a few thousand pellets out the muzzle.

Fourth, I plan to buy this ASP and find out the hard way, while owning a piece of history.

john

who hopes Pyramyd will have predetermined the ideal mounts for the intended scope BEFORE i call in the order.

John,

If you buy the gun with the SIG scope you get the SIG mounts too. Specially made for this gun.

-Y

I believe the term “barrel droop” is confusing some folks. Droop is defined in the dictionary as a sagging, sinking, bending, or hanging down, as from weakness, exhaustion, or lack of support. This is not how it relates to break barrel airguns. When the dovetail scope mount is not machined parallel with the barrel centerline, we call that barrel droop. The barrel is pointing downward relative to the scope rail.

Geo

Yep you got it.

I still maintain that Robert Law had it right when he stated that (paraphrasing) droop was inherent in European guns (primarily German) because scopes were not popular for airgun shooting. Also, stocks were designed differently, being intended more for offhand shooting. If you trying shooting offhand with an old-style stock, barrel angle, and barrel mounted front and rear sights, you find everything just lines up perfectly with your eye.

Conversely, the Americans bought into scopes almost immediately and developed a passion for long range shooting. Scopes mounted back on the receiver and stocks evolved from the straight American design to extreme Monte Carlo’s. (Which seem to have fallen out of favor in recent decades.)

Americans being the obnoxious breed that we are insisted that the whole world do what we do. We were quickly accumulating the most marbles in the game and, of course, money talks.

Starting with the word “conversely”, these are my words and not something Robert Law would say.

LMo

Larry

Yep know what you mean.

Well Godfather you certainly have my attention on this one. Currently my favorite break barrel is my tuned Walther LGV Master, the barrel lock comforts my mechanical sensibilities. I refuse to scope my air rifles and will do so until my Optometrist can no longer make good correction to my optical challenges. I like to install receiver mounted peep sights and shoot that way so barrel lock up is important to me. Looking forward to more on this, Thanks.