by Tom Gaylord

Writing as B.B. Pelletier

A Benjamin 310 multi-pump BB gun from 1952.

This report covers:

- Smoothbore single shot

- Trigger

- Sights

- Size and weight

- How many pumps?

- Manual

- Adjust bolt for best air seal

- Walnut stock and pump handle

- Summary

Today we continue our look at the Benjamin 310 BB gun.

Smoothbore single shot

I make no attempt at hiding the fact that I like single shot rifles and guns. Usually their actions are simple enough that there is flexibility to do things you can’t with a repeater. For example, I had a problem with lead balls jamming in the Benjamin 700, and there is no easy way to clear the jam. The 700 action is all buttoned up. But the 310 is a simple bolt action that will allow me to test varying sizes of lead balls. If one gets stuck all I have to do is rod it out and keep on going.

The end cap of the box says this is a BB caliber gun — none of this .177 garbage that isn’t true!

Trigger

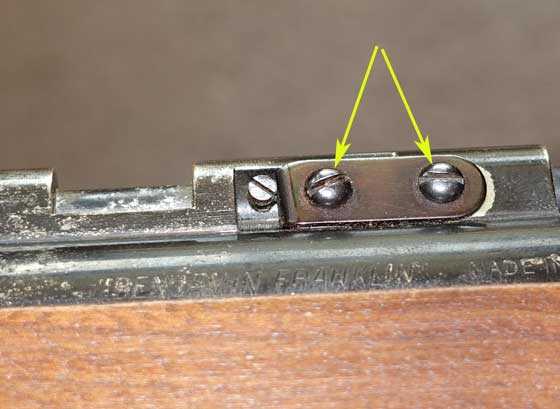

The trigger has a direct sear that holds the striker when the gun is cocked. This type of trigger was common on this range of youth-oriented airgun, but Benjamin did something extra. The blades on most direct-sear triggers wobble from side to side when wiggled. That’s why you read that so many owners have shimmed their triggers. They want to stop the wobble. Well, the 310 trigger has no wobble.

The trigger is direct sear with no adjustments. Notice the wire spring legs go between the sear and the trigger anchor. They take the place of shims.

The picture shows how they did it. The legs of the wire trigger return spring fit between the sear and the trigger anchor, shimming the dead space very well. That’s engineering in action!

Sights

The sights are pretty basic. A notch in the rear slides side to side in a dovetail for what little windage adjustment there is and the front post stands straight with no possibility of adjustment. The barrel is soldered to the pump tube, so you don’t want to put any side pressure on it. Once broken, that solder is very difficult to repair, though I have heard that Tim McMurray of Mac-1 Airguns has done it.

That said, the sights offer a clear sight picture that’s sharp. The rear notch is a V and the front blade seems rounded on top as you look at it.

Size and weight

The 310 is 34-3/4-inches long with a 19-1/4-inch barrel. The length of pull is 13-1/4-inches. The gun weighs 4 lbs. 4.5 oz. That makes it a small shoulder gun. It’s longer than a carbine, but very handy for woods walking or barn sniping. I said earlier that it was made for youth, but I know for a fact that more adults used them than kids. That was particularly true of the front-pumpers that are too hard for kids to operate, but it carried over to these underlever pumpers, as well. Maybe it was due to the higher prices (than typical BB guns of the time), or perhaps it was the perception that these were more powerful and therefore should be taken more seriously.

How many pumps?

Here is question number one for any multi-pump. How many pumps are maximum? We saw that the Benjamin 700 repeater said it could take up to 12 pumps, but 10 was where I had to stop. The 700 is a repeater that gets several (3 or 4) shots on a fill, or you can pump it 5 times initially, and then twice after each shot to maintain velocity.

The 700 is a front-pumper and front-pumpers have a longer pump stroke, so they don’t have to be pumped as many times to get the same results. At the same time the 310 was being made Benjamin modernized the 700 into the 710 BB gun that was also an underlever pumper. They recommend pumping that gun up to 20 times, where the 700 stopped at 12. So the underlever pumpers need roughly twice as many pump strokes to get the same power as the front-pumpers. But their pumping geometry makes them much easier to pump!

The manual for the 310 says to pump it 7 or 8 times, maximum. That holds for the 317 and 312 rifles, as well. Four strokes should be enough for indoor target shooting, but we’ll see in the velocity test. This is one airgun I will definitely not over-pump.

Manual

I don’t have the original manual for the airgun, but I do have a book — The St. Louis and Benjamin Air Rifle Co.’s — written by Dean Fletcher, that includes many of the early sales brochures and manuals of these early airguns. That’s where I’m getting my information.

The other day I had a call from someone with questions about early gallery airguns. He told me there was some information about them in Larry Behling’s book on BB Machine Guns, but he didn’t buy one when they were available because, to quote him, “I didn’t have a need for one at the time.” Guys — buy the books when they are available. If you are an airgunner you never know when you will need them!

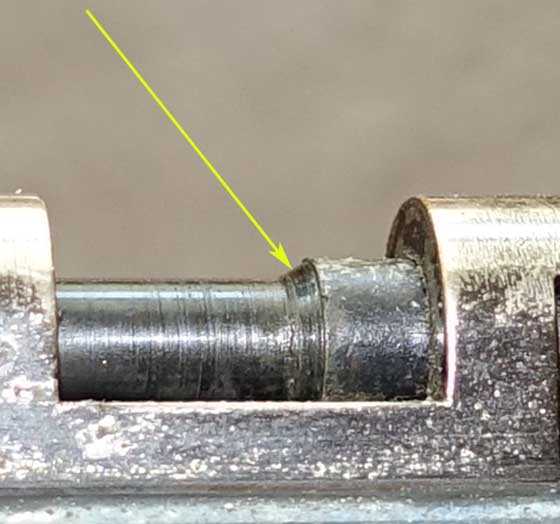

Adjust bolt for best air seal

Here is something novel. The 310 bolt doesn’t have any o-rings. It seals on an angled bolt shoulder that butts up against a chamfered breech. Benjamin provided a means of tightening this joint though a cammed plate on the left side of the receiver. Loosen two screws and tap the cam plate forward with the bolt held in the right position, and when you close it the cam will be tight. All this on a $15 airgun!

The bolt face is angled (arrow) to interface with the breech in an airtight seal.

Loosen the two screws and tap the cam plate forward (left) to tighten the bolt interface.

Walnut stock and pump handle

All Benjamin airguns had stocks made from American walnut. They bought the wood in Stover, MO. American walnut is one of the fastest growing hardwoods, so it is practically a sustainable resource. It is usually very plain and straight-grained, but that gives it strength that a fast-growing wood often lacks.

Combining the walnut furniture with the shiny black nickel gave the Benjamins of this era a firearms’ look other airguns didn’t equal. Sheridan came the closest, but they used paint instead of plating on their blued rifles.

The problem is that black finish is extremely fragile. I just wipe it with a clean cloth because I don’t want any of the black to come off. I told you my gun has 80 percent of the original finish, but it’s closer to 90. I always like to rate them conservatively because nobody wants to be disappointed when they see the gun in person.

Summary

That’s the end of the description. Next time I will do the velocity test — though I have so much to test that it may take more than one report, as well.

Myearly benjamin 312 I grew up on uses the same bolt interface

I love these old guns.

B.B.,

I suppose the decrease in the relative stroke volume from the underlever also contributes to the increased number of pumps required to equal the pressure of the front pumper. It is indeed more convenient to use an underlever in the field than a front pumper. Can you imagine looking for a hard enough surface to press against in the middle of a muddy field?

Siraniko

B.B.,

Thanks for showing the trigger spring also acting as shim washers and the adjustable breech seal. It is fun to see the little engineering innovations like these.

Good Day to one and all,….. Chris

BB

The cam lock is cool. My neighbor at my old house I use to live at had a Benjamin pumper with that cam lock bolt. But it didn’t have the tootsie roll pump handle. I guess it must of been a later model than what you have.

I guess they had to do some pretty good machining on the angles and fit to make the bolt seal good though. Probably the finish is pretty smooth too when you open the bolt.

And waiting for the velocity test. But more so the accuracy test.

Forgot with the picture of the bolt it looks like the angle finnish was worried about more than the rest of the bolt or breech. Or maybe it’s just the picture.

BB,

As Chris noted, quite a bit of thought went into this bb gun. I know many of these innovations were to keep the manufacturing costs down but at the same time present the customer with the quality they desire and need. As you said, the price and the power was almost prohibitive for youth. I can well imagine most of these were used by adults.

I personally would like to see something like this come back on the market, but I think the legal departments would have the screamin’ meemees about a bb gun this powerful. After all, a bb gun is a toy, isn’t it?

RidgeRunner,

Daisy might have toned it down a little over the years, but the 880 shoots BBs pretty fast.

Michael

Michael,

That may be so, but looking at it I figure it would probably last me about two weeks. I might go for an old 760 though.

RidgeRunner,

If you search for one, I believe some early incarnations of the 880 had not only metal receivers but metal levers as well.

Michael

The bolt face on my 101 has rings worn into it from usage. I do like this bolt sealing adjustment. On my 101 the factory would braze a small blob on the back side of the bolt lock and file and polish it down for a tight fit.

Just another little note. I too am quite irratated with the labeling of bb guns as .177 caliber.

B.B.,

The metal-to-metal seal no doubt requires tight tolerances, but ——this is one breech that will never need a reseal. :^)

By the way the extra-long dash above was courtesy of my cat Ben. As he often does, he lies on his back next to my keyboard, and I rub his belly now and then. This time his head depressed the far right dash key. Ah cat typing!/////////// (More Ben typing.)

Michael

Michael,

If you can teach Ben to conjugate verbs I might have a part-tim job for him. 😉

B.B.

B.B.,

I just read your response to my wife and she laughed. Good way to start one’s day.

Michael

BB

We have one we’ll send you. Leo struggles with verbs but he bites for free.

Decksniper

Deck,

Are they sound bites? 😉

B.B.

BB

Only if you are quick enough

Deck

A very nice rifle. I like the old ones as they a (usually) well machined metal and wood construction.

I am a bit surprised that the soldered barrel/pump tube is viewed as being something to be cautious about. While I wouldn’t abuse it, I’d expect that it is a very strong joint.

Thought I would ramble on about solder for a bit – its really great stuff…

In order of strength of joints, there is welding, brazing, silver solder and tin/lead solder. The tin/lead solder is at the bottom of the list but it still is very strong.

The beauty of the tin/lead solder is in how it melts at (moderately) low temperature. The solder flows in between the parts filling gaps, and leaving a smooth, clean fillet at the seams. Solder is not an “adhesive” sticking the metal together, the bond is at a molecular level with the solder forming an inter-metallic alloy with the parts being joined.

As a home done “galvanizing” I will often “TIN” (apply a thin layer of solder to the surface and wipe the molten solder off with a rag that has a bit of flux on it) metal parts for corrosion resistance.

For mechanical assemblies subject to a lot of vibration, in addition to fasteners I will often tin the mating surfaces, position them and reflow the solder (with a propane torch) to lock the parts together. The nice thing about using solder is that you can reheat the joint and re position or separate the parts if needed – can’t do that with a welded joint.

With the whole RoHS fiasco there are now a number of “lead free” solder alloys containing other metals (antimony, copper, silver etc.) available. The “new” solders tend to be less ductile than the normal 60/40 SnPb solder so that can be an advantage in the strength department but they don’t flow as nicely (IMHO) as the old formulations and need higher temperatures to melt.

Solder is easy to work with if providing the parts are absolutely clean and both surfaces are brought to the correct temperature. Use a bit of flux when soldering and don’t disturb the parts until the solder has cooled and you will have great joints.

Its amazing what you can make with copper tubing and fittings from the plumbing department 🙂

Hope this is of interest.

Hank

Hank,

I am only telling you what I have seen. Many of the rifles that have scope mounts clamped to the barrel have broken solder joints. And I have seen quite a few of these old Benjamins with them.

B.B.

B.B.

I don’t doubt what you have seen, its just that I am surprised that a commercially done (in ideal conditions??) solder joint of that size should be immensely strong.

Maybe if the rifle is being held by the scope during pumping the mount is applying a lot of leverage (and possibly flexing) the joint to fatigue it.

Hank

“I make no attempt at hiding the fact that I like single shot rifles and guns.”

Amen, B.B.! I’m with you on that.

I took my first pheasant with a Winchester model 37A 20 gauge.

I took a pile of squirrels with a .20 caliber Sheridan C-model.

I took my first turkey with a Stevens model 94 in 12 gauge.

I took my first deer, and many hogs, with my .50 caliber Hawken [replica].

They are single-shots one and all, and they are just as capable as ever!

On to today’s report: thank you for showing the details on the trigger…very interesting.

And as to the velocity testing, heck, we have asked for a LOT from you,

so if it takes two or three reports for that, I think we’ll all be good with that.

Like don’t go burning yourself out on our account; we’d like to see you around for a good spell! =>

Dave,

Pyramyd AIR was very prompt in processing my order for the darts. I think they are as in-tune with this blog as you readers. That makes my job a lot easier.

B.B.

Cool! =>

Dave,

Here’s my two cents. Like most young newbie hunters, I started out with a single shot .410. I never could hit anything with that gun. Then I graduated up to a Remington 11-48 3-shot auto in 20 gage. Right away I started collecting rabbits, squirrels, and pheasants. That was a great gun. Later I bought a 12 gage double with 3″ chambers. I loved that gun for the shortness and quickness of it, especially in brushy areas. I still have that double to this day, though I have not shot it in forty years.

What I discovered with my first 3-shot Remington auto was that I tended to shoot too quick with the first shot but usually connected with the second. Seldom did I ever use a third shot. The nice thing about the double barrel shotguns is that one barrel is a modified choke and the second barrel is full choke for the longer shot. I never shot a 3″ shell out of my double barrel shotgun…never thought it was needed. I loaded a lot of my own shells back then too, which was fun too.

Geo

Hi Geo,

That’s some great stuff there; you are bringing to mind my friend, Ronnie,

“the man of 1000 squirrels” as we called him (actually, I think he got over 2000 =>).

He had an open-choked (maybe Skeet2) .410 Remington 870 pump.

In the cypress swamps of Florida, that gun served him well,

as well mostly shot squirrels as they were moving,

and the ranges were close, 20 to 25 yards, as our scrub oaks were small.

Ronnie loaded all his own shells, and if he missed quick on the first shot, he got them on the second.

I don’t recall him ever loading more than two shells, even though his gun could take 5.

Thanks for bringing back old memories of good times! =D

take care,

dave

Geo

If your a good shot with a .410. Your probably real good with a .12 or .20.

A .410 is a fun gun to practice with to me anyway. I was actually over the weekend thinking about getting me a .410. I like the tactical look. They have some semi-auto .410’s based on the AK’s that I have been thinking about.

Yeah, the problem with hitting with a .410 is that the shot pattern is very small. I think the little .410 double barrels are really cute and would be fun to hunt with. My neighbor has a 28 gauge double barrel and it’s really nice too…but the shells for it are very difficult to find.

Geo

I like the 28’s. Nice recoil and good power and shot pattern.

And I like to think of a 410 like shooting a rifle with a bullet or a pellet. But with a big diameter projectile so to speak.

A semi-auto 410 would make for some fun can dance’n in the air. And if your into rifles or should I say long guns for home self defense. I think a semi-auto 410 would be nice.

And I mean based on a AR-15. Not a AK-47 like I said wrongly above. That was my phone again and didn’t notice it changed it. Yep darn stupid smart phone again. 🙂

GF1,

You know, I’ve never seen a .410 shotgun in a semi-auto. Most of the one’s I have seen are either single shot or a bolt action. The bolt action .410s, because of the screw on chokes, are used a lot for hunting deer here in Michigan. With an open choke, like improved cylinder, or no choke at all, they shoot slugs pretty accurately.

I have a 12 gauge Remington 870 Deluxe with a 20″ slug barrel. This was before the rifled slug barrels appeared on the scene. The slug barrel on my 870 has and improved cylinder choke. I even used is for close in shots in brushy areas for partridge and rabbit. As far as accuracy with slugs, I could easily hit a 2 quart milk carton at 50-75 yards. It has nice rifle sights on it too. I killed a nice 8-point buck at about 110 yards with it. I held just over his back and took out both lungs.

Funny story regarding my Remington 870 slug gun. I went out with a couple of buddies to sight in our guns before deer season. One of my buddies used his jack knife to attach a paper target to a tree. The target was probably 50 yards or so out. He thought that by putting his knife right in the center of the bullseye than no one would hit it. He was wrong! On my first shot I hit the knife dead center. We couldn’t find and part of that knife but the target looked like it had been shot with a shotshell. There were little holes all over the target from the pieces of knife. My buddy just stood there with his mouth open…”My knife!”.

I still have the Remington 870 deer gun but have not shot it in over forty years. I hate to part with it but have often considered selling it because I don’t hunt deer any more. I need more room in my gun cabinet for airguns 😉

Geo

Geo

Yep don’t sell the Remington.

And search. “.410 semi-auto shotgun”

They have them in conventional stocks or the tactical versions. They are a bit pricey in either version for a shot gun. But hey it’s a semi-auto. As the saying goes. You got to pay to play. 🙂

BB

I was going to bring this up in previous reports when you mentioned the Missouri Walnut.

This isn’t exactly related to gun stocks. But it’s something I have thought about before. All kinds of woods have different grains and character. And it’s basically Black Walnut that I’m thinking about.

But Illinois has Walnut and Black Walnut trees pretty abundantly. Well in my area anyway. I can see down one tree line off to the left of where I shoot at least 10 Walnut trees. And that’s just on the outer tree line.

Anyway what I’m getting at is I have to think why wasn’t black Walnut used on the Benjamin guns since they was made in the area I live in. Thinking maybe the regular Walnut was cheaper than Black Walnut even back then.

And this isn’t gun related but here’s a link on furniture and wood working and black Walnut.

https://www.woodworkerssource.com/blog/wood-conversations/4-things-woodworkers-need-to-know-about-walnut/

GF1,

I don’t know the answer and maybe only someone from that time would know for certain. I’m sure cost was a factor in the decision.

B.B.,

BB

Probably so I guess. Cost.

And I’m betting someone probably had connections with Benjamin back then and got wood as needed.

Maybe someone got smart back then and found out what they had in Missouri. Maybe little things like that made it harder for Benjamin to keep producing guns. Maybe that’s how Crosman stepped in and took over Benjamin. And then what if Crosman knew the wood suppliers too.

I know all speculation. But how the heck did Benjamin fold? Anyway. Glad that the Benji line continued.

Gunfun1, I’ve spent the last 2 hours researching your question;

I still don’t know the answer, but I’ve learned one heck of a lot about walnut!!! =>

http://www.gunsandammo.com/gunsmithing/the-future-of-wooden-gun-stocks/

http://americanwalnut.com/gunstock-blanks.html

https://www.americanhunter.org/articles/2013/2/5/whats-the-best-wood-for-a-rifle-stock/

http://innermountainrifles.com/blanks.html

https://www.americanhardwood.org/en/american-hardwood/american-walnut

http://www.nemahaweb.com/blackwalnuts/trees.htm

https://www.canadianwoodworking.com/woods-know-european-walnut

Thanks for the question; I’m sorry I don’t have an answer yet, but at least it forced me to learn a whole bunch about walnut in general and its use in rifle stocks in particular. =>

Dave

I just read all the links. Thank you for the time researching it.

All I can say is what ever type of Walnut it is and where ever it comes from it’s pretty wood.

We have one massive black oak tree down in the valley by the creek where we ride the 4 wheelers. It’s got a trunk easily 3 foot in diameter. Probably more actually. Haven’t measured it. It produced walnuts the first year we moved here. It is by itself. Matter of fact it’s the tree that the big hawk sits in all the time watching to get food.

Definitely would hate to see that tree go. Bet it’s a old one. It’s branches are bigger than some of the other Walnut tree trunks that are around.

Glad it survived. And it’s great shade to stop under when we 4 wheel. 🙂

And I meant one massive black Walnut tree. Not Oak. That was my phone changing things again.

One thing to remember when tightening the cam on the bolt of these guns is that the transfer port goes through the side of the hollow bolt. If the bolt does not close completely the transfer port will be restricted. The bolt handle needs to be all the way down.

Or if you want to play with a multi-shot at lower power, block up the bolt handle and adjust the cam. I could get up to three shots. As a kid without a chroney I bet each shot was half the velocity of the first.

On most of the benjamin 3xx all the way to the 39x the soldered barrel is a solid sturdy and rugged joint. Once in a while one comes out weak not sure why. But the scope mounts on the barrel wedge the solder joint apart with a lot of leverage, even the ones on the breech it is also a soldered joint. I don’t know why Crosman has not changed the breech design on the Benjamin pumpers for scope rings. I guess because it would be a major design change.

Don

Don

Yes. The barrel scope mounts are a bad decision on the soldered barrel Benji’s. Like you described. Plus they won’t hold a scope on the non welded guns even. Like the 1322/77’s and 2240’s and such. And even with long barrels on them. Tryed that years ago and definitely a no go. Not a good design in my opinion.

Now this would be the ideal air pistol collection for me. I want everyone to remember Christmas is right around the corner.