by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Air Arms End Cap tool for the S410/510

- Air Arms piston seal tool

- Seneca tool for ring nuts

- Beeman R9 end cap plug removal tool

- Gene’s special tool

- FWB 124 compression chamber scraper

- Another scraper

- BSA mainspring assembly tool

- Summary

Today’s report was inspired by Gene Salvino, the senior technician at Pyramyd AIR. He showed me the pellet removal tool he made from a broken .177 Dewey cleaning rod and asked me to show it to you. I did in Part One of the 2019 Pyramyd AIR Cup report and there was so much interest that I decided a report on special tools was in order. Now this comes on a Friday, so there is all weekend for you to post pictures of, and tell us about your own special tools.

I will start with the tools I’m the least familiar with. Then I’ll finish with a couple tools I have made myself and used over the years. Let’s get started.

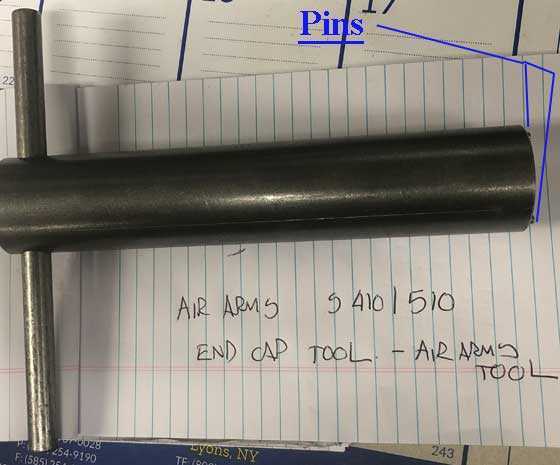

Air Arms End Cap tool for the S410/510

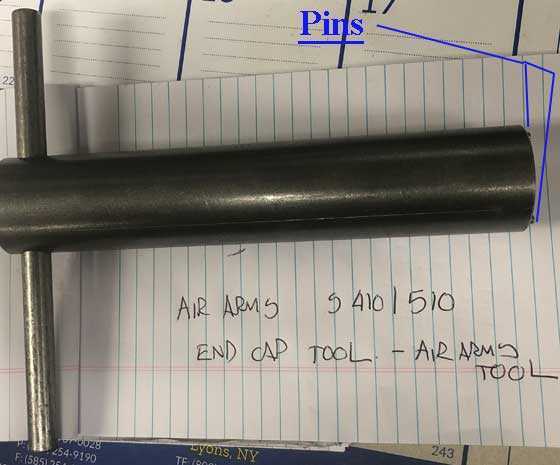

Air Arms PCPs have holes in their end caps (where the filling is done). To remove these caps you need some kind of a spanner with pins that fit into the holes. Air Arms supplies a tool for this job to their dealers, and Gene says he uses it on S400s, S410s, S500s, S510s and whatever other pneumatic Air Arms may bring out, because they keep things standard for reasons like this.

Air Arms provides this spanner to remove the end cap from their pneumatic rifles.

Air Arms piston seal tool

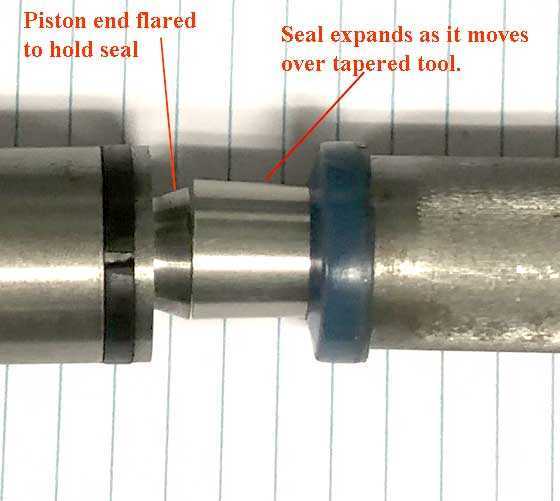

Another special tool Air Arms provides is for installing piston seals on their TX 200. The TX piston has a flared steel top that the seal must expand to go over. The flare then holds the seal firmly on the piston.

I will show you the tool with a seal mounted and piston that’s ready to be sealed. Then I will show the detail of how the tool works.

Here we see the tool with a seal and the piston ready to receive it.

When you see the detail you can see how this tool works.

The tool is two parts. The flared part slips into the handle, so you can install the piston seal easily. Put the seal on the small part of the flare with the bottom heading forward, so it ends up on the TX piston in the right orientation.

Gene says he doesn’t get to use this tool as often on TX200s because they seldom need new piston seals, but the same tool works on all Gamo rifles that have one-inch tubes, Stoegers from the X5 to the X20 and on certain Crosman/Benjamin Trail rifles. So it’s a handy tool to keep around.

He says if you plan to make one for yourself, make the wide end a little larger and it will also work on RWS seals.

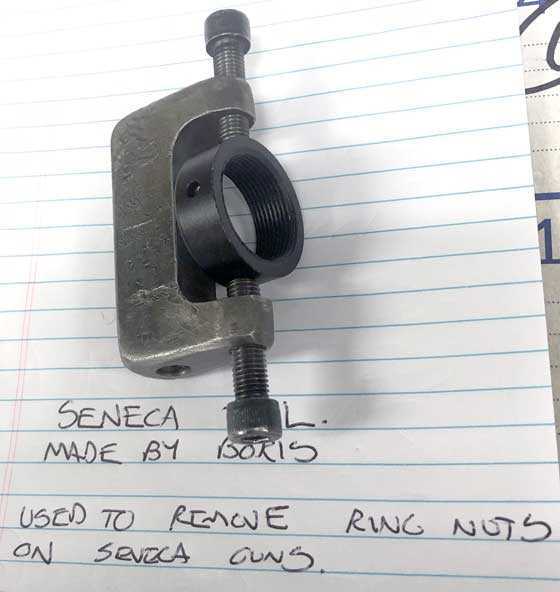

Seneca tool for ring nuts

On Seneca pneumatics the end cap that holds the fill port is in a cap that’s held on by thin ring nuts. The nuts have two small holes on opposite sides that a spanner goes into. Boris made a tool for Gene that has two cap screws with their ends machined round and smaller to fit these holes.

This spanner for Seneca PCPs looks massive, but it’s not. The ring nuts it fits are about an inch in diameter. Boris made it from stock steel, but you could make one from a small C-clamp, too. The screws are M5 metrics.

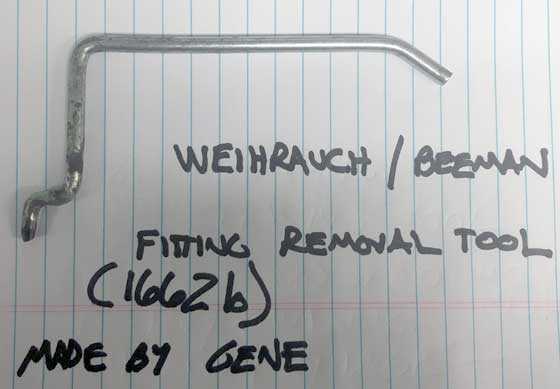

Beeman R9 end cap plug removal tool

Gene made this tool and he says he uses it all the time when working on Beeman R9s. The R9 has an end cap that holds the trigger and keeps the mainspring under tension. It’s a sleeve that fits inside the main spring tube. It’s held in the tube by a single flange, but its also held by 4 square tabs that must be popped out before the sleeve can be rotated so the flange can clear the spring tube.

There are two tabs (arrows) on either side of the R9 spring tube.

I have always popped out the first tab on either side with the short leg of an Allen wrench. The trouble with that is the wrench tries to twist in your hand and sometimes a tab is really stuck tight! Once a tab is popped out a pin punch will pass through the hole to easily pop out the tab on the other side of the tube.

One tab has been pushed out and you can see the inner end cap sleeve I mentioned. Put a pin punch through the hole and tap out the tab on the other side.

This is the inside of the sleeve and you can see the hole that the tab engages (arrow).

Gene’s special tool

Gene bent a heavy piece of wire to reach in and pop out the tabs. He then uses a pin punch for the opposite side.

Gene made this special tool to remove the R9 tabs.

If I’m not mistaken, there are other Weihrauch rifles that use tabs like this. I think the Beeman R10 that is based on the HW 85 uses them, as well.

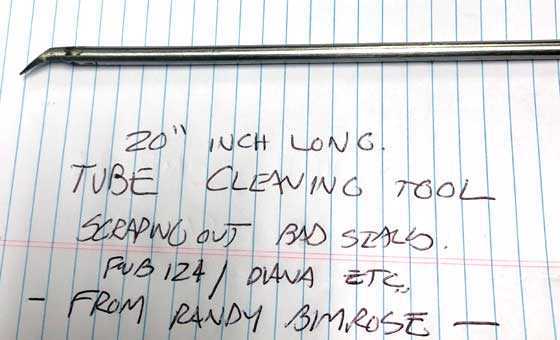

FWB 124 compression chamber scraper

The FWB 124 breakbarrel is a legendary spring piston air rifle. But the original seals dry-rotted inside the gun and all failed over time. When the gun is disassembled for a reseal, you find a lot of old seal material crammed into the corners of the compression chamber deep inside the spring tube where it’s hard to reach. So Gene made a tool to clean the end of the chamber. It includes a sharp point to get into the tight corners of the chamber where it’s hard to reach. It doesn’t look like much but he tells me it’s a tool he uses all the time. He got the idea from attending a class by Randy Bimrose who gave the students drawings of many special tools for working on spring guns.

It doesn’t look like much, but this tool is invaluable when tuning spring-piston airguns.

Another scraper

Let me show you how bad a 124 seal can get. These old rotten seals were stored in the wooden box that my 124 came in. They were in plastic bags that are not airtight. They started out as off-white color but look at them after 30 years!

These FWB seals have rotted and turned to a waxy substance that crumbles to the touch.

Now I’ll show you a couple special tools I have used. I used to scrape the compression chamber with a long-bladed screwdriver. It works but isn’t as good as what Gene has. However, a few years ago I discovered that the patch removal tool for a muzzleloader is just about perfect for the tight corners.

The patch removal tool on a Thompson/Center Hawken ramrod is great for picking old seal material out of the crevices of the compression chamber.

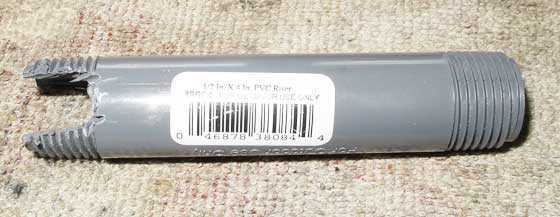

BSA mainspring assembly tool

Some spring rifles have a large pin that stops the mainspring from coming out of the gun. You have to get around this pin to push against the spring guides to take tension off the spring or the pin will not come out.

To compress the mainspring you have to get past that large pin.

This 58-cent plastic sprinkler pipe makes a good mainspring compressor that reaches around the BSA pin with ease. It looks crude, but I have taken several BSA spring guns apart with it.

Summary

That’s it for the special tools. Maybe you have one or more to share?

This is some good stuff. My special tools generally are used to disassemble spring guns. I do have a couple Allen wrenches welded together to get the cap off the trail np.

B.B.

Wish a standard gunsmiths tool set would be enough.

-Y

Yogi,

Gunsmiths make their own special tools also.

BB,

I have a “wrench” for removing AirForce valves. It is a ring with a bolt through it that has a tip to engage the detent on the valve. I’ll post a picture later.

Air Arms Special Seal Tool – Another special tool Arm (Air) Arms provides is… 😉

RR,

Got it. Thanks,

B.B.

Like this sort of blog B.B.!

It’s always nice to be able to look in the tool box to see what special jigs and tools a person has made to make their work easier.

I always try to design something such that and average person with two hands and common tools can perform service and maintenance but often that is not possible – sometimes there is a need for “special stuff”.

While some custom tools require access to a lathe or a milling machine to make, as shown in the report, many can be made from stuff found in the workshop.

Recently I have been working on my old .22 caliber Crosman 101 (now a .177 caliber “100”) and thought I would show a couple of the things I made for it. The hardwood block and a couple of dowels that are used to make the leather pump seals and the bent pipe with the little “tabs” cut into the end is used to disassemble the rifle are easily made at home. The new .177 bolt with a small diameter pellet-probe and O-ring seal (made from a 6 inch long, 3/8-16 stainless steel bolt, a couple of cap-screws and an old drill-bit for the pellet-probe) was not difficult to make but does require access to a lathe.

The wire tool in the picture (made from coat-hanger) is used to lever the “safety spring” on a Maximus out of the way so that the safety can be removed and the rifle disassembled. It was quick to make – a couple of whacks with a hammer, a bit of dressing with a file and then bent to shape. The soldering wasn’t necessary but the soldering-iron was on the bench and it only took a couple of seconds to do.

Thanks for a peek at the tools of the trade!

Hank

Hank,

Thanks for sharing!

B.B.

I think we’re all tools. The evidence is in the lengths we go to in order to get our guns to shoot correctly.

B.B.

The R9 end cap removal process and the Diana 124 ball bearing trigger seem to be the harder ones to do maintenance on. The R10 is simple. two drift pins, ( a pencil should work on those) remove Rekord unit, dont loose

the safety pin and spring, Unthread massive steel endcap. No spring compressor needed. This endcap is part of the ‘secret sauce’ that I think helps tame the vibrations of the shot cycle.

I think the Airarms guns like the TX may be just as simple to get inside, and little or no spring compression?

My first job after school years ago was in a probike shop assembling Gitanes and Raleighs. The bikes that require the most skill in setting up correctly were the department store quality bikes. And no, they made me wait a few seasons before I could lays hands on a top of the line race bike, however, the tools that were needed for those came in a case with a the logo ” Campagnolo” on it. Just beautiful.

Rob

Rob,

Thanks for the R10. I didn’t remember.

B.B.

Mr. Gaylord:

While your posting on special tools used by airgunsmths is interesting as usual, what I’m hoping, however, is that you or others on the blog will post a list of reputable airgunsmths with point of contact information for those of us who are “tool use challenged”

Shalom,

William Schooley

William,

What service do you need specifically?

B.BN.

Specifically. I’d like to find an airgunsmith with the knowledge and tools to have my .22 gauntlet tuned, modified and accurize to the point that I can at least be competitive in the 2020 AirCup benchrest competition.

All I saw, or at least it seemed to me, on the line this year were expensive rifles like Air Arms, Day States and Raws. And these with expensive optics and bipods.

Being retired, these are all too rich for me. I want a price point air rifle modified into something like my modified 10/22 that I use for shooting at Camp Perry.

In the alternative, I’d like to see the AirCup expanded to have “stock events” more geared for shooting with price point air rifles.rifles. Barring that, I’ll see about modifing what I’ve got to be competitive.

P.S. And I like the work to be done in time so I can practice practice and practice some more.

Thanks,

William Schooley

William,

I will post Part 2 of the Pyramyd AIR Cup on Monday. A .22 caliber has almost no chance to place in the 100-yard benchrest unless there is no wind blowing, so your request for a stock rifle competition is more reasonable. But in a stock match the RAW and FX rifle could also compete unless a price limit were imposed.

What I’m saying is what you are asking is like asking to compete in 10 meter rifle with a breakbarrel spring rifle and open sights.

I don’t know how to answer you. This is a case of I don’t think you can get there from here. I hate to be negative, but I think I’m being realistic when I say all of this.

B.B.

BB, I saw .25 Gauntlets in the Benchrest though…

Val,

Yes, but the ones from Umarex were highly reworked, which is why I put in the caveat of cost.

And they didn’t place.

B.B.

What you’re saying is what I want is unrealistic. That’s not negative, but it is realistic . It’s both an honest and helpful answer from a master source that I know and trust.

I thank you for both.

Shlom,

William Schooley.

William,

More on Monday that may shed more light.

B.B.

Wm.Schooley,

What you are asking for is, Single Class (stock from the showroom floor racers with required and standardized safety items)found in boat and auto racing. Unfortunately that usually results in wide scale cheating resulting in challenges and intrusive inspections; unless the weapons used are issued to the shooters by the organizers.

I wish it was different and skill ruled competitive pursuits but money talks louder most of the time.

shootski

B.B.,

All my tools are packed for moving, but the most prevalent tool on my bench is the lowly screwdriver…I have dozens of them. Whether working on shotguns, rifles, or airguns, a good gunsmith buys LOTS of inexpensive screwdrivers and then grinds one to be a perfect fit to whatever screw they are about to remove (in the case that one of their existing ones is not already a perfect fit). Over the years I have learned that: when building wooden boats, you can never have too many clamps; and when working on guns, you can never have too many screwdrivers! =>

Wishing a blessed holiday weekend to all,

dave

I do use some genuine factory tools, but most are home made, my tool for fitting a TX200 or Pro Sport piston seal is the neck of a CO2 capsule fitted with a neo magnet, stick it to the piston, a blob of PTFE, and slide it on with a deep socket in one go.

Clive,

Welcome to the blog!

What an ingenious idea! Everyone asks me what to do with used CO2 cartridges and this is the first good use I have heard of. I don’t suppose you have a picture of that, do you?

B.B.

Yes.

Clive sent the photo to me to post.

B.B.

Sometimes you just have to improvise, especialy with some of the older guns, the Meteor tool is just a bit of broom handle, the QB valve tool is a modified socket.

B.B.,

The plastic pipe tool reminds me of the tool needed to compress the spring in the 499 lever gun. A rearward tab goes through the action to retain the spring. (the rear sight on some guns) A 1 x 2 (3/4″ x 1 1/2″) with 2 cut off coat hangers work better (as Cobalt) posted awhile back. The principle is the same though. The small V spring in the safety mech. is the worst though. That took a thin piece of tag wire to hold in place,… which once assembled,… could be pulled back out.

Most of my mods/inventions are to rest’s/target’s and to the guns themselves. I have always been one to think that I could have made it better. Most of the time,… it works and proves to be true. Then,… there is those “other” times……….. 😉

Chris

B.B.,

Our bulk fed CO2 guns required a longer than usual screwdriver to tighten the valve assembly to expand the O-ring. So we made one from bar stock about 16 inches long. Without it forcing the valve down the tube with the O-ring expanded resulted in a lot of torn O-rings.

Siraniko

Siraniko,

There you go!

In fact, long-bladed screwdrivers are so handy that I always search for them in the old tools pile in pawnshops. I don’t often find one but when I do I always buy it. One can never have too many long-bladed screwdrivers.

B.B.

Oooops!,…. posted on the Thurs. blog,…. I meant to do it on the Friday tool blog. 🙁

Since things seem a bit slow on the blog,…. I thought that I would relay a couple of BEAR stories as relayed to me from a co-worker.

1) While staying at a motel,… 2 story with outdoor entrance doors,…. a bear was in the parking lot and a couple pulled right up right near it (but did not see it) and proceeded to get out of their car. People already on the balcony and watching the bear quickly warned them. Later that night,…. the bear went up on the 2nd floor balcony and rummaged through the trash cans. This was in Virginia.

2) Again at a similar motel,…. he was on the first floor just chilling out on his private patio just out the back of the room. A big mama bear and 2 cubs walked right up past the privacy fence between the room patios. He said he never moved inside so fast in his life! This was in Pennsylvania.

I found it all quite humorous. Lesson?,….maybe think twice about going to the ice machine at 12:30 AM for a refill!

Chris

ChrisUSA,

WHAT!!!!!! You don’t wear your Bear Bells to go to motels?

Bearspray is my soft first response.

I follow that, if necessary, by having Mr. Smith & Wesson delivering a .44 magnum dis-invite to the party.

Bear are NOT = to the plush stuffed variant; just like those big pussycats that people only believe live in the mountains.

shootski

More bear information,

https://www.ammoland.com/2019/08/handgun-or-pistol-defense-against-bear-attack-73-cases-96-effective/#axzz5yIR01UbM

shootski

Shootski,

Very informative and resourceful.. you are. Living in in central-ish Ohio,… I have not had the displeasure of surprise teddy bear or kitty cat encounters.

My ex-sister in law did get run up a tree by a Moose in Colorado when jogging. Being all of 110# soaking wet and well fit,… she managed quite well. A passerby in an SUV saw the dilemma and pulled up next to the pine tree and she jumped on the roof and hopped inside. A common occurrence/scenario in Colorado,.. I suppose?

Luckily I live in an area that I am not faced with “critters” that can maul/eat me on a regular/daily basis.

Thank you for the added insight,……….. Chris

HAPPY BELATED BIRTHDAY, TOM!

Sorry this is late…I was in the middle of moving on your actual birthday.

—Joe B on Maui

Joe,

No problem.

How is your health?

B.B.

B.B.,

My health’s about the same: end stage diabetes. I go to dialysis 3 times a week just to stay alive.

How’s YOUR health, my friend?

Regards,

Joe (who’s really on Maui, not Bainbridge Is.)

Joe,

I’m using progressively more insulin. I think a large part of that is diet that I need to control better, but it seems like I’m always experimenting. Meals eaten out are usually a tough thing to recover from, but at this year’s SHOT Show I fasted breakfast and lunch and did very well.

Getting older isn’t for sissies!

B.B.

BB

Isn’t that the truth. And that’s part of why I didn’t comment this weekend. Been a hectic weekend. My wife ended up having a heart attack Thursday evening. And to note she’s only 55. I thought I would be the first to have one since it runs in both sides of my family.

But anyway they did a cath and found one artery 70% blocked. They put a stint in and she came home Saturday. And of course then had to run and get medicine and stuff. And everybody calling and coming over. But she says she feels real good now.

But yep definitely getting old isn’t for sissies.

GF1,

Best wishes and a prayer on the wife being and staying well. You TOO old man! 😉

Actually getting ready to head out and shoot the RW. Records indicate that it was 5/27/19 since the last time I was out,… if that tells you anything on what the Summer has been like. 🙁

Getting Mom and Dad downsized/moved is coming to an end and their old house should be on the market within a month.

Chris

Chris

Thanks.

And yep that is a long time of not shooting. Glad your getting out to shoot finally. I bet you do better than you think.

And yep I know what you mean about moving the parents. Went through that too. Not easy that’s for sure.

But have a good day shooting. Let me know how it goes.

GF1,

I did not do too bad. No major flubs. It was still wet from last night’s rain. If the wind even thought about blowing,.. I would get wet from the trees. Luckily it was 99.5% dead calm but I was still getting dripped on.

I did a 40 yard sight in verification to see if the scope needed a click or 2 first. 5 shots. No adjustment required.

Next was the 50 yard. The target was so dark at 20 yards into the woods that I had to use a flashlight to see the bull clearly. I just rubber banded it to one of the electric fence poles that I use for holding my targets. (1 pole target, 1 pole light) Much better. Turning the mag. down was no help in case you are wondering. I ended up going with 24x,…. but love the 34x when light permits.

I did a mag first, followed by my 2nd mag. and then the single shot tray. .721, .502 and .471″ respectively. All 10 shots.

Glad I got out. Time to do some more weekend chores,……. Chris

( I forget now who also here bought an Athlon scope,…. but if they see this and find/see a side wheel for it,…. let me know. The side AO is pretty stiff. I have looked pretty hard on line and am turning up nothing other than maybe something that is called “universal”. )

Chris

Pretty good. You haven’t shot anything else inbetween now and May?

GF1,

Nope,…. other than that one super sweet 25 yarder at Mr. Groundhog. That was with the .22 Maximus,.. standing but braced off the corner of the porch.

You are lucky to have your stuff at the 24/7 ready and not have haul stuff out to set up.

Chris

Chris

I guess shooting is like riding a bicycle. Once you got it, you got it. 😉

And yep definitely grateful I’m lucky to have the breezeway. This house and the last house I lived in both had a breezeway to shoot from. The other house breezeway was kind of small actually but it worked. It had a couch and a TV in it so not really much room to do anything in there. I had the Shoebox at that time and it was out in the garage. So I had to go out there at the end of my shooting session since I was filling a buddy bottle at that time to fill back up.

This house the breezeway is actually like a room I have the tv out there but no couch. But a full size old table. So my compressor and tools are all setup out there. In other words plenty of room to have guns leaning everywhere and plenty of room to move around. Most definitely happy with it.

GF1,

Yeah,…. up to a point. I am not naïve enough to think that I was shooting anywhere near my personal best after not picking one up for 4 months. There is after all a difference in just doing it,… doing it well,… and then doing it (very) well.

There was some real exciting moments when I had pellet on pellet for like 4-5 in a row. You would have sworn that I missing the target all together,.. but I knew better. I love those moments! 🙂

I was just happy to get out,……….. Chris

Chris

Yep just getting out is a big thing.

GF1,

I will add your wife to my daily prayer list.

B.B.

Thanks BB.

GF1,

I will too. Take care.

Joe

Thank you.

GF

Wow! That had to be a very scary and stressful time for you and the family. Hopefully, the attack wasn’t too severe and there wasn’t too much damage to the heart. It may be a blessing in disguise that it happened sooner, rather than later. With only a 70% blockage, I would assume there was no heart damage and she will make a full recovery. You can’t beat the genes, but diet is everything. My thoughts and prayers are with you my friend.

Geo

Geo

Before they did the cath they did bunches and bunches of ultra sounds. I was there as well as the heart doctor. And to say I’m sure he was probably a little more than half my age. I’ll be 58 in a couple months. But he was right on it with the ultrasound. He said he could see a little spot in the heart that was moving slow by that particular artery. He predicted that there was a 80% or more blockage. He was pretty close when they did the cath they did follow up ultra sounds and said that part of the heart was functioning more free after the stint.

But yep it was a surprise. My wife is always going. It just hit all of a sudden. Yipes is alll I can say. And yep very lucky it wasn’t worse.

B.B.,

“I fasted breakfast and lunch and did very well.” Sounds like you’re doing Intermittent Fasting. My wife & I do this and have lost weight. And having lost weight I can breath better too.

“Getting older isn’t for sissies!” That’s for darn sure! I’m constantly amazed to see which part of me is going to sag next. :^>

Maui Joe

My doctor once told me that she had a patient who ate too much sugar, but then just increased his insulin. :^>

Joe,

When I was in the hospital in 2010 I was in a room with a guy who was there to have his foot removed because of diabetes. His girlfriend was sneaking candy bars in to him every day!

B.B.

B..B.

I had a dear friend with diabetes. He was pretty heavy and would not follow his doctor’s orders…because he just knew better, and the doctors didn’t know what they were talking about. He was a very stubborn guy. First he lost the end of one foot. Then not long after they had to take his whole leg off. I and a another friend from church built a nice ramp for him so he could get in and out on his own. Sadly, not too long after that his wife came home and found him dead in bed. Rick was only in his 50s and a real sweet guy, just would not do as the doctors ordered.

He passed away on my birthday, and there wasn’t much to celebrate that day :'(

Geo

BB

My mom passed at 67. She was diabetic and had heart conditions. Followed the rules and still lost both legs below the knees. She was a go getter. Always was. She learned to walk again on prosthetics. Guess she was alive for about 4 years with the prosthetics. The heart is what got her.

I really haven’t watched my diet and other things till about a year ago when I started getting dizzy spells and found my blood pressure extremely high. So started doing alot of things at that time. My wife didn’t care what she ate. But I think she got woke up this time around.

So even if you follow the rules your body will still getcha. All you can do is try to make a effort to help. I know I’m trying. Probably a little late in the game I would say. But as it goes better late than never.

I should of made my reply to Geo about my mom and diabetes. Don’t know why I said BB. Sorry.

GF1,

I would like to encourage you that it is never too late to change your eating habits. This is a true story about my father-in-law. He worked for GM as a maintenance welder. When he was 53 years of age he came home from work with severe pain in his left arm. Apparently he had been having symptoms for sometime and hadn’t told anyone.

He went to ER and then to a cardiologist. They told him nothing could be done because his body had already created many new small arteries to replace the ones that were blocked, and if they did surgery, he would bleed to death. He could no longer work and they sent him home with a shoe box full of medications. He brought this condition on himself because he worked second shift seven days a week and every night when he came home he would eat a fat steak and drink two or three beers, then go to bed.

He did not accept that his condition could not be reversed. He did research and found the Pritikin Center in California. He traveled by train from MI to CA by himself and stayed there for several weeks. He learned what he needed to eat and how to cook it. He also learned that he needed to walk several miles each day. When he came back home he was very strict about the diet and cooked most of his meals himself. He walked four to five miles each day.

After following this regimen for about two years, he went back to GM and worked for another two years to qualify for his pension. He was totally faithful to the Pritikin plan right up until he passed at age 74 from lung cancer in 2001. When the doctors examined him, they told him that they would never have known that he had ever had coronary disease if he hadn’t told them. The diet completely reversed his heart disease.

This was at a time before doctors would accept that diet and exercise could prevent, or reverse, coronary heart disease. But he was living proof to us that it in fact it could. So, now both you and your wife need to be more selective in your diets. Try to eat more organic foods and stay away from preservatives, those are killing us.

Geo

Geo

That’s a good story.

I know I have changed alot of my eating and drinking habits the last year. I do feel better. I’m actually pretty active at work and home so I believe that helps too.

And as the saying goes. You only live once. Yep it’s never to late to start trying.

BB

Crazy about the girl bringing in chocolate to her boyfriend.

B.B., GF1,

My wife is working with a young man who’s in the hospital with a platelet count of 4! He asks all his friends to sneak him Taco Bell food and chocolate milk.

Back in the ’70s she was working with a woman who had cancer. The woman was dying and her kids wanted her to follow a strict diet. She asked my wife, “Do I have to follow this diet, or can I just go out in a blaze of Big Macs?”

Joe

Joe

This may sound bad. But if I’m really bad off and in the hospital I think I’m going to have to ask for a beer and probably not a Big Mac. Don’t know what food it would be right now. But some filet

and battered and deep fryed Blue gill or Crappie comes to mind. If it’s getting ready to be lights out for me I think that’s the food and drink I would ask for.

GF1

:^>

—JoeB

Joe

🙂